Professional Documents

Culture Documents

Si 6th0a 002 Eng

Uploaded by

A340_600Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Si 6th0a 002 Eng

Uploaded by

A340_600Copyright:

Available Formats

SI-6TH0A-002-00

General Safety Information

Operation of rear derailleur lever

Operation of front derailleur levers

Lever A : Shifts from smaller to larger rear sprocket.

Lever A has a click stop at positions and .

WARNING

Obtain and read the service instructions carefully prior to

installing the parts. Loose, worn or damaged parts may cause

the bicycle to fall over and serious injury may occur as a

result. We strongly recommend only using genuine Shimano

replacement parts.

Obtain and read the service instructions carefully prior to

installing the parts. If adjustments are not carried out

correctly, the chain may come off and this may cause you to

fall off the bicycle which could result in serious injury.

Use the ST-5700/5703, BL-TT79 with the BR-5700. Do not use

the BR-5700 in combination with previous STI levers for road

riding or with the BL-R770/BL-R550 brake levers for flat

handlebars, otherwise the braking performance provided will

be much too strong.

Read these Technical Service Instructions carefully, and keep

them in a safe place for later reference.

Pass the inner cable through as shown in the illustration, and then

set the inner cable drum into the cable hook.

(FD-5700)

Lever a : Shifts from smaller to larger front chainring.

Bracket body

Lever b

Cable hook

Lever A

Lever a

start position

Click

4 3

: Shifts one sprocket

E.x. : from 3rd to 4th

Name plate

If operation of lever a dose not complete the

chainring shift stroke, operate lever a again

for the distance (X') to complete that part of

the lever stroke (X) which was short.

Inner cable drum

SP41 sealed outer casing ()

f 4 mm

Main lever support

SP41

Notch

CAUTION

Lever b : Shifts from larger to smaller front chainring.

4-mm cap

Be sure to install the shifting cable cover before use. If it is not

installed, injury may occur.

Derailleur side

Lever B : Shifts from larger to smaller rear sprocket.

Press lever B once to shift from a larger to one smaller sprocket.

Plastic cap

Plastic cap or 4-mm cap

2. Align the stud holes, and then set the special tool (1) in the

position shown in the illustration to press-fit the lever stud.

Unit cover

Cutting the outer casing

Lever B

start position

Lever B

When lever b is operated, there is

one click where trimming (the noise

prevention mechanism) engages,

and a second stronger click when the

gear shift stroke is completed. After

trimming, the next push will complete

the gear shift stroke.

E-ring groove

When cutting the outer casing, cut the opposite end to the end with

the marking. After cutting the outer casing, make the end round so

that the inside of the hole has a uniform

diameter.

Lever b

start position

Outer stopper

Gear shift

complete

stroke

Lever stroke adjustment

Gears

3mm Allen key

Direct mount seat (M5)

Front derailleur

FD-5700

Front chainwheel

FC-5700

Rear derailleur

Installation and removal of the pad spacer

FH-5700

Cassette sprocket

CS-5700

Chain

CN-5701

Bottom bracket cable guide

SM-SP17

Cable adjuster

<Installation>

Front

Lever B

Lever b

Lever A

Lever a

Lever B

rear sprocket.

rear sprocket.

chainring.

chainring.

then use the special tool (2) to

install the E-ring.

Be sure leave some excess in the outer casing, even if cutting it

to the full length of the handlebars.

Operate at least 9 times

Pass the inner cable through the cable hole.

The outer casing can be routed in two directions: either through

cable guide (1) (inside) or cable guide 2 (outside).

Replacing the main lever support

Installation:

Note:

Outer stopper

Insert the inner cable so that the inner cable drum goes into the

winder unit as far as it can go.

Outer casing

Insert the main lever support so that it

pushes against the lever body dropprevention notch.

Inner cable

Caution on operation

Main lever support

(1)

Cable hole

Confirm

Make sure the outer casing is firmly

seated in the outer stopper.

(2)

Be sure to read these service instructions in conjunction with the service

instructions for the RD-5700, FD-5700 before use.

Replacing the cable guide

Maintenance

Installation

Installation to the handlebar

Installation of the brake cable

Move the bracket cover forward, and then securely tightening the

mounting nut with a 5 mm Allen key.

Cable used

f 1.6 mm

Inner cable (stainless steel)

f 5 mm

Bracket cover

smaller to larger

larger to smaller

smaller to larger

larger to smaller

3. Remove the special tool (1), and

2. Pass the inner cable through, and set the outer casing.

Inner cable

Rear

from

from

from

from

Install with the adjustment bolt tightened.

The adjustment range for the adjustment bolt is six full turns.

Operate lever B at least 9 times to set the lever

to the highest position.

