Professional Documents

Culture Documents

Bbrav11isep193 199

Uploaded by

Putri Defriska SiagianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bbrav11isep193 199

Uploaded by

Putri Defriska SiagianCopyright:

Available Formats

BIOSCIENCES BIOTECHNOLOGY RESEARCH ASIA, October 2014.

Vol. 11(Spl. Edn. 1), p. 193-199

Production of Bioethanol from Papaya and Pineapple

Wastes using Marine Associated Microorganisms

M. Jayaprakashvel1,4*, S. Akila2, M. Venkatramani1,

S. Vinothini1, S, Jacky Bhagat3 and A. Jaffar Hussain1,4

Department of Marine Biotechnology, AMET University

135, East Coast Road, Kanathur, Chennai-603112, India

2

Department of Microbiology, Muthayammal College of Arts and Science

Rasipuram 637408, Namakkal, India

3

Biological Oceanographic Division,

National Institute of Oceanography, Dona Paula, Goa 403004, India

4

Centre for Marine Bioprospecting, AMET University

135, East Coast Road, Kanathur, Chennai-603112, India.

1

doi: http://dx.doi.org/10.13005/bbra/1410

(Received: 15 August 2014; accepted: 10 October 2014)

In the era of declining fossil fuel resources, the World is in urgent need to look

into the possibilities of alternate energies which shall sustain the energy resources. Among

the alternative energies, biofuels such as bioethanol, biodiesel and methane are

advantageous. In this study, an attempt was made to produce bio-ethanol by marine

fungi in fermentation process with the use of fruit wastes (papaya and pine apple) as

substrates. A total of 19 marine fungi were isolated from various marine and marine

related specimens such as sea surface water, rotten woods found along beaches, marine

sediment sample and rhizosphere soil from coastal sand dunes. The isolates were studied

for their capability to produce enzymes to help in fermentation processes like pectinase,

amylase and cellulase. Amongst these isolates, strain AMETF018 was selected because of

its potential in producing pectinase, amylase and cellulase. The fungus was grown in

liquid culture and mycelia biomass was immobized with calcium alginate. A total of 12

set of fermentation experiments were carried out by immobilized fungus and commercial

bakers yeast Sacchromyces cerevisiae using papaya and pineapple wastes as substrates

for ethanol production. The combination of pineapple fruit waste, immobilized marine

fungus AMETF018 and fermentative yeast S. cerevisiae, was found to be the best suited

for higher production of ethanol. This study thus concludes that marine fungi in

combination with yeast could be a potential source for the effective utilization of fruit

wastes as biofuel.

Key words: Fruit wastes, marine fungi, enzymes, bioethanol, fermentation.

Rapid increase in energy consumption

and depletion of fossil fuel has lead to an extensive

research in the field of alternative fuel. In this

context, bioethanol has been reported as an

alternative fuel because it is renewable, non toxic

* To whom all correspondence should be addressed.

E-mail: jayaprakashvel@gmail.com

and biodegradable (Harun et al., 2011; Borines et

al., 2013). Bioethanol can be derived from biomass

with many different varieties of feed stocks such

as corn, sugarcane, wood and fruits wastes which

are easily accessible and reliable and can help to

clean the environment from the wastes (Patni et

al., 2013; Suryaningsih et al., 2014). According to

Berg (2001), fuel ethanol, besides its environmental

value, is and will remain first and foremost an

instrument to support farmers, as they will profit

194

JAYAPRAKASHVEL et al., Biosci., Biotech. Res. Asia, Vol. 11(Spl. Edn. 1), 193-199 (2014)

from fuel ethanol programmes. Biofuels give more

benefit since it comes from renewable resources.

Its sustainability reduces greenhouse gas

emission, regional development, social structure,

agriculture and security supply (Demirbas 2006).

However, to date most of the bioethanol is being

produced by using food crops which may surely

affect the food security in this population exploding

era.

Waste is an inheritable consequence of

the food industry (Rodriguez et al., 2003). Food

industry produces large volumes of wastes, both

solids and liquid, resulting from the production,

preparation and consumption of food. These

wastes pose increasing disposal and potential

severe pollution problems and represent a loss of

valuable biomass and nutrients. The wastes

contain valuable components such as: sucrose,

glucose, fructose and other Nutrients (Sasaki et

al. 1991; David et al., 2008). Various studies have

suggested utilization of these wastes for the

production of single cell protein, ethanol, enzymes

etc. (Van Dyk et al., 2013). Ethanol fermentation

depends on the nature of the substrate used.

Therefore, it is important to select efficient raw

materials for ethanol fermentation (Baptista et al.,

2006). Fruit pulp wastes after extracting juices are

one of the major by products of food processing

industries. By-products of plant food processing

represent a major disposal problem for the industry

concerned, but they are also promising sources of

biomaterials (Schieber, 2001). These biomaterials

can be used as substartes for bioethanol

production. Hydrolysing enzymes ferment the

complex sugars to reducing sugars and then to

high concentrations of ethanol. It is also being

made from a variety of agricultural by-products

such as grain, fruit juices, fruit extracts, whey, sulfite

waste liquor and molasses (Nigam et al., 1998). In

the early 1970s, the oil crisis generated interest in

using cellulose as a chemical and energy resource.

