Professional Documents

Culture Documents

A2 3 PDF

Uploaded by

Hoang NamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A2 3 PDF

Uploaded by

Hoang NamCopyright:

Available Formats

Chemical Engineering Research Bulletin 14(2010) 25-28 / Josiah and Ikiensikimama

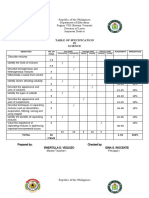

Table 4: Result of specific gravity and API gravity

Experiment Number

Desludging ratio

Adsorption ratio

Specific gravity at 40 C

API gravity

1

3:01

5:01

0.893

26.95

2

5:01

5:01

0.871

30.96

3

10:01

5:01

0.894

26.76

Table 6: Comparison of the properties of the recycle, fresh and spent oils

4

15:01

5:01

0.865

32.08

5

20:01

5:01

0.865

32.08

Table 5: Result of viscosity, flash point and pour point measurements

Experiment Number

Desludging ratio

Adsorption ratio

Viscosity at 40 C

Viscosity at 100 C

Viscosity index

Flash point ( C))

Pour point ( C)

1

3:01

5:01

120.54

12.55

94.95

144

-11

2

5:01

5:01

120.5

12.53

94.72

144

-14

3

10:01

5:01

110.14

11.82

95.08

148

-13

27

4

15:01

5:01

110.3

11.82

94.91

153

-18

5

20:01

5:01

110.3

11.8

94.6

152

-16

4. Discussion

Two major unit operations were employed in the regeneration of the spent automobile engine oil. They include

desludging and adsorption operations. In the desludging

step, most of the oxidative and degraded products were removed. This was accomplished with the use of the sulfuric

acid, which proved very effective and efficient because of its

poly-functional nature.

4.1. Effect of desludging ratio on recovery

The desludging temperature was 50 C to avoid the adverse

effect of sulfuric acid oxidation of the oil at higher temperatures. However, at such low temperature the desludging reaction is slow. Hence sufficient time and rigorous agitation

was employed to enable the reaction reach completion. Different desludging ratios were used. As shown in Table 1, a

recovery of 83.7% was obtained for a ratio of 3:1, 88.40% for

a ratio of 5:1 and 89.40% for a ratio of 10:1. This shows that

the higher the ratio, the higher the recovery. The observed

increase in recovery would depend on the grade of the acid

used as well as the original source of the used oil and the

level of contamination [8].

4.2. Effect of desludging and adsorption ratios on recovery

In the chemisorption step, the remaining contaminants

were removed by adsorption using activated clay as the

adsorbing agent. To enhance adsorption, fine particles (75/+150) of the adsorbent were used coupled with vigorous

stirring. Sufficient time was used so as to allow the adsorption reach completion (equilibrium). The oil from the adsorption stage was clear enough.

The adsorption ratio was kept constant at 5:1 and the

desludging ratio varied to obtain different recoveries, the result presented in Table 2. This table shows a recovery of

59.1% for a ratio of 3:1, 59.3% for a ratio of 5:1, and 69.9%

for the ratio of 10:1. This shows that the higher the ratio

the higher the recovery. Next, for a desludging ratio of 20:1,

the adsorption ratio was varied. The results show that for

adsorption ratio of 3:1, a recovery of 66.7% was obtained;

for the ratio of 5:1 a recovery of 74.8% and for a ratio of

10:1 a recovery of 82.9%. This also shows that the recovery

increases with adsorption ratio (Table 3). These various recovery values are in agreement with those stated by Graziano

Oil type

Specific gravity API gravity Pour point Flash point Viscosity

(40 C)

( C)

( C)

index

Fresh oil

0.897

26.25

-21

182

98

Spent oil

0.901

25.55

185

111.4

Recycled oil

0.865

32.08

-16

152

94.6

and Daniels [6], and Rahman et al [3]; though the 82.9% recovery is slightly higher.

4.3. Comparison of the properties of recycled, fresh and

spent oils

The results of the tests carried out on the recycled oil

showed that the specific gravity, pour point, flash point and

viscosity of the recycled oil are all lower than those of the

fresh oil and spent oil (Table 6).

The work by Bobmanuel [14] on the spent engine oil recycling, using activated sand as filtering media, gave a value of

specific gravity, flash point and viscosity much higher than

the values obtained here. This may be due to the fact that

only physical separation methods were used to recycle the

oil. Physical separation methods will not be expected to improve on the chemical properties. Bobmanuel [14] also reported that there was no appreciable color change in the recycled oil. A very good improvement in color was obtained

using desludging and adsorption operations in recycling the

oil.

