Professional Documents

Culture Documents

VRM Hydraulic System

Uploaded by

Bhaskar ReddyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VRM Hydraulic System

Uploaded by

Bhaskar ReddyCopyright:

Available Formats

VEDAA CMS

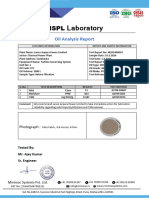

Oil Analysis Report

Machine condition monitoring specialists

1-2-18, Flat No 104, Mohini Mansion

Domalguda, Hyderabad - 500029

Email: vedaacms@gmail.com, (M)+919000319441

Lubricant Condition:

Contamination Levels:

Viscosity@40C in cSt Trend Graph

600

500

400

300

200

100

0

CAUTION

UNACCEPTABLE

PENNA CEMENTS LIMITED - TALARICHERUVU

SAMPLE ID : VEDAA/PCL-T/VRMHS/048T

EQUIPMENT : VRM Hydraulic system

COMPONENT : Hydraulic system

LUBRICANT NAME : 46 Grade Oil

RESERVOIR CAP. :

SAMPLE DATE:

RECEIVED DATE:

TEST DATE:

Prev.SAMPLE Dt:

FIRST SAMPLE Date:

No. of SAMPLES:

Prev.SAMPLE Condition:

SAMPLE LOCATION:

Last OIL CHANGE Dt:

11/05/15

12/05/15

18/05/15

04/06/14

20/10/13

4

Normal

Dipstick

800

700

600

500

400

300

200

100

0

MACHINE HOURS :

LUBE TIME :

LCR Recommendations :

Viscosity @ 40 deg.C value is on the higher side so that it is recommended to drain 30 ltrs of old oil and

refill with same quantity of fresh oil to regain viscosity levels. Filter the oil after the above maintenance

action to extend the life of the oil. This high viscosity is due to improper functioning of air breather

so that check and clean the air breather by applying compressed oil to prevent high viscosity levels.

Lube Oil Test Parameters

Sample

Date

Viscosity @ 40C

Limits

Moisture in ppm

Limits

TAN in mgKOH/g

Limits

ASTM D 445

41.4-50.6

ASTM D 1744

95

99

104

156

500 Max

ASTM D 664

1.0 Max

20/10/13

28/02/14

04/06/14

49.2

11/05/15

58.3

47.3

46.9

0.13

0.22

0.26

0.37

Particle Count

ISO 4406:1999: Number of Particles Per Milliliter (Counts/ml)

Sample Date(s):

04/06/14

11/5/2015

Size Range

No.of Particles

No.of Particles

Class

Class

>4 microns

>6 microns

>14 microns

ISO 4406 Result

2015 VEDAA CMS, Hyderabad,India.

688

351

92

17/16/14

17

16

14

8542

1938

246

20/18/15

20

18

15

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

49.2 47.3 46.9 58.3

Moisture in ppm

95 99 104

156

TAN in mgKOH/g

0.37

0.13 0.22 0.26

Particle Count ISO 4406:1999: Number of Particles Per

Milliliter (Counts/ml)

28

24

20

16

12

8

4

0

VEDAA CMS

Machine condition monitoring specialists

1-2-18, Flat No 104, Mohini Mansion

Domalguda, Hyderabad - 500029

Email: vedaacms@gmail.com, (M)+919000319441

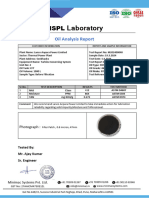

FERROGRAPHY REPORT

Machine Condition

MARGINAL

Ferrous

Wear

Particles

Last OIL CHANGE Dt:

MACHINE HOURS :

LUBE TIME :

MCR Recommendations:

Filter the oil as wear particle concentration is high.

