Professional Documents

Culture Documents

Shimano XTR M980 Shift Lever Set Manual

Uploaded by

Nick SpeisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shimano XTR M980 Shift Lever Set Manual

Uploaded by

Nick SpeisCopyright:

Available Formats

!

"#$#%&'()'*+$,+-+*

!"#$

%&'

S

8

=

_

E

Q

T

.D40EFG

?G@H$FGI

^#+@(!V"!&%

:;"<123=3

:;"2123=3

:;"<123>3

:;?@AA333

:;"<123A3

:;"<123B3

:;"<123C3

:;"2123>3

:;"2C>333

:;"<123;3

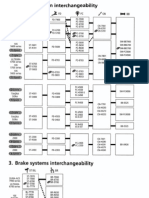

(')'*+,-./-01*23435*60-/

2')'*+,-./-01*23435*60-/

+,-./-01*23435*9-:-01*+;53<*60-/

!0035*)>?3*@AB

60-/*9-:-01*C>?/*D$E*:*F'EG*H*IAJ,35

60-/*9-:-01*C>?/*D$E*:*F'EG*H*IAJ,35*.>5*+$K+2FL

(')'*@AM?3*7NOPJ//-01*C>?/*60-/

2')'*@AM?3*7NOPJ//-01*C>?/*60-/

@?ARB*C>?/*D$E*:*S='EG

C>?/*D$E*:*S8'EG*H*%P/*.>5*+$K+2FL

7U*+AR3*BA5/J'

CU*VA5/J*A53*PJAM?3W*MP/*N-..35*-0*RA/35-5A?JW*ABB3A5A0;3W*.-0-J,W*J-X3W*3/;'

7MJ30;3*>.*RA5Z*-0N-;A/3J*0>0K-0/35;,A013AM-?-/['

!"#$%&%$'(%)*+,'-#,+./0#$(,(),$1'*2#,3%(1).(,*)(%$#4

+2

K$

TT

`

+2

K$

FL

`

K!

.,/0123$$#%&'()'*+$,+-+*

.0/.,12$$45&+6$7*%68+9

!%"#(@)7%\#7C!2!"]

7

7

7

7

7

7

7

7

!"#$%&'('%)'*)+

Y +,-RA0>*!0;'*7

SI-5M80A-002-00

General Safety Information

Spacer installation method

Specifications

Front Derailleur

WARNING

Maintenance interval depends on the usage and riding circumstances. Clean regularly the chain

with an appropriate chaincleaner. Never use alkali based or acid based solvents such as rust

cleaners. If those solvent be used chain might break and cause serious injury.

Model number

In order to obtain good gear shifting performance, this chain has a forward side and a reverse side, and the

sides are marked so that the chain will face the correct way when installed. The proper design performance

will be obtained when the chain is installed so that it faces the correct way. If it is installed so that it faces

the opposite way, the chain may come off and the bicycle may fall over and serious injury may occur as a

result.

Use the reinforced connecting pin only for connecting the narrow type of chain.

If connecting pins other than reinforced connecting pins

Reinforced

are used, or if a reinforced connecting pin or tool which

Chain

Chain tool

connecting pin

is not suitable for the type of chain is used, sufficient

connection force may not be obtained, which could

with groove (3)

TL-CN32

cause the chain to break or fall off.

10-speed super narrow

chain for

TL-CN23

If it is necessary to adjust the length of the chain due to

MTB

TL-CN27

a change in the number of sprocket teeth, make the cut

with groove (2)

at some other place than the place where the chain has

been joined using a reinforced connecting pin. The chain will be damaged if it is cut at a place

Reinforced Connecting Pin

where it has been joined with a reinforced connecting pin.

Be careful not to let the cuffs of your clothes get caught in the chain while riding, otherwise you

may fall off the bicycle.

Check that the tension of the chain is correct and that the chain is not damaged. If the tension

Link Pin

Link Pin

is too weak or the chain is damaged, the chain should be replaced. If this is not done, the chain

may break and cause serious injury.

The two left crank arm mounting bolts should be tightened alternately in stages rather than each bolt being fully tightened all at

once. Use a torque wrench to check that the final tightening torques are within the range of 12 - 14 Nm. Furthermore, after

riding approximately 100 km (60 miles), use a torque wrench to re-check the tightening torques. It is also important to

periodically check the tightening torques. If the tightening torques are too weak or if the mounting bolts are not tightened

alternately in stages, the left crank arm may come off and the bicycle may fall over, and serious injury may occur as a result.

Check that there are no cracks in the crank arms before riding the bicycle. If there are any cracks, the crank arm may break and

you may fall off the bicycle.

If the inner cover is not installed correctly, the axle may rust and become damaged, and the bicycle may fall over and serious

injury may occur as a result.

Obtain and read the service instructions carefully prior to installing the parts. Loose, worn or damaged parts may cause the

bicycle to fall over and serious injury may occur as a result. We strongly recommend only using genuine Shimano replacement

parts.

Obtain and read the service instructions carefully prior to installing the parts. If adjustments are not carried out correctly, the

chain may come off and this may cause you to fall off the bicycle which could result in serious injury.

Read these Technical Service Instructions carefully, and keep them in a safe place for later reference.

CAUTION

If the chain is on the smallest or intermediate chainring, there is the danger of injury from the tips of the teeth on the largest

chainring.

X = Available

FD-M985

FD-M985-E

FD-M985-E2

FD-M986

FD-M986-D

Normal type

Top route type

Front chainwheel tooth difference

14, 12T

14, 12T

12T

14, 12T

14, 12T

Front derailleur installation band diameter

S, M, L

S, M, L

66 - 69

66 - 69

66 - 69

66 - 69

66 - 69

46.8 mm

38T

38T

38T

38T

48.8 mm

40-44T

40-44T

40T

40-44T

40-44T

Chainstay angle (a)

Applicable chain line

Technical Service Instructions

Model number

FC-M985

FC-M980

Chainwheel tooth combination

40-28T

38-26T

Bolt circle diameter

Crank arm length

Chain line

Bottom bracket shell width

Thread dimensions

Applicable bottom bracket

F

A

2.5 mm

Band Type

42-30T

44-30T

104 / 64 mm

88 mm

165, 170, 175, 180 mm

170, 172.5, 175, 180 mm

46.8 mm

48.8 mm

68, 73 mm

68, 73 mm

BC1.37 (68, 73mm)

BC1.37 (68, 73mm)

SM-BB90-A

SM-BB90-A

When using the S, M size, use an

installation band with a diameter of 28.6

mm, 31.8mm and install it to a L size

adapter.

68 mm

Front derailleur

Front chainwheel

68 mm

F

A

BB mount-type

bracket

Mode select switch

Note:

The mode converter cannot be switched while the lever is at the

lowest position. Be sure to operate lever (A) one or more times

before switching. Do not turn the mode converter by force, otherwise

it may break.

Inner hole cover

F

A

F

A

F

A

73 mm

Install the inner hole cover by turning it as

shown in the illustration until it stops.

Do not turn it any further than this, otherwise

it may damage the thread on the cover.

F

A

73 mm

Chainstay angle

F

A

* If using a bottom bracket shell having a width of 68 mm which is a

band type, an 1.8 mm spacer and a 0.7 mm spacer can be used

together instead of a 2.5 mm spacer.