If the chain is on the large front chainwheel

and the larger rear sprocket, the chain will

rub in the front derailleur plate, producing a

characteristic noise. When this happens,

press lever b lightly (to the point where it

clicks); this causes the front derailleur to

move slightly towards the smaller chainwheel,

thereby eliminating the noise.

SM-CA70 / SM-CA50

<Removal>

: Shifts

: Shifts

: Shifts

: Shifts

Chain position

Lever Bb will also move when lever Aa is operated, but be

careful not to apply pressure to lever Bb. Similarly be careful

not to press lever Aa when operating lever Bb. Gears will not

shift when both levers are pressed simultaneously.

Pad spacer

Operation

Lever A

Lever B

Lever a

Lever b

The correct direction for the lever stud to face is with the E-ring

groove at the top.

Check that the surface of the bracket body is flush with the top

of the lever stud to ensure that the E-ring can fit into the

groove.

Tightening torque:

1.5 - 2 Nm {13 - 18 in. lbs.}

Outer casing

RD-5700-SS

Freehub

Trim

operation

Rear lever

Trimming (noise prevention operation)

Do not press-fit the lever stud

from this direction, otherwise it

may damage the bracket body.

Installation bolt

Outer end cap

If the chain is on the smallest front chainring

and a smaller rear sprocket, the chain will rub

in the front derailleur plate, producing a

characteristic noise. When this happens,

press lever a lightly (to the point where it

Movement of the

clicks); this causes the front derailleur to

front derailleur

move slightly towards the larger chainring,

thereby eliminating the noise.

20

Adjustment bolt

SP41

Click

10 mm pad spacer

Outer stopper

1. Install the outer stopper to the down tube.

Attach the same outer end cap to the cut end of the outer casing.

Click

105

OT-SP41 (SIS-SP41)

Return spring

Wire lead

In order to realize the best performance, we recommend that

the following combination be used.

Outer casing

Do not disassemble the unit cover

at the front, otherwise it may

cause problems with operation.

Lever b

5 mm pad spacer (default)

ST-5700

Connector lever

Shifting cable cover

SP41 outer casing ()

If you would like to make the lever stroke larger, remove the pad

spacer.

If you would like to make the lever stroke smaller, replace the

pad spacer with the accessory pad spacer (10 mm).

Shifting lever

assemble the bracket

body and lever body.

Next, insert the end of

the return spring into

the notch.

SEALED

SP41

Series

Assembling the bracket body and lever

body

(2)

SP41

Actual stroke

E.x. : from 4th to 3rd

Shimano Total Integration

Lever stud

Lever body

1. Insert the connector lever into the main lever support, and then

(1)

f 4 mm

: Quick-shifts two sprockets

E.x. : from 3rd to 5th

4 3

ST-5700

Insert the inner cable so that the inner cable drum goes into the

winder unit as far as it can go.

f 1.2 mm

Inner cable (PTFE inner cable)

Always be sure to remove

the lever stud in this

direction. If it is removed in

the opposite direction, it

may damage the bracket

body.

Note:

Installing the shifting cable

Full gear shift stroke

Operate at least once

Pass the inner cable through the cable hole.

The outer casing can be routed in two directions: either through

cable guide (1) (inside) or cable guide 2 (outside).

Lever a

Click

Lever A

start position

Cable used

Technical Service Instructions SI-6TH0A-002

lever stud hole, and then tap it gently with

a plastic mallet to push out the lever stud.

When the lever stud comes out, the

bracket body and lever body can be

disassembled.

Operate lever b once or more to set the lever to

the low position.

Outer casing

Note

For triple front chainwheel specifications, be sure to read these

Service Instructions in conjunction with the Service

Instructions for the ST-5703 and FD-5703.

Operation of the levers related to gear shifting should be made

only when the front chainwheel is turning.

For smooth operation, use the specified outer casing and the

bottom bracket cable guide.

Grease the inner cable and the inside of the outer casing

before use to ensure that they slide properly.

Because the high cable resistance of a frame with internal

cable routing would impair the SIS function, this type of frame

should not be used.

A special grease is used for the gear shifting cable. Do not use

DURA-ACE grease or other types of grease, otherwise they

may cause deterioration in gear shifting performance.

Parts are not guaranteed against natural wear or deterioration

resulting from normal use.

For maximum performance we highly recommend Shimano

lubricants and maintenance products.

For any questions regarding methods of installation,

adjustment, maintenance or operation, please contact a

professional bicycle dealer.

2. Insert an Allen key or similar tool into the

Front lever

SLR outer casing

Cable guide

* The illustration shows the right-hand lever.

When removing parts in order to

replace the inner cable, the work can

be carried out more easily if the unit

cover is removed as shown in the

illustration.

Bracket and lever disassembly

Use this hole to replace the cable guide.