9 10

Normal Rubbing

32

Severe Sliding Wear

Cutting Wear

Gear Wear

PENNA CEMENTS LIMITED - TALARICHERUVU

SAMPLE ID : VEDAA/PCL-T/VRMHS/048T

EQUIPMENT : VRM Hydraulic system

COMPONENT : Hydraulic system

LUBRICANT NAME : 46 Grade Oil

RESERVOIR CAP. :

Ferrous Metal Wear Severity Rating

SAMPLE DATE:

RECEIVED DATE:

TEST DATE:

Prev.SAMPLE Dt:

FIRST SAMPLE Date:

No. of SAMPLES:

Prev.SAMPLE Condition:

SAMPLE LOCATION:

Bearing Wear

11/05/15

12/05/15

18/05/15

04/06/14

20/10/13

4

Normal

Dipstick

Spheres

BlackOxides(Fe3O4)

Red Oxides(Fe2O3)

Corrosive(FeO)

Other

Non-Ferrous

Wear

Particles

Non-Ferrous Metal Wear Severity Rating

0 1 2 3 4 5 6 7 8 9 10

Normal Rubbing

Severe Sliding Wear

Cutting Wear

Gear Wear

Bearing Wear

Other

Analytical Ferrography - Detailed Analysis of wear regimes evident in component.

Contaminants:

Normal rubbing wear particles(15 microns) are observed in marginal quanitites.

Low alloy steel severe sliding wear particles of size ranging up to 32 microns are observed in small quantities.

Red oxides are observed in negligible quantities.

Sand/dirt particles are observed in small quantities.

Subjective Rating

0 1 2 3 4 5 6 7 8 9 10

Sand/Dirt

Fibers

Cont.Spheres

Lube Degradion

Other

Overall Wear Severity Trend

11/0

05/15

04/0

06/14

The microscopic image depicts normal rubbing wear particles.

28/0

02/14

The image captured at 500X magnification

20/1

10/13

10

9

8

7

6

5

4

3

2

1

0

You might also like

- Loesche Round Table VICATDocument20 pagesLoesche Round Table VICATFirdaus Azizan86% (7)

- KHD Praesentation ZementDocument19 pagesKHD Praesentation ZementAnonymous Cxriyx9HIXNo ratings yet

- Summary of Raw Grinding System PDFDocument1 pageSummary of Raw Grinding System PDFNaelNo ratings yet

- Cement Mill Calculation DesaignDocument1 pageCement Mill Calculation DesaignHilmy MuhammadNo ratings yet

- VRM - PaperDocument9 pagesVRM - PaperJoko Dewoto100% (1)

- Report On Cement MillDocument9 pagesReport On Cement MillYounas Khan100% (1)

- Quest - Vertical Roller Mill - KM (Rough)Document6 pagesQuest - Vertical Roller Mill - KM (Rough)Raji SuriNo ratings yet

- Gebr. Pfeiffer Brochure Passion For Grinding enDocument28 pagesGebr. Pfeiffer Brochure Passion For Grinding enRollerJonnyNo ratings yet

- Loesche Grinding Plants For Coal GasificationDocument45 pagesLoesche Grinding Plants For Coal GasificationMaxim Polevoy100% (1)

- Ilara RM - CS P.11002 - P.12610 - 15092021 - 18092021 - Technichal ReportDocument16 pagesIlara RM - CS P.11002 - P.12610 - 15092021 - 18092021 - Technichal ReportBen100% (1)

- 04 Vertical Roller MillsDocument12 pages04 Vertical Roller MillsaktaserdincNo ratings yet

- Grinding System and Circuit of VRM Process Data Plant DataDocument58 pagesGrinding System and Circuit of VRM Process Data Plant DataFasil Ayele60% (5)

- VRM Operation and OptimizationDocument39 pagesVRM Operation and OptimizationJitendra Jangid100% (5)

- 13-IMS 2021 Roller PressDocument63 pages13-IMS 2021 Roller Presshmaza shakeelNo ratings yet

- Unwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyDocument5 pagesUnwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyharyantoaditNo ratings yet

- 031 Introduction Cement Grinding With Ball Mill SystemsDocument4 pages031 Introduction Cement Grinding With Ball Mill SystemsCesar Orlando Guarniz JustinianoNo ratings yet

- Grinding Mills Optimisation: Magotteaux / Slegten / Sturtevant SolutionsDocument44 pagesGrinding Mills Optimisation: Magotteaux / Slegten / Sturtevant Solutionsshani5573100% (1)

- Cement Mill Control PDFDocument30 pagesCement Mill Control PDFJackson Vu100% (2)

- 3500TPD Cement Plant Heat BalanceDocument2 pages3500TPD Cement Plant Heat BalanceIrshad HussainNo ratings yet

