Professional Documents

Culture Documents

8 Padeye - Spreadsheet Check1

Uploaded by

oluomo1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8 Padeye - Spreadsheet Check1

Uploaded by

oluomo1Copyright:

Available Formats

Page 1 of 4

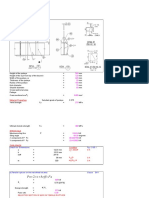

8 TON PADEYE

1.0 Inputs

1.1 Padeye characteristics

R_eye

R_main

R_cheek

th_main

th_cheek

a_weld

H_stiff1

H_stiff2

th_stiff1

th_stff2

H_eye

V

V_s1

Lenth

Width1

Width2

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

27.5

95

0

50

0

0

0

0

0

0

48

0

0

200

0

0

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

eye radius

main plate radius

cheek plates radius

main plate thickness

cheek plate thickness

welding dimension between main & cheek plates

stiffner 1 height

stiffner 2 height

stiffner 1 thickness

stiffner 2 thickness

height of eye

distance between center of stiffners

distance eye-center to stiffner 1

total length of padeye (stiffners included)

width of stiffner 1 at feet

width of stiffner 2 at feet

118 kN

Nominal applied load

=

=

=

60 deg.

31 deg.

2.00

angle between applied load & Y-Z plane

additional sling deviation

safety coefficient applied to get design load

=

=

=

=

50

146

17

60.5

pin diameter

Inside length

Safe working load

Shackle inside width

1.2 Applied loads

b

S

1.3a Shackle characteristics

d_pin

in_length

shackle_safe_load

Ash

1

3b Need

N d ffor centralizer

t li

l t during

d i

lifti

1.3b

plates

lifting

:

Tt

Ash - Tt

mm

mm

MT

mm

THIS CHECK IS NOT PART OF STRENGTH CHECK CALCULATIONS

=

=

50.00 mm

10.50 mm

Total padeye thickness (both main & cheek plates)

No Centralizer plates reqd

1.4 Material characteristics

Fy

E

=

=

345.00 Mpa yield strength

20000.00 Kn/sqc Young elastic modulus

2.0 Design load

The lifting eye is checked for a maximum static sling load of 118 kN

together with an inclination angle of 60 deg. to Y-Z plane, and 31 deg. additional sling deviation

x

F

a

236.00 kN

H_eye

Hole

Design load applied in the plane of padeye

This results in the following padeye loading

FDy = FD*cosa*cosb

FDx = FD*sina

Main

Applying a safely factor of 2 gives a design load of:

FD = F*S

Cheek

Stiffner 1

=

=

101.15 kN

204.38 kN

Stiffner 2

Design load applied perpendicular to padeye plane

H

FDz = FD*cosa*sinb+0.05*FD

72.57 kN

as per API-RP-2A recommendations

Page 2 of 4

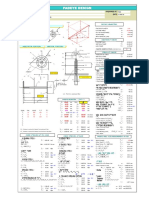

8 TON PADEYE

3.0 Check stresses at eye location

th_cheek

3.1 Check shear stress: fy = FD/As

th main

As = 2*(th_main*(R_main R_eye)+(2*th_cheek)*(R_cheek - R_eye))

fv = FD*10^3/As

fallowable_v = 0.4*Fy

=

=

=

6750.00 mm^2

34.96 Mpa

138.00 Mpa

Stress ratio:

Rv = fv / fallowable_v

0.25 < 1 ok

z

3.2 Check bearing shear stress or radial pressure: fp = FD/Ax

r_axe = d_pin/2

Ax = 2*r_axe*(th_main + 2*th_cheek)

fx = FD*10^3/Ax

fallowabe_x = 0.9*Fy

=

=

=

Stress ratio:

Rx = fx / fallowable_x

25.00

2500.00

94.40

310.50

mm

mm^2

MPa

MPa

0.30 < 1 ok

3.3 Check Hertz pressure: fm

Checking in line with the Hertz Formula (Roark -Table 33-2c)

Kb=2*R_eye*d_pin/(2*R_eye-d_pin)

=

fm=0.591*sqrt(F*E/(2*th_cheek+th_main))

=

fallowable_m = 2.5*Fy

=

Stress ratio:

Rm = fm / fallowable_m

3 4 Check welding between cheek plates & main plate:

