Professional Documents

Culture Documents

Y.R. Goh C.N. Lim R. Zakaria K.H. Chan G. Reynolds Y.B. Yan - Mixing, Modelling and Measurement

Uploaded by

kunlecorneliusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Y.R. Goh C.N. Lim R. Zakaria K.H. Chan G. Reynolds Y.B. Yan - Mixing, Modelling and Measurement

Uploaded by

kunlecorneliusCopyright:

Available Formats

09575820/00/$10.00+0.

00

q Institution of Chemical Engineers

Trans IChemE, Vol 78, Part B, January 2000

MIXING, MODELLING AND MEASUREMENTS OF

INCINERATOR BED COMBUSTION

Y. R. GOH (ASSOCIATE MEMBER), C. N. LIM (ASSOCIATE MEMBER), R. ZAKARIA, K. H. CHAN (ASSOCIATE MEMBER),

G. REYNOLDS (ASSOCIATE MEMBER), Y. B. YANG, R. G. SIDDALL, V. NASSERZADEH (ASSOCIATE MEMBER) and

J. SWITHENBANK (FELLOW)

Shefeld University Waste Incineration Centre (SUWIC), Department of Chemical and Process Engineering, University of Shefeld, Shefeld, UK

he safe disposal of municipal solid waste has now become an urgent environmental

problem. The traditional method of landlling waste has created so many

environmental problems that countries including Denmark, Holland and Germany

have imposed severe restrictions on landlling burnable waste. With up to 1 tonne of municipal

waste being generated by every individual annually in the UK, incineration is now at the

forefront of combustion research, as developed countries recognize the environmentally

friendly advantages of this technology. An efcient incinerator is not only assessed by the

amount of heat recovery but also by the levels of emissions and quality of the ash it produces.

Incinerator designs must therefore be fully optimized so that they can control emissions by

reducing the production of harmful pollutants such as dioxins, furans, NOx and SOx. Hence,

incinerator bed combustion is a vital area that urgently needs further investigation. At

SUWIC, the present work concentrates on the development of a comprehensive and reliable

model for the incinerator bed combustion process. The results from the incinerator burning

bed model can then provide the much needed boundary conditions for Computational

Fluid Dynamics (CFD) modelling of the gas phase reacting turbulent ow in the freeboard

region of an incinerator. In addition to the development of the computational model,

the work involves several parallel activities, including experimental investigations into

waste combustion, solid mixing and prevention of slag formation and instrumentation

development.

Keywords: waste incineration; slag formation; instrumentation; mixing; mathematical

modelling; pollution.

INTRODUCTION

for assessing proposed designs of incinerator, or troubleshooting existing plant designs, without building the plant

or small-scale accurate physical models.

The evolution of better and more efcient incinerators

in the UK is currently hindered by the lack of reliable data,

and fundamentally based design procedures to assist their

design/manufacture, operation and control. The combustion of waste in incinerators is complex, and the design

and control of such processes poses many problems. For

example, many existing grate systems do not agitate the

burning refuse efciently. Consequently, a large volume of

excess air is required to achieve a good burn-out. This leads

to problems with the gas phase combustion, overloading

of the electrostatic precipitators and/or scrubbers, and high

particulate emissions from the bed. SUWIC studies at some

UK municipal incinerators with moving grate systems

also showed high levels of unburned carbon in the residual

and y ash, which increases the cost of ash disposal. In

contrast to the progress in gas phase combustion modelling

with CFD, the open literature contains no satisfactory model

for the burning of municipal solid waste on a travelling

grate. The prediction of the ow rate and composition of

gases emerging from the bed is particularly important as

it provides the upstream boundary conditions for the ow

calculation in the gas phase region.

The amount of waste generated by mankind and the growing

concern over health and environmental problems related

to landll has risen to a point where incineration is perceived to be the best option to dispose of most wastes,

especially when some of the energy content of the waste can

be recovered. Incineration is an environmentally friendly

process for the disposal of municipal solid waste, provided

that it is properly carried out. The main objective of

incineration is to convert a large volume of chemically

and biologically active waste into a small volume of inert

matter.

In any technology, the design process depends on a clear

understanding of the fundamental scientic principles

on which the design is to be based. These fundamental

principles are usually expressed in terms of the governing

differential equations of the process under consideration.

