Professional Documents

Culture Documents

F 0077 e 55

Uploaded by

Bùi Cảnh TrungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F 0077 e 55

Uploaded by

Bùi Cảnh TrungCopyright:

Available Formats

High Flow High Pressure Solenoid Valve

Double 3/2 N.C. solenoid valve

with manual override

General

The high pressure/high flow capacity

solenoid valve, as not available on the

market, was especially engineered by

BIFFI in the early '70s for the specific

operation of gas-over-oil actuators,

suitable for high and low pressure,

with natural gas and in ambient

temperatures from -60C to +100C.

After many tests in the range of the

specific parameters, Biffi dedicated

know-how and experience designed a

solenoid valve which was later

improved and is still in use in the '90s.

About 60,000 solenoid valves are now

in good operation all over the world as

the heart of the high pressure

pneumatic control systems.

The extreme temperatures of Siberia

and Africa were the test benches of our

solenoid valve, as well as the hostile

ambient conditions of the production

platforms in the North Sea or the

tropical jungle of Nigeria or Malaysia.

The unit is guaranteed for good

operation, and as such it is particularly

suitable in those fields which are not

surveyed by technical personnel, e.g.

gas pipelines in remote desert areas

where actuators operated by the

natural gas of the line are most

convenient since it is not necessary to

lay power supply lines (electric,

hydraulic or pneumatic). If required, it is

enough to provide electric remote

control signals. The reliability of

operation after long periods of

inactivity is a vital requirement of the

field: the dynamic components of Biffi

solenoid valve are specifically designed

to this purpose with special PTFE

dynamic seals which nullify the

sticking effects due to long idle periods

or extreme temperatures.

Zero leakage is assured by the

poppet-type trims combined with PTFE

resilient seals. The high flow capacity

allows the operation of large actuators

even with short stroking times.

Contents may change without notice

Versatility is another basic characteristic

of this unit: a range of materials,

additional components and

accessories is available to obtain a

wide selection of complete control

systems. A low power consumption

version of solenoid valve is also

available: this is a basic requirement in

case of long-length electric lines to

reduce the voltage drop. It is also ideal

in case of electric supply from

batteries, when, in lack of electric lines,

actuator control is made via radio and

power is supplied by solar panels.

The vibrations always present in the

plant piping were also taken into

consideration: this is why we have

designed a compact unit where the

connections between the pilot zone

and the power/inlet/filtering/exhaust

zone are totally manifolded.

The associated optional accessories to

obtain special control system units were

also designed to be manifolded to the

solenoid valve body or to the manifold

plate: this reduces as much as possible

the connections by piping, which are

possible points of leakage, highly

increasing the total reliability of the

system. Maintenance is also made

easier as only the damaged component

is removed from the unit. The unit

needs no maintenance for its service

life but, just in case, trouble-shooting is

very intuitive and the maintenance

operation is very quick and easy; parts

can be replaced on field minimising all

possible troubles to the plant process.

The reliability of an entire system is due

to the reliability of every single

component: by choosing a Biffi

solenoid valve our customer can rest

assured of the trouble-free operation

of his plant application.

General application

- Especially suitable and utilised in the

gas applications: gas pipelines, gas

reduction stations, compressor

stations, gas gathering, storage

plants, manifolds, LNG plants and

everywhere high-pressure gas can be

utilised as a power medium

- Heavy duty service where the

combination of high pressure gas

supply, hostile environment,

hazardous areas and extreme

temperatures suggest the use of high

reliability components

- Generally used for control systems

of gas-over-oil actuators (GPO and

OGK Series) and of direct gas

actuators (GIG and GIGS Series)

- Also used for low pressure actuators

(ALGA, ALGAS, RPD, and RPS

Series) acting at low temperature

F Copyright by BIFFI Italia. All rights reserved.

BIFFI is a subsidiary of Keystone International, Inc.

BIFFC-0077-EN-9505

High Flow High Pressure Solenoid Valve

Features

- This solenoid valve is in the heart of the

high pressure control systems.