3.4

550.00 mm

774.27 Mpa

862.50 Mpa

0.90 < 1 ok

fvs = FJ/Avs

Welding characteristics

d_weld = a_weld/sqrt(2)

0.00 mm

Avs = 2*pi*r_cheek*d_weld

0.00 mm^2

Load applied per cheek plate

Fj = FD*th_cheek/(2*th_cheek+th_main)

fvs = Fj*10^3/Avs

fallowable_vs = 0.4*Fy

=

=

=

0.00 kN

#DIV/0! Mpa

138.00 MPa

Stress ratio:

Rm = fm/fallowable_m

#DIV/0!

tw = Fj/sqrt(2)

Nw = Fj/sqrt(2)

0.00 kN

0.00 kN

Stresses:

fwa = Nw/Avs

fwv = Tw/(Avs*2/3)

fwVM = sqrt(fwa^2+3fwv^2)

Stress ratio:

Rwa = fwa/(0.6*Fy)

Rwv = fwv/(0.4*Fy)

RwVM = fwVM/(0.66*Fy)

#####

=

=

=

#DIV/0!

#DIV/0!

#DIV/0!

MPa

MPa

MPa

#DIV/0!

#DIV/0!

#DIV/0!

#####

#####

#####

1 - 1

8 TON PADEYE

Page 3 of 4

4.0 Check Shear between Main Plate and Flanges:

F1 = Mz/H - Fx/2

F2 = Mz/H + Fx/2

=

=

fva=Max(F1,F2)/(h*th_main)<=0.4*FY

fvb=Max(F1,F2)/(h*th_main)<=0.4*FY

#DIV/0!

#DIV/0!

N/mm2Shear stress in Main plate

N/mm2

=

=

#DIV/0!

#DIV/0!

#####

#####

Stress ratio:

Rva = fva/(0.4*Fy)

Rvb = fvb/(0.4*Fy)

77.91602 kN

126.46598 kN

Shear force b/w stiffner 1 and Main plate

Shear force b/w stiffner 2 and Main plate

5.0 Check Shear in the Chord at Chord / Main Plate Connection

T = Fdy

t (Chord thickness)

=

=

Tv = T/(2*H*t)<=0.4*FY

Stress ratio:

RTV = Tv/(0.4*FY)

101.15 kN

31.75 mm

7.9642316

0.06 < 1 ok

6.0 Checking of I-shaped section based on AISC formulae

6.1. Applied load parameters toward the checked section:

I

=

6.2. Checked section geometrical parameters :

H

ew

B

ef

dg

=

=

=

=

=

48.00 mm

Length between the applied load

section and the section checked

along x-axis

0.00 mm

Length between the applied load

point and the section checked

COG along y-axis

200.00

50 00

50.00

50.00

0.00

0.00

mm

mm

mm

mm

mm

length of the section along y-axis

axis

thickness of the section parallel to yy-axis

length of the section along z-axis

thickness of the section parallel to z-axis

distance between z-axis and gusset plate axis

6.3. Miscellaneous points definition :

Vy (cm)

Vz (cm)

2.50 10.00

2.50 0.00

2.50 0.00

2.50 0.00

0.00 0.00

point1

point2

point3

point4

CoA

6.4. Checked section geometrical parameters :

Areas

Ay

=

=

=

10000.00 mm^2

0.00 mm^2

10000.00 mm^2

Iy

Iz

=

=

208.33 cm^4

3333.33 cm^4

Ny1 = Iy/Vy1

Ny2= Iy/Vy2

Ny3= Iy/Vy3

Ny4= Iy/Vy4

Nz1 = Iz/Vz1

Nz2= Iz/Vz2

Nz3= Iz/Vz3

Nz4= Iz/Vz4

=

=

=

=

=

=

=

=

Az

Ax

Inertias

Inertia modulus

83.33

83.33

83.33

83.33

333.33

0.00

0.00

0.00

cm^3

cm^3

cm^3

cm^3

cm^3

cm^3

cm^3

cm^3

Static moment

MsyCoA

Msy3

Msy4

Msz3

Msz4

Page 4 of 4

8 TON PADEYE

=

=

=

=

=

250.00

250.00

250.00

0.00

0.00

=

=

=

=

=

236.00

3483.58

4855.00

101.15

72.57

cm^3

cm^3

cm^3

cm^3

cm^3

6.5. Loading :

N = FD

My = -FDz*I

Mz = -FDy*I - FDx*d

Ty = FDy

Tz = FDz

kN

kN.mm

kN.mm

kN

kN

6.6. Resulting stresses :

Normal stress

Bending stresses

Shear stresses

fa:

fby1=

fby2=

fby3=

fby4=

fbz1=

fbz2=

fbz3=

fbz4=

fvyCoA=

23.60 N/mm^

=

=

=

=

=

=

=

=

41.80

41.80

41.80

41.80

14.56

0.00

0.00

0.00

N/mm^2

N/mm^2

N/mm^2

N/mm^

N/mm^2

N/mm^2

N/mm^2

N/mm^

15.17

fvy3= Ty*msy3/Iz*t

15.17 N/mm^2

fvy4= Ty*msy4/Iz*t

15.17 N/mm^2

fvz3=Tz*msz3/Iy*t

0.00 N/mm^2

fvz4= Tz*msz4/Iy*t

fv3=

fv4=

=

=

=

0.00 N/mm^2

15.17 N/mm^2

15.17 N/mm^

Ra =

0.11 < 1 O.K.

Rby =

0.18 < 1 O.K.

Rbz =

0.06 < 1 O.K.

Rv =

0.11 < 1 O.K.

7. AISC streess interaction ratio & Von-Mises stress ratio :

R = fai/0.6 x Fy + (fbyi + fbzi)/0.66 x Fy

(AISC stress interaction ratio)

dVM

= [(fai + fbyi + fbzi)^2 + 3 x fvi^2]^1/2

Rvm = dVM/0.66 x Fy (Von - Mises stress ratio)

Point 1 Axial stress + bending y + bending z

R

=

0.36

R=

0.36 < 1 O.K.

0.30

R=

0.30 < 1 O.K.

Point 2 Axial stress + bending y + bending z

R

Point 3 Axial stress + bending y + bending z

R

dVM

=

=

0.30

70.48 N/mm^

R=

0.30 < 1 O.K.

Rvm =

0.31 < 1 O.K.

Point 4 Axial stress + bending y + bending z

R

dVM

R=

0.30 < 1 O.K.

70.48 N/mm^

0.30

Rvm =

0.31 < 1 O.K.

=

=

0.11

35.32 N/mm^

R=

Rvm =

0.11 < 1 O.K.

0.16 < 1 O.K.

CoA Axial stress + bending y + bending z

R

dVM

You might also like

- 17 TonsDocument8 pages17 Tonsabuzahrau100% (3)

- Padeye Calculation LatestDocument10 pagesPadeye Calculation LatestPavan RayNo ratings yet

- Lifting Lug Calculation RefDocument2 pagesLifting Lug Calculation Refmarc_albertoNo ratings yet

- Section Properties: Design of Padeye As Per Aisc 360-2005Document5 pagesSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaNo ratings yet

- TrunnionDocument7 pagesTrunnionRUDHRA DHANASEKAR100% (1)

- Design of Pad Eye Using Check PlatesDocument3 pagesDesign of Pad Eye Using Check Plateshyoung65No ratings yet

- Padeye DesignDocument2 pagesPadeye DesignChiedu Okondu100% (1)

- Padeye CalculationDocument6 pagesPadeye CalculationKarun DasNo ratings yet

- Sendai Project Lifting Lug DesignDocument6 pagesSendai Project Lifting Lug DesignkalpanaadhiNo ratings yet

- 17 TON PADEYE STRENGTH CHECKDocument12 pages17 TON PADEYE STRENGTH CHECKoluomo1No ratings yet

- Crack Width Calc - BS 8110Document1 pageCrack Width Calc - BS 8110Thomas Crowe100% (2)

- Weld strength calculation guide for fillet weldsDocument20 pagesWeld strength calculation guide for fillet weldsVikash Yadav100% (1)

- Maintenance & Trouble Shooting of Voith CouplingDocument20 pagesMaintenance & Trouble Shooting of Voith Couplingsen_subhasis_58100% (1)

- Shear Strength Calculation For Lifting Lug For Plate FlippingDocument16 pagesShear Strength Calculation For Lifting Lug For Plate FlippingKarthikeyan VisvakNo ratings yet

- #754 v-3103 Spreader & Lifting 60 DegreeDocument12 pages#754 v-3103 Spreader & Lifting 60 DegreeHafizi HZnumismatic100% (1)

