Professional Documents

Culture Documents

Hydrogen from refinery offgas: Three schemes compared

Uploaded by

kulaspiroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrogen from refinery offgas: Three schemes compared

Uploaded by

kulaspiroCopyright:

Available Formats

Hydrogen from refinery offgas

Utilisation of refinery offgases for hydrogen production. Three basic schemes of

ROG integration into a steam reformer plant were investigated

Harald Klein Linde Engineering Division

n the past, hydrogen containing refinery offgas plant producing 100,000Nm3/h of pure hydro(ROG) has been routed into the refinery fuel gen was selected. The purge gas from the steam

gas system where only the heating value of the reformer plant PSA system is routed to the

gas has been used. Since the hydrogen demand burner system of the steam reformer firing. It

for refinery operations is growing, these gases was assumed that fuel export to the refinery fuel

become more and more attractive as a source for system was not feasible. ROG containing 80 per

hydrogen production. This requires purification cent and 50 per cent hydrogen were

steps such as pressure swing adsorption (PSA) investigated.

or membrane systems. However, if the ROG

hydrogen content is too low, these options Common PSA system

become less economical and the direct usage of In the process scheme configured with a PSA

ROG as steam reformer feed is an attractive system, the ROG is routed directly to the PSA

alternative. This presentation outlines the key system of the steam reformer plant. Depending

features of the described processes and intro- on the pressure of the ROG, it may be required

duces a guideline for optimised process to compress it to the required PSA pressure.

selection.

However, in the present study it was assumed

The hydrogen content in ROG varies from 5-10 that ROG is available at a pressure high enough

per cent, up to values of90 per cent. Therefore, to meet the required PSA pressure, which is

their utilisation in the hydrogen production usually fixed by the desired hydrogen product

scheme of a refinery must be evaluated on a pressure.

case-by-case basis. Hydrogen recovery from ROG

Due to the additional feed stream to the steam

using PSA, membrane technology or cryogenic reformer plant PSA system, the purge gas steam

processes can be appliedto generate hydrogen from the PSA increases. Since all purge gas must

streams of any required purity. The offgas be utilised in the steam reformer firing system,

streamsfrom these processes

can be routed to the refinery

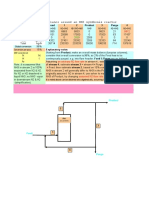

Hydrogen

24 bar

fuel gas system. Another

Pressure 100,000 Nm3/h

Feed

Free

Steam

Co-shift

swing

option is using the offgas as

pretreatreforming

conversion

NG

adsorption

ment

(supplementary) feedstock to a

40 bar

steam reformer plant, which

Purge

Fuel

also generates hydrogen from

hydrocarbons such as natural

gas, LPG or naphtha. Three

basic schemes of ROG integraImpurities

Pressure swing

tion into a steam reformer

removal

adsorption

ROG

80%, 50% H2

plant were investigated within

25 bar

Linde Engineering. As a basis

for all comparisons, a natural Figure 1 Common PSA system schematic with ROG pressure high enough to

gas-based steam reformer meet required PSA pressure

www.digitalrefining.com/article/1000529

Gas 2007 1

ROG contribution must limited

to 8 per cent. The savings of

this process scheme for an

amortisation time of five years

show

approximately

$1.6

million/yr at 80 per cent

hydrogen contribution and

approximately $0.5 million/yr

at 50 per cent hydrogen contribution. It was assumed that

the heat value-based price for

the ROG is the same as the

natural gas price (1 $/

MMBtu).

100

Design capacity

90

80

70

Reformer, 80% H2

PSA, 50% H

PSA, 80% H2

60

50

10

20

30

40

50

60

70

Contribution of ROG, %

80

90

100

Figure 2 Design capacity of the steam reformer can be reduced by increasing

the amount of ROG to the PSA

12.0

80% H2

50% H2

10.0

Total savings, Mio $

8.0

6.0

4.0

2.0

0.0

2.0

4.0

20

40

60

Contribution of ROG, %

80

100

Figure 3 Savings available from common PSA process scheme

the amount of ROG, which can be routed to the

common PSA, is limited. With this type of

scheme, it can be shown how the design capacity

of the steam reformer can be reduced by increasing the amount of ROG routed to the PSA, which

cannot be decreased in size. This process scheme

is a very economical option to utilise ROG in a

steam reformer plant. However, due to the purge

gas increase along with reduced reformer firing,

the amount of ROG must be limited to12 per

cent if the ROG contains 80 per cent of hydrogen. If the hydrogen content is 50 per cent the

