Professional Documents

Culture Documents

US5231917 - Wobble Piston

Uploaded by

devheadbotCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

US5231917 - Wobble Piston

Uploaded by

devheadbotCopyright:

Available Formats

US005231917A

UllltBd States Patent [19]

[11] Patent Number:

Wood

[45]

[54]

4,304,173 12/1981

Brille ..................................... .. 74/60

4,577,595

Deutschman et a1. ......... .. 123/4135

[75]

WOBBLE PISTON

Invcmon

Mlrk W- Wood, Jackson, Tcnn-

[73] Assignee:

DeVilbiss Air Power Company,

Jackson Tenn

[21] Appl. No.: 944,400

[22] Filed:

[51]

[52]

Sep. 14, 1992

Date of Patent:

3/1986

5,231,917

Aug. 3, 1993

4,995,795 2/1991 Hetzel =1 a1. ...................... .. 417/571

Primary Examiner_Edward K. Look

Assistant Examiner-F. Daniel Lopez

Attorney, Agent, or Firm-MacMillan, Sobanski & Todd

[57]

ABSTRACT

Int. Cl.5 ............................................ .. M18 31/08

US. Cl. ................................ .. 92/186; 92/240

of Search ............... ..

240,

An improved wobble piston for an air compressor. The

piston has a hgad intggrally connecmd to a connccting

rod_ The connecting rod has a frcc end for connection

92/255

to a rotating eccentric. The piston head has an internal

[56]

References Cited

chamber. Openings are formed through the piston head

into the chamber on opposite sides of the connecting

US' PATENT DOCUMENTS

1,115,176 10/1914 Daniel .

1,226,631 5/ 1917 B18 ;

2,042,673

6/1986

2,058,485 10/1936

2,092,920 9/1937

2,361,316 10/1944

Manlscalco ....................... .. 230/211

Miller ............ ..

230/221

Johnson ........ ..

230/174

Newton et al. ................... .. 230/179

rod in a plane perpendicular to the eccentric axis. The

location of the chamber openings establishes a ?ow of

cooling air through the chamber as the piston is recipro

cated in a cylinder.

5 Claims, 2 Drawing Sheets

J .44

3/

US. Patent

Aug. 3, 1993

Sheet 1 of 2

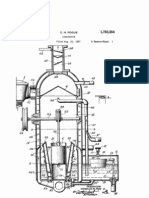

FIG. 2

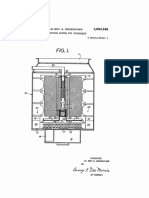

FIG. I

(PRIOR ART)

FIG. 3

5,231,917

US. Patent

Aug. 3, 1993

Sheet 2 of 2

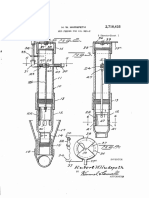

FIG. 4

5,231,917

5,231,9l7

each other as the piston rotates. This causes a pressure

WOBBLE PISTON

TECHNICAL FIELD

The invention relates to pistons for reciprocating

piston air compressors and more particularly to an im

proved air cooled wobble piston for an air compressor.

BACKGROUND ART

Two types of pistons are used in reciprocating piston

air compressors. In a ?rst piston design, the piston has a

cylindrical shape and is con?ned to slide in a cylinder

without rotating relative to the cylinder. A connecting

differential between the two vent openings which in

turn establishes an air ?ow through the internal piston

chamber to cool the piston and particularly to cool the

piston cap. The cooling air flow both reduces the piston

seal temperature and increases the volumetric ef?ciency

of the compressor.

Accordingly, it is an object of the invention to pro

vide an improved wobble piston or a reciprocating

piston air compressor.

Other objects and advantages of the invention will

become apparent from the following detailed descrip

tion of the invention and the accompanying drawings.

rod has an end connected to the piston and has a free

end connected to a rotating eccentric. Since the piston

cannot rotate with the connecting rod, it is necessary to

provide a hinge connection between the connecting rod

and the piston through the use of a wrist pin. In order

for the compressor to operate, oil lubrication must be

provided for the reciprocating piston. The oil also may

be sprayed at the bottom of the piston and in chambers

inside the piston for cooling. Although the piston may

have internal chambers in which cooling oil is sprayed

or circulated and to reduce the weight of the piston,

there is essentially no induced air flow through the

piston because the linear reciprocation of the piston

BRIEF DESCRIPTION OF THE DRAWINGS

FIG. 1 is a cross sectional view through a typical

prior art wobble piston for an air compressor;