The standard version is fitted with:

- manifold plate

- control unit container with vent valve

- terminal board

- gas filter, condensate separator

with drain valve

- exhaust check valve

- Body in anodised aluminium for high

reliability in light weight; suitable for

every environment condition

- Main and pilot trims are poppet-type

in order to provide bubble tightness

- Internals in stainless steel and

anodised aluminium to obtain highest

compatibility with the power gas

- Sealing seats in teflon, thus granting

chemical resistance, lack of sticking

and ageing effects

- Double solenoid valve in a single

body to obtain compact design and

avoid external piping interconnection

- Solenoid enclosures in weatherproof

and explosionproof construction,

designed and manufactured by Biffi in

accordance with European Norms

(CENELEC) certified by the Italian Lab

CESI and in accordance with American

Standards certified by Factory Mutual

Lab

- Local operation, in lack of electrical

power, by means of manual override

consisting in two levers, one for closing

and one for opening

- Mounting on the proper manifold

plate that includes the power and

exhaust ports

- Weatherproof control unit container

to increase the environmental and

mechanical protection; the container

includes a vent valve to exhaust the

pilot gas and to maintain a small

pressure inside the container,

necessary to avoid the entry of

environmental moisture. The container

is padlockable to prevent the manual

operation by non-authorised

personnel.

- Gas filter unit to clean the power gas

- Terminal board in weatherproof and

explosionproof construction; body and

cover in die-cast aluminium

- Suitable to operate with high pressure

gas with no need for pressure

Contents may change without notice

reducer, thus increasing the reliability

of the control system

- Remote control for closing and

opening operation through the solenoid

valves available with various power

supply voltages

- Modular construction allowing

maximum flexibility to obtain special

control schematic by assembling

various control components directly to

the solenoid valve body or to the

manifold plate; this modularity

minimises interconnecting piping

between the control components,

therefore the safety and reliability of the

complete system is increased.

Optional features and

special constructions

An extensive range of optional

characteristics is available. Instead of

the standard construction we can offer

the following alternatives already studied

and experienced on field:

- Materials: stainless steel for the body

only or for the whole

- Body configuration: double or single

3/2 valve

- Function modes: Normally closed or

Normally open

- Control modes:

- one or two solenoid valves which

can be variously combined with a

manual override

- external pneumatic pilot signal;

- electric impulsive signal: the valve is

kept actuated by means of a

pneumatic timer device

- manual reset after ESD operation, to

be performed locally thus increasing

the plant safety

- Action:

- pilot controlled with orifice nominal

diameter of 9 mm (standard) or 12

or 15 mm (special)

- direct acting with flow orifice nominal

diameter of 0.8 or 1.25 mm

or 2.5 mm (low pressure)

- Connection modes:

- flanged to manifold;

- 1/8 threaded ports for pilot solenoid

valves

- Flow capacity: various orifices to

enable the operation of small or large

actuators within the required stroking

times

- Ambient temperatures:

- extensive experience with

temperatures as low as -60C

- heating trace for the body to

increase the operation reliability at

extreme temperatures lower than

-60C

- Medium: experienced and proven

selection of materials for operation

with highly corrosive sour gas

- Gas conditioning unit: gas

de-hydrating unit available in case of

low working temperature and wet gas

- Supply voltages: all the standard

voltages in direct or alternate current

are available; the solenoid valve

construction is for direct current, but

we accept any alternate voltage

through a proper AC/DC rectifier

placed on the terminal box enclosure;

suppression diodes available to

protect the coil from voltage transients

- Terminal box:

- different dimensions in function of

the quantity and size of the cable

entries and of the terminals;

- padlockable local selector switch

integral with the terminal box

- Control unit container: three different

dimensions are available, according to

the size and the number of components

fitted on the manifold plate

- Pressure measure: gauge with

needle valve to check the supply

pressure

All the above alternatives , already

studied and experienced on field, can

be combined in various solutions to

obtain the required unit.