2 Gas 2007

Direct feed to reformer

If the hydrogen content of the

refinery fuel gas becomes as

low as 50 per cent, the usage

of ROG as direct reformer feed

is the preferred option. It can

be seen that the reformer size

can be reduced by more than

10 per cent such that the

savings can add up to a significant value of $4 million. If the

hydrogen content of the ROG

is as high as 80 per cent, the

contribution must be limited

to approximately 40 per cent:

too much hydrogen is routed

to the reformer along with the

ROG feed, such that the

required reformer heating

drops below the available heat

supply via purge gas from the

PSA system.

Dedicated PSA system for

ROG

A dedicated PSA system for the refinery offgas

upstream of the steam reformer plant is shown

in Figure 1. No upper limitation concerning the

contribution of ROG must be considered

(Figure 2). However, the option is not economical for refinery offgases showing the lower

hydrogen content of 50 per cent resulting in

negative savings (Figure 3). The re-compression

of the offgas from the ROG PSA requires additional investment as well as a significant

amount of electrical compression power.

Therefore, the implementation of a dedicated

www.digitalrefining.com/article/1000529

ROG PSA system pays off only if the

hydrogen content is as high as 80 per

cent and the ROG contribution is above

40 per cent.

Summary

ROG utilisation in steam reformer hydrogen plant

Common PSA

8%

Direct feed to reformer 74%

Dedicated PSA for ROG 100%

Table 1 summarises the described process option of ROG utilisation in a steam

reformer hydrogen plant. The recommen- Table 1

dations are rough guidelines, the actual

process selection must be evaluated caseby-case, depending on the actual economical

figures of the project.

Harald Klein is manager process engineering, hydrogen and

synthesis gas plants, Linde Engineering Division.

Email: harald.klein@lindegas.com

www.digitalrefining.com/article/1000529

Max. ROG contribution

50% H2

80% H2

12%

39%

100%

Savings (million $)

50% H2 80% H2

0.6

4.0

-3.3

1.6

4.0

10.4

Links

More articles from: Linde Engineering

More articles from the following category:

Hydrogen Management

Gas 2007 3

You might also like

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- Hydrogen Production by Steam Reforming of HC by TopsoeDocument2 pagesHydrogen Production by Steam Reforming of HC by TopsoeMainak Sarkar100% (1)

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- Ammonia Energy - EfficiencyDocument4 pagesAmmonia Energy - Efficiencyanupam01013787No ratings yet

- Shift Conversion OperationDocument26 pagesShift Conversion OperationMuhammad JunaidNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Reformer Technology For HydrogenDocument6 pagesReformer Technology For Hydrogensaleh4060No ratings yet

- KBR Advanced Ammonia Process PlusDocument1 pageKBR Advanced Ammonia Process PlusGajanan PadamwarNo ratings yet

- Ammonia TechnologyDocument13 pagesAmmonia TechnologyMihaela Popescu-NeagoeNo ratings yet

- Process DescriptionDocument6 pagesProcess Descriptionافكر اشتري كورياNo ratings yet

- Comparative Evaluation of Cryogenic Air SeparationDocument21 pagesComparative Evaluation of Cryogenic Air SeparationmuratNo ratings yet

- Advanced Gas-Heated Reformer: P. W. FarneilDocument9 pagesAdvanced Gas-Heated Reformer: P. W. FarneilAlfonso BlancoNo ratings yet

- HTCR Vs HTERDocument7 pagesHTCR Vs HTERlaquetengoNo ratings yet

- Ammonia Synthesis Material Balence CalulDocument1 pageAmmonia Synthesis Material Balence CalulDhruv RanaNo ratings yet

- Df-25054-Rep-03-001 (Proceso H2)Document110 pagesDf-25054-Rep-03-001 (Proceso H2)María Macharé GutierrezNo ratings yet

- 3 3 MR Robert PardemannDocument47 pages3 3 MR Robert Pardemannhoremheb1No ratings yet