The INSTANT RELEASE mechanism makes fast releasing possible because cable tension is released immediately when a lever is

depressed.

This release lever is equipped with a 2-way release mechanism which allows release operations to be carried out by either pushing or

pulling the lever.

Both lever (A) and lever (B) always return to the initial position when they are released after shifting.

When operating one of the levers, always be sure to turn the crank arm at the same time.

To shift from the smaller chainring to the larger chainring

(Lever A)

To shift from the larger chainring to the smaller chainring

(Lever B)

When lever (A) is pressed once, there is a shift of one step from the

smaller chainring to the larger chainring.

When lever (B) is pressed once, there is a shift of one step from the

larger chainring to the smaller chainring.

Example:

Example:

From smaller chainring to larger chainring.

From larger chainring to smaller chainring.

Chain length

Add 2 links (with the chain on both

the largest sprocket and the large

chainring)

Largest sprocket

Large chainring

Cutting the outer casing

When cutting the outer casing, cut the opposite end to the end with

the marking. After cutting the outer casing,

make the end round so that the inside of the

hole has a uniform diameter.

Attach the same outer end cap to the cut end of the outer casing.

Outer end cap

Chain

Replacement of the shifting lever unit

Installation of the shifting lever

4 mm Allen key

Use a handlebar grip with a maximum

outer diameter of 32 mm.

Disassembly and reassembly should only be carried out when

replacing the shifting lever unit.

Bracket

Unit fixing bolt

Tightening torque:

2.5 Nm {22 in. lbs.}

Tightening torque :

3 Nm {27 in. lbs.}

Washer

Adjustment barrel

Lever (A) initial position

The shifting lever position can be

adjusted by sliding it to the left or right.

Lever (B)

2-WAY RELEASE

Shifting lever mounting screws (Small)

Tightening torque :

2.5 Nm {22 in. lbs.}

Installation of the Front Chainwheel

1, 2 Use the special tool TL-FC32/36 to install the right adapter

(counterclockwise thread) and the left adapter (clockwise

thread).

Tightening torque: 35 - 50 Nm {305 - 435 in. lbs.}

Note : Spacers may be necessary depending on the bottom

bracket shell width. For details, refer to "Spacer

installation method.

3

4

Insert the right crank unit.

Use the TL-FC16/18 to tighten the cap.

Tightening torque: 0.7 - 1.5 Nm {6 - 13 in. lbs.}

Push in the stopper plate and check that the plate pin is

securely in place, and then tighten the bolt of the left crank

arm. (5 mm Allen key)

Note : Each of the bolts should be evenly and equally

tightened to 12 - 14 Nm {106 - 122 in. lbs.}.

Set section A of the left crank into the axle of the right crank

unit where the groove is wide.

(A)

Note:

When installing the components to carbon frame/handle bar

surfaces, verify with the manufacturer of the carbon frame/parts for

their recommendation on tightening torque in order to prevent over

tightening that can cause damage to the carbon material and/or

under tightening that can cause lack of fixing strength for the

components.

Refer to the FD-M985 / M985-E / M985-E2 / M986 / M986-D

(Front Derailleur) Service Instructions for details on installing

the front derailleur and SIS adjustment.

TL-FC32

Wide groove area

Connecting and securing the inner cable

SI-5M80A-002

Tightening torque:

0.08 Nm {0.7 in. lbs.}

Install the shifting lever in a position where it will not obstruct

brake operation and gear shifting operation.

Do not use in a combination which causes brake operation to be

obstructed.

Follow the procedure in the figure.

Shifting lever mounting screws (Large)

Tightening torque:

0.14 Nm {1.2 in. lbs.}

1. Loosen the cable fixing bolt (nut) of the front derailleur, and then

pull the inner cable out of the shifting lever unit in the same way

as when installing the inner cable.

2. Remove the adjustment barrel.

3. First remove the unit fixing bolt.

4. Remove the four shifting lever mounting screws, and then remove

the shifting lever unit as shown in the illustration.

5. To assemble, align the shifting lever unit and the bracket and then

secure the shifting lever mounting screws.

6. Place the washer onto the bolt, and then secure the unit fixing

bolt.

7. Install the adjustment barrel.

Switch the mode converter to the 3x (triple mode) position, and then

check the lowest position. Operate lever B two times or more to set

the lever to the lowest position. Remove the inner hole cover, and

install the cable.

1

This service instruction explains how to use and maintain the

Shimano bicycle parts which have been used on your new bicycle.

For any questions regarding your bicycle or other matters which

are not related to Shimano parts, please contact the place of

purchase or the bicycle manufacturer.

Lever (B)

Inner cable

Inner hole cover

In order to realize the best performance, we recommend that the following combination be used.

Outer casing

Bracket Type

Gear shifting operation

TL-FC16

Rapidfire (Shifting lever)

Mode converter

Spacer

Front Drive System

Series

Lever (A)

Installation band diameters:

S (28.6 mm), M (31.8 mm), L (34.9 mm)

Chainwheel

Note

In addition, if pedaling performance does not feel normal, check this once more.

Before riding the bicycle, check that there is no play or looseness in the connection. Also, be sure to retighten the crank arms

and pedals at periodic intervals.

If a squeaking noise is heard coming from the bottom bracket axle and the left crank arm connector, apply grease to the

connector and then tighten it to the specified torque.

Use a neutral detergent to clean the crank arm and the bottom bracket. Using alkaline or acidic detergents may cause

discoloration.

Do not wash the bottom bracket with high-pressure jets of water.

If you feel any looseness in the bearings, the bottom bracket should be replaced.

If gear shifting operations do not feel smooth, wash the derailleur and lubricate all moving parts.

If the amount of looseness in the links is so great that adjustment is not possible, you should replace the derailleur.

You should periodically wash the chainrings in a neutral detergent and then lubricate them again. In addition, cleaning the chain

with neutral detergent and lubricating it can be an effective way of extending the useful life of the

chainrings and the chain.

Front

If the chain keeps coming off the chainrings during use, replace the chainrings and the chain.

chainrings

When the chain is in the position shown in the illustration, the chain may contact the front chainrings

or front derailleur and generate noise. If the noise is a problem, shift the chain onto the next-larger

Rear

rear sprocket or the one after.

sprockets

For frames with suspension, the chain stay angle will vary depending on whether the bicycle is being

ridden or not being ridden. When the bicycle is not being ridden and the chain is positioned on the

largest/larger chainring and on the smallest sprocket, the chain guide outer plate of the front derailleur

Outer casing holders

may touch the chain.

The cuffs of your clothing may get dirty from the chain while riding.

Apply grease to the left and right adapters before installing them.

For smooth operation, use the specified outer casing and the bottom bracket cable guide.

The front derailleur is for double front chainwheels only. It cannot be used with triple front chainwheels, as

the shifting points will not match.

When installing the top route type, choose a frame that has three outer casing holders as shown in the

illustration at right.

Use an outer casing which still has some length to spare even when the handlebars are turned all the way to both sides.

Furthermore, check that the shifting lever does not touch the bicycle frame when the handlebars are turned all the way.