Many high pressure modular control

components designed and

manufactured by Biffi are available on

request:

- pneumatic pressure switches with

intervention for high, low or differential

pressure values to obtain ESD

automatic operation control or

prevention

- "line break" detection control

device that automatically closes the

pipeline valve when the rate of the

pressure drop in the gasline exceeds

a pre-set value

- electric signalling of the emergency

operation (i.e., line break intervention)

- pneumatic timer device for ESD

operation delay

- pneumatic device to dedicate the

gas supply from the storage tank only

to the ESD operation, to increase the

safety of the process

- pneumatic device to exclude the

actuator manoeuvre opposite to

the fail operation

- pressure regulators

This wide variety of solutions allows to

obtain the desired control units to suit the

most various customer requirements.

Biffi continues with research and

development in this field, always to

be in line with new technologies and

customer requirements of plant

automation and safety.

F Copyright by BIFFI Italia. All rights reserved.

BIFFI is a subsidiary of Keystone International, Inc.

BIFFC-0077-EN-9505

High Flow High Pressure Solenoid Valve

47

46

45

44

43

42

41

40

39

10

38

11

37

12

36

13

35

14

34

15

33

16

32

17

31

18

30

19

29

20

28

21

27

22

26

23

24

25

Contents may change without notice

F Copyright by BIFFI Italia. All rights reserved.

BIFFI is a subsidiary of Keystone International, Inc.

BIFFC-0077-EN-9505

High Flow High Pressure Solenoid Valve

48

60 59 58

49

57

50

51

52

53

54

55

56

De-energised

Contents may change without notice

Energised

Manually operated

Power gas in pressure

Pilot gas in exhaust

Pilot gas in pressure

Pilot gas in pressure

F Copyright by BIFFI Italia. All rights reserved.

BIFFI is a subsidiary of Keystone International, Inc.

BIFFC-0077-EN-9505

High Flow High Pressure Solenoid Valve

Technical data

- Type: double 3-way/2-position N.C.,

poppet-type spring return solenoid

valve

- Supply medium: sweet natural gas,

air, nitrogen.

Sour gas version according to NACE

standard MR0175 available

- Max operating pressure: 120 bar

(1700 psi).

Special version up to 160 bar (2300 psi)

available

- Min working pressure: 7 bar (100 psi)

Special version for pressures as low as

3 bar (43 psi) with max working

pressure 60 bar (850 psi) available

- Ambient temperature: -30 to +100C

Special version for temperatures as

low as -60C available

- Flow orifice nominal diameter: 9 mm

Special diameters 12 and 15 mm

available

- Direct acting version: 0.8, 1.25 and

2.5 mm flow orifice diameters available

- Available voltage supplies:

12, 24, 48, 110, 115, 125, 220 VDC

110, 120V/50Hz and 120, 240V/60Hz

VAC

- Solenoid insulation: class H; epoxy

resin moulded coils available

- Nominal power:

24W for continuos duty version (standard)

9W for low consumption requirements

available

Explosionproof degrees:

CENELEC:

EEx-d IIC T5

Factory Mutual:

Class 1, Divisions 1 & 2, Groups C & D

Class 2, Divisions 1 & 2, Groups E, F & G

Class 3, Divisions 1 & 2

Temperature class: T4

Weatherproof degrees:

CENELEC:

IP 45 for solenoid valve stand-alone

IP 67 fitted into the control unit

container

Factory Mutual:

NEMA 4 fitted into the control unit

container

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

Name

Data plate

Coil cover

Coil

Gap washer

Spring pin

Exhaust plug spring

Core enclosure

O-Ring

Inlet plug pusher

Core spring

Inlet plug

Plug

Core ring nut

Inlet nozzle

Taper plug

Cover

Screw

O-Ring

Inlet seat plug

O-Ring

Piston

O-Ring

Piston ring seal

O-Ring

Piston ring seal

Back-up washer for O-Ring

O-Ring

Inlet seat

Seat lock ring nut

Index ring

Index ring

Cable terminal

Index ring

Index ring

Plug spring

O-Ring

Spring guide

Pipe lock screw

Pusher spring

Wires passage pipe

Coil lower enclosure

Exhaust plug

Coil container

Core

Exhaust nozzle

Washer

Rivet

Manual override lever

Manual override left thrust block

Spring pin

O-Ring

Screw

Spring washer

Manual override pin

Body

Plug

Manual override right thrust block

Screw

Manual override spring

Plug

Recommended spare parts; items additionally marked with

whole with the core (item 44)

Contents may change without notice

F Copyright by BIFFI Italia. All rights reserved.

BIFFI is a subsidiary of Keystone International, Inc.

Q.ty

2

2

2

2

2

2

2

2

2

2

2

4

2

2

2

1

6

2

2

2

2

2

2

2

2

4

4

2

2

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

2

2

6

2

1

2

2

4

4

4

1

2

1

3

2

2

*

*

*

*

*

*

*

*

* can only be supplied as a

BIFFC-0077-EN-9505

High Flow High Pressure Solenoid Valve

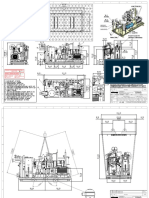

Overall dimensions and mounting data

156

60

Socket head cap screws

M6X1 for valve fastening

to the plate

(socket wrench 5mm)

Manual override lever

87

16

25

,

X1

12

K

X

DETAIL K

DETAIL W

Coil terminals

n 2 leads

(AWG19

cross section)

11

1,25

1,25

33

Protection pipe

10

O-ring groove

O-ring 2-11

ID= 7,65 W= 1,78

17

184

Actuated

position

10

Open-Close

instruction plate

110

15

Signal manifold

(removable )

O-ring groove

O-ring 2-25

ID= 29,87 W= 1,78

1,25

2

O-ring groove

O-ring 2-13

ID=10,82

W= 1,78

9

14

14

View from Y

(Signals manifold removed)

56

E

N 8 M8X1,25 (12mm deep)

threaded holes for manifold

or valves assembly

70

View from X

6

58

B C

87

C

DO

A D

Symbol of double 3/2 N.C.

solenoid valve with manual

override

28

28

40

92

PC = 3/2 N.C. Pilot solenoid valve,

with manual override (to Close)

PO = 3/2 N.C. Pilot solenoid valve,

with manual override (to Open)

DC = 3/2 N.C. Pneumatic pilot/spring

return valve (to Close)

DO = 3/2 N.C. Pneumatic pilot/spring

return valve (to Open)

A =

B =

C =

D =

E =

F =

G =

H =

J-L =

M =

Supply port (see detail K)

Outlet port to close (see detail K)

Outlet port to open (see detail K)

Power exhaust port (see detail K)

Closing pilot valve outlet port

Opening pilot valve outlet port

Closing power valve pilot

Opening power valve pilot

Pilot valves exhaust ports

N 3 6,5 Through holes for

assembly

F Copyright by BIFFI Italia. All rights reserved.

BIFFI is a subsidiary of Keystone International, Inc.

BIFFC-0077-EN-9505

Weight = 4.8 Kg

All dimensions are in mm

Contents may change without notice

Publis/Grafiche Cesina/3.000/11.94

DC

48

35

22

Connections made

by signals manifold

J L

110

PO

PC

Note: the connection between the port E-G

and F-H is made by the signals

manifold (removable)

40

40

140

PST-CS/SV-E

25

35

10

60.5

You might also like

- Dynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionFrom EverandDynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionNo ratings yet

- Turbine Off-Frequency Operation: GE Power SystemsDocument4 pagesTurbine Off-Frequency Operation: GE Power Systemskcirrenwod100% (1)

- Gas Turbine in Cairo North Power StationDocument38 pagesGas Turbine in Cairo North Power StationAbdul Moeed Kalson0% (1)