FIG. 2 is a cross sectional view through an improved

air cooled wobble piston for an air compressor in accor

dance with the invention;

FIG. 3 is a cross sectional view taken along line 3-3

of FIG. 2; and

FIG. 4 is an enlarged cross sectional showing the

piston of FIG. 2 as it moves and tilts in a cylinder during

operation of a compressor.

establishes a uniform air pressure across the bottom of

BEST MODE FOR CARRYING OUT THE

INVENTION

A second common piston design does not require oil

Referring

to

FIG.

1 of the drawings, an exemplary

lubrication. The piston is rigidly secured to the connect

prior art wobble piston 10 is illustrated in section. The

ing rod. The piston is provided with a sufficiently thin

piston 10 includes a head 11 and an integral connecting

pro?le to allow the piston to wobble or rock in the

rod 12. The head 11 and connecting rod 12 are typically

cylinder with the connecting rod as the piston is recip

rocated. A resilient seal is provided around the periph

cast from a strong light weight material such as an alu

ery of the piston to allow the piston to tilt in the cylin

minum alloy. The head 11 has a generally flat circular

der without loss of a gas tight seal between the piston

con?guration with a groove 13 formed in its periphery

and the cylinder. The sliding seal and a smooth coating

14 for receiving a cup shaped ring or seal 15. The head

on the cylinder reduce friction so that oil lubrication is

11 must have sufficient thickness to withstand the pres

not required.

sures exerted by compressed air on the head 11. The

The service life of a wobble piston compressor is 40 needed thickness of the head 11 presents a relatively

often limited by the life of the piston seal. Many factors

high thermal resistance which transfers an unnecessar

have been found to affect the seal life. In general, seal

ily high amount of heat to the seal 15 and to intake air

life is improved both by reducing friction between the

contacting a top surface 16 of the piston head 11. The

seal and the cylinder band by reducing the temperature

periphery 14 may be slightly conical to provide clear

of the seal. Since heat is released when air is com 45 ance when the piston head 11 tilts in a cylinder (not

pressed, it has been found important to cool the cylinder

shown). A circular opening 17 is formed in a free end 18

and the piston as much as possible to enhance sea] life.

of

the connecting rod 12. An eccentric bearing 19 is

The operating ef?ciency of a compressor also can be

clamped in the opening 17 by a screw 20.

degraded by heat. For strength while minimizing

FIGS. 2-4 show an improved air cooled piston 25

weight, the prior rt piston typically has been formed as

constructed

in accordance with the invention. The pis

a relatively thick aluminum casting. Heat absorbed by

the piston.

the piston during the compression stroke is transferred

ton 25 has a head 26 formed integrally with it connect

ing rod 27. The connecting rod 27 has a free end 28

from the piston top to air drawn into the cylinder dur

which mounts a bearing 29 in a conventional manner.

ing the subsequent intake stroke. This causes the air to

expand and consequently reduces the volumetric ef? 55 The bearing 29 has an axis 30 (extending perpendicular

to the drawings in FIGS. 2 and 4) and receives an ec~

ciency of the compressor.

DISCLOSURE OF INVENTION

The invention is directed to a wobble piston having

centric (not shown) mounted on a ?ywheel or on a

crankshaft. The eccentric moves the free end so that the

axis 30 moves around a circle 31 (FIG. 4).

cavity which is closed by a cap. The cap, which is ex

The piston head 26 is generally conical r cup shaped

and has an upwardly opening top edge 32. A cap 33 is

posed to the compressed air, is thinner than prior art

pistons to reduce the thermal resistance and enhance

heat transfer form the compression chamber. Two vent

positioned on the top edge 32 to de?ne an enclosed

chamber 34 in the piston head 26. A rib 35 on a bottom

surface 36 of the cap 33 for centering the cap 33 on the

improved cooling. The piston is formed with an internal 60

openings are formed in the bottom of the piston on 65 piston head 26. An annular groove 37 is formed be

opposite sides of the connecting rod. The vent openings

are located in a plane perpendicular to the axis of the

eccentric so that the vent openings rotate relative to

tween the piston head top edge 38 and the cap 33 for

retaining an annular piston ring or seal 38. The bottom

39 of a recess 40 in the center of the cap 32 abuts a pillar

5,231,917

41 which extends into the chamber 34. A screw 42 in the

recess 40 secures the cap 33 to the pillar 41.

