Professional Documents

Culture Documents

Class PPT Upto 20 Aug PDF

Uploaded by

RahulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Class PPT Upto 20 Aug PDF

Uploaded by

RahulCopyright:

Available Formats

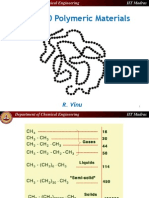

Department of Chemical Engineering

IIT Madras

CH 3160 Polymeric Materials

R. Vinu

Department of Chemical Engineering

IIT Madras

Department of Chemical Engineering

IIT Madras

Classification of polymers based on application

1. Elastomers

2. Plastics

Commodity plastics

Engineering plastics

3. Fibers

4. Coatings and Adhesives

Department of Chemical Engineering

IIT Madras

Application

Department of Chemical Engineering

IIT Madras

Homo- vs copolymers

Copolymers are not alloys of

homopolymers!

Synthesized by step or chain

growth polymerization

E.g. Poly(acrylamide-ranacrylic acid)

Poly(styrene-alt-maleic

anhydride)

Polystyrene-block-polymethyl

methacrylate

Polystyrene-graft-polymethyl

methacrylate

5

Department of Chemical Engineering

IIT Madras

Polymer Blends

Department of Chemical Engineering

IIT Madras

Topology linear vs branched

E.g. HDPE

(High density)

LLDPE

(Linear low density)

LDPE

(Low density)

7

Department of Chemical Engineering

IIT Madras

Special Polymer Topologies / Architectures

Semi-ladder Polymer

Star polymer

Comb Polymer

Ladder Polymer

Polyrotaxene

Dendrimer

Polycatenane

8

Department of Chemical Engineering

IIT Madras

Dendrimers

Hyperbranched polymers

with controlled structure

1st - generation polyphenylene dendrimer

Globular in shape

Special applications drug

delivery, separations,

nanoparticles, sensors, etc.

Degree of branching

DB =

D+T

(D + T + L)

Department of Chemical Engineering

IIT Madras

Interrelation of states of bulk polymers

MELT

RUBBER or

FLEXIBLE

PLASTIC

Temperature

High

THERMOSET

ENGINEERING

PLASTIC

GLASS

CRYSTALLINE

PLASTIC

FIBER

Low

Low

Intermolecular forces

High

10

Department of Chemical Engineering

IIT Madras

Forces of interaction in polymers

Dispersion / van der Waals forces

Nonpolar

6

Short range, varies as (-1/r )

Energy ~ 0.2 0.5 kcal/mol

Polyethylene, polystyrene, other hydrocarbon polymers

Dipole/dipole interactions

Short range, varies as (-1/r6)

Energy ~ 0.5 2 kcal/mol

Polyacrylonitrile, PVC

Strongly polar interactions / hydrogen bonds

Short range

Energy ~ 1 10 kcal/mol

Polyamide (nylon), polyurethanes

Coulombic interactions (Ionomers)

Long range, varies as 1/r

Energy ~ 10 20 kcal/mol

Surlyn

Highly polar

11

Department of Chemical Engineering

IIT Madras

Hydrogen bonding in Nylon

Paulings description:

under certain circumstances , an

atom of hydrogen is attracted by

rather strong forces to two atoms

instead of only one, so that it may

be considered to be acting as a

bond between them. This is called

a hydrogen bond.

The chains stack so as to allow all

the amide groups to hydrogen bond

12

Department of Chemical Engineering

IIT Madras

Polymer Molecular Weight

13

Department of Chemical Engineering

IIT Madras

What is the mean (or) average mass?

5 milligrams

5 tons

14

Department of Chemical Engineering

IIT Madras

Average Molecular Weights

Number average molecular weight, Mn

Weight average molecular weight, Mw

15

Department of Chemical Engineering

IIT Madras

Average Molecular Weights

Generalized expression

k = 0, Mn

k = 1, Mw

k = 2, Mz

k = 3, Mz+1

Viscosity average molecular weight, Mv

16

Department of Chemical Engineering

IIT Madras

Typical Molecular Weight Distribution (MWD)

17

Department of Chemical Engineering

IIT Madras

Mechanical properties depend on molecular weight

18

Department of Chemical Engineering

IIT Madras

Simple Problem

Consider a mixture containing 95 wt.% of PS of

molecular weight 10,000, and 5 wt.% of plasticizer of

molecular weight 100. Determine Mn and Mw.