A special grease is used for the gear shifting cable. Do not use DURA-ACE grease or other types of grease, otherwise they may

cause deterioration in gear shifting performance.

Grease the inner cable and the inside of the outer casing before use to ensure that they slide properly.

Operation of the levers related to gear shifting should be made only when the front chainwheel is turning.

If the brake fluid used in the oil disc brakes is of a type which tends to adhere to the plastic parts of the shifting lever, this may

cause the plastic parts to crack or become discolored. Therefore, you should make sure that the brake fluid does not adhere to

these plastic parts. The mineral oil which is used in SHIMANO disc brakes does not cause cracking or discoloration if it adheres

to plastic parts, but such parts should be cleaned with alcohol beforehand to prevent foreign particles from adhering.

Do not disassemble the shifting lever unit, as this may damage it or cause mis-operation.

Be sure to read the service instructions for the Rear Drive System in conjunction with these service instructions (SL-M980-I).

Parts are not guaranteed against natural wear or deterioration resulting from normal use.

For maximum performance we highly recommend Shimano lubricants and maintenance products

For any questions regarding methods of installation, adjustment, maintenance or operation, please contact a professional

bicycle dealer.

Operate lever A once to set it to the middle position. Switch the

mode converter to the 2x (double mode) position.

(1) Check whether the width of the bottom

bracket shell is 68 mm or 73 mm.

(2) Next, install the adapter while referring to the

illustrations below.

Inner cover

Mode converter

XTR

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

SL-M980-L / SL-M980-IL

OT-SP41 (SIS-SP41)

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222

Plate pin

FD-M985 / FD-M985-E / FD-M985-E2 / FD-M986 / FD-M986-D

Mode select switch

FC-M980 / FC-M985

Chain

CN-M980

Bottom bracket cable guide

SM-SP17

Stopper plate

Push up

Note :

Set the stopper plate in the right direction as shown

in illustration.

Note:

Do not force the mode select switch to turn. If you force it to turn, it

will break.

3-77 Oimatsu-cho, Sakai-ku, Sakai-shi, Osaka 590-8577, Japan

* Service Instructions in further languages are available at :

http://techdocs.shimano.com

Please note: specifications are subject to change for improvement without notice. (English)

Jul. 2010 by Shimano Inc. XBC SZK Printed in Japan.

SI-5M40A-003-00

General Safety Information

Spacer installation method

Specifications

Front Derailleur

WARNING

X = Available

Maintenance interval depends on the usage and riding circumstances. Clean regularly the chain with

an appropriate chaincleaner. Never use alkali based or acid based solvents such as rust cleaners. If

those solvent be used chain might break and cause serious injury.

Model number

In order to obtain good gear shifting performance, applicable chains have a forward side and a reverse side, and

the sides are marked so that the chains will face the correct way when installed. The proper design performance

will be obtained when the chains are installed so that they face the correct way. If the chains are installed so that

they face the opposite way, they may come off and the bicycle may fall over and serious injury may occur as a

result.

Use the reinforced connecting pin only for connecting the narrow type of chain.

If connecting pins other than reinforced connecting pins are

Reinforced

used, or if a reinforced connecting pin or tool which is not

Chain

Chain tool

connecting pin

suitable for the type of chain is used, sufficient connection

force may not be obtained, which could cause the chain to

with groove (3)

TL-CN32

10-speed super narrow

break or fall off.

TL-CN23

chain for

If it is necessary to adjust the length of the chain due to a

MTB

TL-CN27

with groove (2)

change in the number of sprocket teeth, make the cut at

some other place than the place where the chain has been

joined using a reinforced connecting pin. The chain will be damaged if it is cut at a place where it has

Reinforced Connecting Pin

been joined with a reinforced connecting pin.

Be careful not to let the cuffs of your clothes get caught in the chain while riding, otherwise you may

fall off the bicycle.

Check that the tension of the chain is correct and that the chain is not damaged. If the tension is too

Link Pin

Link Pin

weak or the chain is damaged, the chain should be replaced. If this is not done, the chain may break

and cause serious injury.

The two left crank arm mounting bolts should be tightened alternately in stages rather than each bolt being fully tightened all at once.

Use a torque wrench to check that the final tightening torques are within the range of 12 - 14 Nm. Furthermore, after riding

approximately 100 km (60 miles), use a torque wrench to re-check the tightening torques. It is also important to periodically check the

tightening torques. If the tightening torques are too weak or if the mounting bolts are not tightened alternately in stages, the left crank

arm may come off and the bicycle may fall over, and serious injury may occur as a result.

Check that there are no cracks in the crank arms before riding the bicycle. If there are any cracks, the crank arm may break and you

may fall off the bicycle.

If the inner cover is not installed correctly, the axle may rust and become damaged, and the bicycle may fall over and serious injury may

occur as a result.

Obtain and read the service instructions carefully prior to installing the parts. Loose, worn or damaged parts may cause the bicycle

to fall over and serious injury may occur as a result. We strongly recommend only using genuine Shimano replacement parts.

Obtain and read the service instructions carefully prior to installing the parts. If adjustments are not carried out correctly, the chain

may come off and this may cause you to fall off the bicycle which could result in serious injury.

Read these Technical Service Instructions carefully, and keep them in a safe place for later reference.

Front chainwheel tooth difference

18T

Min. difference between top and intermediate

10T

CAUTION

If the chain is on the smallest or intermediate chainring, there is the danger of injury from the tips of the teeth on the largest chainring.

Note

In addition, if pedaling performance does not feel normal, check this once more.

Before riding the bicycle, check that there is no play or looseness in the connection. Also, be sure to retighten the crank arms and

pedals at periodic intervals.

When installing the pedals, apply a small amount of grease to the threads to prevent the pedals from sticking. Use a torque wrench to

securely tighten the pedals. Tightening torque: 35 - 55 Nm {305 - 479 in. lbs.}. The right-hand crank arm has a right-hand thread, and

the left-hand crank arm has a left-hand thread.

If a squeaking noise is heard coming from the bottom bracket axle and the left crank arm connector, apply grease to the connector and

then tighten it to the specified torque.

Use a neutral detergent to clean the crank arm and the bottom bracket. Using alkaline or acidic detergents may cause discoloration.

Do not wash the bottom bracket with high-pressure jets of water.

If you feel any looseness in the bearings, the bottom bracket should be replaced.

If gear shifting operations do not feel smooth, wash the derailleur and lubricate all moving parts.

If the amount of looseness in the links is so great that adjustment is not possible, you should replace the derailleur.

You should periodically wash the chainrings in a neutral detergent and then lubricate them again. In addition, cleaning the chain with

neutral detergent and lubricating it can be an effective way of extending the useful life of the chainrings and the chain.

If the chain keeps coming off the chainrings during use, replace the chainrings and the chain.

When the chain is in the position shown in the illustration, the chain may contact the

Fig.1

Fig.2

front chainrings or front derailleur and generate noise. If the noise is a problem, shift

the chain onto the next-larger rear sprocket or the one after if the chain is in the

Front

position shown in Figure 1. Shift the chain onto the next-smaller sprocket or the one

chainrings

after if it is in the position shown in Figure 2.

