Professional Documents

Culture Documents

Poster T05 Bartelt PDF

Uploaded by

Darren Pinto0 ratings0% found this document useful (0 votes)

21 views1 pagePIV has been successfully used for the determination of planar velocity fields. SPIV has proved to be particularly suitable for the investigation of strongly unsteady, turbulent flow structures in turbomachines. Endoscopic PIV gives an advantage for investigating more complex measurement setups and even real machines. A method is developed to realize SPIV measurements only by means of endoscopic entrances (both camera and light sheet) a low interference into the existing system is ensured, since only three entrance drillings in the machine casing are needed

Original Description:

Original Title

Poster_T05_Bartelt.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPIV has been successfully used for the determination of planar velocity fields. SPIV has proved to be particularly suitable for the investigation of strongly unsteady, turbulent flow structures in turbomachines. Endoscopic PIV gives an advantage for investigating more complex measurement setups and even real machines. A method is developed to realize SPIV measurements only by means of endoscopic entrances (both camera and light sheet) a low interference into the existing system is ensured, since only three entrance drillings in the machine casing are needed

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views1 pagePoster T05 Bartelt PDF

Uploaded by

Darren PintoPIV has been successfully used for the determination of planar velocity fields. SPIV has proved to be particularly suitable for the investigation of strongly unsteady, turbulent flow structures in turbomachines. Endoscopic PIV gives an advantage for investigating more complex measurement setups and even real machines. A method is developed to realize SPIV measurements only by means of endoscopic entrances (both camera and light sheet) a low interference into the existing system is ensured, since only three entrance drillings in the machine casing are needed

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Endoscopic Stereoscopic PIV for

Turbomachinery Applications

25 Years of Particle Image Velocimetry in Aerodynamics

Sept. 23 25, 2009, DLR Center Gttingen, Germany

Headline

Axial

Exhaust

Diffuser

7-Stage Air

Turbine

For several years, Particle Image

Velocimetry (PIV) has been successfully used for the determination of

planar velocity fields. With the introduction of the Stereoscopic PIV

(SPIV) all components of internal

velocity fields can be captured in

enclosed spaces. This method has

proved to be particularly suitable for

the

investigation

of

strongly

unsteady, turbulent flow structures in

turbomachines.

However, compared to conventional

applications, PIV measurements in

turbomachines are more challenging.

Limited access to measurement

section, light reflections, camera

calibration, and machine vibration

must be taken into account, to name

but a few. The implementation of

endoscopic PIV in turbomachines

gives an advantage for investigating

more complex measurement setups

and even real machines.

The axial exhaust diffuser test facility

at the institute of turbomachinery and

fluid dynamics is a 1:10 scaled

model of a heavy duty gas turbine

exhaust diffuser with a last turbine

stage simulation in form of a rotating

spoke wheel. The variable inlet

velocity can reach up to Mach 0.15.

The purpose of the PIV application is

to capture unsteady structures in the

diffuser flow and to find information

about their influence on the flow

separation. The velocity distribution

is measured 15 mm downstream of

the blade passage. An external

trigger synchronizes PIV images and

the rotor position. For seeding very

lightweight hollow glass particles are

used, which are brought into inlet by

a powder dispersion generator.

In the present work a method is

developed to realize SPIV measurements only by means of endoscopic

entrances (both camera and light

sheet). Using the endoscope technology a low interference into the

existing system is ensured, since

only three entrance drillings in the

machine casing are needed. However, this requires a camera calibration outside of the machine. The

endoscopic SPIV system is employed to a complex test facility of a

700 kW 7-stage thermal working air

turbine to study the wake structures

behind the last stage. It is shown that

a

precise

detection

of

the

3component velocity field can be

achieved with this kind of SPIV

application (at medium loading of

40% mass flow and 83% of design

speed). In comparison with a

1dimensional calculation and conventional 5-hole probe measurements the results of velocity magnitude and flow angles are in range.

Fig.:Typical endoscopic stereoscopic PIV setup in

an axial machine

Fig.: PIV in exhaust diffuser. (a) SPIV setup, (b) diffuser test

facility, (c) evaluated image, (d) velocity distribution.

b

Fig.: (a) ESPIV setup on air turbine, (b) measurement principle,

(c) velocity distribution and vector field of turbine outlet flow.