move at the same velocity and the air pressure at the

two openings would be balanced throughout the stroke

of the piston 25. Consequently, there would be no flow

According to the invention, two openings 43 and 44

extend through the head 26 into the chamber 34. The

openings 43 and 44 are located on opposite sides of the

connecting rod 27 in a plane perpendicular to the axis

30. This location of the openings 43 and 44 causes air to

flow through the chamber 34 as the piston 25 is recipro

cated.

FIG. 4 illustrates the piston 25 moving in a cylinder

45 as the eccentric moves the free connecting rod end

28 about the circle 31. At the illustrated position, the

piston is moving downwardly on an intake or suction

stroke and the free connecting rod end 28 has moved

90 about the circle 31 from to dead center. As is illus

trated, the piston head 26 tilts or rotates as it is recipro

cated in the cylinder 45 so that a side 46 of the piston

head 26 adjacent the opening 43 is above a side 47 of the

of cooling air through the chamber 34.

It should also be appreciated that the piston 25 may

be used in a compressor having other ?uid cooling such

as oil splash cooling. The air flow through the piston

chamber 34 will carry oil droplets through the chamber

34 to enhance cooling to the piston head 26 and the cap

33. It will be appreciated that various modi?cations and

changes may be made to the above described preferred

embodiments of a wobble piston without departing

from the spirit and the scope of the following claims.

I claim:

1. In a wobble piston of the type having a piston head

rigidly connected to a connecting rod, said connecting

rod having a free end for movement by an eccentric

about a circle, said piston head reciprocating and rotat

piston head 26 adjacent the opening 44. As the piston 25

ing in a cylinder as said free end is moved, the improve

moves to the illustrated position, the side 47 will accel 20 ment comprising a chamber formed in said wobble pis

erate and move faster than the side 46. Consequently,

ton head, and at least two openings through said wobble

the air pressure at the opening 44 will be above the air

piston head into said chamber, said openings being

pressure at the opening 43 and air will ?ow from the

spaced apart in a plane wherein said openings rotate

relative to one another as said piston is reciprocated in

opening 44 through the chamber 34 and exit the open

ing 43 as illustrated by arrows 48. The direction of the 25 a cylinder whereby air is caused to flow through said

piston head chamber.

air ?ow through the chamber 34 will change with

changes is the relative rotational motion or velocity

2. An improved wobble piston, as set forth in claim 1,

between the openings 43 and 44. The air ?ow through

wherein said at least two openings are two openings

the chamber 34 cools the piston cap 33 and the piston

located in said piston head on opposite sides of said

connecting rod.

head 26 which both reduces the operating temperature

of the seal 38 and reduces heat transferred to air in a

3. An improved wobble piston, as set forth in claim 2,

compression chamber 49 in the cylinder 45 above the

and including a cap secured to said piston head, said cap

closing said chamber.

piston 25. This both increases the operating life of the

seal 38 and increases the volumetric efficiency of the

4. An improved wobble piston, as set forth in claim 3,

35 wherein said piston head is generally conically shaped

compressor.

It should be appreciated that the locations of the

and has a central pillar, said pillar having a threaded

chamber openings 43 and 44 are critical to establishing

opening, and wherein said cap is secured to said piston

' air flow through the chamber 34. If the openings 43 and

head by a screw engaging said threaded opening.

44 were to be located on opposite sides of the connect

5. An improved wobble piston, as set forth in claim 4,

ing rod 27 in a plane parallel to the axis 30, the openings 40 and including an annular seal clamped between said cap

and said piston head.

would not rotate relative to one another as the piston

head reciprocates. The two openings would always

45

50

55

65

You might also like

- Friction heat space heater patentDocument6 pagesFriction heat space heater patentBastien Gall de SilléNo ratings yet

- United States Patent (191: McguganDocument6 pagesUnited States Patent (191: McguganJamesStenhouseNo ratings yet