For frames with suspension, the chain stay angle will vary depending on whether the

Rear

bicycle is being ridden or not being ridden. When the bicycle is not being ridden and

the chain is positioned on the largest/larger chainring and on the smallest sprocket, the sprockets

chain guide outer plate of the front derailleur may touch the chain.

Outer casing holders

The cuffs of your clothing may get dirty from the chain while riding.

Apply grease to the left and right adapters before installing them.

For smooth operation, use the specified outer casing and the bottom bracket cable guide.

This front derailleur is for triple front chainwheel use only. It cannot be used with the double front chainwheel, as

the shifting points do not match.

When installing the top route type, choose a frame that has three outer casing holders as shown in the illustration

at right.

Use an outer casing which still has some length to spare even when the handlebars are turned all the way to both

sides. Furthermore, check that the shifting lever does not touch the bicycle frame when the handlebars are turned all the way.

A special grease is used for the gear shifting cable. Do not use DURA-ACE grease or other types of grease, otherwise they may cause

deterioration in gear shifting performance.

Grease the inner cable and the inside of the outer casing before use to ensure that they slide properly.

Operation of the levers related to gear shifting should be made only when the front chainwheel is turning.

If the brake fluid used in the oil disc brakes is of a type which tends to adhere to the plastic parts of the shifting lever, this may cause

the plastic parts to crack or become discolored. Therefore, you should make sure that the brake fluid does not adhere to these plastic

parts. The mineral oil which is used in SHIMANO disc brakes does not cause cracking or discoloration if it adheres to plastic parts, but

such parts should be cleaned with alcohol beforehand to prevent foreign particles from adhering.

Do not disassemble the shifting lever unit, as this may damage it or cause mis-operation.

Be sure to read the service instructions for the Rear Drive System in conjunction with these service instructions (SL-M980-I).

Parts are not guaranteed against natural wear or deterioration resulting from normal use.

For maximum performance we highly recommend Shimano lubricants and maintenance products

For any questions regarding methods of installation, adjustment, maintenance or operation, please contact a professional bicycle dealer.

SI-5M40A-003

FD-M980

FD-M980-E

FD-M981

Normal type

FD-M981-D

Top route type

Spacer

S, M, L

Front derailleur installation band diameter

F

A

S, M, L

Chainstay angle (a)

66 - 69

Applicable chain line

50 mm

Band Type

Model number

FC-M980

Chainwheel tooth combination

42-32-24T

Bolt circle diameter

When using the S, M size, use an

installation band with a diameter of 28.6

mm, 31.8mm and install it to a L size

adapter.

104 mm / 64 mm

Front derailleur

F

A

BB mount-type

bracket

Chain line

F

A

F

A

F

A

73 mm

Cutting the outer casing

When cutting the outer casing, cut the opposite end to the end with

the marking. After cutting the outer casing,

make the end round so that the inside of the

hole has a uniform diameter.

Attach the same outer end cap to the cut end of the outer casing.

F

A

73 mm

Chainstay angle

165 mm, 170 mm, 175 mm, 180 mm

Crank arm length

Outer end cap

50 mm

Bottom bracket shell width

68, 73 mm

BC1.37 (68, 73mm)

Thread dimensions

F

A

SM-BB90-A

Bottom bracket adapters

* If using a bottom bracket shell having a width of 68 mm which is a

band type, an 1.8 mm spacer and a 0.7 mm spacer can be used

together instead of a 2.5 mm spacer.

Gear shifting operation

Replacement of the shifting lever unit

Disassembly and reassembly should only be carried out when

replacing the shifting lever unit.

Bracket

The INSTANT RELEASE mechanism makes fast releasing possible because cable tension is released immediately when a lever is

depressed.

This release lever is equipped with a 2-way release mechanism which allows release operations to be carried out by either pushing or

pulling the lever.

Both lever (A) and lever (B) always return to the initial position when they are released after shifting.

When operating one of the levers, always be sure to turn the crank arm at the same time.

To shift from a small chainring to a larger chainring

(Lever A)

To shift from a large chainring to a smaller chainring

(Lever B)

When lever (A) is pressed once, there is a shift of one step from a

small chainring to a larger chainring.

When lever (B) is pressed once, there is a shift of one step from a

large chainring to a smaller chainring.

Example:

Example:

from intermediate chainring to largest chainring.

from largest chainring to intermediate chainring.

Unit fixing bolt

Chain length

Tightening torque:

2.5 Nm {22 in. lbs.}

Add 2 links (with the chain on both

the largest sprocket and the largest

chainring)

Largest sprocket

Largest chainring

Washer

Adjustment barrel

Chain

Installation of the shifting lever

Shifting lever mounting screws (Small)

Tightening torque:

0.08 Nm {0.7 in. lbs.}

4 mm Allen key

Use a handlebar grip with a maximum

outer diameter of 32 mm.

Tightening torque :

3 Nm {27 in. lbs.}

Shifting lever mounting screws (Large)

Tightening torque:

0.14 Nm {1.2 in. lbs.}

Lever (A) initial position

The shifting lever position can be

adjusted by sliding it to the left or right.

Lever (B)

2-WAY RELEASE

Tightening torque :

2.5 Nm {22 in. lbs.}

Installation of the Front Chainwheel

Follow the procedure in the figure.

1, 2 Use the TL-FC32/33/36 special tool to install the right adapter

(counterclockwise thread) of the bottom bracket, the inner cover

and the left adapter (clockwise thread) of the bottom bracket.

6

Tightening torque: 35 - 50 Nm {305 - 435 in. lbs.}

Note : Spacers may be necessary depending on the bottom

bracket shell width. For details, refer to "Spacer

installation method.

3

4

Insert the right crank arm unit.

Install the shifting lever in a position where it will not obstruct

brake operation and gear shifting operation.

Do not use in a combination which causes brake operation to be

obstructed.

Use the TL-FC16/18 to tighten the cap.

Tightening torque: 0.7 - 1.5 Nm {6 - 13 in. lbs.}

Push in the stopper plate and check that the plate pin is

securely in place, and then tighten the bolt of the left crank

arm. (5 mm Allen key)

Note : Each of the bolts should be evenly and equally

tightened to 12 - 14 Nm {106 - 122 in. lbs.}.

Set section A of the left crank arm into the axle of the right

crank arm unit where the groove is wide.

(A)

Wide groove area

Note:

When installing the components to carbon frame/handle bar

surfaces, verify with the manufacturer of the carbon frame/parts for

their recommendation on tightening torque in order to prevent over

tightening that can cause damage to the carbon material and/or

under tightening that can cause lack of fixing strength for the

components.

Connecting and securing the inner cable

Technical Service Instructions

1. Loosen the cable fixing bolt (nut) of the front derailleur, and then

pull the inner cable out of the shifting lever unit in the same way

as when installing the inner cable.

2. Remove the adjustment barrel.

3. First remove the unit fixing bolt.

4. Remove the four shifting lever mounting screws, and then remove

the shifting lever unit as shown in the illustration.

5. To assemble, align the shifting lever unit and the bracket and then

secure the shifting lever mounting screws.

6. Place the washer onto the bolt, and then secure the unit fixing

bolt.

7. Install the adjustment barrel.

Refer to the FD-M980 / M980-E / M981 / M981-D (Front

Derailleur) Service Instructions for details on installing the

front derailleur and SIS adjustment.