Mn = (0.95/10000 + 0.05/100)-1 = 1680.67 g/mol

Mw = (0.95*10000 + 0.05*100) = 9505 g/mol

PDI = 9505/1680.67 = 5.655

19

Department of Chemical Engineering

IIT Madras

Mn measured using methods involving colligative

property measurement

Vapor pressure lowering

Elevation in boiling pt.

Depression of freezing point

Osmotic pressure

Mw measured using light scattering

Mv determined using solution viscosity

20

Department of Chemical Engineering

IIT Madras

Modeling MWDs

Log-normal distribution

Gamma distribution

21

Department of Chemical Engineering

Poisson distribution

IIT Madras

Lorentzian distribution

22

Department of Chemical Engineering

IIT Madras

Classification of Polymerization

1.

2.

3.

4.

Step growth polymerization

Chain growth polymerization

Coordination polymerization

Ring opening polymerization

23

Department of Chemical Engineering

IIT Madras

Step growth - Condensation polymerization

Polyester

Polycarbonate

24

Department of Chemical Engineering

IIT Madras

Step growth - Condensation polymerization

Polyamide Nylon 6,6

25

Department of Chemical Engineering

IIT Madras

Step growth non-condensation polymerization

(or) Polyaddition

Polyurethane

Diol

Diisocyanate

Other examples: Epoxy resins, chlorinated polyether, crosslinked

polyurethane

26

Department of Chemical Engineering

IIT Madras

Few other examples

Condensation Polymers

Polyamide

Polycarbonate

Polyester

Polyimide

Polysulfone

Dicarboxylic acid

Bisphenol-A

Dicarboxylic acid

Tetracarboxylic acid

Bisphenol-A

+

+

+

+

+

Diamine

Phosgene

Diol or polyol

Diamine

Dichlorophenyl

sulfone

Noncondensation or Addition polymers

Polyurethane

Diisocyanate

Poly(phenylene oxide) 2,6-disubstituted phenol

+ Diol or polyol

+ Oxygen

27

Department of Chemical Engineering

IIT Madras

Chain growth polymerization

1. Free radical

2. Ionic (cationic, anionic)

e.g. PE, PP, PS, PMMA, PA,

Key steps

Initiation

Propagation

Termination

Chain transfer

28

Department of Chemical Engineering

IIT Madras

Coordination polymerization

Ziegler-Natta catalysts

(organometallic compound + transition metal salt)

e.g. Al (C2H5)3 + TiCl4 , Li(C4H9) + TiCl4

Homogeneous or heterogeneous catalyst

Used for producing isotactic/stereoregular polymers

Follows insertion mechanism

29

Department of Chemical Engineering

IIT Madras

Polymer tacticity

Isotactic

Syndiotactic

Atactic

30

Department of Chemical Engineering

IIT Madras

Example

Ziegler-Natta

catalysts

HDPE

(Essentially

linear)

Ethylene

High pressure

free radical

polymerization

LDPE

(significantly

branched)

31

Department of Chemical Engineering

IIT Madras

Ring Opening Polymerization

533 K, N2

n

-Caprolactam

Ethylene oxide

Nylon-6

Polyethylene oxide

32

Department of Chemical Engineering

Condensation polymerization

Thermosets / duroplastics

Phenol resin

Urea, thiourea resin

Melamine resin

Alkyd resin

Allyl resin

Silicon resin

Polyimide

Unsaturated polyester resin

Polybenzimidazole

Thermoplastics

Polyamides

Polycarbonates

Polyester

Polyphenylene oxide

Polysulfone

Polyvinyl acetate

IIT Madras

Chain growth polymerization

Thermoplastics

Polyethylene (PE)

Polypropylene (PP)

Polybutylene

Poly-4-methyl-1-pentene

Polyvinyl chloride (PVC)