- Shift CatalystDocument8 pagesShift Catalystraju100% (3)

- Heat Exchange Reforming Technology - Indo Club - June 2008 SNL PDFDocument17 pagesHeat Exchange Reforming Technology - Indo Club - June 2008 SNL PDFJaved MohammedNo ratings yet

- Conversion of SulfinolSM To BASF's aMDEADocument12 pagesConversion of SulfinolSM To BASF's aMDEAAna Carolina AbrantesNo ratings yet

- 50 Olefin ReductionDocument2 pages50 Olefin ReductiondimkuhNo ratings yet

- Q1 Catalyst CatastrophesDocument6 pagesQ1 Catalyst CatastrophesGhulam RasoolNo ratings yet

- Reformer Presentation: Key Aspects and Case StudiesDocument43 pagesReformer Presentation: Key Aspects and Case Studiessagarlambariya123456No ratings yet

- Uop Benfield DatasheetDocument2 pagesUop Benfield DatasheetSusan Monteza GrandezNo ratings yet

- Methanol DistillationDocument6 pagesMethanol DistillationNaseeb AliNo ratings yet

- Uop Polybed Psa For Gas Extraction Purification DatasheetDocument2 pagesUop Polybed Psa For Gas Extraction Purification DatasheetRaji RauofNo ratings yet

- Implementing a Feed Gas Saturation System to Improve Reformer EfficiencyDocument8 pagesImplementing a Feed Gas Saturation System to Improve Reformer EfficiencyDavid PierreNo ratings yet

- 34perr PDFDocument18 pages34perr PDFAlek KrótkiNo ratings yet

- 100 Years of Ammonia Synthesis: A Review of DevelopmentsDocument10 pages100 Years of Ammonia Synthesis: A Review of DevelopmentsGrootNo ratings yet

- KRES TechnologyDocument10 pagesKRES TechnologyabubakarNo ratings yet

- KSFL ReportDocument56 pagesKSFL ReportAbhishek KumarNo ratings yet

- The Theory and Practice of Steam Reforming: By: Gerard B. Hawkins Managing Director, CEODocument0 pagesThe Theory and Practice of Steam Reforming: By: Gerard B. Hawkins Managing Director, CEOBalaji RamanNo ratings yet

- Ammonia Energy 2520 BalanceDocument7 pagesAmmonia Energy 2520 Balanceapi-3714811No ratings yet

- Choosing A Selective Hydrogenation SystemDocument9 pagesChoosing A Selective Hydrogenation SystemrizaherNo ratings yet

- Haldor Topsoe Hter First ExperiencesDocument8 pagesHaldor Topsoe Hter First ExperiencesGeorge Van BommelNo ratings yet

- What A Low Delta Coke Catalyst Means To The Refiner2Document4 pagesWhat A Low Delta Coke Catalyst Means To The Refiner2Nagaphani Kumar RavuriNo ratings yet

- Basics of Hydrotreating Catalyst Sulfiding - Reactor Resources - Sulfiding Services, Alumina, Metal Reclamation, CatalystsDocument5 pagesBasics of Hydrotreating Catalyst Sulfiding - Reactor Resources - Sulfiding Services, Alumina, Metal Reclamation, Catalystsonizuka-t2263No ratings yet

- HYDROCARBON PROCESSING, Choosing The Rigth Liq. ProcessDocument6 pagesHYDROCARBON PROCESSING, Choosing The Rigth Liq. ProcessTino KhamphasithNo ratings yet

- Topsoe Claus Tail Aug09 Low Res - AshxDocument8 pagesTopsoe Claus Tail Aug09 Low Res - AshxJustin DeVitoNo ratings yet

- Ammonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEODocument33 pagesAmmonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEOAkil PrabhuNo ratings yet

- AmmoniaDocument24 pagesAmmoniaCamilo GarzonNo ratings yet

- PSA GeneralDocument17 pagesPSA GeneralMohammed AhmedNo ratings yet

- Xu and FromentDocument9 pagesXu and FromentJhimmy Terceros100% (1)

- Hydroprocessing Reactor and Process Design To Optimize Performance (Topsoe - 1998)Document18 pagesHydroprocessing Reactor and Process Design To Optimize Performance (Topsoe - 1998)yliangcaNo ratings yet