TL-FC32

Switch the mode converter to the 3x (triple mode) position, and then

check the lowest position. Operate lever B two times or more to set

the lever to the lowest position. Remove the inner hole cover, and

install the cable.

1

This service instruction explains how to use and maintain the

Shimano bicycle parts which have been used on your new bicycle.

For any questions regarding your bicycle or other matters which

are not related to Shimano parts, please contact the place of

purchase or the bicycle manufacturer.

Lever (B)

Inner cable

Inner hole cover

In order to realize the best performance, we recommend that the following combination be used.

Outer casing

68 mm

Installation band diameters:

S (28.6 mm), M (31.8 mm), L (34.9 mm)

Chainwheel

TL-FC16

Rapidfire (Shifting lever)

Bracket Type

68 mm

Front Drive System

Series

Inner hole cover

Install the inner hole cover by turning it as

shown in the illustration until it stops.

Do not turn it any further than this, otherwise

it may damage the thread on the cover.

(1) Check whether the width of the bottom

bracket shell is 68 mm or 73 mm.

(2) Next, install the adapter while referring to the

illustrations below.

Inner cover

Mode converter

XTR

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

SL-M980-L / SL-M980-IL

OT-SP41 (SIS-SP41)

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222

Plate pin

FD-M980 / FD-M980-E / FD-M981 / FD-M981-D

Front chainwheel

FC-M980

Chain

CN-M980

Bottom bracket cable guide

SM-SP17

Mode select switch

Stopper plate

Push up

Note :

Set the stopper plate in the right direction as shown

in illustration.

Note:

Do not force the mode select switch to turn. If you force it to turn, it

will break.

3-77 Oimatsu-cho, Sakai-ku, Sakai-shi, Osaka 590-8577, Japan

* Service Instructions in further languages are available at :

http://techdocs.shimano.com

Please note: specifications are subject to change for improvement without notice. (English)

Jun. 2011 by Shimano Inc. XBC SZK Printed in Japan.

SI-6T70A-001-00

General Safety Information

Specifications

Rear Derailleur

WARNING

Maintenance interval depends on the usage and riding circumstances. Clean regularly the chain

with an appropriate chaincleaner. Never use alkali based or acid based solvents such as rust

cleaners. If those solvent be used chain might break and cause serious injury.

Model number

In order to obtain good gear shifting performance, this chain has a forward side and a reverse side, and the

sides are marked so that the chain will face the correct way when installed. The proper design performance

will be obtained when the chain is installed so that it faces the correct way. If it is installed so that it faces

the opposite way, the chain may come off and the bicycle may fall over and serious injury may occur as a

result.

Check that the wheels are fastened securely before riding the bicycle. If the wheels are loose in any way, they may come off the

bicycle and serious injury may result.

Use the reinforced connecting pin only for connecting

Reinforced

the narrow type of chain.

Chain

Chain tool

connecting pin

If connecting pins other than reinforced connecting pins

are used, or if a reinforced connecting pin or tool which

with groove (3)

TL-CN32

10-speed

is not suitable for the type of chain is used, sufficient

super narrow chain

TL-CN23

connection force may not be obtained, which could

for MTB

TL-CN27

with groove (2)

cause the chain to break or fall off.

If it is necessary to adjust the length of the chain due to

a change in the number of sprocket teeth, make the cut at some other place than the place

Reinforced Connecting Pin

where the chain has been joined using a reinforced connecting pin. The chain will be damaged

if it is cut at a place where it has been joined with a reinforced connecting pin.

Check that the tension of the chain is correct and that the chain is not damaged. If the tension

is too weak or the chain is damaged, the chain should be replaced. If this is not done, the chain

Link Pin

Link Pin

may break and cause serious injury.

Obtain and read the service instructions carefully prior to installing the parts. Loose, worn or damaged parts may cause the

bicycle to fall over and serious injury may occur as a result. We strongly recommend only using genuine Shimano replacement

parts.

Obtain and read the service instructions carefully prior to installing the parts. If adjustments are not carried out correctly, the

chain may come off and this may cause you to fall off the bicycle which could result in serious injury.

Read these Technical Service Instructions carefully, and keep them in a safe place for later reference.

Total capacity

41 T

35 T

Largest sprocket

36 T

36 T

Smallest sprocket

11 T

11 T

Front chainwheel tooth difference

18 T

18 T

Note

If gear shifting operations do not feel smooth, wash the derailleur and lubricate all moving parts.

If the amount of looseness in the links is so great that adjustment is not possible, you should replace the derailleur.

You should periodically clean the derailleur and lubricate all moving parts (mechanism and pulleys).

If gear shifting adjustment cannot be carried out, check the degree of parallelism at the rear end of the bicycle. Also check if the

cable is lubricated and if the outer casing is too long or too short.

If you hear abnormal noise as a result of looseness in a pulley, you should replace the pulley.

If the wheel becomes stiff and difficult to turn, you should lubricate it with grease.

Do not apply any oil to the inside of the hub, otherwise the grease will come out.

You should periodically wash the sprockets in a neutral detergent and then lubricate them again. In addition, cleaning the chain

with neutral detergent and lubricating it can be a effective way of extending the useful life of the sprockets and the chain.

If the chain keeps coming off the sprockets during use, replace the sprockets and the chain.

Use a frame with internal cable routing is strongly discouraged as it has tendencies to impair the SIS shifting function due to its

high cable resistance.

Always be sure to use the sprocket set bearing the same group marks. Never use in combination with a

Group marks

sprocket bearing a different group mark.

Use an outer casing which still has some length to spare even when the handlebars are turned all the way

to both sides. Furthermore, check that the shifting lever does not touch the bicycle frame when the

handlebars are turned all the way.

A special grease is used for the gear shifting cable. Do not use DURA-ACE grease or other types of

grease, otherwise they may cause deterioration in gear shifting performance.

Grease the inner cable and the inside of the outer casing before use to ensure that they slide properly.

For smooth operation, use the specified outer casing and the bottom bracket cable guide.

Operation of the levers related to gear shifting should be made only when the front chainwheel is turning.

If the brake fluid used in the oil disc brakes is of a type which tends to adhere to the plastic parts of the shifting lever, this may

cause the plastic parts to crack or become discolored. Therefore, you should make sure that the brake fluid does not adhere to

these plastic parts.

The mineral oil which is used in SHIMANO disc brakes does not cause cracking or discoloration if it adheres to plastic parts, but

such parts should be cleaned with alcohol beforehand to prevent foreign particles from adhering.

Do not disassemble the shifting lever unit, as this may damage it or cause mis-operation.

Parts are not guaranteed against natural wear or deterioration resulting from normal use.

Read these Service Instructions in conjunction with the Service Instructions for the FH-M985 / M988.