- LIFTING LUG Weld Check KGDocument4 pagesLIFTING LUG Weld Check KGjoerijiNo ratings yet

- Padeye .5MT CHKDocument12 pagesPadeye .5MT CHKDhanraj VasanthNo ratings yet

- Spreader Beam (Planning)Document28 pagesSpreader Beam (Planning)AKSHAY BHATKARNo ratings yet

- Lifting LugDocument39 pagesLifting LugSasikumar JothiNo ratings yet

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADocument1 page2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanNo ratings yet

- Lifting Lug AnalysisDocument3 pagesLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Horizontal Lifting LugDocument1 pageHorizontal Lifting LugTushar MangratiNo ratings yet

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsYash RamiNo ratings yet

- Skid LiftDocument2 pagesSkid LiftAmi PutraNo ratings yet

- Structural Study Report of MRU Gas AGS Platform Hook Point CalculationDocument32 pagesStructural Study Report of MRU Gas AGS Platform Hook Point CalculationMuhammad Iqbal100% (1)

- Pad EyesDocument12 pagesPad EyesRachmad HidayatNo ratings yet

- Gross weight lifting lug dimensionsDocument10 pagesGross weight lifting lug dimensionsReda Elawady100% (1)

- UB 610 X 179 - BP - PinnedDocument3 pagesUB 610 X 179 - BP - PinnedArivoli JayaramanNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug CalculationAnonymous sfkedkymNo ratings yet

- Spreader Beam SampleDocument10 pagesSpreader Beam SampleAdi SutardiNo ratings yet

- Spreader Beam DesignDocument3 pagesSpreader Beam DesignCHENo ratings yet

- Padeye CheckDocument12 pagesPadeye CheckBen100% (1)

- Lifting Lug CalculationDocument1 pageLifting Lug CalculationshazanNo ratings yet

- Lifting Lug DesignDocument18 pagesLifting Lug DesignRui Salvador0% (1)

- Lifting LugDocument24 pagesLifting LugMas Arman Tewo100% (6)

- Padeye DolphinDocument38 pagesPadeye DolphinMuhammad FadelNo ratings yet

- Sfex Pad Eyes Calculations 35T - 32MMDocument1 pageSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaNo ratings yet

- CEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveDocument5 pagesCEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveLaurentiu TeacaNo ratings yet

- EC3 - Offshore Padeye DesignDocument4 pagesEC3 - Offshore Padeye Designscaricatutto100% (1)

- 6a Padeye Aisc 360 2005Document6 pages6a Padeye Aisc 360 2005mjlazoNo ratings yet

- LiftingLug TrunnionDocument22 pagesLiftingLug Trunnionrichardchiam100% (2)

- LIFTING LUG AND LIFTING COVER DESIGN REFERENCEDocument4 pagesLIFTING LUG AND LIFTING COVER DESIGN REFERENCERohith V VNo ratings yet

- 11, Tuas Basin Close. Singapore, 638806: 集永成預制水泥廠私人有限公司 Ces-Precast Pte LtdDocument3 pages11, Tuas Basin Close. Singapore, 638806: 集永成預制水泥廠私人有限公司 Ces-Precast Pte LtdSiow TingNo ratings yet

- PadeyeDocument14 pagesPadeyeMarshall Minggat AmpiNo ratings yet

- Beam DesignDocument6 pagesBeam DesignrustamriyadiNo ratings yet

- Pad Eye Design AnalysisDocument10 pagesPad Eye Design AnalysisRaza AidanNo ratings yet

- PADEYE DESIGN FOR BANGGAI AMMONIA PLANTDocument11 pagesPADEYE DESIGN FOR BANGGAI AMMONIA PLANTMarvan100% (2)

- Grating DesignDocument1 pageGrating DesigngaratetaNo ratings yet

- 28 Roark Flat PlatesDocument4 pages28 Roark Flat PlatesJorge Silva100% (1)

- PadEye Design CalculationDocument7 pagesPadEye Design Calculationhyoung65No ratings yet

- SWI PadeyeDocument11 pagesSWI PadeyeFian ArdiyanaNo ratings yet

- Spreader BeamDocument7 pagesSpreader BeamAnonymous sfkedkymNo ratings yet

- Twenty Five Ton Padeye - SpreadsheetDocument4 pagesTwenty Five Ton Padeye - Spreadsheetoluomo1No ratings yet