Cellulose is a secondary nutrient source for fungi

Eriksson et al. 1990). One promising approach was

to hydrolyse the cellulose to glucose with fungal

enzymes and then to ferment the glucose to ethanol

which could be used as a liquid fuel (Mandelset

al., 1974). A variety of microbes are shown to

produce ethanol (Soccol et al., 2010; Dias et al.,

2011). The role of the microorganisms (bacteria and

fungi) in the process of fermentation showed that

waste pineapple, banana and pawpaw fruits

contain a fermentable material which was evident

from the increase in the acidity of the fermenting

juice (Ogunjobiet al., 2005). A number of organisms

including fungi, yeast and bacteria have been

screened for ethanol fermentation. Extensive

studies have been carried out on the fermentation

process of ethanol by these organisms, especially

through yeast cells (Bajaj et al., 2001). Ethanol is

produced by fermentation: when certain species

of yeast (notably Saccharomyces cerevisiae)

metabolize sugar in the absence of oxygen, they

produce ethanol and carbon dioxide. (Anxoet al.,

2008). Immobilization of microbes has been reported

to enhance the production of ethanol (Mariam et

al., 2009). Hence in the present investigation we

have attempted to produce ethanol from pineapple

and papaya waste using immobilized fungi and

commercial yeast, Saccharomyces cerevisiae.

MATERIALSAND METHODS

Isolation of marine associated fungi from coastal

samples

Sea surface water, wood wastes, coastal

sediments and and rhizosphere soil of plants

(Ipomoea sp. and Spinifex sp.) were collected from

the coastal area of Uthandi, Chennai (Lattitude

12.872854, Longitude 80.250851), India during

March 2012. Immediately after collection, samples

were brought to the laboratory in sterile polythene

bags. Marine associated fungi were isolated using

serial dilution plating technique in potato dextrose

agar prepared in 50% of seawater (Muthezhilan,

2008).

Screening the isolated fungi for the production

enzyme activity

Screening of enzyme activity by marine

fungi was tested by qualitative plate assay. Minimal

salts medium (K2HPO4 25.6 g/L; KH2PO4 6 g/L ;

NaCl 1 g/L ; NH4Cl 2 g/L; Agar 20 g/L; pH 6.5)

supplemented with different substrates for the test

enzymes was prepared separately and mycelia

discs (6 mm diameter) from actively growing

regions of individual marine fungi was inoculated

and incubated for 7 days. Pectin (0.3%), CM

Cellulose (0.3%) and soluble starch (0.3%) were

used as substrates for pectinase, cellulose and

amylase respectively. Pectinase and CM Cellulase

activity was visualized as a zone of clearance

JAYAPRAKASHVEL et al., Biosci., Biotech. Res. Asia, Vol. 11(Spl. Edn. 1), 193-199 (2014)

against red background when the plates were

stained with congo red (0.3% for 15 minutes)

followed by destaining with 1N NaCl (for 15

minutes). Amylase activity was visualized as a zone

of clearance against dark blue background when

the plates were flooded with Grams Iodine. Zone

of clearance of all the enzyme activities were

recorded.

Immobilization of fungal mycelia using calcium

alginate

The selected marine fungus AMETF18

which produced enzyme activities for pectinase,

cellulose and amylase was chosen for further

studies. The fungus was grown on potato dextrose

broth and incubated for 3 to 5 days. After

incubation, the liquid cultures were centrifuged at

3000 rpm at 10C for 8 min and the pellet was

suspended with a previously autoclaved solution

of sodium alginate. The mixture was added drop

wise into an autoclaved solution of calcium

chloride to form beads. The beads were left in the

gelling solution for 5 min before being harvested

and rinsed with sterilized physiological saline

solution. It was then chilled overnight at 4C.

Immobilization of commercial yeast (dry and grape

yeast) - calcium alginate

Two types of yeast cultures were used

the immobilization. Dry Yeast (Y1) was obtained as

a granulated formulation of Saccharomyces

cerevisea. Fresh yeast (Y2) was isolated freshly

from the grapes. They were grown on malt yeast

glucose peptone broth and incubated for 4 days. 2

g sodium alginate was mixed in 100 ml of boiling

water with constant stirring on magnetic stirrer.

After cooling sodium alginate solution, 2 g of yeast

cells were added to the slurry under stirring

conditions for even dispersal. The slurry solution,

with yeast biomass was dispersed drop wise into

2% chilled CaCl2 solution. Spherical beads were

formed which were washed with 0.2% chilled CaCl2

solution and stored at 4C for further use to carry

out fermentation.

Fermentation of papaya and pineapple wastes with

immobilized yeast and fungi

Fermentation was carried out in 100 ml

Erlenmeyer flasks using immobilized beads. Briefly,

50 ml of sterile distilled water with 10 g pine apple

or papaya waste was added in each flask according

to the treatment. 500 immobilized fungal beads or

immobilized yeast beads or both were added as

195

per the treatment. It was then mixed properly and

maintained at 30C for about 4 weeks. After

incubation, the beads were separated for further

use and the fermented medium was used for

estimation of ethanol contents using a simple

formula as given below

Alcohol by volume (ABV)=

[initial gravity final gravity] / 0.0075

RESULTS AND DISCUSSION

The unique physico-chemical properties

of the marine environment are likely to have

conferred marine fungi with special physiological

adaptations that could be exploited in

Biotechnology. Fungi occurring in decomposing

plant organic material or detritus in the sea have

been shown to be source of several wooddegrading enzymes of importance in paper and pulp

industries and bioremediation (Raghukumar, 2008).

Agro-industrial wastes are generated during the

industrial processing of agricultural products.

Although the production of bioethanol offers many

benefits, more research is needed in the aspects

like feedstock preparation, fermentation technology

modification, etc., to make bioethanol more

economically viable (Bhatia et al., 2012). In this

context, we have undertaken a preliminary study

on the suitability of marine associated fungi for

the production of ethanol using fruit wastes such

as papaya and pineapple. These marine associated

fungi are having the ability to produce enzymes

such as pectinase, cellualse and amylase. These

enzymes are having inherent potential to convert

complex biomass in to simpler and fermentable

carbohydrates or similar biomolecules. Such

converted biomaterials then be fermented with

fermenting yeasts to produce ethanol.