Polyvinylidene chloride

Polymethyl methacrylate (PMMA)

Polyacrylonitrile (PAN)

Polystyrene (PS)

Polyacetal

Polyvinyl acetate

Fluorine based plastics

Poly-p-xylene

33

Department of Chemical Engineering

IIT Madras

Polymerization techniques

Bulk polymerization (monomer + initiator + )

Solution polymerization

(monomer + solvent + initiator + )

Monomer and polymer soluble in solvent

Precipitation polymerization

(monomer + solvent + initiator + )

Monomer soluble in solvent, but polymer is not

Suspension polymerization

Emulsion polymerization

34

Department of Chemical Engineering

IIT Madras

Variation of conversion in free radical polymerization

Monomer conc. in solvent

Diffusion free regime

Autoacceleration

Reaction diffusion

Autodeceleration

Benzoyl peroxide-initiated polymerization of methyl methacrylate

in benzene at 50 oC

35

Department of Chemical Engineering

IIT Madras

Suspension polymerization

Suitable for

water insoluble

polymers

Polymerization medium water

Droplets of monomer + initiator + chain transfer agent

Controlling parameters:

monomer:water ratio

stirring speed

surfactant / colloid concentration

E.g. PVC, butyl rubber, PVDF, 100-5000 m polymer beads

36

Department of Chemical Engineering

Emulsion polymerization

IIT Madras

Water is the medium

Initiator is water soluble

Monomer and polymer water

insoluble

Surfactant / emulsifiers

Excellent heat transfer

Very high monomer conversions

Very low PDI, particle size (0.1 m)

E.g. chloroprene, vinyl acetate,

vinyl chloride

Recipe for emulsion co-polymerization

of styrene-butadiene (World war II)

Butadiene

Styrene

Water

Soap

Lorol mercaptan

K2S2O8

75 (parts by wt.)

25

180

5

0.5

0.3

37

Department of Chemical Engineering

IIT Madras

Typical PDI of Polymers

Free radical polymerization

1.5 2

(solution, suspension, emulsion)

Free radical polymerization (bulk)

2-5

Free radical polymerization (without

8 10

temperature control)

Cationic/anionic (homogeneous)

< 1.5

Cationic/anionic (heterogeneous)

> 10

Step growth polymerization

23

Coordination polymerization

> 10

Polymerization with branches

> 20

38

Department of Chemical Engineering

IIT Madras

39

Department of Chemical Engineering

IIT Madras

Ceiling Temperature

Odian, Chap. 3-9c

40

Department of Chemical Engineering

IIT Madras

Ceiling Temperature

At equilibrium,

G G0 RT ln Keq

G0 H 0 Tc S 0 RT ln Keq

Keq

[ M n 1 ]

1

[ M n ][ M ] c [ M ]c

H 0

Tc

S 0 R ln[ M ]c

41

Department of Chemical Engineering

IIT Madras

Ionic polymerization

Cationic polymers polyisobutylene, polybutylene,

isobutylene-isoprene copolymer, poly(vinyl ether)s

Electrophilic addition to monomers

Carbocation initiators mineral acids (H2SO4, H3PO4), Aprotonic

acids (Lewis acids, Friedel-Crafts halides) like AlCl3, BF3, TiCl4,

SnCl4, Protonic (Brnsted) acids

Anionic polymers 1,4-polybutadiene, 1,4-polyisoprene,

styrene-butadiene rubber

Carbanion initiators organometallic compounds of alkali

metals (butyl lithium), Grignard reagents

Nucleophilic addition to monomers

42

Department of Chemical Engineering

IIT Madras

Free radical vs Ionic/Co-ordination polymerization

43

Department of Chemical Engineering

IIT Madras

Cationic polymerization

Protonation by mineral acids

HSO4-

Termination by the counterion

HSO4-

44

Department of Chemical Engineering

IIT Madras

Initiation

Catalyst Co-catalyst

Stable carbocation

Propagation

Reaction rate is high at low temperatures (e.g. -80 oC in chlorinated

solvents like CH3Cl

Head-to-tail addition is energetically favored

45

Department of Chemical Engineering

IIT Madras

Effect of solvent polarity on rate of cationic

polymerization of -methyl styrene

Solvent

Cyclohexane

Dielectric

constant

1.9

Polymerization rate

mol/min

1.25

Dichloroethane

10

3.30

Nitroethane

28

20.40

Nitrobenzene

36

150.00

Solvent polarity also affects the degree and type of stereoregularity

(isotactic or syndiotactic)

