Professional Documents

Culture Documents

Polycarbonate 8mm

Uploaded by

Cheung LeeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polycarbonate 8mm

Uploaded by

Cheung LeeCopyright:

Available Formats

8mm Twin Wall

Polycarbonate Sheets

Macrolux 8mm twin wall is ideal for sloped glazing,

curved and cold formed barrel vaults, signs, displays,

home improvement projects such as hobby greenhouses,

carports, partitions, patio covers and more!

Excellent Insulation: 8mm twin wall:

U Value = .59

R Value = 1.69

Stocked in Clear, Bronze and Opal

Lightweight, durable and virtually unbreakable

Custom cut to specified size

Macrolux 8mm twin wall

is perfect for applications

requiring material which

offers high light transmission,

thermal insulation, light in weight yet strong, high shock resistance,

flame resistant, great economy, vandal resistance and design flexibility. Consider using Macrolux panels in your project.

FEATURES

Macrolux is co-extruded with a U.V. stabilizer which provides high

stability against the effects of U.V. radiation, and provides excellent

weatherability. Lightweight, virtually unbreakable and durable,

Macrolux panels can be readily cold formed to many bending radii,

and are backed by a 10 year non-prorated warranty.

ENERGY SAVING

The multi-layered construction of this new, energy saving polycarbonate sheet creates increased thermal insulation. When compared

with the traditional glazing, the 8mm twin wall Macrolux sheet

offers up to 60% increases in the U value and R factor producing

real dollar savings in energy costs.

IMPACT RESISTANCE

Macrolux is so strong it withstands the impact of 16 lbs. dropped

25 feet on an 8mm panel with no breakage. It will maintain its

mechanical properties over a wide temperature range from - 40F

to 250F.

tel:

5 Alexander Drive, Wallingford, CT 06492

800/888-5364

203/679-0500

fax: 203/679-0600

web: www.co-excorp.com

e-mail: coexcorp.@aol.com

8mm Twin Wall

Polycarbonate Sheets

8MM TWIN WALL TECHNICAL DATA

removed before drying by rubbing lightly with a good grade of naptha or

isopropyl alcohol followed by a final wash with mild soap or detergent and

final rinse.

SHEET THICKNESS ........................................................... 8mm

INCH ................................................................................ 5/16

WALL TYPE ...................................................................... Twin

WEIGHT (lbs./ft.2) ............................................................. .35

LIGHT TRANSMISSION ASTM-D1003 (%)

CLEAR ...................................................................... 81%

BRONZE ................................................................... 50%

OPAL ........................................................................ 46%

MINIMUM BENDING RADIUS ........................................ 3' 11"

U FACTOR (BTU/hr. ft.2F) ............................................... .59

R-VALUE .......................................................................... 1.69

MACROLUX shall be stored in warehouse areas not exposed to direct heat

or light, with sloped stacking recommended. All panels shall be shipped

with protective polyethylene film.

INSTALLATION

Stiff fixing by means of adhesive or putty is to be avoided. If using sealants,

contact CO-EX for recommended sealants.

Tolerances: Thickness 5% , Length 1/4", Width 1/8", Weight 5%

RECOMMENDED LOADING

Exposed top and bottom ends of a sheet must always be sealed by means

of the proper polycarbonate "U" profiles or an adhesive aluminum tape to

prevent dust and dirt penetrating inside the ribs.

Guidelines for Selecting Sheet Thickness and Purlin Spacing (Sheet

Supported on the Four Sides)

It is advisable to drill

small weep holes every

12 inches in the bottom

"U" profile for condensation drainage.

MAXIMUM PURLIN SPACING (inches) DEFLECTION 1"

4' WIDTH

LOAD PER

GAUGE (lb./ft.2)

15

30

45

60

8 mm 5/16"

38"

28"

18"

MAXIMUM PURLIN SPACING (inches) DEFLECTION 3"

4' WIDTH

15

30

45

60

80"

54"

46"

40"

LOAD PER

GAUGE (lb./ft.2)

8 mm 5/16"

H PROFILE Transition between 2 sheets

Extruded ribs shall be installed in a

vertical direction for drainage.