- TCXDVN 338-2005 Design Calculation of Flexural Column - EnglishDocument28 pagesTCXDVN 338-2005 Design Calculation of Flexural Column - EnglishUmdpmg Ursa100% (3)

- Name of work:-LSD Design For Doubly Reinforced Simply Supported BeamDocument13 pagesName of work:-LSD Design For Doubly Reinforced Simply Supported BeamEngr SwapanNo ratings yet

- Final Design of Angle Members For 4leged Single Angle TowersDocument65 pagesFinal Design of Angle Members For 4leged Single Angle Towersks_raghuveerNo ratings yet

- PF2Document4 pagesPF2nhulugallaNo ratings yet

- Padeye CALCULATIONDocument9 pagesPadeye CALCULATIONramana_96392699No ratings yet

- End-Plate - Beam to Beam Connection Design 3Document8 pagesEnd-Plate - Beam to Beam Connection Design 3gianniorlatiNo ratings yet

- Fiber Glass SystemDocument36 pagesFiber Glass SystemLe Ngoc AnhNo ratings yet

- EiDocument21 pagesEioluomo1No ratings yet

- Statement of Purpose GuidelinesDocument2 pagesStatement of Purpose Guidelinesparin advaniNo ratings yet

- MosesDocument34 pagesMosesoluomo1No ratings yet

- Welds Connection PDFDocument27 pagesWelds Connection PDFoluomo1No ratings yet

- Bolt Design For Steel Connections As Per AISCDocument24 pagesBolt Design For Steel Connections As Per AISCJayachandra PelluruNo ratings yet

- Pin Connections// Top and Bottom Flange Crop Parallel To Plane of ConnectionDocument3 pagesPin Connections// Top and Bottom Flange Crop Parallel To Plane of Connectionoluomo1No ratings yet

- Usfos HydrodynamicsDocument95 pagesUsfos Hydrodynamicsabhinavka123No ratings yet

- Tool For Ssuccess PDFDocument1 pageTool For Ssuccess PDFoluomo1No ratings yet

- Field2 MaginalDocument1 pageField2 Maginaloluomo1No ratings yet

- Ce 1353 - Construction Planning and Scheduling: Noorul Islam College of EngineeringDocument67 pagesCe 1353 - Construction Planning and Scheduling: Noorul Islam College of EngineeringMarimuthu Kannimuthu100% (1)

- CARFAX Vehicle History Report OnDocument4 pagesCARFAX Vehicle History Report Onoluomo1No ratings yet

- Bill Gates - The Skills You Need To SucceedDocument3 pagesBill Gates - The Skills You Need To SucceedCedric NiamkéNo ratings yet

- SFM NotesDocument11 pagesSFM NotesHanuma GonellaNo ratings yet

- 3293 14043 1 PBDocument18 pages3293 14043 1 PBoluomo1No ratings yet

- Numerical Reasoning Formulas PDFDocument7 pagesNumerical Reasoning Formulas PDFandreea_zgrNo ratings yet

- Safety Nets: Fall Protection For The Construction Industry: National Safety Council Data Sheet 608 Rev. February 2006Document14 pagesSafety Nets: Fall Protection For The Construction Industry: National Safety Council Data Sheet 608 Rev. February 2006oluomo1No ratings yet

- OGUNDocument1 pageOGUNoluomo1No ratings yet

- Maginal FieldDocument1 pageMaginal Fieldoluomo1No ratings yet

- MFM PrayersDocument1 pageMFM Prayersoluomo1No ratings yet

- Position Details - Construction AdvisorDocument2 pagesPosition Details - Construction Advisoroluomo1No ratings yet

- Position Detials - Project Manager Non-ITDocument1 pagePosition Detials - Project Manager Non-IToluomo1No ratings yet

- Catalog - ISO 1161 Steel Container Corner Castings - Cargo Container PartsDocument2 pagesCatalog - ISO 1161 Steel Container Corner Castings - Cargo Container Partsoluomo1100% (1)

- Statement of Purpose GuidelinesDocument2 pagesStatement of Purpose Guidelinesparin advaniNo ratings yet

- Sheduling TOOLDocument1 pageSheduling TOOLoluomo1No ratings yet

- Sheduling TOOLDocument1 pageSheduling TOOLoluomo1No ratings yet

- Position Details - Construction AdvisorDocument2 pagesPosition Details - Construction Advisoroluomo1No ratings yet