46

Department of Chemical Engineering

IIT Madras

Effect of temperature on Mv of

polyisobutylene

Temperature, oC

Viscosity average

molecular weight, Mv

-10

10,000

-25

13,000

-45

25,000

-80

74,000

-90

1,20,000

Higher stereoregularity is achieved at lower temperatures

47

Department of Chemical Engineering

IIT Madras

Kinetics of cationic polymerization

Typical reactions

Formation of catalystco-catalyst complex

Initiation

Propagation

Termination

Chain transfer

A RH H AR

ki

H AR M

HM AR

HM x AR M

HM

ki

x 1

AR

HM x AR

M x H AR

kt

HM x AR M

M x HM AR

kt

Billmeyer, page 87

48

Department of Chemical Engineering

IIT Madras

Kinetics of cationic polymerization

Same analysis as free radical polymerization, except

for the termination step

Chain transfer steps to monomer, polymer and solvent

are possible

Rp = Kkpki[A][RH][M]2 / kt

Kinetic chain length, DP = kp[M]/kt

<only termination>

Kinetic chain length, DP = kp/ktr

<only chain transfer>

Billmeyer, page 87

49

Department of Chemical Engineering

IIT Madras

Anionic (Living) Polymerization

Initiation

Propagation

Solvents aliphatic and aromatic hydrocarbons, ethers

Anionic polymerization not too much temperature sensitive as

cationic polymerization

50

Department of Chemical Engineering

IIT Madras

Kinetics

Initiation:

KNH2 K+ + NH2

NH2 + M H2N-M

Ri = ki[NH2][M]

Propagation: H2N-(M)n-M + M H2N-(M)n+1-M

Rp = kp[M][M]

Chain transfer: H2N-(M)n-M + NH3 H2N-(M)n-MH + NH2

Rtr = ktr[M][NH3]

Kinetic chain length, DP = kp[M]/ktr[NH3]

51

Department of Chemical Engineering

IIT Madras

When there is no termination by chain transfer

DP = Rp/Ri

DP = no. of monomer molecules / no. of chains initiated

DP = ([M]0 [M])/[I]0 = [M]0/[I]0 for X = 1 & high rates of

initiation

Vary narrow MWD can be obtained

Effect of ion-pair association and solvent polarity affect

kp

52

Department of Chemical Engineering

IIT Madras

Effect of solvent on kp for polystyrene

Solvent

Counter ion

Tetrahydrofuran

Na+

kp,

L/mol-s

80*

1,2-Dimethoxy ethane

Na+

3600*

Tetrahydrofuran

Li+

160*

Benzene

Li+

0.001 0.1 #

Cyclohexane

Li+

(5 100)10-5 #

* - at 25 oC, # - variable temperature

53

Department of Chemical Engineering

IIT Madras

Effect of solvent and counter ion on polymer structure

54

Department of Chemical Engineering

IIT Madras

Geometric isomerism in polyisoprene

55

Department of Chemical Engineering

IIT Madras

Cis- and Trans- 1,4-isoprene polymers

Trans-

Cis-

56

Department of Chemical Engineering

IIT Madras

Ziegler-Natta / Coordination polymerization

Nobel prize contribution Ziegler (1964) and Natta (1965)

