Professional Documents

Culture Documents

Materials Properties

Uploaded by

Vishal NimbrayanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Materials Properties

Uploaded by

Vishal NimbrayanCopyright:

Available Formats

As to the designation -www.castingquality.

com

C (first letter) -means the service it is intended to be used in this case corrosion resistant service , b

F(second letter) -The second letter indicates the approximate location of the alloy on the iron-chromiu

8 the third and fourth digits represent the maximum permitted carbon content in units of 0.01% (e.g

www.castingquality.com

M it means the Molybdenum contained, if no M such as CF8 just means no Molybdenum contained.

osion resistant service , butCastingQuality think sometimes it means of CASTINGusage because you will find F

alloy on the iron-chromium-nickel (FeCrNi) ternary diagram. For users familiar with the diagram, the second lette

ent in units of 0.01% (e.g., CF8 has a maximum of 0.08% carbon)

Molybdenum contained.

e because you will find F316 in ASTM A 350 ( F = FORGing)www.castingquality.com

diagram, the second letter does provide an indication of the nominal iron, nickel, and chromium content, but mo

hromium content, but most people would have to obtain alloying information from a material specification. www.

terial specification. www.castingquality.com

Cast Stainless Steel CD4MCu, ASTM A351

Categories:

Material Notes:

Key Words:

Vendors:

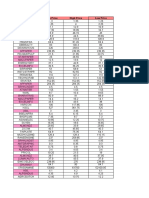

Mechanical Properties

Tensile Strength, Ultimate

Tensile Strength, Yield

Elongation at Break

Component Elements Properties

Carbon, C

Chromium, Cr

Copper, Cu

Iron, Fe

Manganese, Mn

Molybdenum, Mo

Nickel, Ni

Phosphorous, P

Silicon, Si

Sulfur, S

Cast Stainless Steel CD4MCu, ASTM A351

Metal; Ferrous Metal; ASTM Steel; Stainless Steel; Cast Stainless Steel

Pressure vessel

ASTM A351(94)

No vendors are listed for this material. Please click here if you are a supplier and would like informatio

Metric

>= 690 MPa

>= 485 MPa

>= 16 %

Metric

<= 0.040 %

24.5 - 26.5 %

2.75 - 3.25 %

59.9 - 66.3 %

<= 1.0 %

1.75 - 2.25 %

4.75 - 6.0 %

<= 0.040 %

<= 1.0 %

<= 0.040 %

English

Comments

>= 100000 psi

>= 70300 psi

>= 16 %

English

<= 0.040 %

24.5 - 26.5 %

2.75 - 3.25 %

59.9 - 66.3 %

<= 1.0 %

1.75 - 2.25 %

4.75 - 6.0 %

<= 0.040 %

<= 1.0 %

<= 0.040 %

Comments

As remainder

Cast Stainless Steel CA6NM, ASTM A352

Categories:

Material Notes:

Key Words:

Vendors:

Mechanical Properties

Tensile Strength, Ultimate

Tensile Strength, Yield

Elongation at Break

Component Elements Properties

Carbon, C

Chromium, Cr

Iron, Fe

Manganese, Mn

Molybdenum, Mo

Nickel, Ni

Phosphorous, P

Silicon, Si

Sulfur, S

Cast Stainless Steel CA6NM, ASTM A352

Metal; Ferrous Metal; ASTM Steel; Stainless Steel; Cast Stainless Steel

Martensitic, Pressure, Low Temperature

ASTM A352/A352M(98), UNS J91540

No vendors are listed for this material. Please click here if you are a supplier and would like informatio

Metric

760 - 930 MPa

>= 550 MPa

>= 15 %

Metric

<= 0.060 %

11.5 - 14 %

78.4 - 84.6 %

<= 1.0 %

0.40 - 1.0 %

3.5 - 4.5 %

<= 0.040 %

<= 1.0 %

<= 0.030 %

English

Comments

110000 - 135000 psi

>= 79800 psi

>= 15 %

English

<= 0.060 %

11.5 - 14 %

78.4 - 84.6 %

<= 1.0 %

0.40 - 1.0 %

3.5 - 4.5 %

<= 0.040 %

<= 1.0 %

<= 0.030 %

Comments

As remainder

Cast Stainless Steel CF8M, ASTM A351

Categories:

Material Notes:

Key Words:

Vendors:

Mechanical Properties

Tensile Strength, Ultimate

Tensile Strength, Yield

Elongation at Break

Component Elements Properties

Carbon, C

Chromium, Cr

Iron, Fe

Manganese, Mn

Molybdenum, Mo

Nickel, Ni

Phosphorous, P

Silicon, Si

Sulfur, S

Cast Stainless Steel CF8M, ASTM A351

Metal; Ferrous Metal; ASTM Steel; Stainless Steel; Cast Stainless Steel

Pressure vessel

ASTM A351(94)

No vendors are listed for this material. Please click here if you are a supplier and would like informatio

Metric

>= 485 MPa

>= 205 MPa

>= 30 %

Metric

<= 0.080 %

18 - 21 %

60.8 - 71 %

<= 1.5 %

2.0 - 3.0 %

9.0 - 12 %

<= 0.040 %

<= 1.5 %

<= 0.040 %

English

Comments

>= 70300 psi

>= 29700 psi

>= 30 %

English

<= 0.080 %

18 - 21 %

60.8 - 71 %

<= 1.5 %

2.0 - 3.0 %

9.0 - 12 %

<= 0.040 %

<= 1.5 %

<= 0.040 %

Comments

As remainder

MetalTek WCB UNS J13345 Cast Alloy Steel

Categories:

Material Notes:

Key Words:

Vendors:

Mechanical Properties

Hardness, Brinell

Tensile Strength, Ultimate

Tensile Strength, Yield

Elongation at Break

Component Elements Properties

Carbon, C

Iron, Fe

Manganese, Mn

Silicon, Si

Descriptive Properties

Heat Treatment

MetalTek WCB UNS J13345 Cast Alloy Steel

Metal; Ferrous Metal; Alloy Steel; AISI 4000 Series Steel

General structural use.

Applications: Cylinders, rolls, hollow shafts.

Information provided by MetalTek

Cast UNS J13345; Cast Grade 9B; Cast ASTM A216; Wrought UNS G41300; Wrought Grade AISI 4130

No vendors are listed for this material. Please click here if you are a supplier and would like informa

M

480 - 655

>= 275

>= 2

<= 0.3

>= 98

<= 1

<= 0.6

English

Comments

255

69600 - 95000 psi

>= 39900 psi

>= 22 %

English

<= 0.30 %

>= 98.1 %

<= 1.0 %

<= 0.60 %

Quench & Temper

Comments

As Balance

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 3.5 Horizontal Well Completions PDFDocument29 pages3.5 Horizontal Well Completions PDFJohn CooperNo ratings yet

- Wrox - Professional Windows Phone 7 Game DevelopmentDocument554 pagesWrox - Professional Windows Phone 7 Game DevelopmentMassimiliano X-anteNo ratings yet

- IPTV CodesDocument27 pagesIPTV CodesAbdul Aziz0% (1)

- Fire Protection SystemDocument63 pagesFire Protection SystemVishal Nimbrayan100% (1)

- Cyberpunk 2020 Ammo & Add-Ons PDFDocument6 pagesCyberpunk 2020 Ammo & Add-Ons PDFFabricio MoreiraNo ratings yet

- T Series TorqueDocument8 pagesT Series TorqueBrian OctavianusNo ratings yet

- Transaction Acknowledgment: Thank YouDocument1 pageTransaction Acknowledgment: Thank YouVishal NimbrayanNo ratings yet

- I.M.pei Tanya2k6.628Document33 pagesI.M.pei Tanya2k6.628Vishal NimbrayanNo ratings yet

- Nasa PresentationDocument16 pagesNasa PresentationVishal NimbrayanNo ratings yet