SPIV on

Centrifugal

Compressor

The centrifugal compressor test facility at the institute of turbomachinery

and fluid dynamics consists of a

onestage centrifugal air compressor

with inlet guide vanes (IGV), capable

of operating in open and closed-loop

modes. During successive projects,

the compressor has been equipped

with new and optimized IGV and

impeller. Current research activities

involve the use of endoscopic stereoscopic particle image velocimetry

(ESPIV) in order to investigate the

flow phenomena at compressor inlet,

including flow interaction between

IGV and impeller. The design of PIV

setup pro-vides the ability to capture

spatial steady state phase-resolved

three-component

velocity

fields

between IGV and impeller by

sectionwise PIV measurements.

Fig.: ESPIV measurement between IGV and impeller. (a) assembly

of PIV system, (b) ESPIV setup, (c) a typical single exposure

double image, (d) and (e) three-component velocity field.

Michael Bartelt, Arman Mohseni, Victor Opilat, Jrg R. Seume ( )

Leibniz Universitt Hannover

Institute of Turbomachinery and Fluid Dynamics (TFD)

Appelstr. 9, De-30167 Hannover

Email: seume@tfd.uni-hannover.de

Tel +49 (0)511 762-2732

www.tfd.uni-hannover.de

You might also like

- Anti Vortex DeviceDocument12 pagesAnti Vortex DeviceVipin JoseNo ratings yet

- 049 FrankDocument12 pages049 FrankMaroknightNo ratings yet

- Ms Nerturk MeqipDocument44 pagesMs Nerturk MeqipBIPIN SHARMANo ratings yet

- 1) Effect of Engine Speed On Intake Valve Flow Characteristics of A Diesel EngineDocument6 pages1) Effect of Engine Speed On Intake Valve Flow Characteristics of A Diesel EnginefitriasyrafNo ratings yet

- PPTDocument13 pagesPPTamns99No ratings yet

- Jacobs 2011 Final Wind Tunnel DesignDocument8 pagesJacobs 2011 Final Wind Tunnel DesignAhmed AdelNo ratings yet

- 1996investigation of Turbulent Flow by Means of The PIV MethoDocument9 pages1996investigation of Turbulent Flow by Means of The PIV MethoAjita NeogiNo ratings yet

- The Internal Flow Investigation of A Centrifugal PumpDocument8 pagesThe Internal Flow Investigation of A Centrifugal Pumppreetham108No ratings yet

- PIV Measurements On A Kaplan Turbine and Comparison With Scale-Adaptive Numerical AnalysisDocument8 pagesPIV Measurements On A Kaplan Turbine and Comparison With Scale-Adaptive Numerical AnalysisAdam Saeed FNo ratings yet

- Conclusions and Future Scope: 7.0 ConclusionDocument3 pagesConclusions and Future Scope: 7.0 ConclusionFattihiEkhmalNo ratings yet

- J. David Powell, N.: P. Fekete, and Chen-Fang ChangDocument12 pagesJ. David Powell, N.: P. Fekete, and Chen-Fang Changdimoi6640No ratings yet

- Implementation of Fuzzy Technique Based On Labview For Control Gas System Using Usb 6009Document10 pagesImplementation of Fuzzy Technique Based On Labview For Control Gas System Using Usb 6009Damir MiletaNo ratings yet

- Testing and Simulation of SuspensionDocument10 pagesTesting and Simulation of SuspensionAjeet PrasadNo ratings yet

- A High-Speed All-Digital Technique For Cycle-Resolved 2-D Flow Measurement and Flow Visualisation Within SI Engine CylindersDocument26 pagesA High-Speed All-Digital Technique For Cycle-Resolved 2-D Flow Measurement and Flow Visualisation Within SI Engine Cylinderssantosh2159No ratings yet

- CFD 01Document7 pagesCFD 01estebang79No ratings yet

- $MP 008 22 PDFDocument12 pages$MP 008 22 PDFmoustafaNo ratings yet

- Numerical and Experimental Analysis of Transient FDocument13 pagesNumerical and Experimental Analysis of Transient FSynbedNo ratings yet

- Head and Efficiency Prediction Methods For Centrifugal Pumps2 PDFDocument9 pagesHead and Efficiency Prediction Methods For Centrifugal Pumps2 PDFSimon TudorNo ratings yet

- Turbofan Engine Control Design Using Robust Multivariable Control TechnologiesDocument10 pagesTurbofan Engine Control Design Using Robust Multivariable Control TechnologiesPeter MalatinNo ratings yet

- Towards Intelligent Miniature Flying RobotsDocument12 pagesTowards Intelligent Miniature Flying RobotsAlexandreSidantNo ratings yet

