Professional Documents

Culture Documents

HEGA 2502 6510: Technical Data

Uploaded by

gchaoul87Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HEGA 2502 6510: Technical Data

Uploaded by

gchaoul87Copyright:

Available Formats

SIHI HALBERG HEGA

HEGA 2502 6510

TECHNICAL DATA

Capacity

Head

Speed

Temperature

Casing pressure

Shaft seal

Direction of rotation

: Max.

638 gpm

(145) m3/h

: Max. 1279 ft

(390) m

: Max. 3600 r.p.m.

: Max.

380 F

(194) C

: Max.

580 PSI

(40)

bar

: Stuffing box or mechanical seal

: To the right (clockwise),

looking at shaft end

APPLICATION

Series HEG multistage centrifugal pumps are used in

applications where the requirement is for trouble-free

pumping of clear or slightly dirty liquids. They are used in:

-

Heating plants

Waterworks and water supply plants

Pressure raising plants

Circulating water and condensate plants

Fire extinguishing plants

Purification plants

Irrigation plants

Boiler feed water plants

Pressurized water producing stations

DESCRIPTION AND DESIGN DETAILS

Horizontal multistage centrifugal pumps with sectional casing

and closed impellers.

The manufacturing program covers five sizes, with 2 to

maximum 13 stages, according to the size, the speed and

the shaft seal. Axial thrust balancing is carried out by

balancing the impellers separately. The remaining axial

thrusts are taken up by adequately sized antifriction

bearings.

The impellers, diffusers, as also the wear rings on size 65,

are interchangeable between stages.

Arrangements combining impeller of differing diameter

permit, within the application field, an optimum adaptation

of the performance curve of the pump to the required

performance characteristics.

On the suction side, the mounting feet are arranged on the

casing of the first stage. By this means, it is possible to

ensure easy adaptation to different installation conditions,

even subsequent to initial installation, by pivoting the suction

head casing. The driver is arranged on the suction side but

discharge side driver or driver on both sides are possible on

request.

All sizes can be supplied with one or more dummy stages

upon request.

Reserved the right to make modifications

Maximum casing pressure [PSI (bar)]:

(1)

Suction

Discharge

14 to 248F (-10 to 120 C)

232 (16)

580 (40)

up to 140 C

232 (16)

551 (38)

up to 194 C

188.5 (13)

472.7 (32.6)

Temperature range

(1) Limitations due to type of shaft sealing used

ATTENTION: The maximum casing pressure is equal to suction

pressure plus zero flow head.

Flanges:

The suction side flange according to DIN 2533 PN16 and

the discharge side to DIN 2535 PN40. The flanges can be

drilled according to ANSI B16.1 class 250, on request.

Flange positions:

Suction flange arranged horizontally towards the right

hand side (looking at the shaft end) and discharge flange

radially upwards. On request, the suction flange can be

arranged on the left and, in the case of pumps with

three or more stages, vertically upwards.

Bearings:

One cylindrical roller bearing according to DIN 5412 and

one deep-groove roller bearing to DIN 625, both lubricated

by grease.

Shaft sealing:

Sealing of the shaft can be carried out either by a stuffing

box or mechanical seal as required.

-

Sealing Code 001: Un-cooled stuffing box.

Temperature range: 14 to 230F (-10 to 110 C.)

Sealing Code 022: Externally flushed, un-cooled, lengthened

stuffing box (only for sizes 40, 50 and 65).

Temperature range: to 230F (-10 to 110 C.).

Sealing Code 511: Cooled stuffing box.

Temperature range: up to 284F (140 C) [refer factory for

higher temperatures]

Mechanical Seal Code BK3/BKS/BKU: Unbalanced single

mechanical seal with rubber bellows, lubricated by pumpage.

Temperature range: 14 to 230F (-10 to 110 C.) [refer

factory for higher temperatures when mechanical seal is

required.]

SIHI Pumps, Inc. / June 2007

SIHI HALBERG HEGA

Page

Materials of construction

Pos.