- Tea KityDocument4 pagesTea KityVishal NimbrayanNo ratings yet

- MCQDocument15 pagesMCQVishal NimbrayanNo ratings yet

- Symbol Open Price High Price Low PriceDocument24 pagesSymbol Open Price High Price Low PriceVishal NimbrayanNo ratings yet

- MCQDocument15 pagesMCQVishal NimbrayanNo ratings yet

- Vigilohm 2019 Catalogue - PLSED310020ENDocument96 pagesVigilohm 2019 Catalogue - PLSED310020ENRodrigo Jacy Monteiro MartinsNo ratings yet

- PA Process: Thermal EngineeringDocument8 pagesPA Process: Thermal Engineeringlulis171No ratings yet

- How To Check The Lms For MR PostingDocument7 pagesHow To Check The Lms For MR PostingMica FloresNo ratings yet

- Arduino DisassemblyDocument2 pagesArduino DisassemblyJose100% (1)

- M337x 387x 407x Release Note EnglishDocument3 pagesM337x 387x 407x Release Note EnglishIoana Codrea OrtelecanNo ratings yet

- Manual Sales Order Processing System: Vanessa GabriellaDocument1 pageManual Sales Order Processing System: Vanessa GabriellaVanessa GabriellaNo ratings yet

- Process-Flow Analysis: Mcgraw-Hill/IrwinDocument26 pagesProcess-Flow Analysis: Mcgraw-Hill/IrwinVanessa Aulia PutriNo ratings yet

- Ghost Adventures S13e04 Reseda House of Evil HDTV x264-w4fDocument2 pagesGhost Adventures S13e04 Reseda House of Evil HDTV x264-w4fAnonymous wISY6CIf8No ratings yet

- Ax1g OmDocument59 pagesAx1g Omskipscooter100% (1)

- Programmable Logic ControllerDocument11 pagesProgrammable Logic ControllerRohit AgrawalNo ratings yet

- #SM4J Recap Fall 2019Document5 pages#SM4J Recap Fall 2019Damian RadcliffeNo ratings yet

- Mystery 20a30amanual PDFDocument3 pagesMystery 20a30amanual PDFJerson Briones SeguraNo ratings yet

- Motor Vehicle Traffic Fatalities & Fatality Rate: 1899 - 2003Document2 pagesMotor Vehicle Traffic Fatalities & Fatality Rate: 1899 - 2003Yoni ReinónNo ratings yet

- Chapter 3 Dec 50143Document29 pagesChapter 3 Dec 50143Kohilan VenugopalNo ratings yet

- Sequence Based SpecificationsDocument11 pagesSequence Based SpecificationsrexthrottleNo ratings yet

- Four Quadrant ChopperDocument18 pagesFour Quadrant ChopperShipra singhNo ratings yet

- Transformer 1Document13 pagesTransformer 1Zulfadhli ZainudinNo ratings yet

- RETS Developer Start GuideDocument10 pagesRETS Developer Start GuideKlemNo ratings yet

- MBA Final MIS ProjectDocument11 pagesMBA Final MIS ProjectNurul HasnainNo ratings yet

- 40 Must Know Web 2.0 EdutoolsDocument521 pages40 Must Know Web 2.0 EdutoolsDaniela BozganNo ratings yet

- MANIEGODocument11 pagesMANIEGONakanakanaknakNo ratings yet

- Netsure-731-A41-User-Manual (Manual) PDFDocument38 pagesNetsure-731-A41-User-Manual (Manual) PDFRoger Alfaro GNo ratings yet

- Rittal 3245500 Anleitung 3 4847Document20 pagesRittal 3245500 Anleitung 3 4847esicafgNo ratings yet

- A SWOT Analysis of Planning Support Systems: G.A. V Onk at G M A I L.C O MDocument23 pagesA SWOT Analysis of Planning Support Systems: G.A. V Onk at G M A I L.C O MDannyRamadhanNo ratings yet

- PTW Logic DiagramDocument1 pagePTW Logic DiagramAdrianNo ratings yet