A total of nineteen different fungal

isolates were isolated from four different samples

such as sea surface water, wood wastes, coastal

sediments and rhizosphere soil of plants Ipomoea

sp and Spinifex sp collected from Uthandi, Chennai,

India and named as AMETF1 to AMETF19. In the

present study, all the 19 strains were subjected to

screen for the production of different hydrolytic

enzymes. Out of 19 strains, twelve strains were

able to show cellulolytic activity. Among then a

strain AMETF6 produced maximum cellulose

activity (2.7 cm zone of clearance). Further, 11

196

JAYAPRAKASHVEL et al., Biosci., Biotech. Res. Asia, Vol. 11(Spl. Edn. 1), 193-199 (2014)

strains showed pectinolytic activity using pectin

as substrate and AMETF7 showed the highest

pectinase activity (2.7 cm zone of clearance) and

three strains showed amylolytic activity.

Interestingly, a strain AMETF18 strains produced

all the three enzymes, hence, it was selected as

potential strain for further study (Table 1). In

general, biomass to ethanol bioconversion process

consists of several steps, including pretreatment

of biomass, enzymatic hydrolysis, fermentation and

product recovery. Enzymatic hydrolysis is the key

to cost-effective ethanol production from

lignocellulosic substrates in the long run, as it is

very mild process, gives potentially high yields,

and the maintenance costs are low compared to

acid or alkaline hydrolysis (Kuhad et al. 1997; Saini

et al., 2014). Cellulose and pectin are the most

dominantly present biomolecules in the agricultural

wastes such as fruit wastes. Hence organisms

producing cellulase and pectinase have the great

potential for the bioconversion of complex

agriwastes in to fermentable sugars. The selected

strain AMETF18 has the potential to produce

pectinase, cellulase and amylase.

Pineapple waste is rich in cellulose,

hemicelluloses, sugar and other carbohydrates.

Several authors has used pineapple waste for the

production of ethanol (Alan et al., 1987; Nigam,

1999; Tanaka et al., 1999; Chanprasartsuk et al.,

2010). Recently, pineapple peel has been reported

to yield ethanol (9.69 g/L) after 72 h of fermentaion

by S. cerevisiae (Choonut et al., 2014). Protease

produced during maturation of pineapple fruit can

cause lysis of microbial cell wall (Singleton and

Gortner, 1965; Uhlig and Linsmaier-Bednar, 1998),

which in turn can damage the yeast cells. In this

regard, immbolization can be suggested as an

efficient methods in fermentation (Kaetsu et al.,

1987; Agudelo and Penuela, 2010 ). Sharma and

Ogbeide, (1982) have suggested papaya as a

renewable energy resource for the production of

alcohol using yeast Sacchromyces carlsbengensis.

Lee et al. (2010) have investigated the formation

of compounds such as fatty acids, alcohols,

aldehydes and esters in papaya juice fermented

by a mixed culture of Saccharomyces cerevisiae

and Williopsis saturnus. Papaya juice fermentation

with yeast W. saturnus var mrakii NCYC 2251 was

carried out by Lee et al. (2011). Nigam, 2000 has

used immobilized yeast cells to produce ethanol

production from pineapple cannery waste.

Table 1. Screening of Marine fungi for the production of fermentative enzymes

S.

Strain No

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

AMETF1

AMETF2

AMETF3

AMETF4

AMETF5

AMETF6

AMETF7

AMETF8

AMETF9

AMETF10

AMETF11

AMETF12

AMETF13

AMETF14

AMETF15

AMETF16

AMETF17

AMETF18

AMETF19

Production of Enzyme Activity/Zone of Lysis (cm)

Cellulase

Pectinase

Amylase

1.2 0.1

1.1 0.1

1.4 0.05

2.7 0.05

1.6 0.1

1 0.05

1.4 0.1

1.1 0.05

1.1 0.1

2 0.2

1 0.04

1 0.04

2.4 0.1

2.5 0.1

2.5 0.1

2.7 0.1

1.3 0.1

2.1 0.1

2.1 0.3

2 0.1

1.4 0.2

1.3 0.1

1.3 0.1

1.1 0.1

1.4 0.05

1.3 0.1

-

JAYAPRAKASHVEL et al., Biosci., Biotech. Res. Asia, Vol. 11(Spl. Edn. 1), 193-199 (2014)

In this context, we have immobilized both

selected marine fungus and fermentative yeasts

using calcium alginate as matrix and got

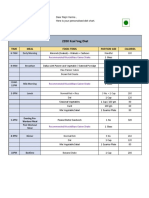

Table 2. Estimation of ethanol content

in different fermentation experiments

Fermentation treatment

Alcohol by

volume (%)

Pine apple waste

0

Papaya waste

0

Fungus+ Dry yeast + Pine apple waste 7.5 0.04

Fungus+ Fresh yeast + Papaya waste

6.5 0.04

Fungus + Fresh yeast + Pine apple waste 5.6 0.04

Fungus + Dry yeast + Papaya waste

5.5 0.04

Fungus + Pine apple waste

3.4 0.04

Fungus + Papaya waste

2.1 0.05

Dry yeast + Pine apple waste

2.1 0.08

Dry yeast + Papaya waste

2.3 0.05

Fresh yeast + Pine apple waste

1.6 0.05

Fresh yeast + Papaya waste

1.6 0.1

Fig. 1. Pure cultures of Marine associated fungi

197

immobilized beads with desirable qualities.