- Hydraulic Thrust DeviceDocument2 pagesHydraulic Thrust DeviceAlbar Budiman100% (6)

- Equip. Name:-RAW MILL Equip. TAG No. 300 RM-1Document1 pageEquip. Name:-RAW MILL Equip. TAG No. 300 RM-1vinodsnNo ratings yet

- Chuong 2-Roller MillDocument24 pagesChuong 2-Roller MillAmit Sharma0% (1)

- LoescheDocument35 pagesLoescheayaskant751001No ratings yet

- A Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BDocument4 pagesA Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BYhaneNo ratings yet

- Raw Mill Balance SheetsDocument4 pagesRaw Mill Balance SheetsAli Hüthüt100% (1)

- Bab 2 Raw Mill System DG VRMDocument80 pagesBab 2 Raw Mill System DG VRMJoko DewotoNo ratings yet

- Loesche-Mills: For Cement Raw MaterialDocument28 pagesLoesche-Mills: For Cement Raw Materialboyka yuriNo ratings yet

- Repair and Maintenance: CoolerDocument61 pagesRepair and Maintenance: CoolerYhaneNo ratings yet

- Separation SBDocument50 pagesSeparation SBSuchismita Bhattacharya Bhaumik100% (4)

- Vertical Roller Mill SummaryDocument20 pagesVertical Roller Mill SummaryPhyo Thura Htay100% (6)

- Vertical Roller MillDocument3 pagesVertical Roller MillChaitanya Chinta0% (1)

- VRM PresentationDocument49 pagesVRM Presentationrecai100% (3)

- Ball Mill Ventilation AirDocument1 pageBall Mill Ventilation AirVijay BhanNo ratings yet

- Blaine Reference Blaine Required e KDocument4 pagesBlaine Reference Blaine Required e KNael100% (3)

- Atox 45 Raw Mill Critical Interlock SheetDocument6 pagesAtox 45 Raw Mill Critical Interlock SheetValipireddy NagarjunNo ratings yet

- Review RollerPress OperationsDocument331 pagesReview RollerPress OperationsAnonymous 3ESYcrKPNo ratings yet

- Heat Balance DiagramDocument29 pagesHeat Balance Diagramsanju_cgh100% (2)

- Cement Mill Shell LinerDocument7 pagesCement Mill Shell LinerMahaveer SinghNo ratings yet

- RP MaintenanceDocument31 pagesRP Maintenanceshannu826826100% (2)

- Studies of Cement Mill CircuitDocument3 pagesStudies of Cement Mill CircuitRobson de Freitas Werling100% (1)

- Alkali Khaled PDFDocument21 pagesAlkali Khaled PDFbulentbulut100% (1)

- Mill Ventilation MeasurementDocument5 pagesMill Ventilation MeasurementBùi Hắc HảiNo ratings yet

- Rueddenklau Snowman PreventionDocument102 pagesRueddenklau Snowman PreventionIonela Dorobantu100% (2)

- Introduction To Vertical Roller MillDocument35 pagesIntroduction To Vertical Roller MillUtkarshKatiyarNo ratings yet

- Holcim Material Bulk Density PDFDocument1 pageHolcim Material Bulk Density PDFEdgar Raul RomeroNo ratings yet

- Loesche Round Table VICAT PDFDocument20 pagesLoesche Round Table VICAT PDFrecaiNo ratings yet

- VRM OperationsDocument35 pagesVRM OperationsJitendra Jangid100% (1)

- Raw Mill Vertical Roller Mill PDFDocument58 pagesRaw Mill Vertical Roller Mill PDFManpreetSaran92% (12)

- VRM PresentationDocument49 pagesVRM PresentationMKPashaPasha100% (4)

- Vertical Roller Mill SummaryDocument20 pagesVertical Roller Mill SummaryPhyo Thura Htay100% (3)

- What Kiln Operator Should Do in Emergency SituationDocument12 pagesWhat Kiln Operator Should Do in Emergency SituationLe HoangNo ratings yet

- Upendra KumarDocument46 pagesUpendra Kumardasleo546No ratings yet

- Lanco Anpara M202400040Document1 pageLanco Anpara M202400040moms1No ratings yet

- Lanco Anpara M202400039Document1 pageLanco Anpara M202400039moms1No ratings yet