- Air Flow Test Method-EuroventDocument8 pagesAir Flow Test Method-Euroventsiva_nagesh_2No ratings yet

- Measurements Water: SystemsDocument9 pagesMeasurements Water: SystemsDina ANDRIAMAHEFAHERYNo ratings yet

- Interfacing Matlab-2591 PDFDocument8 pagesInterfacing Matlab-2591 PDFBourrasNo ratings yet

- Model Based Controller Design For A Spherical TankDocument6 pagesModel Based Controller Design For A Spherical TankInternational Organization of Scientific Research (IOSR)No ratings yet

- Constraintoptimal Control For GyroscopeDocument7 pagesConstraintoptimal Control For GyroscopeInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Aircraft Fan Noise Reduction Technology Using Leaned Stator BladesDocument9 pagesAircraft Fan Noise Reduction Technology Using Leaned Stator BladesRou MàissàNo ratings yet

- CentrifugalPump V56Document9 pagesCentrifugalPump V56MANFOUMBINo ratings yet

- Toward The CFD Simulation of Sirocco Fans: From Selecting A Turbulence Model To The Role of Cell ShapesDocument12 pagesToward The CFD Simulation of Sirocco Fans: From Selecting A Turbulence Model To The Role of Cell ShapesGuyfawkesNo ratings yet

- Three-Dimensional Particle Image Velocimetry: Experimental Error Analysis of A Digital Angular Stereoscopic SystemDocument11 pagesThree-Dimensional Particle Image Velocimetry: Experimental Error Analysis of A Digital Angular Stereoscopic Systemsamik4uNo ratings yet

- Unsteady Velocity Measurements Taken Behind A Model Helicopter Rotor Hub in Forward FlightDocument248 pagesUnsteady Velocity Measurements Taken Behind A Model Helicopter Rotor Hub in Forward FlightHyunJoon, KimNo ratings yet

- Design and Implementation of A Nonlinear Flight Control Law For The Yaw Channel of A UAV HelicopterDocument6 pagesDesign and Implementation of A Nonlinear Flight Control Law For The Yaw Channel of A UAV HelicopterAbdallah Omar Al AyoubiNo ratings yet

- Modeling Press Brake Machine PDFDocument88 pagesModeling Press Brake Machine PDFLê Duy MinhNo ratings yet

- Test Methods For Air Curtain Units: Amca Standard 220-91Document17 pagesTest Methods For Air Curtain Units: Amca Standard 220-91Jay SuguitanNo ratings yet

- 17-2 Stroke Engine-Queens UniDocument10 pages17-2 Stroke Engine-Queens UnipeterNo ratings yet

- 300 e Cr595 Fluid-Velocity enDocument6 pages300 e Cr595 Fluid-Velocity enLazar MihailNo ratings yet

- 6/Oydlq7Ulgrq Dqg6Wpskdqh%Duuh Deulho'Dq&Lrfdqdqg/Dxuhqw7RpdvDocument12 pages6/Oydlq7Ulgrq Dqg6Wpskdqh%Duuh Deulho'Dq&Lrfdqdqg/Dxuhqw7RpdvHugh MolletNo ratings yet

- 07-264 1896-1901 PDFDocument6 pages07-264 1896-1901 PDFSugianto BarusNo ratings yet

- Blackrgdsfdasgd SG DSD Gdgs D Gaweagdasddasg Asdfkjfjd S F Kdnfkjnafk KN KNNSD nsndlsanODNa Nfdand NANDSANNAsnlanFONEDocument12 pagesBlackrgdsfdasgd SG DSD Gdgs D Gaweagdasddasg Asdfkjfjd S F Kdnfkjnafk KN KNNSD nsndlsanODNa Nfdand NANDSANNAsnlanFONEHariharanNo ratings yet

- Tumble Motion in I.C EnginesDocument27 pagesTumble Motion in I.C EnginesSajil SreedharanNo ratings yet

- Experimental Investigation of An Axisymmetric Turbofan DiffuserDocument9 pagesExperimental Investigation of An Axisymmetric Turbofan DiffuserMohsen PeykaranNo ratings yet

- Abec - Steer by Wire PDFDocument4 pagesAbec - Steer by Wire PDFKatherine DukeNo ratings yet

- Bridge Deck Active Damper Wind Tunnel Test PreprintDocument10 pagesBridge Deck Active Damper Wind Tunnel Test PreprintJose Manuel Gonzalez ContrerasNo ratings yet