- G761 CDS6673 D Moog Trubleshooting ManualDocument4 pagesG761 CDS6673 D Moog Trubleshooting ManualRamesh BabuNo ratings yet

- Manual 99 LDDocument20 pagesManual 99 LDCristianNo ratings yet

- Operating and maintenance norms for hydraulic cylindersDocument4 pagesOperating and maintenance norms for hydraulic cylinderszsmithNo ratings yet

- Automation of Reciprocating Gas Engine Compressor Packages UsingDocument7 pagesAutomation of Reciprocating Gas Engine Compressor Packages UsingGnanaSekar0% (1)

- ARIEL Maint intervalSEK PDFDocument7 pagesARIEL Maint intervalSEK PDFMargaret Daugherty100% (1)

- المستندDocument5 pagesالمستندMahdi HassanNo ratings yet

- Analisis de Valvula Anti Surge y Fast StopDocument17 pagesAnalisis de Valvula Anti Surge y Fast Stopmcs21187No ratings yet

- Reciprocating Diaphragm Pumps PDFDocument16 pagesReciprocating Diaphragm Pumps PDFSushil GoswamiNo ratings yet

- LMF-GP LX15-8 - 10 - 13Document2 pagesLMF-GP LX15-8 - 10 - 13MAZEN0% (1)

- VH60-100 Presentation Philippe ChabinDocument46 pagesVH60-100 Presentation Philippe ChabinMohamedMansour50% (2)

- GE Air Valve Installation and Maintenance GuideDocument7 pagesGE Air Valve Installation and Maintenance Guidecachuco1234No ratings yet

- 2.4 MBM Combustor Dilution Air SystemDocument6 pages2.4 MBM Combustor Dilution Air SystemmiladNo ratings yet

- Peppers Catalogue PDFDocument64 pagesPeppers Catalogue PDFStone123456789No ratings yet

- DNFT A-6348 Led-Ps PDFDocument4 pagesDNFT A-6348 Led-Ps PDFhugoheloNo ratings yet

- D1-170 Ecosmart en PDFDocument8 pagesD1-170 Ecosmart en PDFrakacyuNo ratings yet

- U of I Facilities Standards - Control ValvesDocument25 pagesU of I Facilities Standards - Control Valvesforevertay2000No ratings yet

- Modeling Frequency Dependency of Gas Turbine OutputDocument6 pagesModeling Frequency Dependency of Gas Turbine OutputDiego CarpioNo ratings yet

- Sotera Diaphragm Pumps (DV Motor)Document8 pagesSotera Diaphragm Pumps (DV Motor)Imran Shahzad KhanNo ratings yet

- 6 Konitzer2Document32 pages6 Konitzer2mchramziNo ratings yet

- Project ReportDocument36 pagesProject Reportvishi89No ratings yet

- Centrifugal Compressor: Key Components and ApplicationsDocument14 pagesCentrifugal Compressor: Key Components and ApplicationsAnis FarhanaNo ratings yet

- NIC 13.20 Rev.01Document15 pagesNIC 13.20 Rev.01Mahmoud Ahmed100% (1)

- Atmospheric Relief Valve ManualDocument12 pagesAtmospheric Relief Valve ManualTarun ChandraNo ratings yet

- ESD White Paper From NorgrenDocument24 pagesESD White Paper From NorgrenArun BalajiNo ratings yet

- Baa1 PDFDocument149 pagesBaa1 PDFfebyNo ratings yet

- Gas Turbine Lubricating System Starting MeansDocument3 pagesGas Turbine Lubricating System Starting MeansGuruprasathNo ratings yet

- Adjust Axial Bently Nevada ProbesDocument3 pagesAdjust Axial Bently Nevada Probesmic-grNo ratings yet

- Guidelines For Preventing Torsional Vibration Problems in Reciprocating MachineryDocument48 pagesGuidelines For Preventing Torsional Vibration Problems in Reciprocating MachineryFabbrox100% (2)