- Ammonia Process For FutureDocument5 pagesAmmonia Process For FutureSARFRAZ ALINo ratings yet

- Background And: Introducti OnDocument173 pagesBackground And: Introducti Onengr_aqeelNo ratings yet

- GAS TREATING PLANTS: IMPROVE EFFICIENCY BY OPTIMIZING CONDITIONSDocument4 pagesGAS TREATING PLANTS: IMPROVE EFFICIENCY BY OPTIMIZING CONDITIONSRobert MontoyaNo ratings yet

- Options For Economical Supply of Hydrogen: Special EquipmentDocument4 pagesOptions For Economical Supply of Hydrogen: Special EquipmentsaadashfaqNo ratings yet

- Documents - Pub - Front End Selective Hydrogenation Catalysts Enhance 2 1200 DR Wolffront EndDocument28 pagesDocuments - Pub - Front End Selective Hydrogenation Catalysts Enhance 2 1200 DR Wolffront Endnafees ahmadNo ratings yet

- Lurgi MegamethanolDocument8 pagesLurgi MegamethanolAngeloNo ratings yet

- 4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev ClaesDocument8 pages4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev Claesvaratharajan g rNo ratings yet

- Hydroprocessing: Hydrocracking & HydrotreatingDocument45 pagesHydroprocessing: Hydrocracking & HydrotreatingRobin ZwartNo ratings yet

- HYSYS For Ammonia Plants Using Johnson Matthey Catalysts TechnologyDocument1 pageHYSYS For Ammonia Plants Using Johnson Matthey Catalysts TechnologyAhmed Ali0% (2)

- Final ReportDocument46 pagesFinal ReportVarun Gupta100% (1)

- Operating Manual Ammonia Synthesis Jan 08Document20 pagesOperating Manual Ammonia Synthesis Jan 08Gaurav GuptaNo ratings yet

- Hydrotreating - UOP - A Honeywell CompanyDocument59 pagesHydrotreating - UOP - A Honeywell CompanySamNo ratings yet

- Fluidized Catalytic Cracking-An: Luidized Atalytic Racking-AnDocument47 pagesFluidized Catalytic Cracking-An: Luidized Atalytic Racking-AnChakravarthy BharathNo ratings yet

- Twenty Years of Progress with TEG DehydrationDocument5 pagesTwenty Years of Progress with TEG Dehydrationsejerson07No ratings yet

- Gbhe Ammonia Co2 Removal Systems WSV PDFDocument20 pagesGbhe Ammonia Co2 Removal Systems WSV PDFAaserElkenanyNo ratings yet

- Team BuildingDocument24 pagesTeam BuildingrithikkumuthaNo ratings yet

- Apac 052416 Models Methods Data Behind ACCE V3Document40 pagesApac 052416 Models Methods Data Behind ACCE V3kulaspiroNo ratings yet

- Hysy 8.8-Overpressure D FINALDocument28 pagesHysy 8.8-Overpressure D FINALOlalemi AdedoyinNo ratings yet

- Apac 052416 Models Methods Data Behind ACCE V3Document40 pagesApac 052416 Models Methods Data Behind ACCE V3kulaspiroNo ratings yet

- PTQ Enhancing Heat TransferDocument5 pagesPTQ Enhancing Heat TransferkulaspiroNo ratings yet

- Process Heaters Furnaces and Fired HeatersDocument12 pagesProcess Heaters Furnaces and Fired Heatersamidi5555913No ratings yet

- Combating Green Oil PDFDocument5 pagesCombating Green Oil PDFkulaspiroNo ratings yet

- A I Che Weir Loading SPR 2009Document13 pagesA I Che Weir Loading SPR 2009mehul10941No ratings yet

- MAINTAIN COOLANT LEVELDocument6 pagesMAINTAIN COOLANT LEVELAgustin BerriosNo ratings yet

- DbintfcDocument80 pagesDbintfchnr.uninstallNo ratings yet

- CH 07Document27 pagesCH 07Jessica Ibarreta100% (1)

- Seksioni I Kabllos Per Rrymat e Lidhjes Se ShkurteDocument1 pageSeksioni I Kabllos Per Rrymat e Lidhjes Se ShkurteDukagjin Ramqaj100% (1)