Materials of construction(1)

Pump parts

10.6

Suction casing

10.7

Discharge casing

10.8

Stage casing

23.0

Impeller

17.1

Diffuser

0B

0C

0D

0E

4B

1.4410

0.6020

2.1060

0.6020

1.4410

2.1060

0.6020

0.6020

Shaft

52.4

Shaft protection sleeve (stuffing box)

1.4301

52.32

Shaft protection sleeve (mechanical seal)

1.4301

46.1

Stuffing box

(1)

(2)

0S

0.6020

21.1

43.3

0R

2.1060

0.6020

1.7225

1.4021

1.4021

Synthetic fiber with PTFE impregnation

AQ1EGG [Carbon graphite / Silicon carbide / EPDM (2) ]

AQ1VGG [Carbon graphite / Silicon carbide / FKM (2) (Viton)]

Q1Q1VGG [Silicon carbide / Silicon carbide / FKM (2) (Viton)]

Mechanical seal

Material number according to German Standard - DIN.

Abbreviation according to ISO 1629

Equivalent materials

German Standard - DIN

Name

Material Nr.

Short name or Description

European Standard - EN

USA - Standard

Gray cast iron

0.6020

GG-20

EN-GJL-200

ASTM A48 clase 30

Cast nickel tin bronze

2.1060

G-CuSn 12 Ni

EN-CC484K

UNS C91700

Cast Duplex stainless steel

1.4410

G-X10CrNiMo 18 9

EN-1.4410

ASTM A351 clase CF12M

Alloyed high-strength steel

1.7225

42 CrMo 4

EN-1.7225

AISI 4140

Martensitic stainless steel

1.4021

X20Cr 13

EN-1.4021

AISI 420

Austenitic stainless steel

1.4301

X5CrNi 18 9

EN-1.4301

AISI 304

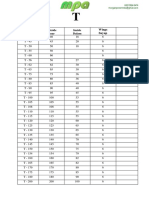

Speed / Number of stages

Maximum speed and maximum number of stages according to shaft seal option.

Pump size

2500

3200

4000

5000

6500

Maximum speed

[r.p.m.]

Maximum number of stages for the shaft seal

001

022

511

BK3

BKS

BKU

1 800

13

11

13

13

13

3 000

11

13

13

13

10

3 600

10

10

1 800

12

10

12

12

12

3 000

11

11

11

3 600

1 800

12

10

10

12

12

12

3 000

3 600

1 800

11

11

11

11

3 000

3 600

1 800

10

10

10

10

3 000

3 600

Reserved the right to make modifications

SIHI Pumps, Inc. / June 2007

You might also like

- Catalogo Motor BeideDocument28 pagesCatalogo Motor BeidealejandroNo ratings yet

- Perhitungan Dan Desain Pressure VesselDocument4 pagesPerhitungan Dan Desain Pressure VesselSyarifudin AliNo ratings yet

- Cp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Document1 pageCp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Triana Rosma Fikriyati DinaNo ratings yet

- BOQ Nego Penggantian Tanki Air (Roof Tank)Document1 pageBOQ Nego Penggantian Tanki Air (Roof Tank)Hendra Ginting100% (1)

- Motors CatalogueDocument32 pagesMotors CatalogueosbianiNo ratings yet

- Standard U BoltDocument4 pagesStandard U BoltSyifa Alfi HabibiNo ratings yet

- Rubber Coupling Type and SizeDocument4 pagesRubber Coupling Type and SizeErick Parlindungan MorganNo ratings yet

- Table Pengecekan Hydrostatic Pressure Test Product ValvesDocument31 pagesTable Pengecekan Hydrostatic Pressure Test Product ValvesIksan Mustofa50% (2)

- Product CatalogDocument20 pagesProduct CatalogRezhaNo ratings yet

- Price List Pompa HIFLOW 2018Document9 pagesPrice List Pompa HIFLOW 2018syahidianNo ratings yet

- MizuDocument1 pageMizuPrima Fitra SaputraNo ratings yet

- Contoh Schedule RepairDocument17 pagesContoh Schedule RepairUdoy LahNo ratings yet