- Us2181099 PDFDocument4 pagesUs2181099 PDFAt ChecoNo ratings yet

- US3200917Document5 pagesUS3200917张淼No ratings yet

- Us2960824 PDFDocument5 pagesUs2960824 PDFgrigNo ratings yet

- V-shaped engine cylinder block designDocument8 pagesV-shaped engine cylinder block designLalit KumarNo ratings yet

- Illlllllllllllillllllllllllllllllllllillllllllllllllllllll - L - L - L - L - LLDocument18 pagesIlllllllllllllillllllllllllllllllllllillllllllllllllllllll - L - L - L - L - LLSteric ZeytraNo ratings yet

- Us4589264 PDFDocument6 pagesUs4589264 PDFRodrigoPomaNo ratings yet

- AIR COMPRESSORS: EFFICIENT GAS PRESSURIZATIONDocument11 pagesAIR COMPRESSORS: EFFICIENT GAS PRESSURIZATIONHafizuddin RazakNo ratings yet

- US1926463Document3 pagesUS1926463Kamal Vijay Ram R SNo ratings yet

- Chlorine CylinderDocument9 pagesChlorine Cylinderjoseph_mscNo ratings yet

- Us 3823668Document4 pagesUs 3823668wewewewNo ratings yet

- (1966, May 3) US3248803 Rotary Drum Heat ExchangerDocument6 pages(1966, May 3) US3248803 Rotary Drum Heat ExchangeraegosmithNo ratings yet

- Reciprocating EngineDocument4 pagesReciprocating EnginePaulFerryNo ratings yet

- US3094165 Wheeler Manfac-PatentDocument7 pagesUS3094165 Wheeler Manfac-Patentsoubhadra nagNo ratings yet

- Rotor Rim-Ventilated Generator with Turning Vanes for Rotor Inlet Coolant Gas FlowDocument4 pagesRotor Rim-Ventilated Generator with Turning Vanes for Rotor Inlet Coolant Gas FlowHamedJamshidiNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 7,377,754 B2Document23 pagesUnited States Patent: (12) (10) Patent N0.: US 7,377,754 B2Selvaraji MuthuNo ratings yet

- United States Patent: (72) 3,195,589 7/1965 Houda, Jr..................... 141/82 XDocument6 pagesUnited States Patent: (72) 3,195,589 7/1965 Houda, Jr..................... 141/82 XMustafa ŞENNo ratings yet

- Mam II, Answers To Question Bank, 20-4-11Document57 pagesMam II, Answers To Question Bank, 20-4-11Giri VenkatesanNo ratings yet

- CompressorsDocument51 pagesCompressorsReza RahmanudinNo ratings yet

- Rotating double shell heat exchange drumDocument5 pagesRotating double shell heat exchange drumaegosmithNo ratings yet

- Recip. CompressorDocument19 pagesRecip. CompressorSubbarayan SaravanakumarNo ratings yet

- April 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965Document4 pagesApril 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965fgrt490No ratings yet

- Pocket Lighter Patent from 1936 Describes Zippo DesignDocument3 pagesPocket Lighter Patent from 1936 Describes Zippo DesignRakeshNo ratings yet

- Inflation Of/ Balloon: Filed Mar-Ch 5, 1959Document4 pagesInflation Of/ Balloon: Filed Mar-Ch 5, 1959david19775891No ratings yet

- Bob Neal Overunity Compression Unit - US2030759Document5 pagesBob Neal Overunity Compression Unit - US2030759John CarterNo ratings yet

- Charles Nelson Pouge (US Pat. 1750354)Document5 pagesCharles Nelson Pouge (US Pat. 1750354)GaleriaTechniki.PLNo ratings yet

- Surface Condenser Eng2Document5 pagesSurface Condenser Eng2MuhammadFikriNo ratings yet

- Tanks for Fluid Media Storage and Transport Under PressureDocument8 pagesTanks for Fluid Media Storage and Transport Under Pressurevenkatrangan2003No ratings yet

- Materials Used For Construction: 1. Reciprocating CompressorDocument6 pagesMaterials Used For Construction: 1. Reciprocating CompressorEdemNo ratings yet

- SU Carbs TuningDocument13 pagesSU Carbs TuningXDBDNo ratings yet

- Description: (OCR Text May Contain Errors)Document3 pagesDescription: (OCR Text May Contain Errors)SachinNo ratings yet

- Gas Turbine - Traning Report Bhel - 14 PageDocument14 pagesGas Turbine - Traning Report Bhel - 14 PageVivek PatelNo ratings yet