Simultaneous saccharification and fermentation

was carried out with 12 different combinations of

treatments. The application of simultaneous

saccharification and fermentation (SSF) for the

conversion of lignocellulosics to alcohol would

result in a more cost-effective process. Aptly,

lignocellulosic substrates were examined in SSF

experiments for the production of ethanol using

two yeast strains (a commercially available

bakers yeast and a thermotolerant Kluyveromyces

marxianus) (Kdr et al., 2004). In our study,

high level of ethanol yield was obtained only with

the combined fermentation of both the waste

(papaya and pineapple) with both selected marine

fungus AMETF18 and commercial bakers yeast

and the results of fermentation experiment was

provided in Table 2. The highest ethanol

production i.e. alcohol by volume was observed

in the Fungus+ Dry yeast + Pine apple waste

treatment (7.5%) followed by Fungus+ Fresh

yeast + Papaya waste treatment which yield 6.5%

alcohol. Previously, studies were carried out on

the ethanol production by free and immobilized

Saccharomyces cerevisiae GC-IIB31 under

stationary culture. Cane molasses in different

concentration was used as sugar source for

maximum conversion of reducing sugar into

ethanol (Mariam et al., 2009). Thus the present

study indicates the potential of selected marine

fungus AMETF18 along with bakers yeast for

simultaneous saccharification and alcohol

fermentation in laboratory conditions. However,

these studies are further to be refined by

experiments with bioreactors.

CONCLUSION

In our study pineapple and papaya

wastes were used as a substrate by fungus to

produce ethanol with a maximum yield of 7.5 % v/

v. In conclusion, our study suggests the possible

use of pineapple and papaya wastes with

immobilized marine fungus and bakers years.

Nevertheless, more studies are required to identify,

isolate, and study potential fungus for the

production of bioethanol from these wastes.

Fig. 2. Fermentation of papaya and pineapple

wastes using different combinations of

immobilized marine fungi and yeast

198

JAYAPRAKASHVEL et al., Biosci., Biotech. Res. Asia, Vol. 11(Spl. Edn. 1), 193-199 (2014)

REFERENCES

12.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Agudelo, L.M., M. Penuela, Yeast

immobilization on lignocellulosic materials for

ethanol production used as fuel, Journal of

Biotechnology, 2010; 150, Supplement, 346.

Alain, K., Agbo Nzi Georges, Yeboua Aka,

Ethanol production from pineapple juice in Cte

dIvoire with preselected yeast strains, Journal

of Fermentation Technology, 1987; 65(4): 475481.

Baptista, C.M.S.G., J.M.A. Coias, A.C.M.

Oliveira, N.M.C. Oliveira, J.M.S. Rocha, M.J.

Dempsey, K.C. Lannigan and B.S. Benson.

Natural immobilization of microorganisms for

continuous ethanol production. Enzyme

Microbial Technol., 2006; 40: 127-131

Bhatia, L., Johri, S., Ahmad, R., An economic

and ecological perspective of ethanol production

from renewable agro waste: a review. AMB

Express 2012; 2: 65.

Borines, MG., Rizalinda L. de Leon, Joel L.

Cuello, Bioethanol production from the

macroalgae Sargassum spp., Bioresource

Technology, 2013; 138: 22-29.

Chanprasartsuk, O., Cheunjit Prakitchaiwattana,

Romanee Sanguandeekul, Graham H. Fleet,

Autochthonous yeasts associated with mature

pineapple fruits, freshly crushed juice and their

ferments; and the chemical changes during natural

fermentation, Bioresource Technology, 2010;

101(19): 7500-7509.

Choonut, A., Makorn Saejong, Kanokphorn

Sangkharak, The Production of Ethanol and

Hydrogen from Pineapple Peel by

Saccharomyces Cerevisiae and Enterobacter

Aerogenes, Energy Procedia, 2014; 52: 242-249

Choonut, A., Makorn Saejong, Kanokphorn

Sangkharak, The Production of Ethanol and

Hydrogen from Pineapple Peel by

Saccharomyces Cerevisiae and Enterobacter

Aerogenes, Energy Procedia, 2014; 52: 242-249

Dias, M.O.S., M.P. Cunha, C.D.F. Jesus, G.J.M.

Rocha, J.G.C. Pradella, C.E.V. Rossell, et al.

Second generation ethanol in Brazil: can it

compete with electricity production? Bioresour

Technol, 2011; 102: 89648971

Harun, R., Michael K. Danquah, Enzymatic

hydrolysis of microalgal biomass for bioethanol

production, Chemical Engineering Journal,

Volume 2011; 168(3): 1079-1084

Kdr, Zs., Szengyel, Zs. And Rczey, K.

Simultaneous saccharification and fermentation

(SSF) of industrial wastes for the production of

ethanol. Industrial Crops and Products. 2004;

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

20(1): 103110.

Kaetsu, I Minoru Kumakura, Takashi Fujimura,

Noboru Kasai, Masao Tamada, Immobilization

of microbial cell and yeast cell and its application

to biomass conversion using radiation techniques,

International Journal of Radiation Applications

and Instrumentation. Part C. Radiation Physics

and Chemistry, 1987; 29(3): 191-193

Kuhad RC, Singh A, Ericksson KE.,

Microorganisms and enzymes involved in the

degradation of plant fiber cell walls. Adv Biochem

Eng Biotechnol 1997; 57:45125

Lee, P.R., Y.-L. Ong, B. Yu, P. Curran, S.-Q. Liu,

Profile of volatile compounds during papaya

juice fermentation by a mixed culture of

Saccharomyces cerevisiae and Williopsis

saturnus, Food Microbiology, 2010; 27(7): 853861.

Lee, PR., Bin Yu, Philip Curran, Shao-Quan Liu,

Effect of fusel oil addition on volatile compounds

in papaya wine fermented with Williopsis

saturnus var. mrakii NCYC 2251, Food Research

International, 2011; 44(5): 1292-1298.

Mariam, I., Manzoor, K., Ali, S. and Ikram-ulHaq., Enhanced production of ethanol from free

and immobilized Saccharomyces cerevisiae

under stationary culture. Pakistan Journal of

Botany 2009; 41(2): 821-833.