- Scheduling STD PDFDocument1 pageScheduling STD PDFoluomo1No ratings yet

- Knight LeaderDocument1 pageKnight Leaderoluomo1No ratings yet

- Scheduling STDDocument1 pageScheduling STDoluomo1No ratings yet

- Thiourea PDFDocument43 pagesThiourea PDFMohamad EshraNo ratings yet

- System ConfigurationDocument13 pagesSystem ConfigurationEdlyn Estopa BuenoNo ratings yet

- GE Con Perkins Más StamfordDocument2 pagesGE Con Perkins Más Stamfordjim perdigonNo ratings yet

- Vol 4 Div G ODS Part 1 of 2-Pages-18-55Document38 pagesVol 4 Div G ODS Part 1 of 2-Pages-18-55debapriyoNo ratings yet

- BV DoshiDocument29 pagesBV DoshiAnkit LuthraNo ratings yet

- Inductance Measurements For Synchronous MachinesDocument2 pagesInductance Measurements For Synchronous MachinesYusuf YaşaNo ratings yet

- Mohr's Circle Analysis of Rock Failure Under StressDocument26 pagesMohr's Circle Analysis of Rock Failure Under StressNitishNo ratings yet

- Project-BOQ - (Excluding VUP, LVUP)Document127 pagesProject-BOQ - (Excluding VUP, LVUP)Shivendra KumarNo ratings yet

- Life 365 V 2 Users ManualDocument67 pagesLife 365 V 2 Users ManualAmanda VegaNo ratings yet

- University Institute of Information Technology: Ouick Learn - MCQDocument53 pagesUniversity Institute of Information Technology: Ouick Learn - MCQvimalNo ratings yet

- 9mm!ূຌዡገ๕ۉ࿋ഗ Rotary Potentiometers With Metal Shaft Series: WH9011A-1-18TDocument26 pages9mm!ূຌዡገ๕ۉ࿋ഗ Rotary Potentiometers With Metal Shaft Series: WH9011A-1-18TpeterfunNo ratings yet

- Osciloscopio 1006Document74 pagesOsciloscopio 1006ERNESTO BRAVONo ratings yet

- Part Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Document11 pagesPart Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Anonymous KHIyWRIWmaNo ratings yet

- Emergency Stop Valve PDFDocument4 pagesEmergency Stop Valve PDFMauricio GarciaNo ratings yet

- Joker User Guide 3dlabgang Rev2019 12Document14 pagesJoker User Guide 3dlabgang Rev2019 12HD's RC ChannelNo ratings yet

- Ibm Lenovo Whistler Rev s1.3 SCHDocument52 pagesIbm Lenovo Whistler Rev s1.3 SCH1cvbnmNo ratings yet

- MEP Work Checklist and Plan For KhairyDocument6 pagesMEP Work Checklist and Plan For KhairyAhmadNo ratings yet

- Control your ship with Kobelt electronic controlsDocument36 pagesControl your ship with Kobelt electronic controlsBERANGER DAVESNE DJOMALIA SIEWENo ratings yet

- Soil CompactionDocument13 pagesSoil Compactionbishry ahamedNo ratings yet

- Elsa CableDocument2 pagesElsa CableJay WangNo ratings yet

- Manufacturing of Urea Through Synthetic Ammonia Project ReportDocument5 pagesManufacturing of Urea Through Synthetic Ammonia Project ReportvishnuNo ratings yet

- Slides - OOP With SmalltalkDocument51 pagesSlides - OOP With Smalltalkapi-3728136No ratings yet

- Bunker SiloDocument3 pagesBunker SiloManju Civil PNo ratings yet

- Updated Infra-IIVendor ListDocument22 pagesUpdated Infra-IIVendor ListabhibaikarNo ratings yet

- Tivizen Iplug Greek GuideDocument13 pagesTivizen Iplug Greek GuideDenexoNo ratings yet

- Pass4sure 200-120 PDF DownloadDocument8 pagesPass4sure 200-120 PDF DownloadEleanor19No ratings yet

- Iec 62097-2009Document170 pagesIec 62097-2009luis.alvaradoNo ratings yet

- Introduction To Oil RigsDocument25 pagesIntroduction To Oil RigsballasreedharNo ratings yet

- Fundamentals of Ship ConstructionDocument18 pagesFundamentals of Ship ConstructionWAREKARNo ratings yet