Polymers with unusual stereospecific structures

Usually carried out in industry in fluidized bed reactors with

supported solid catalyst in the form of slurry

Components Organometallic compound + transition-metal salt

Organometallic compound

Transition metal salt

Triethyl aluminium

Titanium tetrachloride

Diethyl aluminium chloride

Vanadium trichloride / triacetyl acetone

vanadium / triacetyl acetone vanadium /

Co-chloride-pyridine complex

Butyl lithium

Titanium tetrachloride

57

Department of Chemical Engineering

Crystal structure of -TiCl3

IIT Madras

Ti

Vacancy

Cl

58

Department of Chemical Engineering

IIT Madras

Mechanism of Ziegler-Natta polymerization

Catalyst activation / adsorption

Ethyl aluminium

dichloride

Dicyclopentadienyl

ethyl titanium

chloride

First monomer addition

59

Department of Chemical Engineering

IIT Madras

Formation of a new Ti-C bond

Polyinsertion

60

Department of Chemical Engineering

IIT Madras

Chain transfer to monomer or alkyl alumina

-Elimination at high temp. to form transition metal hydrides

Termination by addition of H2

61

Department of Chemical Engineering

IIT Madras

Variation of polypropylene isotacticity with catalyst

Catalyst

AlEt3 + TiCl4

AlEt3 + -TiCl3

AlEt3 + -TiCl3

AlEt3 + ZrCl4

AlEt3 + VCl3

AlEt3 + TiCl4 + P, As or Sb

AlEt2X + TiCl3

AlEtX2 + -TiCl3 + amine

Stereoregularity (%)

35

45

85

55

73

35

90-99

99

62

Department of Chemical Engineering

Monomer type

Ethylene

Propylene

Isobutylene

Dienes

Styrene

Vinyl chloride

Acrylonitrile

Tetrafluoroethylene

IIT Madras

Radical

Cationic

Anionic

Coordination

+

+

+

+

+

+

+

+

+

-

+

+

+

-

+

+

+

+

+

+

+

+

+ denotes formation of long chain polymers

- Denotes formation of oligomers or no polymerization at all

63

Department of Chemical Engineering

IIT Madras

Specific References

Billmeyer, Textbook of polymer science

Chapters 1-5, Chapter 13,14,15,16 self study

Odian, Principles of polymerization

Chapters 1, 2 (upto page 53, 69-92), 3 (upto page 214, 236-246, 279-287), 6

(464-481, 487-502)

Pg. 92-101, 300-313 (specific commercial polymers) - Self study

Pg. 264-271 (determination of rate constants) Self study

Gowariker et al. Polymer science

Chapters 1, 2, 3, 4, 8

64

Department of Chemical Engineering

IIT Madras

Potential paper topics

Gradient copolymerization kinetics

Penultimate effect in copolymerization

Sequence length distribution in copolymers

Kinetics of emulsion polymerization

Kinetics of branching, crosslinking and gelation

Kinetics of Ziegler-Natta / Alfin polymerization

Other polymerization techniques

CRP Controlled Radical Polymerization

RAFT Radical Addition Fragmentation Termination

ATRP Atom Transfer Radical Polymerization

NMP Nitroxide Mediated Polymerization

65

Department of Chemical Engineering

IIT Madras

www.scopus.com

Potential journals

Polymer

Progress in Polymer Science

European Polymer Journal (Elsevier)

Journal of Physical Chemistry

Macromolecules (ACS)

Journal of Polymer Science

Macromolecular Chemistry and Physics

Macromolecular Reaction Engineering (Wiley)

66

You might also like

- Polymer 3 PDFDocument3 pagesPolymer 3 PDFAyman N YassinNo ratings yet

- En - O1.1 - EEM EXP1 PolymersDocument100 pagesEn - O1.1 - EEM EXP1 PolymersJean Orveil PAMBOUNo ratings yet

- Introduction To Polymer ScienceDocument19 pagesIntroduction To Polymer ScienceAnshul GautampurkarNo ratings yet

- PolymersDocument106 pagesPolymersmambouhpriscaNo ratings yet

- Bulk and Suspenshion Polynerization of MMA Into PMMADocument5 pagesBulk and Suspenshion Polynerization of MMA Into PMMADavid Meza CarbajalNo ratings yet

- Polymerization of Acrylic EsterDocument7 pagesPolymerization of Acrylic EsterMichelleYapNo ratings yet