Nigam, J.N., Continuous ethanol production

from pineapple cannery waste, Journal of

Biotechnology, 1999; 72(3): 197-202.

Nigam, J.N., Continuous ethanol production

from pineapple cannery waste using immobilized

yeast cells, Journal of Biotechnology, 80, Issue

2, 23 June 2000, Pages 189-193.

Patni, N., Shibu G. Pillai, Ankur H. Dwivedi,

Wheat as a Promising Substitute of Corn for

Bioethanol Production, Procedia Engineering,

2013; 51: 355-362

Raghukumar, C., Marine fungal biotechnology:

an ecological perspective. Fungal Diversity

2008; 31: 1935

Saini, JK., Saini, R., and Tewari, L.,

Lignocellulosic agriculture wastes as biomass

feedstocks for second-generation bioethanol

production: concepts and recent developments.

3 Biotech. DOI: 10.1007/s13205-014-0246-5,

2014.

Schieber, A., F.C Stintzing, R Carle. By-products

of plant food processing as a source of functional

compounds-recent developments. Trends in

Food Science & Technology. 2001; 12(11): 401

413

Sharma, V.C., O.N. Ogbeide, Pawpaw as a

renewable energy resource for the production of

JAYAPRAKASHVEL et al., Biosci., Biotech. Res. Asia, Vol. 11(Spl. Edn. 1), 193-199 (2014)

24.

25.

26.

27.

alcohol fuels, Energy, 1982; 7(10): 871-873

Singleton, V.L., W.A. Gortner Chemical and

physical development of the pineapple fruit II.

Carbohydrate and acid constituents J. Food Sci.,

1965; 30: 19-23.

Soccol, C.R., L.P. Vandenberghe, A.B. Medeiros,

S.G. Karp, M. Buckeridge, L.P. Ramos, et al.

Bioethanol from lignocelluloses: status and

perspectives in Brazil Bioresour Technol, 2010;

101 : 48204825

Suryaningsih, R., Irhas, Bioenergy Plants in

Indonesia: Sorghum for Producing Bioethanol

as an Alternative Energy Substitute of Fossil

Fuels, Energy Procedia, 2014; 47: 211-216

Tanaka, K., Zakpaa D. Hilary, Ayaaki Ishizaki,

Investigation of the utility of pineapple juice

and pineapple waste material as low-cost

28.

29.

30.

199

substrate for ethanol fermentation by

Zymomonas mobilis, Journal of Bioscience and

Bioengineering, 1999; 87(5): 642-646.

Tomas L.C. and Chamberlain G.J., Colorimetric

Chemical Analytical Methods, Tintometer Ltd.,

Salisbury, UK, 1980; 3-5.

Uhlig, H., E.M. Linsmaier-Bednar Lysis of

microbial cellwalls U. Helmut (Ed.), Industrial

Enzymes and their Applications, John Wiley

and Sons, Inc., New York, USA 1998; 397-400

Van Dyk, J.S., R. Gama, D. Morrison, S. Swart,

B.I. Pletschke, Food processing waste:

Problems, current management and prospects

for utilisation of the lignocellulose component

through enzyme synergistic degradation,

Renewable and Sustainable Energy Reviews,

2013; 26: 521-531.

You might also like

- MATH 5 - Q1 - Mod1 PDFDocument25 pagesMATH 5 - Q1 - Mod1 PDFJESSIE CUTARA76% (41)

- Production of Animal Feed Concentrates From Sour Sop and Pineapple Peels Using Solid State Fermentation.Document5 pagesProduction of Animal Feed Concentrates From Sour Sop and Pineapple Peels Using Solid State Fermentation.Gregory Kalona100% (1)

- Vaxa - UltraNanno+ Product Data Sheet FFDocument3 pagesVaxa - UltraNanno+ Product Data Sheet FFLuan NguyenNo ratings yet

- Bio-Ethanol Production From Banana Peel by Simultaneous Saccharification and Fermentation Process PDFDocument13 pagesBio-Ethanol Production From Banana Peel by Simultaneous Saccharification and Fermentation Process PDFBench GuecoNo ratings yet

- Ajay Kumar Singh, Et AlDocument13 pagesAjay Kumar Singh, Et AlapocNo ratings yet

- Biodegradation of Agricultural Wastes (Rice Straw and Sorghum Stalk) Into Substrates of Utilizable Products Using White Rot FungusDocument7 pagesBiodegradation of Agricultural Wastes (Rice Straw and Sorghum Stalk) Into Substrates of Utilizable Products Using White Rot FungusInes HrastinskiNo ratings yet

- Isolation, Identification and Characterization of Ethanol Tolerant Yeast Species From Fruits For Production of Bio-EthanolDocument7 pagesIsolation, Identification and Characterization of Ethanol Tolerant Yeast Species From Fruits For Production of Bio-Ethanolinternational journal of modern chemistry and applied scienceNo ratings yet

- Environmental BiotechnologyDocument8 pagesEnvironmental BiotechnologyIshwar ChandraNo ratings yet

- Optimization of Culture Condition in The Production of Bioenzymes by Bacteria Isolated From Poultry Waste in Sokoto State, NigeriaDocument8 pagesOptimization of Culture Condition in The Production of Bioenzymes by Bacteria Isolated From Poultry Waste in Sokoto State, NigeriaUMYU Journal of Microbiology Research (UJMR)No ratings yet

- Production of Lactic Acid From Starchy-Based Food SubstratesDocument9 pagesProduction of Lactic Acid From Starchy-Based Food SubstratesYoali HdezNo ratings yet

- Determination of Bioethanol Potential From Banana Waste Using Indigenous Yeast (Saccharomyces Cerevisiae. KX033583)Document9 pagesDetermination of Bioethanol Potential From Banana Waste Using Indigenous Yeast (Saccharomyces Cerevisiae. KX033583)siboyif881No ratings yet