- Altronic V Installation Manual (FORM AV II)Document12 pagesAltronic V Installation Manual (FORM AV II)francis_mouille_iiNo ratings yet

- GT24/GT26 Operation Training Module: Jacking Oil SystemDocument15 pagesGT24/GT26 Operation Training Module: Jacking Oil SystemAli HegaigNo ratings yet

- Device Summary EnglishDocument14 pagesDevice Summary Englishكاظم محمدNo ratings yet

- Axial Comp On OffDocument4 pagesAxial Comp On OffMohamed OmarNo ratings yet

- Compressor Exams SolutionsDocument18 pagesCompressor Exams SolutionsMohamed BalbaaNo ratings yet

- Screw CompDocument6 pagesScrew ComplaxminarayanNo ratings yet

- Samsung - UA32EH4003M CHASIS U8BApdfDocument40 pagesSamsung - UA32EH4003M CHASIS U8BApdfRoberto PompaNo ratings yet

- Samson PRV Mounting and Operating InstructionDocument20 pagesSamson PRV Mounting and Operating InstructionRick CalaguiNo ratings yet

- Nireco Servojet Sj2: GeneralDocument8 pagesNireco Servojet Sj2: GeneralKen JunNo ratings yet

- Past and Future of Electrohydraulic ServovalvesDocument20 pagesPast and Future of Electrohydraulic Servovalves1sympatyaga100% (1)

- Maintenance/clearance Area: Dimensions Could Be Change +/-5 MMDocument2 pagesMaintenance/clearance Area: Dimensions Could Be Change +/-5 MMZander MctrevorNo ratings yet

- Dresser-Rand Company Profile and Project Impact AnalysisDocument24 pagesDresser-Rand Company Profile and Project Impact AnalysisMatt JonesNo ratings yet

- 3050-OlvDocument86 pages3050-OlvMuhammad Darussalam Herdani100% (1)

- Wauksha Inspeccion Multiple AdmisionDocument2 pagesWauksha Inspeccion Multiple AdmisionLenin Marcel Fajardo AlmeidaNo ratings yet

- Gas Turbine NotesDocument21 pagesGas Turbine NotesJohn BlackburnNo ratings yet

- ELP End User Rev10Document38 pagesELP End User Rev10hugoheloNo ratings yet

- Gas Turbines and Turbocompressors For LNG ServiceDocument35 pagesGas Turbines and Turbocompressors For LNG ServiceRiza Agung NugrahaNo ratings yet

- Simjet Miniature Turbojet Engine: Owner'S ManualDocument20 pagesSimjet Miniature Turbojet Engine: Owner'S Manualamir hosseinNo ratings yet

- EPS GT Base PrinciplesDocument32 pagesEPS GT Base PrinciplescdbeardsallNo ratings yet

- GE LM2500, LM5000, LM6000 and LMS100 Gas Turbine Engines GuideDocument35 pagesGE LM2500, LM5000, LM6000 and LMS100 Gas Turbine Engines GuidesppramNo ratings yet

- Moog Pumps RKP Catalog enDocument75 pagesMoog Pumps RKP Catalog enSantiago Bonilla RiveraNo ratings yet

- Peppers Catalogue GlandsDocument28 pagesPeppers Catalogue GlandsVlad Andronache100% (1)

- Gas Transport-Mallnow-Natural-Gas-Compressor-Station PDFDocument8 pagesGas Transport-Mallnow-Natural-Gas-Compressor-Station PDFJaswindersingh BhatiaNo ratings yet

- Emergency Stop Valve BelummDocument7 pagesEmergency Stop Valve BelummhardaniNo ratings yet

- Recent Advances Turbine BypassDocument4 pagesRecent Advances Turbine BypassretrogradesNo ratings yet

- ACHE Windmill DraftguardDocument5 pagesACHE Windmill DraftguardTIKSHALANo ratings yet