This work shows that a high proportion of good oil can

still be recovered from the numerous gallons of useless

waste engine oil being thrown away everyday in Port Harcourt and Nigeria in general. Regeneration will not only

prove economically profitable [15] but will also minimize

pollution problems being posed by the reckless dumping of

these spent oils into drainage gutters and sewages. However,

the spent engine oil thus recycled could be used as a combustion fuel in cement kilns, since the recycled oil has good

combustion characteristics such as low flash and pour points.

5. Conclusion

The effect of desludging and Adsorption ratio was studied

on the recovery of Low Pour Fuel Oil (LPFO) from spent

engine oil. The result shows that the efficiency of the recycling operation depends on the reagent ratios used i.e on the

desludging and adsorption ratios. It was noted that the recovery increases with increase in these ratios. A maximum

recovery of 82.9% was obtained with a desludging ratio of

20:1 and adsorption ratio of 10:1.

The characterization of the fresh, spent and recycled oils

shows that the specific gravity, API gravity, pour point, flash

point and viscosity index of the recycled oil is lower than

the fresh and the spent oil. Specific gravity of 0.897, 0.901

and 0.865; flash point of 182, 185 and 152 C; and viscosity

index of 98.00, 111.40 and 94.60; were obtained for fresh,

spent and recycled oils respectively. However, the spent engine oil thus recycled could be used as a combustion fuel

in cement kilns, since the recycled oil has good combustion

characteristics such as low flash and pour points.

You might also like

- Thank You: Questions - DiscussionDocument1 pageThank You: Questions - DiscussionHoang NamNo ratings yet

- LPG 51Document1 pageLPG 51Hoang NamNo ratings yet

- LPG 49Document1 pageLPG 49Hoang NamNo ratings yet

- LPG 46Document1 pageLPG 46Hoang NamNo ratings yet

- Top Tier: LNG Contractors Liquefaction PlantsDocument1 pageTop Tier: LNG Contractors Liquefaction PlantsHoang NamNo ratings yet

- LPG 43Document1 pageLPG 43Hoang NamNo ratings yet

- LPG 41Document1 pageLPG 41Hoang NamNo ratings yet

- LPG 50Document1 pageLPG 50Hoang NamNo ratings yet

- LPG 47Document1 pageLPG 47Hoang NamNo ratings yet

- LPG 45Document1 pageLPG 45Hoang NamNo ratings yet

- Shipping and Typical Ship Parameters: Nominal CapacityDocument1 pageShipping and Typical Ship Parameters: Nominal CapacityHoang NamNo ratings yet

- LPG 34Document1 pageLPG 34Hoang NamNo ratings yet

- LPG 44Document1 pageLPG 44Hoang NamNo ratings yet

- LNG Terminal Flow Diagram: Vapor Return Line Boil-Off Gas CompressorDocument1 pageLNG Terminal Flow Diagram: Vapor Return Line Boil-Off Gas CompressorHoang NamNo ratings yet

- LPG 42Document1 pageLPG 42Hoang NamNo ratings yet

- LPG 32Document1 pageLPG 32Hoang NamNo ratings yet

- LPG 28Document1 pageLPG 28Hoang NamNo ratings yet

- LPG 33Document1 pageLPG 33Hoang NamNo ratings yet

- LPG 30Document1 pageLPG 30Hoang NamNo ratings yet

- LPG 24Document1 pageLPG 24Hoang NamNo ratings yet

- Typical LP MR Compressor: Axial Compressor Rotor Lifted From CasingDocument1 pageTypical LP MR Compressor: Axial Compressor Rotor Lifted From CasingHoang NamNo ratings yet

- Frame 7 Cutaway: Axial CompressorDocument1 pageFrame 7 Cutaway: Axial CompressorHoang NamNo ratings yet

- LPG 23Document1 pageLPG 23Hoang NamNo ratings yet

- Propane Compressor Driven by Frame 6 Gas TurbineDocument1 pagePropane Compressor Driven by Frame 6 Gas TurbineHoang NamNo ratings yet

- Propane Precooled Mixed Refrigerant Cycle Pure Propane Refrigerant CycleDocument1 pagePropane Precooled Mixed Refrigerant Cycle Pure Propane Refrigerant CycleHoang NamNo ratings yet

- Basic Refrigeration - Simple PFDDocument1 pageBasic Refrigeration - Simple PFDHoang NamNo ratings yet

- LPG 22Document1 pageLPG 22Hoang NamNo ratings yet

- Typical Propane Circuit Scheme Process FlowDocument1 pageTypical Propane Circuit Scheme Process FlowHoang NamNo ratings yet