- Cause & Effect Diagram PDFDocument1 pageCause & Effect Diagram PDFJetesh DevgunNo ratings yet

- Lubricant Analysis Report: Missing InformationDocument3 pagesLubricant Analysis Report: Missing InformationRaúl GarcíaNo ratings yet

- Excavator Check ListDocument1 pageExcavator Check Listmuhammad.younisNo ratings yet

- Bis BFP Oil FlushingDocument19 pagesBis BFP Oil FlushingShailenderNo ratings yet

- TCR Arabia Company LTD.: Magnetic Particle Testing ReportDocument1 pageTCR Arabia Company LTD.: Magnetic Particle Testing ReportRonel John Rodriguez CustodioNo ratings yet

- 26 Samss 083Document3 pages26 Samss 083Cherukunnon JubuNo ratings yet

- Whitepaper - AlignmentDocument20 pagesWhitepaper - Alignmentmanbkk100% (2)

- Servo Product Data - Industrial GradesDocument23 pagesServo Product Data - Industrial GradesUtkarsh100% (1)

- Servo Product Data - Industrial GradesDocument23 pagesServo Product Data - Industrial GradesUtkarsh100% (1)

- FLENDERDocument79 pagesFLENDERekin100% (4)

- Primecut Manual PDFDocument31 pagesPrimecut Manual PDFBhaskar ReddyNo ratings yet

- Fundamentals of Welding - TechnologyDocument27 pagesFundamentals of Welding - TechnologyArvinth KumarNo ratings yet

- Kumera Girth Gear Technical ManualDocument12 pagesKumera Girth Gear Technical ManualBhaskar Reddy100% (1)

- Introduction To Nondestructive TestingDocument34 pagesIntroduction To Nondestructive TestingNanditha Mandava ChowdaryNo ratings yet

- A Brief Description of NDTDocument22 pagesA Brief Description of NDTranjana3006No ratings yet

- A Brief Description of NDTDocument22 pagesA Brief Description of NDTranjana3006No ratings yet

- Undestanding Factors Taha Cause Shaft FailureDocument4 pagesUndestanding Factors Taha Cause Shaft Failurepaul_tinizarayNo ratings yet

- Disclosure To Promote The Right To InformationDocument68 pagesDisclosure To Promote The Right To InformationchinmoybaruahNo ratings yet

- Excel Training Guide PDFDocument13 pagesExcel Training Guide PDFMoiz IsmailNo ratings yet

- SPM TrainingDocument106 pagesSPM TrainingBhaskar Reddy0% (1)

- HW Installation Maintenance Troubleshooting Guide en PDFDocument48 pagesHW Installation Maintenance Troubleshooting Guide en PDFlukky prasetyoNo ratings yet

- Chapter2 Hydraulics Control in Machine ToolsDocument67 pagesChapter2 Hydraulics Control in Machine ToolsBasha KumeraNo ratings yet

- Hydraulic SystemsDocument63 pagesHydraulic SystemsBhaskar ReddyNo ratings yet

- A Brief Description of NDTDocument22 pagesA Brief Description of NDTranjana3006No ratings yet

- 1 AlignmentDocument62 pages1 AlignmentTanoj PatroNo ratings yet

- Handbook of Mechanical Engineering TermsDocument366 pagesHandbook of Mechanical Engineering Termsjakejohns95% (44)

- A Brief Description of NDTDocument22 pagesA Brief Description of NDTranjana3006No ratings yet

- Hydraulic SymbolsDocument18 pagesHydraulic SymbolsBhaskar Reddy100% (1)

- Handbook of Mechanical Engineering TermsDocument366 pagesHandbook of Mechanical Engineering Termsjakejohns95% (44)

- Impeller TrimmingDocument1 pageImpeller TrimmingicingrockNo ratings yet

- General Studies Economics Part IDocument22 pagesGeneral Studies Economics Part IbusisubbareddyNo ratings yet

- Handbook of Mechanical Engineering TermsDocument366 pagesHandbook of Mechanical Engineering Termsjakejohns95% (44)

- Kumera Girth Gear Technical ManualDocument12 pagesKumera Girth Gear Technical ManualBhaskar Reddy100% (1)