- Metal Tapered Tube Plugs: Tube Plug Sizing ChartDocument1 pageMetal Tapered Tube Plugs: Tube Plug Sizing ChartRaghavanNo ratings yet

- Katalog ARITA - 2019Document68 pagesKatalog ARITA - 2019Sugeng Arief Van'tbowoNo ratings yet

- AMICO Induk BrosurDocument2 pagesAMICO Induk Brosurdzikri nur hNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFHardikNo ratings yet

- Parts List: KewpumpDocument11 pagesParts List: KewpumpAriel Espinoza100% (1)

- (Tabel NPT) Specifications of International Thread StandardsDocument1 page(Tabel NPT) Specifications of International Thread StandardsAan Sarkasi Amd100% (1)

- LSM Product Flyer 2021Document4 pagesLSM Product Flyer 2021JohnsonNo ratings yet

- Sand Blast and Painting Work ProsedurDocument8 pagesSand Blast and Painting Work ProsedurRizki AgustiarNo ratings yet

- Tamping Rammer TGRDocument2 pagesTamping Rammer TGRkarkarkNo ratings yet

- Rotomac Progressive Cavity Pumps: Installation, Operation and Maintenance Manual 'LDocument14 pagesRotomac Progressive Cavity Pumps: Installation, Operation and Maintenance Manual 'Lkallappa naikNo ratings yet

- Alignment Cooling Water Pump 4A: Halaman: 1 Dari 1 HalamanDocument3 pagesAlignment Cooling Water Pump 4A: Halaman: 1 Dari 1 Halamanpemeliharaan.turbin03No ratings yet

- RAB Penambahan Instalasi Pipa Loading CPODocument1 pageRAB Penambahan Instalasi Pipa Loading CPOMuslim MunawarNo ratings yet

- Procedure Fabrikasi TankiDocument10 pagesProcedure Fabrikasi TankiMuhammad Yunus NurdinNo ratings yet

- Riau Jaya Abadi HEGA 4007 & LPHX 55312 MOTOR NEW 17 April 2020Document2 pagesRiau Jaya Abadi HEGA 4007 & LPHX 55312 MOTOR NEW 17 April 2020cia sin kwangNo ratings yet

- Multitec RO - 1777.82-10 Instruciones de OperaciónDocument20 pagesMultitec RO - 1777.82-10 Instruciones de OperaciónAlvialvarezNo ratings yet

- 01 SupportingDocument1 page01 SupportingSaya NamaNo ratings yet

- Table Torque Tabel Torsi Baut Flange PDFDocument1 pageTable Torque Tabel Torsi Baut Flange PDFwibowo wibowoNo ratings yet

- Cover MDR, MDR Index Dan Pembatas (Rev)Document19 pagesCover MDR, MDR Index Dan Pembatas (Rev)Richard Adolf100% (1)

- MSB 6T Ripple Mill PDFDocument18 pagesMSB 6T Ripple Mill PDFVic NosterFishingNo ratings yet

- Ukuran KlepDocument3 pagesUkuran KlepIvhatdharatanX-cobartNo ratings yet

- Nagano Keiki GV Catalog PDFDocument4 pagesNagano Keiki GV Catalog PDFaryopn0% (1)

- Estimasi Harga Hot TapDocument1 pageEstimasi Harga Hot TaprudiawanNo ratings yet

- Inspection of Test Plan: Rotating EquipmentDocument7 pagesInspection of Test Plan: Rotating Equipmentzvlcar nainNo ratings yet

- Eckel Product Catalog - EnglishDocument28 pagesEckel Product Catalog - Englishrafael0% (1)

- Brosur Yuema Helical Bevel TKDocument143 pagesBrosur Yuema Helical Bevel TKbagus saputraNo ratings yet

- Mengatasi Masalah Silica Sand MeltingDocument9 pagesMengatasi Masalah Silica Sand MeltingTb RamdaniNo ratings yet