- Removal of Trace Mercury ContaminantsDocument1 pageRemoval of Trace Mercury ContaminantsHoang NamNo ratings yet

- Refrigeration Cycles: Types of Licensed ProcessesDocument1 pageRefrigeration Cycles: Types of Licensed ProcessesHoang NamNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Enzyme kinetics experiment on starch hydrolysisDocument13 pagesEnzyme kinetics experiment on starch hydrolysisNahusenay TewodrosNo ratings yet

- Autodock2 4 UserguideDocument48 pagesAutodock2 4 UserguidePowellAbogadoNo ratings yet

- Chemistry Density Problems SEODocument5 pagesChemistry Density Problems SEOTahir SaeedNo ratings yet

- Electric Potential Review & SummaryDocument10 pagesElectric Potential Review & SummaryHassanTahirNo ratings yet

- Module 2 Exam Practice Exam Physics: This Is Exam Number 1. 1. 2 3 4 5 6 7 8 9 10 B C B A A A A B B ADocument79 pagesModule 2 Exam Practice Exam Physics: This Is Exam Number 1. 1. 2 3 4 5 6 7 8 9 10 B C B A A A A B B AJowiNo ratings yet

- 6 - Review - Avances en Tipos de Hidrogeles y Remoción de ColorantesDocument27 pages6 - Review - Avances en Tipos de Hidrogeles y Remoción de ColorantesAlejandro PérezNo ratings yet

- Sigma Marine CoatingsDocument417 pagesSigma Marine CoatingsAhmed Saad80% (5)

- 2 Agrostudies Temperature ManagementDocument62 pages2 Agrostudies Temperature ManagementYolaina EdwarNo ratings yet

- Commercial Main Stub-Out Assembly Product Component Submittal 2010Document53 pagesCommercial Main Stub-Out Assembly Product Component Submittal 2010Jose Andre Flores ChiaNo ratings yet

- Cold AsphaltDocument440 pagesCold AsphaltDem Hasi100% (1)

- Site Lab Checklist1Document4 pagesSite Lab Checklist1layaljamal2No ratings yet

- Niper 2.Document42 pagesNiper 2.GANESH KUMAR JELLANo ratings yet

- 黃光Document12 pages黃光陳彥儒No ratings yet

- AISI 4140 Alloy Steel PropertiesDocument3 pagesAISI 4140 Alloy Steel PropertiesSatrio AmiruddinNo ratings yet

- Indian Earth Science Olympiad 2010Document13 pagesIndian Earth Science Olympiad 2010Science Olympiad Blog100% (2)

- Hard and Soft Acids and BasesDocument17 pagesHard and Soft Acids and BasesSalmi Seprianti100% (2)

- 3m Scotchbrite Quick Clean Griddle Cleaning SystemDocument12 pages3m Scotchbrite Quick Clean Griddle Cleaning Systemarturo gmoNo ratings yet

- NPSH CalculationDocument19 pagesNPSH CalculationPatilea Daniela100% (1)

- Delayed Coker Fired HeatersDocument20 pagesDelayed Coker Fired HeatersJean Carlos Gonzalez Hernandez100% (3)

- Periodical Test in SCIENCE Melc BasedDocument6 pagesPeriodical Test in SCIENCE Melc Basedaiko idioNo ratings yet

- Hydraulic WorkDocument3 pagesHydraulic WorkIrfan ZaidiNo ratings yet

- Counting Atoms Balancing Equations Law of Conservation of Mass Physical Science ABM-12Document10 pagesCounting Atoms Balancing Equations Law of Conservation of Mass Physical Science ABM-12Glenn Segundo AstodilloNo ratings yet

- Sds Oleum Che 1040sDocument8 pagesSds Oleum Che 1040sNITINNo ratings yet

- Visco SinDocument2 pagesVisco SinSyeda Fatima ali100% (1)

- Solvent EndodonticiDocument7 pagesSolvent EndodonticiValentina BadiuNo ratings yet

- Kvasnicka DomitrovicDocument42 pagesKvasnicka DomitrovicMarcusLindonNo ratings yet

- BC 21D Lab Manual2009 - 10edit PDFDocument52 pagesBC 21D Lab Manual2009 - 10edit PDFJoniel GylesNo ratings yet

- Bored pile construction procedureDocument57 pagesBored pile construction procedureOakar MinNo ratings yet

- Statistics 2 For Chemical Engineering: Department of Mathematics and Computer ScienceDocument37 pagesStatistics 2 For Chemical Engineering: Department of Mathematics and Computer ScienceKhuram MaqsoodNo ratings yet