- Workshop Exercise - Fans and BlowersDocument3 pagesWorkshop Exercise - Fans and BlowersShukla SuyashNo ratings yet

- Medieval India General Studies HistoryDocument46 pagesMedieval India General Studies HistoryArjun RathoreNo ratings yet

- The Chattering Problem in Sliding Mode SystemsDocument8 pagesThe Chattering Problem in Sliding Mode SystemsBhaskar BiswasNo ratings yet

- F FiberglassDocument66 pagesF Fiberglassosvald97No ratings yet

- Be Form 3 - Resource Mobilization FormDocument3 pagesBe Form 3 - Resource Mobilization FormDherick RaleighNo ratings yet

- Highway Planning Manual Volume 8 PDFDocument72 pagesHighway Planning Manual Volume 8 PDFHanz Maca-ayanNo ratings yet

- Ingersoll PDFDocument76 pagesIngersoll PDFTirso ArteroNo ratings yet

- (L2) - Mole Concept JEEDocument19 pages(L2) - Mole Concept JEEHYDRA CLAN100% (1)

- 4.2 Beam Post-ProcessingDocument23 pages4.2 Beam Post-Processingjingyong123No ratings yet

- Dead LoadsDocument1 pageDead LoadsShokry AlkissyNo ratings yet

- MCQ Elex-BoylestadDocument216 pagesMCQ Elex-BoylestadJj JumawanNo ratings yet

- 7.3.2.3 Packet Tracer - Configuring RIPng InstructionsDocument3 pages7.3.2.3 Packet Tracer - Configuring RIPng InstructionsCristian GarciaNo ratings yet

- Extended Cell ConfigurationDocument31 pagesExtended Cell Configurationrfabre76No ratings yet

- Fieldbus FoundationDocument38 pagesFieldbus FoundationFelipe Andrés Espinoza RivasNo ratings yet

- Belaire Compressor CatalogDocument12 pagesBelaire Compressor CatalogBillNo ratings yet

- Atlas Metals HandbookDocument45 pagesAtlas Metals HandbookJim GrayNo ratings yet

- Light, Shadow & ReflectionDocument3 pagesLight, Shadow & ReflectionirfannmsNo ratings yet

- IBM Tape in Unix SystemsDocument300 pagesIBM Tape in Unix SystemsChanchal MukherjeeNo ratings yet

- C Library Math.h Functions - GeeksforGeeksDocument11 pagesC Library Math.h Functions - GeeksforGeeksSoumadip Banerjee100% (1)

- Lecture 2Document23 pagesLecture 2Sherif HelmyNo ratings yet

- Review Guide For The Qatar Electrical Engineers GradeDocument84 pagesReview Guide For The Qatar Electrical Engineers GradeHerman ArcalasNo ratings yet

- White Products CatalogDocument49 pagesWhite Products CatalogjesusNo ratings yet

- Solved Problems (1) Draw The Cam Profile For Following ConditionsDocument6 pagesSolved Problems (1) Draw The Cam Profile For Following Conditionsrakesh kumarNo ratings yet

- 1.diesel Engine AssemblyDocument22 pages1.diesel Engine Assemblypepenapao1217No ratings yet

- 6 1 UpDocument102 pages6 1 Upsoraandreea20No ratings yet

- Computer Architecture and Parallel Processing by Kai Hwang PDFDocument6 pagesComputer Architecture and Parallel Processing by Kai Hwang PDFApoorva ursNo ratings yet

- Bearing SPM Condition Analyser BVT 111Document2 pagesBearing SPM Condition Analyser BVT 111industrialindiaNo ratings yet

- JavaScript and XHTML DocumentsDocument40 pagesJavaScript and XHTML Documentstech2click100% (3)

- Experimental Study On The Thermal Performance of R600a PDFDocument9 pagesExperimental Study On The Thermal Performance of R600a PDFEdy MesinNo ratings yet

- Metallographic Sample Preparation Techniques: BackgroundDocument8 pagesMetallographic Sample Preparation Techniques: BackgroundQA LAB ISMNo ratings yet

- Comparative Study of BS5930 and EN ISO PDFDocument14 pagesComparative Study of BS5930 and EN ISO PDFNathan VincentNo ratings yet

- SC200 RevDocument2 pagesSC200 RevAshraf MuhtarNo ratings yet