- Double 3/2 N.C. Solenoid Valve With Manual Override: GeneralDocument6 pagesDouble 3/2 N.C. Solenoid Valve With Manual Override: Generaljoão oliveiraNo ratings yet

- hp26 Eng HandbookDocument58 pageshp26 Eng HandbookxbinfluxNo ratings yet

- Aquaforce Liquid Chiller High-Efficiency Industrial ChillerDocument24 pagesAquaforce Liquid Chiller High-Efficiency Industrial ChilleragbekasNo ratings yet

- LTMD-Q Series MW Series: Multi-Turn Actuator 0.2 37kW For Nuclear Power Plant Gear Reducer-Worm, Bevel 51 30,600kgf.mDocument10 pagesLTMD-Q Series MW Series: Multi-Turn Actuator 0.2 37kW For Nuclear Power Plant Gear Reducer-Worm, Bevel 51 30,600kgf.mBùi Cảnh TrungNo ratings yet

- LTMD-Q Series MW Series: Multi-Turn Actuator 0.2 37kW Nuclear Power Plant Gear Reducer - Worm, Bevel 51 30,600kgf.mDocument4 pagesLTMD-Q Series MW Series: Multi-Turn Actuator 0.2 37kW Nuclear Power Plant Gear Reducer - Worm, Bevel 51 30,600kgf.mBùi Cảnh TrungNo ratings yet

- Oliver P-T Curves For SeatDocument1 pageOliver P-T Curves For SeatBùi Cảnh TrungNo ratings yet

- Pressure Temp Ratings MSSValves 12 07 PDFDocument1 pagePressure Temp Ratings MSSValves 12 07 PDFSyarif IrwantoNo ratings yet

- FCS Brochure PCV ENG 200316Document2 pagesFCS Brochure PCV ENG 200316Bùi Cảnh TrungNo ratings yet

- Australian Standard: Bolts, Studbolts and Nuts For Flanges and Other High and Low Temperature ApplicationsDocument8 pagesAustralian Standard: Bolts, Studbolts and Nuts For Flanges and Other High and Low Temperature ApplicationsBùi Cảnh Trung50% (2)

- Separator ScrubberDocument34 pagesSeparator ScrubberBùi Cảnh TrungNo ratings yet

- Valve Manual Pocket EditionDocument23 pagesValve Manual Pocket EditionBùi Cảnh Trung100% (1)

- 1st Floor ArrangementDocument1 page1st Floor ArrangementBùi Cảnh TrungNo ratings yet

- Ground Floor ArrangementDocument1 pageGround Floor ArrangementBùi Cảnh TrungNo ratings yet

- Actuation Sizing ChartDocument12 pagesActuation Sizing ChartBùi Cảnh TrungNo ratings yet

- Oia Data Calculator Tool From NAFSADocument16 pagesOia Data Calculator Tool From NAFSAdarenNo ratings yet

- ASME B31.3 InterpretationsDocument44 pagesASME B31.3 InterpretationsChickenChick07No ratings yet

- Example 1 - 3Document248 pagesExample 1 - 3Bùi Cảnh TrungNo ratings yet

- Performance Fluids Oh32 Oh150 Hydraulic OilDocument3 pagesPerformance Fluids Oh32 Oh150 Hydraulic Oilpancho7rNo ratings yet

- Jolywood-JW-HD144N-545-570 Bifacial 2285x1134x30Document2 pagesJolywood-JW-HD144N-545-570 Bifacial 2285x1134x30Agata GuzikNo ratings yet

- Xtrons - TD609 User ManualDocument16 pagesXtrons - TD609 User ManualadrianNo ratings yet

- 5L40EDocument381 pages5L40ERichard Andrianjaka Lucky92% (13)

- Updated Infra-IIVendor ListDocument22 pagesUpdated Infra-IIVendor ListabhibaikarNo ratings yet

- ISa GRAFDocument18 pagesISa GRAFEdwin MateusNo ratings yet

- MS Electrical Cable InstallationDocument11 pagesMS Electrical Cable InstallationAhmed Rashed ANo ratings yet