- Inspection Report - Pumps (Bharti Airtel)Document1 pageInspection Report - Pumps (Bharti Airtel)Ranjit SinghNo ratings yet

- Seal Weld Activ 8Document23 pagesSeal Weld Activ 8Mostafa NabilNo ratings yet

- Instructions On Installation, Operation and Maintenance Manual For Syncroflo Non-Clog Submersible Series (Ie2)Document50 pagesInstructions On Installation, Operation and Maintenance Manual For Syncroflo Non-Clog Submersible Series (Ie2)Denar PurnamaNo ratings yet

- KVC Ball ValvesDocument1 pageKVC Ball ValvesAlex VarHerNo ratings yet

- Axelson ESP Pressure Sensor PDFDocument1 pageAxelson ESP Pressure Sensor PDFAnggi SujiwoNo ratings yet

- Katalog Produk General ARITADocument72 pagesKatalog Produk General ARITAanon_969520527No ratings yet

- Form Welding SchematicDocument1 pageForm Welding SchematicZainudinNo ratings yet

- Meditran SX Plus SAE 15W-40Document2 pagesMeditran SX Plus SAE 15W-40JohnyNo ratings yet

- Table of Content: Elbow Trimming ProcedureDocument5 pagesTable of Content: Elbow Trimming ProcedureMechanical Static WRKNo ratings yet

- 1 VRLA BrochureDocument6 pages1 VRLA BrochurePT Bumi Raya PerkasaNo ratings yet

- Bulletin - PP-005 - FRP Pipe Tee-In Joint ProcedureDocument6 pagesBulletin - PP-005 - FRP Pipe Tee-In Joint ProcedureSatria PradanaNo ratings yet

- API - ANSI Flange Conversation ChartDocument1 pageAPI - ANSI Flange Conversation ChartvaliullahNo ratings yet

- Flameproof MotorsDocument16 pagesFlameproof MotorsKiran KumarNo ratings yet

- The Inside BOP Blowout PreventerDocument1 pageThe Inside BOP Blowout PreventerWanto SupriyoNo ratings yet

- Iso R286Document3 pagesIso R286ka_gho0% (1)

- Welders Identity Card: Project: Sharjah Cement Factory Customer: PhotoDocument1 pageWelders Identity Card: Project: Sharjah Cement Factory Customer: Photoayoki100% (1)

- Time Sheets CraneDocument1 pageTime Sheets CraneBillie Davidson100% (1)

- Panwater Proposal 11309Q3Document4 pagesPanwater Proposal 11309Q3WahidCesarR100% (1)

- Engineering Catalog: HL160M Dri-Prime Pump Engineering DataDocument6 pagesEngineering Catalog: HL160M Dri-Prime Pump Engineering DatamuahdibNo ratings yet

- Multistage Centrifugal Pumps HEGA 2502 ... 8009: Technical DataDocument17 pagesMultistage Centrifugal Pumps HEGA 2502 ... 8009: Technical Datajairo ardilaNo ratings yet

- PU HEGA Esite GBDocument17 pagesPU HEGA Esite GBRinto SilalahiNo ratings yet

- HEGADocument16 pagesHEGAfahruddin muhammad100% (1)

- BUPA Medical Service Providers Lebanon Updated-April 2013Document3 pagesBUPA Medical Service Providers Lebanon Updated-April 2013gchaoul87No ratings yet

- Nigerian MarketDocument28 pagesNigerian Marketgchaoul87No ratings yet

- Ctreat Rep InstallDocument16 pagesCtreat Rep Installgchaoul87No ratings yet

- Pall Filtration ProdsDocument12 pagesPall Filtration ProdsPrasad RamanNo ratings yet

- Types of Oxidation DitchesDocument5 pagesTypes of Oxidation Ditchesgchaoul87No ratings yet

- Step-By-Step Guide - Sensors Alarms1Document14 pagesStep-By-Step Guide - Sensors Alarms1Andy_kokoNo ratings yet