1. First use the special tool to remove the E-ring. Use part (B) of the

special tool (2) to align the E-ring with the direction of removal.

Next, set part A against the E-ring and remove the E-ring.

Be sure to leave some excess cable, even if cutting it to the full

length of the handlebars.

E-ring removal direction

Tightening torque:

0.2 Nm {1.8 in. lbs.}

Unit cover

E-ring

Hollow

All levers return to the starting position when released.

Replacing the bracket cover

The tabs on the bracket cover each fit to a matching slot on the

bracket.

Be careful not to cover the cable holes or the unit cover when

wrapping on the handlebar tape. If the handlebar tape covers these

places, it will not be possible to replace the inner cable.

Special E-ring removal tool

5 mm Allen key

Handlebar tape

Unit cover

(1)

(2)

Cable hole

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222

3-77 Oimatsu-cho, Sakai-ku, Sakai-shi, Osaka 590-8577, Japan

* Service Instructions in further languages are available at :

http://techdocs.shimano.com

Please note: specifications are subject to change for improvement without notice. (English)

Mar. 2010 by Shimano Inc. XBC SZK Printed in Japan.

The correct way for clamp washer

(B) to face is so that the small

hollow on the surface is in the

top-left corner.

CAUTION

Tightening torque:

6 - 8 Nm {52 69 in. lbs.}

When installing the components to carbon frame/handle bar surfaces, verify with the manufacturer of the carbon

frame/parts for their recommendation on tightening torque in order to prevent over tightening that can cause

damage to the carbon material and/or under tightening that can cause lack of fixing strength for the components.

(A)

(B)

When removing the E-ring, it may

suddenly spring out, so check the

safety of any nearby people or

objects before removing it.

Note the markings:

R : for right

L : for left

Wipe a little rubbing alcohol inside the

bracket cover to make installation

easier.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Weatherproof Range LeafletDocument7 pagesWeatherproof Range LeafletA340_600No ratings yet

- Roller Blind Fitting InstructionsDocument2 pagesRoller Blind Fitting InstructionsA340_600No ratings yet

- Clothing Sizing GuideDocument1 pageClothing Sizing GuideA340_600No ratings yet

- The Basics.... : Domestic Re-Wire Check ListDocument1 pageThe Basics.... : Domestic Re-Wire Check ListA340_600No ratings yet

- Cumulus Basic Installation Guide - Aercus - EFDocument6 pagesCumulus Basic Installation Guide - Aercus - EFA340_600No ratings yet

- ADL Initial VerificationDocument2 pagesADL Initial VerificationA340_600No ratings yet

- EGLCDocument24 pagesEGLCA340_600No ratings yet

- KT200 ManualDocument8 pagesKT200 ManualA340_600No ratings yet

- P 4791733Document18 pagesP 4791733A340_600No ratings yet

- LFMNDocument103 pagesLFMNA340_600No ratings yet

- EFJODocument6 pagesEFJOA340_600No ratings yet

- KJAXDocument31 pagesKJAXA340_600No ratings yet

- RJOMDocument12 pagesRJOMA340_600No ratings yet

- RJTTDocument98 pagesRJTTA340_600No ratings yet

- EINNDocument17 pagesEINNA340_600No ratings yet

- Ev WH R501 30 R 3264B PDFDocument1 pageEv WH R501 30 R 3264B PDFA340_600No ratings yet

- CalendarDocument1 pageCalendarA340_600No ratings yet

- Duracell Cr2032 DatasheetDocument1 pageDuracell Cr2032 DatasheetA340_600No ratings yet

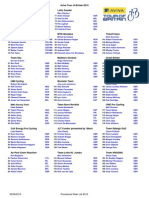

- AvivaToB RiderList v7Document1 pageAvivaToB RiderList v7A340_600No ratings yet

- Loadall - 535-125/535-140 Hiviz: Static Dimensions - 535-125 Hiviz Static Dimensions - 535-140 HivizDocument6 pagesLoadall - 535-125/535-140 Hiviz: Static Dimensions - 535-125 Hiviz Static Dimensions - 535-140 HivizA340_600No ratings yet

- 08 Headsets&acces WDocument5 pages08 Headsets&acces WA340_600No ratings yet

- Ev WH R501 30 R 3264B PDFDocument1 pageEv WH R501 30 R 3264B PDFA340_600No ratings yet

- 1321Document2 pages1321A340_600No ratings yet

- Stage 3 Cambridge - London: Monday 7th July 2014Document1 pageStage 3 Cambridge - London: Monday 7th July 2014A340_600No ratings yet

- GA Network Map PDFDocument1 pageGA Network Map PDFA340_600No ratings yet

- Tire Inflation Under WeightDocument2 pagesTire Inflation Under WeightMichael SeeryNo ratings yet