RIGHT

WRONG

Glazing sheets should be joined by

MACROLUX extruded polycarbonate profiles and be installed with their

protective U.V. stabilized surface

towards the exterior. MACROLUX

should not be used with PVC profiles,

however, a variety of aluminum

systems may be used. Consult with CO-EX for approved systems.

For proper application of MACROLUX in roofing conditions, a slope of

at least 5 or 2/12 pitch is required.

FASTENING

H

8mm

A

10.5

B

13.5

C

80

D

65

E

7

F

12

For proper point fastening, 1" neoprene

bonded washers should be used with

screws.

Measurements shown in millimeters.

48 inch wide sheets should be fastened to

supports at all four corners, and at points

6" in from the edges of each purlin support.

U PROFILE Caps off the sheet ends

TAPES

U

8mm

A

10.5

B

12.5

C

30

D

25

E

7

F

5

Measurements shown in millimeters.

BENDING RADII

MACROLUX panels can be readily cold formed to many bending radii

and can be fabricated on site to precise dimensions. It is important to avoid

over tensing of the sheet, therefore, the minimum bending radius must be

150 times the thickness of the panel. Minimum Bending Radius = 3' 11"

CLEANING AND HANDLING

MACROLUX should be protected from abrasion by the installer. After

installation, panels shall be washed with mild soap or detergent and

lukewarm water using only a clean sponge or soft cloth, then rinsed with

clean water. Fresh paint, grease, and smeared glazing compounds may be

Foil Vent Tape

1 W x 150 L

1.5 W x 150 L

Used on the bottom of sheet to keep debris from getting in the flutes, but

allows condensation to come out. The wider tape used on the thicker sheets.

Solid Foil Tape

1.5 W x 150 L

Used to cap off the top of the sheet so debris cannot get in the flutes.

DISTRIBUTED BY:

TAP PLASTICS Inc.

For the location nearest you please go to

www.tapplastics.com

or call 1-800-894-0827

DS 8MTW 6/03

You might also like

- Foundation Code 2017Document111 pagesFoundation Code 2017Cheung Lee100% (1)

- Sec04 03Document2 pagesSec04 03Cheung LeeNo ratings yet

- Summary of Decisions of The Structural Engineering Committee SEC 4/2004 Held On 16.9.2004Document5 pagesSummary of Decisions of The Structural Engineering Committee SEC 4/2004 Held On 16.9.2004Cheung LeeNo ratings yet

- Summary of Decisions of The Structural Engineering Committee SEC 2/2004 Held On 17.5.2004Document2 pagesSummary of Decisions of The Structural Engineering Committee SEC 2/2004 Held On 17.5.2004Cheung LeeNo ratings yet

- Sec04 01Document2 pagesSec04 01Cheung LeeNo ratings yet

- Catalogue of ProppingDocument3 pagesCatalogue of ProppingCheung LeeNo ratings yet

- Sika - Waterbars: Flexible PVC WaterstopsDocument4 pagesSika - Waterbars: Flexible PVC WaterstopsCheung LeeNo ratings yet

- Pnap 173 PDFDocument8 pagesPnap 173 PDFCheung LeeNo ratings yet

- Ytong Block CatalogueDocument8 pagesYtong Block CatalogueCheung LeeNo ratings yet

- Construction Standard CS3:2013 Aggregates For Concrete: CS 3:2013 Amendment No. 1/2013 October 2013Document1 pageConstruction Standard CS3:2013 Aggregates For Concrete: CS 3:2013 Amendment No. 1/2013 October 2013Cheung LeeNo ratings yet

- Pnap 071Document14 pagesPnap 071Cheung LeeNo ratings yet

- Asp (2013 Oct) PDFDocument19 pagesAsp (2013 Oct) PDFCheung LeeNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Technical BidDocument64 pagesTechnical Bidjhon smithNo ratings yet

- NDA For Consultants Template-1Document4 pagesNDA For Consultants Template-1David Jay Mor100% (1)

- Employee Involvement TQMDocument33 pagesEmployee Involvement TQMAli RazaNo ratings yet