For maximum performance we highly recommend Shimano lubricants and maintenance products

For any questions regarding methods of installation, adjustment, maintenance or operation, please contact a professional

bicycle dealer.

ag - 18T

ag -15

ag

-1

3T

RD-M980

Type

SGS

Tightening torque :

2.5 Nm {22 in. lbs.}

GS

Gears

10

Cassette sprocket tooth combination

Model number

Gears

Tooth combination

bJ

10

11, 13, 15, 17, 19, 21, 23, 26, 30, 34 T

bk

10

11, 13, 15, 17, 19, 21, 24, 28, 32, 36 T

bL

10

11, 12, 14, 16, 18, 20, 22, 25, 28, 32 T

CS-M771-10

Note:

Freehub

Group name

CS-M980

(3)

Install the shifting lever in a position where it will not obstruct brake

operation and gear shifting operation.

Do not use in a combination which causes brake operation to be

obstructed.

Model number

FH-M985 / FH-M988

Gears

10

No. of spoke holes

32

The INSTANT RELEASE mechanism makes fast releasing possible because cable tension is released immediately when a lever is

depressed. The levers are also equipped with 2-WAY RELEASE and MULTI RELEASE mechanisms so that you can now shift two gears

with a single operation, either by pushing or pulling the lever.

Both lever (A) and lever (B) always return to the initial position when they are released after shifting. When operating one of the levers,

always be sure to turn the crank arm at the same time.

To shift from a small sprocket to a larger sprocket

(Lever A)

To shift from a large sprocket to a smaller sprocket

(Lever B)

You can vary the lever stroke to shift the desired number of gears,

so that to shift by one gear only, move the lever to the (1) position,

and to shift by two gears at one time, move the lever to the (2)

position. A maximum two-gear shift can be made in this manner.

You can vary the lever stroke to shift the desired number of gears,

so that to shift by one gear only, move the lever to the (1) position,

and to shift by two gears at one time, move the lever to the (2)

position. A maximum two-gear shift can be made in this manner.

SH

IM

O

AN

HYPERGL I DE - C

Series

RAPIDFIRE (Shifting lever)

Outer casing

Lever (A) initial position

RD-M980

Type

SGS / GS

Freehub

Gears

Cassette sprocket

Chain

Bottom bracket guide

This service instruction explains how to use

and maintain the Shimano bicycle parts

which have been used on your new bicycle.

For any questions regarding your bicycle or

other matters which are not related to

Shimano parts, please contact the place of

purchase or the bicycle manufacturer.

FH-M985 / FH-M988

10

CS-M980 / CS-M771-10

CN-M980

SM-SP17 / SM-BT17

For each sprocket, the surface that has the group mark should face

outward and be positioned so that the wider part of each sprocket

and the A part (where the groove width is wide) of the freewheel

body are aligned.

Freewheel body

fixing bolt

Inner hole cover

Tightening torque:

45 - 50 Nm {392 - 434 in. lbs.}

When cutting the outer casing, cut the

opposite end to the end with the marking.

After cutting the outer casing, make the

end round so that the inside of the hole has a uniform diameter.

Wide part

ac -14T

Attach the same outer

end cap to the cut end

of the outer casing.

place only.

Lock ring

Outer end cap

The sealed cap with

tongue and the rubber

shield should be

installed to the outer

casing stopper of the

frame.

<CS-M980>

(bJ) 11 - 34T

(bk) 11 - 36T

14 mm Allen key

Be careful not to bend

Note:

When replacing the freewheel body, replace the freewheel body

fixing bolt at the same time. Be sure to apply grease to the the

thread of the freewheel body fixing bolt, otherwise looseness or

sticking may occur.

Do not attempt to disassemble the freewheel body, because it

may result in a malfunction.

Installation of the SL-M980-I and

the BL-M985/M988

Shifting lever

Rubber shield

SL-M980-I

Brake levers

Sealed cap with tongue

BL-M985 / M988

OK

Other Brake lever models

Not compatible

Rubber shield

Lock ring spacer

Sprocket spacer

1. Use a 2 mm Allen key to open the

Lock ring

* If the rear derailleur moves to a large degree, such as in

bicycles with rear suspension, it is

recommended that you replace

Derailleur side

the cap with an aluminum cap.

The end of the outer casing which

has the aluminum cap should be

Aluminum cap

at the derailleur side.

Lock ring spacer

Disassembly

Tool

TL-LR15/LR10 (TL-SR21)

Replacement of the freewheel body

(FH-M985)

Chain

The hub cone is made from a

light alloy. Use a suitable tool

which has no wear or other

damage when adjusting the

hub rotation.

Disassembly

Largest

chainring

Add 2 links (with the chain on both

the largest sprocket and the largest

chainring)

3-77 Oimatsu-cho, Sakai-ku, Sakai-shi, Osaka 590-8577, Japan

Left side Tightening torque:

15 - 20 Nm {132 - 172 in. lbs.}

5 mm Allen key

Installation of the shifting lever

(SL-M980-R)

Hook

Note:

Chain length on bicycles with rear suspension

Largest

sprocket

First, pull out the hub axle by following the procedure shown in the

illustration.

The double-lock section at the freewheel side cannot be

disassembled.

(1)

The length of A will vary depending on the movement of the rear

suspension. Because of this, an excessive load may be placed on

the drive system if the chain length is too short. Set the length of

the chain by adding two links to the chain when the rear

suspension is at a position where dimension "A" is longest and the

chain is on the largest sprocket and the largest chainring. If the

amount of movement of the rear suspension is large, the slack in

the chain may not be taken up properly when the chain is on the

smallest chainring and smallest sprocket.

Clamp band

clamp band of the brake lever as

shown in the illustration.

2. Insert the hook of the shifting lever

bracket into the hole in the brake

lever bracket, and then

provisionally tighten the special nut

and special bolt to install it to the

handlebar.

Push

Lock ring

To replace the HG sprockets, use the special tool (TL-LR15/LR10) and TL-SR21 to

remove the lock ring.

A'

Please note: specifications are subject to change for improvement without notice. (English)

Apr. 2010 by Shimano Inc. XBC SZK Printed in Japan.

Do not disassemble

the seal.

Lever (B)

groove is

A The

wide at one

Sprocket spacer

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222

Freewheel body washer

Inner cable

Installation of the sprockets

Use a handlebar grip with a maximum

outer diameter of 32 mm.

* Service Instructions in further languages are available at :

http://techdocs.shimano.com

DURA-ACE grease

(Y-04110000)

Operate the lever (B) 9 times or more

to set the lever to the highest position.

Then remove the inner hole cover and

connect the inner cable.

Cutting the outer casing

XTR

Rear derailleur

Applying grease

Connection and securing of the inner

cable

Inner hole cover

Tightening torque:

30 - 50 Nm {261 - 434 in. lbs.}

OT-SP41 (SIS-SP41)

Freewheel body

Lever (B)

For installation of the HG sprockets, use the special tool (TL-LR15/LR10) to tighten

the lock ring.

SL-M980-R / SL-M980-IR

(4) After removing the hub axle, remove the freewheel body fixing

bolt (inside the freewheel body), and then replace the freewheel

body.

2-WAY RELEASE MULTI RELEASE

SI-6T70A-001

In order to realize the best performance, we recommend that the following combination be used.

Hub axle

Install the inner hole cover by turning it as

shown in the illustration until it stops.

Do not turn it any further than this,

otherwise it may damage the screw

thread.

(bL) 11 - 32T

Rear Drive System

When installing the components to carbon frame/handle bar

surfaces, verify with the manufacturer of the carbon frame/parts for

their recommendation on tightening torque in order to prevent over

tightening that can cause damage to the carbon material and/or

under tightening that can cause lack of fixing strength for the

components.