- Physical parameters shaping of Farwa Lagoon - LibyaDocument7 pagesPhysical parameters shaping of Farwa Lagoon - LibyaAsadeg ZaidNo ratings yet

- Product Presentation Nova Blood Gas AnalyzerDocument38 pagesProduct Presentation Nova Blood Gas Analyzerlaboratorium rsdmadani100% (1)

- Hydrocarbons NotesDocument15 pagesHydrocarbons Notesarjunrkumar2024No ratings yet

- Enzyme Inhibition and ToxicityDocument12 pagesEnzyme Inhibition and ToxicityDaniel OmolewaNo ratings yet

- General 04 Fixed Flow Pump To Three TanksDocument13 pagesGeneral 04 Fixed Flow Pump To Three TanksjpalauguillemNo ratings yet

- Max Born, Albert Einstein-The Born-Einstein Letters-Macmillan (1971)Document132 pagesMax Born, Albert Einstein-The Born-Einstein Letters-Macmillan (1971)Brian O'SullivanNo ratings yet

- ICSE Mathematics X PapersDocument22 pagesICSE Mathematics X PapersImmortal TechNo ratings yet

- Affixation (Landscape)Document4 pagesAffixation (Landscape)difafalahudinNo ratings yet

- Mitsubishi diesel forklifts 1.5-3.5 tonnesDocument2 pagesMitsubishi diesel forklifts 1.5-3.5 tonnesJoniNo ratings yet

- Huawei Mediapad m5 10.8inch Ръководство За Потребителя (Cmr-Al09, 01, Neu)Document6 pagesHuawei Mediapad m5 10.8inch Ръководство За Потребителя (Cmr-Al09, 01, Neu)Галина ЦеноваNo ratings yet

- Lecture 2 Principle of EMRDocument33 pagesLecture 2 Principle of EMRizhar engkuNo ratings yet

- Ikan Di Kepualauan Indo-AustraliaDocument480 pagesIkan Di Kepualauan Indo-AustraliaDediNo ratings yet

- HFM Currency CubeDocument2 pagesHFM Currency CubeSudhakar kNo ratings yet

- Curtis CatalogDocument9 pagesCurtis CatalogtharngalNo ratings yet

- Solomons Organic Chemistry Solution Manual - Chapter 3Document12 pagesSolomons Organic Chemistry Solution Manual - Chapter 3Imanghh25% (4)

- Hawking-Brief History of TimeDocument336 pagesHawking-Brief History of TimeAlbert Kristian0% (1)

- Developmental Morphology and Physiology of GrassesDocument26 pagesDevelopmental Morphology and Physiology of GrassesAnonymous xGVfcqNo ratings yet

- SPPID QuestionsDocument2 pagesSPPID Questionsvivek83% (12)

- Development of A Highway Performance Index For Upgrading Decision Making - Case Study For A Provincial Road Network in A Developing CountryDocument6 pagesDevelopment of A Highway Performance Index For Upgrading Decision Making - Case Study For A Provincial Road Network in A Developing CountryAshen MinolNo ratings yet

- VLSI Design: Introduction & Motivation Introduction & MotivationDocument33 pagesVLSI Design: Introduction & Motivation Introduction & MotivationPriyanka SharmaNo ratings yet

- PDS OperatorStationDocument7 pagesPDS OperatorStationMisael Castillo CamachoNo ratings yet

- Tutorial CorelDRAW-X8Document10 pagesTutorial CorelDRAW-X8Ajay BhargavaNo ratings yet

- A Guide To The Preparation of Civil Engineering Drawing PDFDocument186 pagesA Guide To The Preparation of Civil Engineering Drawing PDFEraj100% (3)

- Serial Port InterfacingDocument5 pagesSerial Port Interfacingyampire100% (1)

- Delta VFD E Series User ManualDocument399 pagesDelta VFD E Series User ManualTendai AlfaceNo ratings yet

- Ibrahim Zeid: RsrecialDocument96 pagesIbrahim Zeid: RsrecialengrodeNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Basic Alarm Electronics: Toolbox Guides for Security TechniciansFrom EverandBasic Alarm Electronics: Toolbox Guides for Security TechniciansJohn SangerRating: 4 out of 5 stars4/5 (1)

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)