- Uncertainty and Reproducibility Analysis of A Laboratorial Scaled Pipe ProverDocument8 pagesUncertainty and Reproducibility Analysis of A Laboratorial Scaled Pipe ProverOrlando GomezNo ratings yet

- Methodology of CFD Computations Applied For Analysing Flows Through Steam Turbine Exhaust HoodsDocument12 pagesMethodology of CFD Computations Applied For Analysing Flows Through Steam Turbine Exhaust HoodsvcharlesNo ratings yet

- Kim 2015 IOP Conf. Ser. Mater. Sci. Eng. 72 042044 PDFDocument8 pagesKim 2015 IOP Conf. Ser. Mater. Sci. Eng. 72 042044 PDFHema KumarNo ratings yet

- Ravi 2015 IOP Conf. Ser. - Mater. Sci. Eng. 90 012042 2Document11 pagesRavi 2015 IOP Conf. Ser. - Mater. Sci. Eng. 90 012042 2hasantapNo ratings yet

- 10 1016@j Measurement 2013 05 008 PDFDocument12 pages10 1016@j Measurement 2013 05 008 PDFgbook picsNo ratings yet

- Test and Control System Development and Application of Landing Gear Drop Test RigDocument7 pagesTest and Control System Development and Application of Landing Gear Drop Test RigAli100% (1)

- Klemm - Application of A Cross Flow Fan As Wind TurbineDocument11 pagesKlemm - Application of A Cross Flow Fan As Wind TurbineDanang JoyoeNo ratings yet

- Design and Wind-Tunnel Analysis of A Fully Adaptive Aircraft ConfigurationDocument9 pagesDesign and Wind-Tunnel Analysis of A Fully Adaptive Aircraft ConfigurationRicardo MinetteNo ratings yet

- Improvement of Wankel Engine Performance at High Altitudes: L. Tartakovsky, V. Baibikov, M. VeinblatDocument23 pagesImprovement of Wankel Engine Performance at High Altitudes: L. Tartakovsky, V. Baibikov, M. VeinblatjavadjjjNo ratings yet

- 10132Document10 pages10132dramsree1No ratings yet

- Cao Lin, Fan Wei, Yue Guangzhao and Lei Yan: DCU Development of Diesel Engines Under V-Type ProcedureDocument6 pagesCao Lin, Fan Wei, Yue Guangzhao and Lei Yan: DCU Development of Diesel Engines Under V-Type Procedurekeltoma.boutaNo ratings yet

- Notice of RetractionDocument6 pagesNotice of RetractionErna UtamiNo ratings yet

- A New Method For Aerodynamic Test of High Altitude Prop - 2017 - Results in PhysDocument3 pagesA New Method For Aerodynamic Test of High Altitude Prop - 2017 - Results in PhysEduardo CandelaNo ratings yet

- Tests of The Acoustic Emission of The Power Steering Column Equipped With A Modified Composite Worm Gear HousingDocument6 pagesTests of The Acoustic Emission of The Power Steering Column Equipped With A Modified Composite Worm Gear HousingnajibNo ratings yet

- Intelligent Control and Navigation of An Indoor Quad-Copter: Yiwen Luo Meng Joo Er Li Ling YongDocument6 pagesIntelligent Control and Navigation of An Indoor Quad-Copter: Yiwen Luo Meng Joo Er Li Ling YongKat WolfNo ratings yet

- Turgo Spear Nozzle DesignDocument15 pagesTurgo Spear Nozzle DesignCliff smythNo ratings yet

- Classical Approach to Constrained and Unconstrained Molecular DynamicsFrom EverandClassical Approach to Constrained and Unconstrained Molecular DynamicsNo ratings yet

- Model Predictive Control for Doubly-Fed Induction Generators and Three-Phase Power ConvertersFrom EverandModel Predictive Control for Doubly-Fed Induction Generators and Three-Phase Power ConvertersNo ratings yet

- Rocket Engine Nozzle Using 2D Analysis On Ansys PDFDocument8 pagesRocket Engine Nozzle Using 2D Analysis On Ansys PDFDarren Pinto100% (1)

- Comparison of A Commercial and An Open Source CFD Software PackageDocument4 pagesComparison of A Commercial and An Open Source CFD Software PackageDarren PintoNo ratings yet

- Piv Open SourceDocument19 pagesPiv Open SourceDarren PintoNo ratings yet

- Belgeler Dosya20140130113152 File PDFDocument64 pagesBelgeler Dosya20140130113152 File PDFDarren PintoNo ratings yet