- Rotary Dryer Steam Distribution SystemDocument7 pagesRotary Dryer Steam Distribution SystemDouglas TondelloNo ratings yet

- GT LL: NN W///, WM)Document5 pagesGT LL: NN W///, WM)lfilippiniNo ratings yet

- (1975, Sept. 9) US3903963 Heat ExchangerDocument4 pages(1975, Sept. 9) US3903963 Heat ExchangeraegosmithNo ratings yet

- GE Frame 9E Turbine Stator and Rotor ConstructionDocument14 pagesGE Frame 9E Turbine Stator and Rotor ConstructionMohammad Ibnul Hossain100% (1)

- Wash and Humidify Air with Early Air Washer DesignDocument3 pagesWash and Humidify Air with Early Air Washer DesignPriya TiwariNo ratings yet

- IC Engine Valve Gear MechanismDocument6 pagesIC Engine Valve Gear MechanismAnimesh RoyNo ratings yet

- Analysis of Stiction Effect On The Dynamics of Compressor Suction ValveDocument13 pagesAnalysis of Stiction Effect On The Dynamics of Compressor Suction ValvehrsotherNo ratings yet

- CarburettorsDocument3 pagesCarburettorsAlejandro GonzalezNo ratings yet

- Automotive Engineering Module 1Document27 pagesAutomotive Engineering Module 1ANSH RANKANo ratings yet

- Final Internal and External Cooling of Gas Turbine BladeDocument5 pagesFinal Internal and External Cooling of Gas Turbine BladeSIDDHANT KUMAR 17BEM0015100% (1)

- March 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1Document5 pagesMarch 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1david19775891No ratings yet

- Hyper Valve PatentDocument15 pagesHyper Valve PatenttonytayicNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,430,626 B1Document9 pagesUlllted States Patent (10) Patent N0.: US 8,430,626 B1shamsNo ratings yet

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocument4 pagesSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshNo ratings yet

- Us4070957 PDFDocument8 pagesUs4070957 PDFpertmasterNo ratings yet

- Marine Vol 1 Part 3Document79 pagesMarine Vol 1 Part 3VaradrajNo ratings yet

- (1947, June 21) US2547086 Heating DrumDocument3 pages(1947, June 21) US2547086 Heating DrumaegosmithNo ratings yet

- European Patent Specification: Turbine Engine With An Abradable SealDocument10 pagesEuropean Patent Specification: Turbine Engine With An Abradable SealshamsNo ratings yet

- Jan. 4, L 1966 T. W. Spack 3,227,148Document6 pagesJan. 4, L 1966 T. W. Spack 3,227,148MainAvelNo ratings yet

- CFD - Piston CoolingDocument2 pagesCFD - Piston CoolingVijay KrishnanNo ratings yet

- Jan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LDocument6 pagesJan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LJesus ValleNo ratings yet

- Tài liệu5Document12 pagesTài liệu5Hoàng ĐứcNo ratings yet

- Wellhead Connector H4 TypeDocument9 pagesWellhead Connector H4 Typeste7ieNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- PEN TURNING 101: Getting Started GuideDocument2 pagesPEN TURNING 101: Getting Started GuidedevheadbotNo ratings yet

- US4938388 - Glue Transport Mechanism For A Molten Glue Discharging DeviceDocument7 pagesUS4938388 - Glue Transport Mechanism For A Molten Glue Discharging DevicedevheadbotNo ratings yet

- US20150038915 - Injection Device With A Sliding ScaleDocument9 pagesUS20150038915 - Injection Device With A Sliding ScaledevheadbotNo ratings yet

- EP1990275A1 - Coaxial Contrarotating Helicopter RotorDocument6 pagesEP1990275A1 - Coaxial Contrarotating Helicopter RotordevheadbotNo ratings yet

- US4938388 - Glue Transport Mechanism For A Molten Glue Discharging DeviceDocument7 pagesUS4938388 - Glue Transport Mechanism For A Molten Glue Discharging DevicedevheadbotNo ratings yet

- Vaclav Smil - Creating The 20th Century & Transforming The 20th Century - Review - MokyrDocument7 pagesVaclav Smil - Creating The 20th Century & Transforming The 20th Century - Review - MokyrdevheadbotNo ratings yet