- BX Tuner ManualDocument4 pagesBX Tuner ManualdanielthemanNo ratings yet

- Kevin D Thomas - Activated Carbon and Lemon Peels As Adsorbent For Removing Oil From Waste WaterDocument37 pagesKevin D Thomas - Activated Carbon and Lemon Peels As Adsorbent For Removing Oil From Waste WaterRejinNo ratings yet

- Solucionario Libro Infotech 4th EditionDocument32 pagesSolucionario Libro Infotech 4th EditionGisella Espinoza BarberenaNo ratings yet

- Solution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Document10 pagesSolution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Shroyon100% (2)

- Halo Lighting Product Catalog 1974Document68 pagesHalo Lighting Product Catalog 1974Alan Masters100% (1)

- Sikafloor Morritex Self-Levelling Broadcast SystemDocument4 pagesSikafloor Morritex Self-Levelling Broadcast SystemTPNo ratings yet

- CVDocument2 pagesCVAkash JainNo ratings yet

- Applies To:: The Beginner's Guide To Oracle Solaris Patching (ID 1005835.1)Document5 pagesApplies To:: The Beginner's Guide To Oracle Solaris Patching (ID 1005835.1)apletonprinceNo ratings yet

- Molded Case Circuit Breakers Section 6: Spectra RMSDocument1 pageMolded Case Circuit Breakers Section 6: Spectra RMSArslan LashariNo ratings yet

- Illumination: "The Established Leader Ee Review"Document6 pagesIllumination: "The Established Leader Ee Review"IVex Brykz Jay Ro60% (5)

- NTSE MAT Chattisgarh Paper 2011 PDFDocument14 pagesNTSE MAT Chattisgarh Paper 2011 PDFKareena GuptaNo ratings yet

- Product Presentation PPT NeerajDocument8 pagesProduct Presentation PPT NeerajNeeraj UdiniyaNo ratings yet

- DE GUZMAN - Module 2 Activity No. 2Document4 pagesDE GUZMAN - Module 2 Activity No. 2Alvin De GuzmanNo ratings yet

- 390 Track Bolt M0079195Document2 pages390 Track Bolt M0079195joshpbenzNo ratings yet

- Case Study FormatDocument2 pagesCase Study FormatMarianel Antiqueña EspinosaNo ratings yet

- Mohammed JaberDocument768 pagesMohammed JaberMohammed Omar JaberNo ratings yet

- Thyristor PDFDocument10 pagesThyristor PDFMihir HembramNo ratings yet

- 00 Datasheet of STS-6000K-H1 For 185KTL 20200706Document2 pages00 Datasheet of STS-6000K-H1 For 185KTL 20200706Lindy PortsuNo ratings yet

- GCC TutorialDocument4 pagesGCC Tutorialistanbulizma5803100% (5)

- TEX20-NV: Technical and Maintenance ManualDocument110 pagesTEX20-NV: Technical and Maintenance Manualvasilikot50% (2)

- Contactor HassDocument1 pageContactor Hassecaldera10No ratings yet

- Agile Project ManagementDocument109 pagesAgile Project ManagementSundar Varadarajan100% (1)

- CCI Control Valves For Fossil ApplicationsDocument2 pagesCCI Control Valves For Fossil ApplicationsGabrieldiazNo ratings yet

- Pragmatic Electrical Engineering: FundamentalsDocument201 pagesPragmatic Electrical Engineering: FundamentalsaminmominNo ratings yet

- NB! This Price List Applies To Service Agreements, That Are Concluded With Nordea Bank AB Latvia BranchDocument34 pagesNB! This Price List Applies To Service Agreements, That Are Concluded With Nordea Bank AB Latvia Branchwaraxe23No ratings yet

- Manual qf1200Document24 pagesManual qf1200Guilherme MiyashiroNo ratings yet

- Role of Technology in AdvertisementtDocument29 pagesRole of Technology in AdvertisementtShalini ChatterjeeNo ratings yet

- Case StudyDocument2 pagesCase StudyAyeng 1502100% (1)

- RAEX 300 DatasheetDocument2 pagesRAEX 300 Datasheetabdulloh_99No ratings yet