- Clewell, T - Mourning Beyond Melancholia, (2004) 52 J American Psychoanalytic Association 43Document25 pagesClewell, T - Mourning Beyond Melancholia, (2004) 52 J American Psychoanalytic Association 43A340_600No ratings yet

- Music Theory Worksheet 9 Ledger LinesDocument1 pageMusic Theory Worksheet 9 Ledger LinesKaty-Gianina Strugaru83% (6)

- Music Theory Practice Paper Grade 1 Mark SchemeDocument4 pagesMusic Theory Practice Paper Grade 1 Mark SchemeA340_600No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lesson 2 - Frequency, Intensity, Time, Type (F.i.t.t.) ModuleDocument3 pagesLesson 2 - Frequency, Intensity, Time, Type (F.i.t.t.) ModuleMr. Vander Jhon OlvezNo ratings yet

- 2010 LeftySpeed Oms en 0Document29 pages2010 LeftySpeed Oms en 0Discord ShadowNo ratings yet

- Crochet Save The Earth Bag - CrochetDocument2 pagesCrochet Save The Earth Bag - Crochetlauratoma_2002No ratings yet

- Sports Analytics - Davernport PDFDocument28 pagesSports Analytics - Davernport PDFRC TanNo ratings yet

- Canon in D Guitar TabDocument3 pagesCanon in D Guitar TabCleanTab100% (4)

- 2008 GPB Catalog PDFDocument11 pages2008 GPB Catalog PDFAntal KabácsNo ratings yet

- Engine Range VolvoTADDocument2 pagesEngine Range VolvoTADNQTNo ratings yet

- Playbook Ofensivo Troyanos 2017.Document30 pagesPlaybook Ofensivo Troyanos 2017.flash300% (1)

- SweatDocument1 pageSweatcrizadexNo ratings yet

- Ashes Remain - On My Own LyricsDocument2 pagesAshes Remain - On My Own LyricsYair YintNo ratings yet

- Singer Collection 1Document156 pagesSinger Collection 1matrices77No ratings yet

- Maricyrene Kanicia M. Cayanan - How To Make AnimationDocument4 pagesMaricyrene Kanicia M. Cayanan - How To Make Animationcyrene cayananNo ratings yet

- Diseño de Pavimento 171-181Document23 pagesDiseño de Pavimento 171-181DiegoGavidiaCNo ratings yet

- Sas #7 Ped 027 PDFDocument5 pagesSas #7 Ped 027 PDFtycheNo ratings yet

- 2 3 Zone PDFDocument12 pages2 3 Zone PDFkelson hedilanNo ratings yet

- Resistance Training Program DesignDocument30 pagesResistance Training Program DesignKostas LiougkosNo ratings yet

- Suspension Front 4wdDocument12 pagesSuspension Front 4wdAnimemanuel MuñozNo ratings yet

- 4.volvo Weekly MaintainanceDocument12 pages4.volvo Weekly MaintainanceAnbarasanNo ratings yet

- A6 Akn Abs Cu Esp SCHDocument7 pagesA6 Akn Abs Cu Esp SCHaritmeticsNo ratings yet

- CC RelatedDocument3 pagesCC RelatedItalo JaureguiNo ratings yet

- Batavia Muckdogs (2023)Document4 pagesBatavia Muckdogs (2023)The Livingston County NewsNo ratings yet

- XK8 1997 Elec GuideDocument123 pagesXK8 1997 Elec Guidewho_we_lookin_for100% (5)

- Ddec-Ecu Wiring Diagram: DDC ResponsibilityDocument1 pageDdec-Ecu Wiring Diagram: DDC ResponsibilitySandy Tello100% (1)

- Paper 003 PEDocument4 pagesPaper 003 PElakshmi.vedanarayanan7785No ratings yet

- BlueprintDocument47 pagesBlueprintRakshit AroraNo ratings yet

- Striking Distance: Charles RussoDocument11 pagesStriking Distance: Charles RussoTBTANo ratings yet

- Odd One Out: Now Do The Rest!Document1 pageOdd One Out: Now Do The Rest!ratiba157630No ratings yet

- Tech Pack For Polo Shirt by Ajay Kalangi-Mft 1 YearDocument10 pagesTech Pack For Polo Shirt by Ajay Kalangi-Mft 1 Yearajay kalangiNo ratings yet

- The Crossover S01E01 - Xs & Os (NetNaija - Xyz) .SRTDocument48 pagesThe Crossover S01E01 - Xs & Os (NetNaija - Xyz) .SRTshedrackoghenetegajasonNo ratings yet

- History of LexuxDocument23 pagesHistory of LexuxRajanikantJadhavNo ratings yet