- US4032046 - Apparatus For Feeding Glue To A Hot Melt Glue GunDocument7 pagesUS4032046 - Apparatus For Feeding Glue To A Hot Melt Glue GundevheadbotNo ratings yet

- US4126067 - Tool Post - Giannetti - 1978Document6 pagesUS4126067 - Tool Post - Giannetti - 1978devheadbotNo ratings yet

- US2543018 - Rivet Cutter - Adjustable PDFDocument4 pagesUS2543018 - Rivet Cutter - Adjustable PDFdevheadbotNo ratings yet

- US6953298 - Pinstripe Painting Device, 2005Document8 pagesUS6953298 - Pinstripe Painting Device, 2005devheadbotNo ratings yet

- US5775921 - Electrical Slip Ring PlugDocument7 pagesUS5775921 - Electrical Slip Ring PlugdevheadbotNo ratings yet

- EP1445049 - Cut Knurling Tool - Swarovski OptikDocument7 pagesEP1445049 - Cut Knurling Tool - Swarovski OptikdevheadbotNo ratings yet

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pages@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNo ratings yet

- US5390854 - Coolant Spray System - Hench, 1995 (Fog Buster)Document5 pagesUS5390854 - Coolant Spray System - Hench, 1995 (Fog Buster)devheadbotNo ratings yet

- LU88631A1 - Drill Stand - ProxxonDocument15 pagesLU88631A1 - Drill Stand - ProxxondevheadbotNo ratings yet

- Anodising - Aluminium Anodising DyesDocument4 pagesAnodising - Aluminium Anodising DyesdevheadbotNo ratings yet

- The SM-3 Block IIA Interceptor - A New Arms Control ChallengeDocument2 pagesThe SM-3 Block IIA Interceptor - A New Arms Control ChallengedevheadbotNo ratings yet

- US4682521 - Quick Change, Adjustable Tool HolderDocument6 pagesUS4682521 - Quick Change, Adjustable Tool HolderdevheadbotNo ratings yet

- US2006252357 - Device For Abrasive-Blasting of Workpieces - Bohler (Gunther Bohler GMBH)Document6 pagesUS2006252357 - Device For Abrasive-Blasting of Workpieces - Bohler (Gunther Bohler GMBH)devheadbotNo ratings yet

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pages@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNo ratings yet

- Lathe AssemblyDocument3 pagesLathe AssemblydevheadbotNo ratings yet

- LU88568A1 - Motor Coupling For Power Tools - ProxxonDocument11 pagesLU88568A1 - Motor Coupling For Power Tools - ProxxondevheadbotNo ratings yet

- US1157800 - Universal Test-Indicator - Oslund, 1915Document3 pagesUS1157800 - Universal Test-Indicator - Oslund, 1915devheadbotNo ratings yet

- US1994497 - Indicator - Winters For Gladwin, 1935Document5 pagesUS1994497 - Indicator - Winters For Gladwin, 1935devheadbotNo ratings yet

- US2151255 - Spring Nut - Lufkin, 1939Document3 pagesUS2151255 - Spring Nut - Lufkin, 1939devheadbotNo ratings yet

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pages@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNo ratings yet

- US3002206 - Tapping Attachment With Adjustable Clutch PDFDocument3 pagesUS3002206 - Tapping Attachment With Adjustable Clutch PDFdevheadbotNo ratings yet

- US2466380 - Precision Centering Device - Leland Clark, 1949Document5 pagesUS2466380 - Precision Centering Device - Leland Clark, 1949devheadbotNo ratings yet

- US2253168 - Frictional Clutch, 1941 PDFDocument3 pagesUS2253168 - Frictional Clutch, 1941 PDFdevheadbotNo ratings yet

- US2006252357 - Device For Abrasive-Blasting of Workpieces - Bohler (Gunther Bohler GMBH)Document8 pagesUS2006252357 - Device For Abrasive-Blasting of Workpieces - Bohler (Gunther Bohler GMBH)devheadbotNo ratings yet

- Erie Canal Harbor Master Plan (2004)Document43 pagesErie Canal Harbor Master Plan (2004)api-3696939No ratings yet

- Understanding Doctoral Nursing Students' Experiences of Blended LearningDocument8 pagesUnderstanding Doctoral Nursing Students' Experiences of Blended LearningZilbran BerontaxNo ratings yet