- Belgeler Dosya20140130113152 File PDFDocument64 pagesBelgeler Dosya20140130113152 File PDFDarren PintoNo ratings yet

- Bisection MethodDocument2 pagesBisection MethodDarren PintoNo ratings yet

- Floating Point ArithmeticDocument9 pagesFloating Point ArithmeticDarren PintoNo ratings yet

- Moringa OleiferaDocument5 pagesMoringa OleiferaDarren PintoNo ratings yet

- Soalan LojiDocument5 pagesSoalan LojiSilver GrayNo ratings yet

- Pttep ZawtikaDocument3 pagesPttep ZawtikaSARAVANANo ratings yet

- English Task 4Document2 pagesEnglish Task 4wahyu ghofurNo ratings yet

- A - O D D P P: IR Perated Ouble Iaphragm UMP ErformanceDocument4 pagesA - O D D P P: IR Perated Ouble Iaphragm UMP ErformanceDarshan PatelNo ratings yet

- High Rise Water DistributionDocument2 pagesHigh Rise Water DistributionzueklateNo ratings yet

- Smart Campus UIMDocument1 pageSmart Campus UIMHadis AzNo ratings yet

- Logssheet Proses PsaDocument33 pagesLogssheet Proses PsaAgustino SianiparNo ratings yet

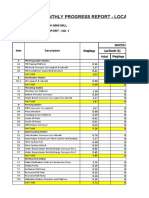

- Monthly Progress Report - Local PortionDocument4 pagesMonthly Progress Report - Local PortionShureendran Muniandy RajanNo ratings yet

- 503 Data SheetDocument2 pages503 Data Sheetklmsllm7002No ratings yet

- Me B 3 Engines With Variable Exhaust Valve TimingDocument3 pagesMe B 3 Engines With Variable Exhaust Valve TimingJatin JainNo ratings yet

- Benchmark 750-6000 Boilers: Technical Data SheetDocument3 pagesBenchmark 750-6000 Boilers: Technical Data SheetAhmed LabibNo ratings yet

- Rei 2021 ListDocument5 pagesRei 2021 ListRavi HanchateNo ratings yet

- Topic 6 - Regenerative Power Cycle and PlantDocument23 pagesTopic 6 - Regenerative Power Cycle and PlantMike MikeNo ratings yet

- Solar PV Balance of SystemDocument24 pagesSolar PV Balance of SystemKishore Krishna50% (2)

- The EPR™ Reactor: The Reference For New BuildDocument8 pagesThe EPR™ Reactor: The Reference For New BuildklareNo ratings yet

- Fired HeatersDocument24 pagesFired HeatersArief RachmanNo ratings yet

- Combustion of ADGTDocument34 pagesCombustion of ADGTthanapaet rittirutNo ratings yet

- EnergyStorage LeafletDocument2 pagesEnergyStorage LeafletcphcricriNo ratings yet

- Pipe Problems Part 1Document100 pagesPipe Problems Part 1Ralph Edward Santiago Moran100% (4)

- Prospekt - SCROLL - ENG RENNERDocument8 pagesProspekt - SCROLL - ENG RENNERAriantoNo ratings yet

- GEK116771Document12 pagesGEK116771Korneev MaximNo ratings yet

- Duflo PompDocument2 pagesDuflo Pomphufuents-1No ratings yet

- Smoke TesterDocument1 pageSmoke TesterashtaxNo ratings yet

- Amended Site Rectification VOsDocument9 pagesAmended Site Rectification VOsLouwell GuetaNo ratings yet

- Me186 Me TC SurgingDocument2 pagesMe186 Me TC SurgingRani NoumanNo ratings yet

- Course Introduction:: Advanced Pump TechnologyDocument9 pagesCourse Introduction:: Advanced Pump TechnologyMoucha JustdoitNo ratings yet

- Abac Formula 18,5 Formula 22 Formula 30Document53 pagesAbac Formula 18,5 Formula 22 Formula 30Renato García EspinosaNo ratings yet

- HW 04Document2 pagesHW 04Icy45No ratings yet

- Manual Liebert DsDocument168 pagesManual Liebert DsderioengenheiroNo ratings yet

- BMW Tab6 M73TU&M62TU Cooling SystemsDocument3 pagesBMW Tab6 M73TU&M62TU Cooling SystemsSalisburNo ratings yet