- Week#1 - Intro To Petro Global MarketDocument39 pagesWeek#1 - Intro To Petro Global MarketRoza SavitriNo ratings yet

- Chapter 8 PolymersDocument53 pagesChapter 8 PolymersStephen IgatNo ratings yet

- Polymer Matrix Composites - Matrix Resins - Thermosetting Resins, Thermoplastic ResinsDocument27 pagesPolymer Matrix Composites - Matrix Resins - Thermosetting Resins, Thermoplastic Resinsgidlavinay100% (1)

- Polymers and Composites: Structure, Properties and ApplicationsDocument21 pagesPolymers and Composites: Structure, Properties and ApplicationsDorothy SaikiaNo ratings yet

- Everything about polymers in one placeDocument26 pagesEverything about polymers in one placeJason Robert VictorNo ratings yet

- FTIR1Document7 pagesFTIR1Ziarat ShahNo ratings yet

- L1 Scope and IntroductionDocument67 pagesL1 Scope and IntroductionAlpha GamingNo ratings yet

- Oo PDFDocument16 pagesOo PDFAyad EmadNo ratings yet

- LektionDocument79 pagesLektionLaura StokholmNo ratings yet

- PolymersDocument12 pagesPolymersNaman SharmaNo ratings yet

- Exp. (2) The Effect of Structure On The Polymers: Year Dr. Farhad & Mr. MohammedDocument16 pagesExp. (2) The Effect of Structure On The Polymers: Year Dr. Farhad & Mr. MohammedNazar AhmedNo ratings yet

- Poly TechniquesDocument19 pagesPoly TechniquesgokulNo ratings yet

- Living Radical Polymerization A ReviewDocument36 pagesLiving Radical Polymerization A ReviewAris SusantoNo ratings yet

- Chapter 4. Condensation PolymerizationDocument51 pagesChapter 4. Condensation PolymerizationSaifuddin AzizNo ratings yet

- Bchec102 Mod4@Azdocuments.inDocument13 pagesBchec102 Mod4@Azdocuments.indanishansari7715954284No ratings yet

- Polymer ScienceDocument101 pagesPolymer SciencereddyNo ratings yet

- polymer-151217133029Document52 pagespolymer-151217133029Sree Info TeluguNo ratings yet

- CY1050 - Class 1, 2 and 3 Slides - Gardas - 2022Document39 pagesCY1050 - Class 1, 2 and 3 Slides - Gardas - 2022Basil Azeem ed20b009No ratings yet

- PolyamideDocument2 pagesPolyamidechristophe100% (1)

- SelviDocument40 pagesSelvirajrudrapaaNo ratings yet

- Separation of Polymers by Solvent FractionationDocument6 pagesSeparation of Polymers by Solvent FractionationSzePT100% (2)

- PolymerisationDocument59 pagesPolymerisationkid unique100% (2)

- Che 2Document32 pagesChe 2dineshsilambam2305No ratings yet

- Matrices: Dr. J. Ramkumar Professor Dept of Mechanical & Design Program IIT Kanpur, IndiaDocument27 pagesMatrices: Dr. J. Ramkumar Professor Dept of Mechanical & Design Program IIT Kanpur, Indiadavid josephNo ratings yet

- Material Selection Guide PDFDocument86 pagesMaterial Selection Guide PDFstaticfactory9281100% (2)

- Molecular Weight Distributions in Ideal Polymerization Reactors. An Introductory ReviewDocument15 pagesMolecular Weight Distributions in Ideal Polymerization Reactors. An Introductory ReviewAhmed SoltanNo ratings yet

- Matrices: Dr. J. Ramkumar Professor Dept of Mechanical & Design Program IIT Kanpur, IndiaDocument27 pagesMatrices: Dr. J. Ramkumar Professor Dept of Mechanical & Design Program IIT Kanpur, IndiaMahesh RajaNo ratings yet

- Petro Chemical-NotesDocument80 pagesPetro Chemical-Notes69 krishna AgrawalNo ratings yet

- Chapter 5 UpdatedDocument10 pagesChapter 5 UpdatedAiman HazimNo ratings yet

- Polymers 07 01379 PDFDocument10 pagesPolymers 07 01379 PDFKristineNo ratings yet