- Research Paper - Shantel Jaskson - .OdtDocument13 pagesResearch Paper - Shantel Jaskson - .OdtMiroNo ratings yet

- Alpha Eco2 Plus enDocument68 pagesAlpha Eco2 Plus ennadaljoachim77No ratings yet

- May I... ?: Activity TypeDocument2 pagesMay I... ?: Activity Typebebyfebri14No ratings yet

- Chap # 14 (Electromagnetic Induction)Document6 pagesChap # 14 (Electromagnetic Induction)Tariq MahmoodNo ratings yet

- Fujifilm Ga645 FullDocument31 pagesFujifilm Ga645 FullWork In ArtNo ratings yet

- Application Engineering Guide: Well Service Air Valves For Vertical PumpsDocument5 pagesApplication Engineering Guide: Well Service Air Valves For Vertical PumpsRoozbeh PNo ratings yet

- BrochureDocument68 pagesBrochure7063673nasNo ratings yet

- The Orderflows Bulge Michael ValtosDocument51 pagesThe Orderflows Bulge Michael Valtosmr100% (1)

- Burgueno Residence: 1325 West Culver Street Phoenix Az 85007Document16 pagesBurgueno Residence: 1325 West Culver Street Phoenix Az 85007michael zNo ratings yet

- First Thousand Words in FrenchDocument72 pagesFirst Thousand Words in FrenchErik SueNo ratings yet

- BSS Steel Guide CataloguesDocument52 pagesBSS Steel Guide Cataloguessaber66No ratings yet

- Assessment of The Visual and Radiographic Changes in Teeth Subjected To High Temperatures: A Forensic StudyDocument6 pagesAssessment of The Visual and Radiographic Changes in Teeth Subjected To High Temperatures: A Forensic StudyInternational Journal of Innovative Science and Research Technology100% (1)

- Heat Load Calculation : J.IlangumaranDocument70 pagesHeat Load Calculation : J.Ilangumaranapi-25999517No ratings yet

- Mockups Showeet (Standard)Document46 pagesMockups Showeet (Standard)Palo Alto Turismo y EntretenimientoNo ratings yet

- Assessing ash fouling and slagging in coal-fired boilersDocument10 pagesAssessing ash fouling and slagging in coal-fired boilersDSGNo ratings yet

- Non-Symmetric Bi-Stable Flow Around The Ahmed Body - Meile WDocument14 pagesNon-Symmetric Bi-Stable Flow Around The Ahmed Body - Meile WJesus AguilarNo ratings yet

- O Level E Math ST Theresas Convent Prelim 2019Document59 pagesO Level E Math ST Theresas Convent Prelim 2019Jefferson LiinNo ratings yet

- Flange Insulation ReducedDocument32 pagesFlange Insulation ReducedVasudev ShanmughanNo ratings yet

- DDL Mapeh 3-10Document8 pagesDDL Mapeh 3-10Reximie D. Dollete Jr.No ratings yet

- Lab 7 Fluid SaturationDocument6 pagesLab 7 Fluid SaturationRichard OwusuNo ratings yet

- Online Bode PlotsDocument8 pagesOnline Bode PlotsJ a i r o Martînez BNo ratings yet

- Taller 1. Task 1 - Ecaes ProDocument4 pagesTaller 1. Task 1 - Ecaes ProValerin RodriguezNo ratings yet

- 2 Oieyqhwgfdewio 9 D 328 eDocument1 page2 Oieyqhwgfdewio 9 D 328 euihgfhjjhghNo ratings yet

- Chapter 2 - PlanningDocument31 pagesChapter 2 - PlanningAlwiCheIsmailNo ratings yet

- Environmental Engineering ExplainedDocument3 pagesEnvironmental Engineering ExplainedElaine Mae ButalonNo ratings yet

- The Impact of Relationship Quality On Business Model Innovation of The Start-Up Firms in Ba Ria - Vung Tau ProvinceDocument4 pagesThe Impact of Relationship Quality On Business Model Innovation of The Start-Up Firms in Ba Ria - Vung Tau ProvinceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Simocode BasicsDocument63 pagesSimocode BasicsMukesh SahuNo ratings yet

- Vocational Guidance and Its StrategiesDocument5 pagesVocational Guidance and Its StrategiesLêHoàiNhưNo ratings yet