- Comprehensive Drug Abuse Prevention and Control Act of 1970Document2 pagesComprehensive Drug Abuse Prevention and Control Act of 1970Bryan AbestaNo ratings yet

- Copyright IP Law Infringment of CopyrightDocument45 pagesCopyright IP Law Infringment of Copyrightshree2485No ratings yet

- Boeing 247 NotesDocument5 pagesBoeing 247 Notesalbloi100% (1)

- Hw5 MaterialsDocument2 pagesHw5 MaterialsmehdiNo ratings yet

- Times Leader 02-06-2012Document36 pagesTimes Leader 02-06-2012The Times LeaderNo ratings yet

- 2018 Master Piping Products Price ListDocument84 pages2018 Master Piping Products Price ListSuman DeyNo ratings yet

- 09 20 17Document26 pages09 20 17WoodsNo ratings yet

- Comparison of BD 37 01 and AASHTO LRFD 2Document59 pagesComparison of BD 37 01 and AASHTO LRFD 2Jan Gerona ApostaderoNo ratings yet

- Role of SpeakerDocument11 pagesRole of SpeakerSnehil AnandNo ratings yet

- Gorlov Wind TurbineDocument3 pagesGorlov Wind TurbineDwayneNo ratings yet

- Standard C4C End User GuideDocument259 pagesStandard C4C End User GuideKanali PaariNo ratings yet

- Facility Management SystemDocument6 pagesFacility Management Systemshah007zaad100% (1)

- Natures CandyDocument19 pagesNatures CandyFanejegNo ratings yet

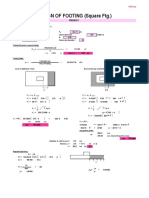

- Design of Footing (Square FTG.) : M Say, L 3.75Document2 pagesDesign of Footing (Square FTG.) : M Say, L 3.75victoriaNo ratings yet

- Class Assignment 2Document3 pagesClass Assignment 2fathiahNo ratings yet

- Challenges Faced by DMRCDocument2 pagesChallenges Faced by DMRCSourabh Kr67% (3)

- ScriptDocument7 pagesScriptAllen Delacruz100% (1)

- Leadership and Decision Making PDFDocument34 pagesLeadership and Decision Making PDFNhi PhamNo ratings yet

- Resume ObjectiveDocument2 pagesResume Objectiveapi-12705072No ratings yet

- Iso 269-2022-014 Rotary Table NDT Cat IV - Rev1Document1 pageIso 269-2022-014 Rotary Table NDT Cat IV - Rev1Durgham Adel EscanderNo ratings yet

- Big Data Hadoop Certification Training CourseDocument12 pagesBig Data Hadoop Certification Training Courseprema vNo ratings yet

- Questions - Mechanical Engineering Principle Lecture and Tutorial - Covering Basics On Distance, Velocity, Time, Pendulum, Hydrostatic Pressure, Fluids, Solids, EtcDocument8 pagesQuestions - Mechanical Engineering Principle Lecture and Tutorial - Covering Basics On Distance, Velocity, Time, Pendulum, Hydrostatic Pressure, Fluids, Solids, EtcshanecarlNo ratings yet

- AP Physics Name: AP Thermal PracticeDocument2 pagesAP Physics Name: AP Thermal PracticeMuddamsetty ArunkalyanNo ratings yet

- CSFP's Annual Executive Budget 2014Document169 pagesCSFP's Annual Executive Budget 2014rizzelmangilitNo ratings yet

- (English) 362L Stereoselective Wittig Reaction - Synthesis of Ethyl Trans-Cinnamate (#7) (DownSub - Com)Document6 pages(English) 362L Stereoselective Wittig Reaction - Synthesis of Ethyl Trans-Cinnamate (#7) (DownSub - Com)moNo ratings yet

- Caso 1 - Tunel Sismico BoluDocument4 pagesCaso 1 - Tunel Sismico BoluCarlos Catalán CórdovaNo ratings yet

- University of MauritiusDocument4 pagesUniversity of MauritiusAtish KissoonNo ratings yet