- Climate Change ArticleDocument7 pagesClimate Change ArticleRay SmithNo ratings yet

- 1 s2.0 S2666154322000084 MainDocument7 pages1 s2.0 S2666154322000084 MainyeishaNo ratings yet

- Freitas2018 PDFDocument11 pagesFreitas2018 PDFVanesa CaroNo ratings yet

- Potential Use of Banana and Its By-Products: A ReviewDocument7 pagesPotential Use of Banana and Its By-Products: A Reviewirawati khasanahNo ratings yet

- Food Microbiology: Rossana Coda, Carlo Giuseppe Rizzello, Antonio Trani, Marco GobbettiDocument11 pagesFood Microbiology: Rossana Coda, Carlo Giuseppe Rizzello, Antonio Trani, Marco GobbettiUMAR IJAZNo ratings yet

- Vaishali Randive, Et AlDocument8 pagesVaishali Randive, Et AlOENDRIL DASNo ratings yet

- 7470148Document25 pages7470148Sine Summsun PradhanNo ratings yet

- Ranscript of Science Investigatory Project On Ethanol From Ripe Banana PeelingsDocument5 pagesRanscript of Science Investigatory Project On Ethanol From Ripe Banana PeelingsYvhone De LimaNo ratings yet

- Optimization of Culture Condition in The Production of Bioenzymes by Bacteria Isolated From Poultry Waste in Sokoto State, NigeriaDocument8 pagesOptimization of Culture Condition in The Production of Bioenzymes by Bacteria Isolated From Poultry Waste in Sokoto State, NigeriaUMYU Journal of Microbiology Research (UJMR)No ratings yet

- Studies On Bio-Ethanol Production From Orange Peels Using Bacillus SubtilisDocument5 pagesStudies On Bio-Ethanol Production From Orange Peels Using Bacillus SubtilisAnoif Naputo AidnamNo ratings yet

- Pomegranate Peel Waste: A New Substrate For Citric Acid Production by Aspergillus Niger in Solid-State Fermentation Under Non-Aseptic ConditionsDocument9 pagesPomegranate Peel Waste: A New Substrate For Citric Acid Production by Aspergillus Niger in Solid-State Fermentation Under Non-Aseptic ConditionsWindy NainggolanNo ratings yet

- Potentials of Acremonium Butyri Fungus in Pre-Treatment and Hydrolysis Using Rice Husk Substrate For Biofuel Production: A Short CommunicationDocument7 pagesPotentials of Acremonium Butyri Fungus in Pre-Treatment and Hydrolysis Using Rice Husk Substrate For Biofuel Production: A Short CommunicationUMYU Journal of Microbiology Research (UJMR)No ratings yet

- Journal of Engineering and Applied ScienceDocument9 pagesJournal of Engineering and Applied Sciencerikaseo rikaNo ratings yet

- Solid-state fermentation of sweet sorghum for bioethanol productionDocument15 pagesSolid-state fermentation of sweet sorghum for bioethanol productionAristy MirandaNo ratings yet

- Ijaerv8n15spl 01Document9 pagesIjaerv8n15spl 01Shera NeazNo ratings yet

- Extraction and Characterization of Gelatin: A Functional BiopolymerDocument4 pagesExtraction and Characterization of Gelatin: A Functional BiopolymerTrần Thị QuỳnhNo ratings yet

- FadilDocument11 pagesFadilSoetantoNo ratings yet

- International Journal of Current Microbiology and Applied SciencesDocument10 pagesInternational Journal of Current Microbiology and Applied SciencesnortojiNo ratings yet

- Aspergillus and Penicillum Genera, Yeast Were Yarrowia Lipolytica, Saccharomyces Cerevisiae and Candida SPP.Document9 pagesAspergillus and Penicillum Genera, Yeast Were Yarrowia Lipolytica, Saccharomyces Cerevisiae and Candida SPP.Yogi FrNo ratings yet

- Bioethanol Production by Mangrove-Derived Marine Yeast, Sacchromyces CerevisiaeDocument7 pagesBioethanol Production by Mangrove-Derived Marine Yeast, Sacchromyces Cerevisiaeေအာင္ ေက်ာ္ စြာNo ratings yet

- Burukutu AnalysisDocument4 pagesBurukutu AnalysisDeji AribukiNo ratings yet

- Nano FertilizerDocument9 pagesNano FertilizerpaoloNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document6 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- Colocasia Esculenta L - ResearchGate PDFDocument6 pagesColocasia Esculenta L - ResearchGate PDFAlfi RifkiNo ratings yet

- مرجينDocument11 pagesمرجينpk9zg2rxkgNo ratings yet

- Plums (Prunus Domestica L.) Are A Good Source of Yeasts Producing Organic Acids of Industrial Interest From GlycerolDocument4 pagesPlums (Prunus Domestica L.) Are A Good Source of Yeasts Producing Organic Acids of Industrial Interest From GlycerolAquiles18No ratings yet

- BioetanolDocument14 pagesBioetanolRomauli NataliaNo ratings yet

- Comparative Study Between The Effects of Mango and Orange Peels Preparations On The Total Dietary FiberDocument8 pagesComparative Study Between The Effects of Mango and Orange Peels Preparations On The Total Dietary FiberIOSRjournalNo ratings yet

- Cagayan State UniversityDocument4 pagesCagayan State UniversityArvin GerlabanNo ratings yet

- 8 LSA - Udhayaraja PDFDocument6 pages8 LSA - Udhayaraja PDFLife Science ArchivesNo ratings yet

- Mutripah 2013Document7 pagesMutripah 2013ArShyhy Citcuit ArsyamaliaNo ratings yet