Refer to the RD-M980 (Rear Derailleur) Service Instructions for

details on installing the rear derailleur and SIS adjustment.

Gear shifting operation

<CS-M771-10>

Technical Service Instructions

Note:

When removing and installing the seal, do it very carefully so that

the seal does not become bent.

When reinstalling the seal, make sure that it is facing the right way,

and insert it as far as it will go.

Do not disassemble the dust cover which is crimped onto the cone.

Shifting lever position is adjustable by

sliding to left or right.

Do not install the nut upsidedown.

If it is installed upside-down, it will

not be possible to secure the

brake lever to the handlebars, and

damage may occur.

1

2

Bolt (M5 x 12.5 mm)

3. Use a 4 mm Allen key to

17 mm spanner

Rotor fixing serrations (FH-M985)

(2)

Nut

Note:

secure the shifting lever to the

brake lever.

4 mm Allen key

Tightening torque:

3 Nm {27 in. lbs.}

Tightening torque:

3 Nm {27 in. lbs.}

Seal

Cone with dust cover

(Cannot be disassembled)

Lip is on the outside

Read these Service Instructions together with the

Service Instructions for the BR-M985 (SI-8J70A).

Refer to the Service Instructions for the Front Drive

System for details on replacing and installing the shifting

lever unit.

You might also like

- JCB 4cx TRANSMISSIONDocument1 pageJCB 4cx TRANSMISSIONJakes Schmidt81% (16)

- Mercedes Benz 722 Series Automatic Transmission Service ManualDocument59 pagesMercedes Benz 722 Series Automatic Transmission Service ManualNick Speis100% (7)

- Mercedes Benz 722 Series Automatic Transmission Service ManualDocument59 pagesMercedes Benz 722 Series Automatic Transmission Service ManualNick Speis100% (7)

- Bruff Hop Picking MachinesDocument61 pagesBruff Hop Picking MachinesSuckley Post Office100% (2)

- 2013 Fork Rockshox Service ManualDocument83 pages2013 Fork Rockshox Service ManualXc Cristi0% (1)

- 33 Ford 3D 4F27E FN4A-EL FNR5 PDFDocument14 pages33 Ford 3D 4F27E FN4A-EL FNR5 PDFCarlos Martinez100% (3)

- Shimano RevoShift - Service InstructionDocument7 pagesShimano RevoShift - Service InstructionAdrian Mihai BorzaNo ratings yet

- Emeraude ManualDocument23 pagesEmeraude ManuallarsandNo ratings yet

- Manitou 2003 Axel Service ManualDocument6 pagesManitou 2003 Axel Service Manualsloth185No ratings yet

- Simrad CX34/44/54: Installation ManualDocument62 pagesSimrad CX34/44/54: Installation ManualVasile NicolaeNo ratings yet

- MTB Technology: FRONT CHAINWHEEL: InstallationDocument4 pagesMTB Technology: FRONT CHAINWHEEL: InstallationRoy Chung Qi Huan100% (1)

- Sturmey Archer S RF3 Hub InstructionsDocument4 pagesSturmey Archer S RF3 Hub Instructionsdupazbita11No ratings yet

- Awc Src3 Manual. 1Document5 pagesAwc Src3 Manual. 1ghionoiucNo ratings yet

- Shimano XTDocument1 pageShimano XTVennia PapadipoulouNo ratings yet

- Cassette Sprocket: Dealer's ManualDocument15 pagesCassette Sprocket: Dealer's ManualrajaNo ratings yet

- Shimano Ultegra Di2 6770 ManualDocument48 pagesShimano Ultegra Di2 6770 ManualAlex YamakiNo ratings yet

- Sturmey Archer S RF5 Hub InstructionsDocument2 pagesSturmey Archer S RF5 Hub InstructionsAndré VuzNo ratings yet

- Magic ManutenzioneDocument200 pagesMagic ManutenzioneJackson Wall100% (1)

- Installation - Operation & Maintenance InstructionsDocument49 pagesInstallation - Operation & Maintenance InstructionsMichael BremnerNo ratings yet

- Materi Penyuluhan Bahaya MerokokDocument24 pagesMateri Penyuluhan Bahaya MerokokWendy Kusuma100% (1)

- Pole Barn Metal DetailsDocument52 pagesPole Barn Metal DetailsKurt Stailey100% (1)

- Sturmey-Archer AWC-SRC3-MANUAL PDFDocument5 pagesSturmey-Archer AWC-SRC3-MANUAL PDFtudorbusuiocNo ratings yet

- Annex6 RMHeaterDocument5 pagesAnnex6 RMHeaterDobri StefNo ratings yet

- NEXUS SG 8C20 WerkstatthandbuchDocument36 pagesNEXUS SG 8C20 Werkstatthandbuchjacek_janikowsk43740% (1)

- 2014-2015 Compatibility v010 enDocument28 pages2014-2015 Compatibility v010 enFreddy KruguerNo ratings yet

- Figure 1: A Ventilated Improved Pit - LatrineDocument7 pagesFigure 1: A Ventilated Improved Pit - LatrineKiran Basu100% (1)

- Sturmey-Archer SRF3 User ManualDocument4 pagesSturmey-Archer SRF3 User Manualksjack100% (1)

- MTB 3Document8 pagesMTB 3bveNo ratings yet

- Drivetrain Compatability Chart PDFDocument3 pagesDrivetrain Compatability Chart PDFSyafiq IshakNo ratings yet

- Sturmey Archer 8speedDocument2 pagesSturmey Archer 8speedLuvikas Maybe KscNo ratings yet

- #5 Chimneys: The Engine of The SystemDocument4 pages#5 Chimneys: The Engine of The Systemईशान्त शर्मा100% (1)

- AM 6A AM 10A Transmitter ManualDocument345 pagesAM 6A AM 10A Transmitter ManualNelson Suarez GNo ratings yet

- Fresh Vegetable Storage For HomeownersDocument2 pagesFresh Vegetable Storage For HomeownersSharad Bhutoria100% (1)

- Sears To Tecumseh NumbersDocument55 pagesSears To Tecumseh NumbersJedediah HugilgameshNo ratings yet

- Sprockets FormulaeDocument5 pagesSprockets Formulae9311000093No ratings yet

- Eliminator Torsion Axles: Shock Cord Cross SectionDocument23 pagesEliminator Torsion Axles: Shock Cord Cross SectionRaju ManjuNo ratings yet

- Vacon AC Drive US Version Product Catalog BC00324CDocument204 pagesVacon AC Drive US Version Product Catalog BC00324CCatalin PelinNo ratings yet

- AIAA 2005-2349 Blended-Wing-Body (BWB) Fuselage Structural Design For Weight ReductionDocument9 pagesAIAA 2005-2349 Blended-Wing-Body (BWB) Fuselage Structural Design For Weight ReductionM. Sadiq. A. PachapuriNo ratings yet

- DX Demo Chapter 17Document132 pagesDX Demo Chapter 17Eliézer LimaNo ratings yet