- Advanced Materials PDFDocument45 pagesAdvanced Materials PDFShahbaz AhmadNo ratings yet

- Engineering ThermoplasticsDocument60 pagesEngineering Thermoplasticsobiwan_vNo ratings yet

- Lipophilic Polymethacrylate Ionic Liquids As Lubricant AdditivesDocument30 pagesLipophilic Polymethacrylate Ionic Liquids As Lubricant AdditivesArun KumarNo ratings yet

- Design For ManufactureDocument14 pagesDesign For ManufacturePriambodo AriewibowoNo ratings yet

- APECETDocument4 pagesAPECETmouli gNo ratings yet

- Polyurethane AdhesivesDocument67 pagesPolyurethane Adhesivesssm_majeed86% (7)

- Catalytic Hydrogenation of Organic Polymers by Mixed Transition Metal OxidesDocument8 pagesCatalytic Hydrogenation of Organic Polymers by Mixed Transition Metal OxidesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Iomaterials: Module 5: Properties and Applications of Polymeric BiomaterialsDocument67 pagesIomaterials: Module 5: Properties and Applications of Polymeric BiomaterialsRishi VakhariaNo ratings yet

- Polymer Engineering MaterialsDocument123 pagesPolymer Engineering Materialscory kurdapyaNo ratings yet

- Types of Polymers: Molecular Weight Crystallinity CrosslinkingDocument13 pagesTypes of Polymers: Molecular Weight Crystallinity CrosslinkingspallocNo ratings yet

- CHP 1Document23 pagesCHP 1Kerem Cengiz KılıçNo ratings yet

- M.Sc. Polymer Science Credit System SyllabusDocument11 pagesM.Sc. Polymer Science Credit System SyllabusUmamaheswari GanesanNo ratings yet

- Plastic Industries: An OverviewDocument10 pagesPlastic Industries: An OverviewKubra ĖdrisNo ratings yet

- ChE 543 W15 After Mid-Term ReviewDocument4 pagesChE 543 W15 After Mid-Term ReviewZohaib NarejoNo ratings yet

- Chapter 3. Acid Gas RemovalDocument88 pagesChapter 3. Acid Gas RemovalTu Dang TrongNo ratings yet

- Biodegradable MaterialsDocument26 pagesBiodegradable MaterialsannaNo ratings yet

- Polyamide 610 KasarDocument8 pagesPolyamide 610 KasarAlison BurksNo ratings yet

- Module-3 ME NotesDocument30 pagesModule-3 ME NotesdnalokeshNo ratings yet

- Presentation 39Document18 pagesPresentation 39Farhad MalikNo ratings yet

- Polystyrene and Styrene-Copolymers Applications, Synthesis and KineticsDocument15 pagesPolystyrene and Styrene-Copolymers Applications, Synthesis and KineticsLWYenNo ratings yet

- Poly(lactic acid): Synthesis, Structures, Properties, Processing, and ApplicationsFrom EverandPoly(lactic acid): Synthesis, Structures, Properties, Processing, and ApplicationsRafael A. AurasNo ratings yet

- Synthesis and Application of Cationic SoDocument5 pagesSynthesis and Application of Cationic SoKushagradhi DebnathNo ratings yet

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionFrom EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionRating: 5 out of 5 stars5/5 (1)

- Shape Memory PolymersDocument24 pagesShape Memory PolymersFarooq MuhammadNo ratings yet

- Mech Ops Lab HandoutsDocument22 pagesMech Ops Lab HandoutsRahulNo ratings yet

- Shape Memory PolymersDocument24 pagesShape Memory PolymersFarooq MuhammadNo ratings yet

- K R Rahul IIT Madras ProfileDocument1 pageK R Rahul IIT Madras ProfileRahulNo ratings yet

- Mech Ops Lab HandoutsDocument22 pagesMech Ops Lab HandoutsRahulNo ratings yet

- Polymeric Materials Classification and PropertiesDocument66 pagesPolymeric Materials Classification and PropertiesRahulNo ratings yet