- Effect of Seaweed Extract On The Growth Yield and Nutrient Uptake of Soybean Glycine Max Under Rainfed ConditionsDocument5 pagesEffect of Seaweed Extract On The Growth Yield and Nutrient Uptake of Soybean Glycine Max Under Rainfed ConditionsRogelyn Mejia BarbocoNo ratings yet

- Principals' Encouragement of Teacher Collaboration and Support For Peer Coaching in Government Secondary Schools, South West Region, of CameroonDocument6 pagesPrincipals' Encouragement of Teacher Collaboration and Support For Peer Coaching in Government Secondary Schools, South West Region, of CameroonEditor IJTSRDNo ratings yet

- ajol-file-journals_82_articles_131997_submission_proof_131997-973-355924-1-10-20160314 (18)Document4 pagesajol-file-journals_82_articles_131997_submission_proof_131997-973-355924-1-10-20160314 (18)phamgiang29032002No ratings yet

- Paper Jan 2016Document7 pagesPaper Jan 2016Syed babar ali shahNo ratings yet

- 25 LSA Jakathi PDFDocument4 pages25 LSA Jakathi PDFLife Science ArchivesNo ratings yet

- Owth and Yield Performances of (Abelmoschus Esculentus) (Nur Suraya Abdullah) PP 230-233Document4 pagesOwth and Yield Performances of (Abelmoschus Esculentus) (Nur Suraya Abdullah) PP 230-233upenapahangNo ratings yet

- Ini DipakeDocument8 pagesIni DipakedwikiNo ratings yet

- 1 s2.0 S2665927121000332 MainDocument10 pages1 s2.0 S2665927121000332 MainLaires AraujoNo ratings yet

- African Journal of Biotechnology Bioreme PDFDocument7 pagesAfrican Journal of Biotechnology Bioreme PDFkarnah nurwendahNo ratings yet

- 2011 Ferm Indonesia The Microbial Ecology of Cocoa Bean Fermentations in IndonesiaDocument13 pages2011 Ferm Indonesia The Microbial Ecology of Cocoa Bean Fermentations in IndonesiaMarcelina Mendoza SalazarNo ratings yet

- Referensi BiostimulanDocument8 pagesReferensi BiostimulanGbryl SilalahiNo ratings yet

- Bioethanols2Document39 pagesBioethanols2ahmad buysyNo ratings yet

- Optimization of Culture Conditions of Streptomyces Rochei (MTCC 10109) For The Production of Antimicrobial MetabolitesDocument9 pagesOptimization of Culture Conditions of Streptomyces Rochei (MTCC 10109) For The Production of Antimicrobial Metabolitesraj252000No ratings yet

- ALIU ProposalDocument10 pagesALIU ProposaldagolddoyinsolaNo ratings yet

- Microbiological and Physico-Chemical Dynamics During The Fermentation of The Millet-Based and The Sorghum-Based in The Republic of BeninDocument9 pagesMicrobiological and Physico-Chemical Dynamics During The Fermentation of The Millet-Based and The Sorghum-Based in The Republic of BeninOpenaccess Research paperNo ratings yet

- Optimized Solid State Fermentation Medium Enhances The Multienzymes Production From Penicillium Citrinum and AspergillusDocument15 pagesOptimized Solid State Fermentation Medium Enhances The Multienzymes Production From Penicillium Citrinum and AspergillusSerafín Pérez ContrerasNo ratings yet

- 1.5141321 Sargassum CrassifoliumDocument7 pages1.5141321 Sargassum CrassifoliumErica ViajedorNo ratings yet

- Utilizationforbyproductsofbanana-AReview Res Environ LifeSci 2016 PDFDocument4 pagesUtilizationforbyproductsofbanana-AReview Res Environ LifeSci 2016 PDFbenjiNo ratings yet

- Isnawati - 2020 - J. - Phys. - Conf. - Ser. - 1569 - 042082Document7 pagesIsnawati - 2020 - J. - Phys. - Conf. - Ser. - 1569 - 042082Jefri Nur HidayatNo ratings yet

- Aquaponics systems, fish. Volume 3: Sistemas de acuaponíaFrom EverandAquaponics systems, fish. Volume 3: Sistemas de acuaponíaNo ratings yet

- Hasil Analisis Buku Teks: Responden Kelayakan IsiDocument6 pagesHasil Analisis Buku Teks: Responden Kelayakan IsiPutri Defriska SiagianNo ratings yet

- Tips and Strategies On Structure and Written ExpressionDocument25 pagesTips and Strategies On Structure and Written ExpressionShantal PolitNo ratings yet

- 339 389 1 PBDocument5 pages339 389 1 PBPutri Defriska SiagianNo ratings yet

- 281 15205 1 PBDocument6 pages281 15205 1 PBPutri Defriska SiagianNo ratings yet

- Antioxidant Properties of Sambung Nyawa Leaves for Coconut Oil PreservationDocument7 pagesAntioxidant Properties of Sambung Nyawa Leaves for Coconut Oil PreservationPutri Defriska SiagianNo ratings yet

- DocumentDocument5 pagesDocumentPutri Defriska SiagianNo ratings yet

- Journal FormatDocument18 pagesJournal FormatDean Refangga SetiadiNo ratings yet

- Passive ExplanationDocument4 pagesPassive Explanationapi-319884721No ratings yet

- Active V PassiveDocument2 pagesActive V PassiveNaqeeb Ullah KakarNo ratings yet

- Kinetics of PFAD Esterification into Biodiesel with Sulfated Zeolite-Zirconia CatalystDocument6 pagesKinetics of PFAD Esterification into Biodiesel with Sulfated Zeolite-Zirconia CatalystPutri Defriska SiagianNo ratings yet

- Production of Fatty Alcohols From Fatty Acids: ManufacturingDocument3 pagesProduction of Fatty Alcohols From Fatty Acids: ManufacturingPutri Defriska SiagianNo ratings yet