- Shimano Dealer's Manual DM PD0002 07 ENGDocument38 pagesShimano Dealer's Manual DM PD0002 07 ENGanon_153179284No ratings yet

- 035 - 37 - Technical Manual - Road Brakes - CampagnoloDocument10 pages035 - 37 - Technical Manual - Road Brakes - Campagnolodcy536No ratings yet

- How To Keep Your Produce Fresh For Weeks - WirecuDocument14 pagesHow To Keep Your Produce Fresh For Weeks - Wirecujunaa Albayati100% (1)

- 01 6Document160 pages01 6Steve BarrowNo ratings yet

- Options For Storing Potatoes at HomeDocument4 pagesOptions For Storing Potatoes at HomeElviraSyamsir-Siswanto100% (1)

- Type of Rotor SystemDocument6 pagesType of Rotor SystemAhmadFaisalNo ratings yet

- Physical Hovercraft DesignDocument28 pagesPhysical Hovercraft DesignPaulPrateekNo ratings yet

- Bicycle Traveler October 2016Document60 pagesBicycle Traveler October 2016Matija PodnarNo ratings yet

- Mazda Wankel 13B Engine Aircraft UseDocument5 pagesMazda Wankel 13B Engine Aircraft UseparyshaanNo ratings yet

- Shimano Line-Up Chart All v017 Public enDocument47 pagesShimano Line-Up Chart All v017 Public enramprasad.raghavanNo ratings yet

- Kohler K Series Single Cylinder Engine Specifications and Tolerances PDFDocument4 pagesKohler K Series Single Cylinder Engine Specifications and Tolerances PDFBillW56100% (1)

- US6182619Document11 pagesUS6182619engine wang100% (1)

- Manual Tractor 1Document267 pagesManual Tractor 1Marcio PisiNo ratings yet

- Fishingboatsofth034718mbp 2Document841 pagesFishingboatsofth034718mbp 2Wahyu Wiyati100% (1)

- 1Document34 pages1Vulebg Vukoic100% (2)

- 2007 Kobelco Stern Tube Seal Installation ManualDocument18 pages2007 Kobelco Stern Tube Seal Installation Manualvjmariner100% (1)

- Manual Fox TalasDocument23 pagesManual Fox TalasseantierryNo ratings yet

- Rural Mechanics Course 2 PDFDocument139 pagesRural Mechanics Course 2 PDFplutocowNo ratings yet

- Park Compact 16 13-6103-19Document2 pagesPark Compact 16 13-6103-19Oana OanaNo ratings yet

- For Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire LeverDocument3 pagesFor Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire Leverlirch5No ratings yet

- Alivio Front Drive SI-6KFFA - v1 - m56577569830565035Document1 pageAlivio Front Drive SI-6KFFA - v1 - m56577569830565035setze16setze16No ratings yet

- rd-m592 2Document1 pagerd-m592 2faizgpNo ratings yet

- Shimano AlivioDocument1 pageShimano AlivioBrent MitchellNo ratings yet

- Si F570CDocument1 pageSi F570CmegclayNo ratings yet

- Shimano Ultegra 6700 Shifters Double Owners ManualDocument2 pagesShimano Ultegra 6700 Shifters Double Owners ManualTimNo ratings yet

- DL ST m975 1 PDFDocument1 pageDL ST m975 1 PDFNick SpeisNo ratings yet

- EWS2Document1 pageEWS2Nick SpeisNo ratings yet

- MSS65 - BDMDocument1 pageMSS65 - BDMNick Speis100% (2)

- Design of ShaftDocument16 pagesDesign of ShaftVPSureshKumar100% (1)

- Example of Gearbox Calculation.: Input ConditionsDocument5 pagesExample of Gearbox Calculation.: Input Conditionsoman1148100% (1)

- Limited Slip Differentials: Type-Rs Type-MzDocument4 pagesLimited Slip Differentials: Type-Rs Type-MzBart Verger RodriguezNo ratings yet

- Removal & Installation: Crankshaft Damper PulleyDocument4 pagesRemoval & Installation: Crankshaft Damper PulleyRamon Alejandro Porras HernandezNo ratings yet

- Renk PSC Propeller Shaft ClutchDocument8 pagesRenk PSC Propeller Shaft Clutchhumayun121No ratings yet

- Automatic TrasnmissionDocument57 pagesAutomatic Trasnmissionmohamed A.abdeltwabNo ratings yet

- Bevel GearDocument9 pagesBevel GearAadil KhanNo ratings yet

- Drive Axle and Defferentials Institutional AssessmentDocument5 pagesDrive Axle and Defferentials Institutional AssessmentMarion ObongNo ratings yet

- Technical Service Information: FORD 5R110W TorqshiftDocument4 pagesTechnical Service Information: FORD 5R110W TorqshiftAranza SuNo ratings yet

- Chapter 4 Gear DrivesDocument65 pagesChapter 4 Gear DrivesabebawalemkerNo ratings yet

- Transfer Case Tech Tips On The Jeep CJ3B PageDocument5 pagesTransfer Case Tech Tips On The Jeep CJ3B PageGerardo Hugo Fernández Silva100% (1)

- Transmission JW5F18C - H320H330RM2B31Document52 pagesTransmission JW5F18C - H320H330RM2B31Amin MombiniNo ratings yet

- Hydramatic TransmissionDocument8 pagesHydramatic TransmissionJZM GulfNo ratings yet

- Gears, Gears and More Gears: Teacher Professional Development Spring, 2002Document14 pagesGears, Gears and More Gears: Teacher Professional Development Spring, 2002Hoda HosnyNo ratings yet

- Hystea: TransmissionDocument33 pagesHystea: TransmissionMelwyn FernandesNo ratings yet

- 3.160dozer Driven Componet PDFDocument53 pages3.160dozer Driven Componet PDFDedi rahmat100% (1)

- Motor Specifications (Listed @12V)Document14 pagesMotor Specifications (Listed @12V)nhstechnologyNo ratings yet

- Worm MeshDocument5 pagesWorm MeshBabalola SundayNo ratings yet

- Carte Automatic TransmissionsDocument20 pagesCarte Automatic TransmissionsGigelNo ratings yet

- 4.final Drive Supply Only 2030 PDFDocument2 pages4.final Drive Supply Only 2030 PDFFauzi AchmadNo ratings yet

- Transfer CaseDocument37 pagesTransfer CaseCarlos VelázquezNo ratings yet

- The Strategy of The 722.9Document8 pagesThe Strategy of The 722.9tejonmxNo ratings yet

- Dp21l, 21s & 23s Parts Ver2 (E)Document91 pagesDp21l, 21s & 23s Parts Ver2 (E)nickypanzeNo ratings yet

- Shimano GRX Doc Consumer EdDocument22 pagesShimano GRX Doc Consumer EdfataldjNo ratings yet

- Twin Clutch / Direct Shift Gearbox (DSG)Document4 pagesTwin Clutch / Direct Shift Gearbox (DSG)vsmurthytNo ratings yet

- Codigos de Falla Transmision Spirit PDFDocument3 pagesCodigos de Falla Transmision Spirit PDFCarlos Arturo de DiosNo ratings yet

- Worm Gear Design ProcedureDocument7 pagesWorm Gear Design ProcedureSzymon RosikNo ratings yet