- Concept of Stress: DR Atul JAIN Mechanical Engineering Department Indian Institute of Technology KharagpurDocument57 pagesConcept of Stress: DR Atul JAIN Mechanical Engineering Department Indian Institute of Technology Kharagpursneha KumariNo ratings yet

- SPE143315-Ultrasound Logging Techniques For The Inspection of Sand Control Screen IntegrityDocument18 pagesSPE143315-Ultrasound Logging Techniques For The Inspection of Sand Control Screen IntegrityYovaraj KarunakaranNo ratings yet

- CoP Fo Petroleum Road Tanker Vapour Collection Systems and Equipment Used in Unloading OperationsDocument29 pagesCoP Fo Petroleum Road Tanker Vapour Collection Systems and Equipment Used in Unloading OperationsMuhammad Ibad AlamNo ratings yet

- A967517734 - 24017 - 22 - 2018 - 10. Header Linked List (2 Files Merged) PDFDocument25 pagesA967517734 - 24017 - 22 - 2018 - 10. Header Linked List (2 Files Merged) PDFKiran KumarNo ratings yet

- PuleyDocument9 pagesPuleynicolasNo ratings yet

- JAYCO CARAVANS - 2016 Silverline and Starcraft PDFDocument12 pagesJAYCO CARAVANS - 2016 Silverline and Starcraft PDFBrisbane CamperlandNo ratings yet

- Alcatel U3 - Alcatel U3 User GuideDocument53 pagesAlcatel U3 - Alcatel U3 User Guideoswaldomarangoni5295100% (11)

- Detailed Lesson Plan in Science IVDocument12 pagesDetailed Lesson Plan in Science IVAgnes DumlaoNo ratings yet

- pd1185 Fire CodeDocument3 pagespd1185 Fire CodeCamille MangaranNo ratings yet

- Tutorial 4 - BMCG 2613 - Hydrostatic Force PDFDocument2 pagesTutorial 4 - BMCG 2613 - Hydrostatic Force PDFmege1105No ratings yet

- Dod P 16232FDocument24 pagesDod P 16232FArturo PalaciosNo ratings yet

- Netsys NVF-200EKIT User Guide 1.0.6Document19 pagesNetsys NVF-200EKIT User Guide 1.0.6pkramellaNo ratings yet

- Classic Petrol 35 SDocument10 pagesClassic Petrol 35 S5432167890OOOONo ratings yet

- Abs/Tcs/Esp Training GuideDocument136 pagesAbs/Tcs/Esp Training GuideKatapangTkrNo ratings yet

- Tetra Cardboard Packer 70 - CopyDocument808 pagesTetra Cardboard Packer 70 - CopyOmar AlneasNo ratings yet

- Mount EFS Across VPCs and Availability ZonesDocument12 pagesMount EFS Across VPCs and Availability Zonesbiswajit patrasecNo ratings yet

- DP TV Aver 15022 DriversDocument94 pagesDP TV Aver 15022 DriversMohammed Tahver Farooqi QuadriNo ratings yet

- Undergraduate Architectural Thesis Site and Village Study PDFDocument4 pagesUndergraduate Architectural Thesis Site and Village Study PDFMalavika LaxmanNo ratings yet

- What Is Physical GeologyDocument25 pagesWhat Is Physical GeologyMelanyNo ratings yet

- M103C 10/11 Meter Maximum Beam AntennaDocument9 pagesM103C 10/11 Meter Maximum Beam AntennaRádio Técnica AuroraNo ratings yet

- Ficha Tecnica Komatsu 400 - 7Document52 pagesFicha Tecnica Komatsu 400 - 7bariciado1No ratings yet

- S Parameter Theory of Lossless BlockDocument14 pagesS Parameter Theory of Lossless BlockthgnguyenNo ratings yet

- Compressors & Compressed Gas Audit ChecklistDocument3 pagesCompressors & Compressed Gas Audit ChecklistPerwez21100% (1)