- Conversion of Used Oil Intolubricatinggrease and Characteristics EvaluationDocument5 pagesConversion of Used Oil Intolubricatinggrease and Characteristics EvaluationPutri Defriska SiagianNo ratings yet

- 283 722 1 PB PDFDocument8 pages283 722 1 PB PDFPutri Defriska SiagianNo ratings yet

- 1162 11393 1 PBDocument6 pages1162 11393 1 PBPutri Defriska SiagianNo ratings yet

- Citric Acid ProductionDocument20 pagesCitric Acid ProductionDiana MuñozNo ratings yet

- Kinetics of PFAD Esterification into Biodiesel with Sulfated Zeolite-Zirconia CatalystDocument6 pagesKinetics of PFAD Esterification into Biodiesel with Sulfated Zeolite-Zirconia CatalystPutri Defriska SiagianNo ratings yet

- Books: The TheDocument1 pageBooks: The ThePutri Defriska SiagianNo ratings yet

- 35 IFRJ 19 (04) 2012 Olorunnisola PDFDocument5 pages35 IFRJ 19 (04) 2012 Olorunnisola PDFPutri Defriska SiagianNo ratings yet

- 1Document10 pages1Putri Defriska SiagianNo ratings yet

- Biotechnology For BiofuelsDocument9 pagesBiotechnology For BiofuelsPutri Defriska SiagianNo ratings yet

- 628 Ijar-3644Document13 pages628 Ijar-3644Putri Defriska SiagianNo ratings yet

- 35 IFRJ 19 (04) 2012 Olorunnisola PDFDocument5 pages35 IFRJ 19 (04) 2012 Olorunnisola PDFPutri Defriska SiagianNo ratings yet

- in PDFDocument6 pagesin PDFPutri Defriska SiagianNo ratings yet

- It Is in Your Hands To Live Without DiseasesDocument33 pagesIt Is in Your Hands To Live Without DiseasesAnbalagan V100% (1)

- Effect of Back Massage On Lactation Amon PDFDocument9 pagesEffect of Back Massage On Lactation Amon PDFfemyNo ratings yet

- Drip Irrigation BenefitsDocument8 pagesDrip Irrigation BenefitsJignesh ChaudharyNo ratings yet

- Retail Store Sales Report and Order RecapDocument3 pagesRetail Store Sales Report and Order RecapKassieNo ratings yet

- Accounting Staff Job VacancyDocument7 pagesAccounting Staff Job VacancyAldiansyah dtsNo ratings yet

- A Maco EncyclopediaDocument47 pagesA Maco EncyclopediaDušanNo ratings yet

- Soal Uts 1 B.inggris Kelas 5Document1 pageSoal Uts 1 B.inggris Kelas 5Gomgom Parlindungan SinuratNo ratings yet

- HACCPDocument47 pagesHACCPSujit Shandilya100% (1)

- BN Commander S Letter PDFDocument6 pagesBN Commander S Letter PDFEchoEagles100% (1)

- Purple Hibsicus QuestionsDocument7 pagesPurple Hibsicus Questionssehaj mNo ratings yet

- Better Late Than NeverDocument2 pagesBetter Late Than NeverAshley MorganNo ratings yet

- Exercise 8 Life SienceDocument2 pagesExercise 8 Life SienceAndré StrevelNo ratings yet

- Pilgrim - S Pride Poultry Records 2017 PDFDocument41 pagesPilgrim - S Pride Poultry Records 2017 PDFAnonymous NSKPIwI1No ratings yet

- Rajni Verma's Diet PlanDocument2 pagesRajni Verma's Diet PlanPiyushNo ratings yet

- NinjaBox & NinjaBuffet menus showcase innovative catering solutionsDocument15 pagesNinjaBox & NinjaBuffet menus showcase innovative catering solutionsMrunalini BNo ratings yet

- Likeri - PrevodDocument2 pagesLikeri - PrevodJelena Koprivica Ex LukicNo ratings yet

- The Complete Crafter - GM BinderDocument26 pagesThe Complete Crafter - GM BinderPhạm Quang0% (1)

- Giving Directions 1. Look at The Map and Answer The QuestionsDocument2 pagesGiving Directions 1. Look at The Map and Answer The QuestionsAnonymous Q21YDaSfNo ratings yet

- WatermelonDocument8 pagesWatermelonDania KumalasariNo ratings yet

- Learn the Spanish alphabet with pronunciation examplesDocument3 pagesLearn the Spanish alphabet with pronunciation examplesEmil Jansen0% (1)

- Royalton Resort MapDocument1 pageRoyalton Resort MapJean-Michel LeclercNo ratings yet

- Mount Athos Plan Healthy Living PT 1Document8 pagesMount Athos Plan Healthy Living PT 1Daniela Ciocodeică100% (1)

- Practice Test: Responda Las Preguntas 1 A 5 de Acuerdo Con El EjemploDocument8 pagesPractice Test: Responda Las Preguntas 1 A 5 de Acuerdo Con El Ejemplocarlos puche ojedaNo ratings yet

- EO No. 015 - 2018 REORGANIZATION OF BNCDocument2 pagesEO No. 015 - 2018 REORGANIZATION OF BNCSherrylin Punzalan Ricafort100% (7)

- Built in Refrigerator Fridge - Freezer: User ManualDocument23 pagesBuilt in Refrigerator Fridge - Freezer: User Manualmartin harteNo ratings yet

- LP FinalDocument4 pagesLP FinalTyrone PelNo ratings yet

- Thermoregulation and Human PerformanceDocument22 pagesThermoregulation and Human PerformanceHyperHodgeyNo ratings yet

- Blue Economy and ShipbreakingDocument8 pagesBlue Economy and ShipbreakingAdeen TariqNo ratings yet