The required design is then obtained by solving these

equations subject to the appropriate boundary conditions,

physical constants, input and output conditions. In incinerators, the main combustion-related design items are the

burning bed of solid waste on the grate and the gas phase

path, including the reactions which take place. For the gas

phase, advances in CFD have proved to be invaluable

21

GOH et al.

22

MODELLING OF SOLID MIXING ON A

MOVING GRATE

A crucial feature of incinerator combustion is the mixing

of the solid material on the grate. To achieve complete combustion of solid waste in a municipal incinerator, producing as few toxic contaminants as possible, it is essential to

acquire experimental information about the combustion

processes on the travelling grate. Existing grate systems

do not produce a uniform gas concentration distribution

above the burning refuse, and a large volume of excess air

is usually required to achieve good ue gas burn-out (typically using 100% excess air). These non-uniformities lead

to the aforementioned problems with the gas phase combustion, overloading of the ue gas scrubbing system, high

particulate carryover from the bed and high levels of

unburned carbon in both the residual ash and the y ash,

which makes it expensive to dispose of the ash.

In this part of the study, the mixing process on scale

models of three industrial grates has been quantitatively

determined by a series of systematic particle movement

experiments (random lateral and vertical motion). For each

conguration, sufcient data have been collected to permit a

new mathematical model for the mixing process statistics

to be developed. To characterize and quantify the mixing

process, experiments were conducted in the following

small-scale industrial grates (1:15 size ratio): (i) Deutsche

Babcock grate (as shown in Figure 1); (ii) Martin grate

(Figure 2); and (iii) ABB double motion overthrust

horizontal grate (Figure 3).

Mixing is essentially the dispersion of material from an

initial position, so to quantify this, it is necessary to see

where material can progress to, once it has left the initial

position. In the experiments, a xed volume of solids was

introduced onto the grate contained in a perspex box, as

shown in Figure 1. Marked or coloured solid tracers were

positioned on the original bed of solids. A digital image

video camera was then used to record the movements of the

tracers. Digital frames of the test were captured at ve

second intervals. The position of each tracer on each frame

was evaluated in terms of (x,y) and time, where x is the

distance measured from the point of refuse input, and y is

the distance measured from the nearest wall. This can then

be used to produce the distribution of the tracers based on

the proportion of tracer at a particular distance and the

number of tests performed.

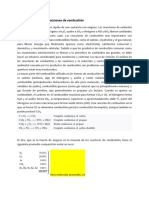

Figure 4 shows the distribution curves of the solid tracers

in a Deutsche Babcock grate experiment, normalized to the

total number of tests performed. The standard deviations1 for

these curves were calculated, and the mean of the calculated

standard deviations was found to have a value close to 2.

A mathematical model has been developed to simulate

the movement of the solid material on the grate based on

the probability for a solid tracer to swap position with the

adjacent tracer. This model can be applied to the movement

of the solid material in three directions, i.e. axial (x),

transverse ( y) and normal to the grate (z).

As an example, consider the solid movement in the

transverse ( y) direction only. The distance travelled by a

solid tracer in the transverse direction is the result of several

local swaps. In this model, the solid bed is divided into a

number of cells nt, as shown in Figure 5. Initially, cell n is

occupied by a tracer n. In Figure 5, C(t,n) is the number

of the tracer in cell n at time t. Each cell n is also given a

variable P(t,n) which is a random number between 0 and 1,

generated during the numerical simulation.

A sequence of `decision-making processes is carried

out across the bed, over several time steps, to determine

Figure 1. Deutsche Babcock rotating drum grate.

Figure 3. ABB horizontal grate.

Figure 2. Martin grate.

Trans IChemE, Vol 78, Part B, January 2000

INCINERATOR BED COMBUSTION

23

Figure 4. Tracer distribution from Deutsche Babcock grate experiment.

whether a tracer in cell n would swap position with the

tracer in cell n + 1. This sequence is as illustrated in

Figure 6. In this `decision-making process, a global value

Pl is rst set for the probability for a local swap. At the

rst time step Dt, if probability of cell 1 at t = 0 or P(0,1)

is larger than Pl, then tracer m = 1 at time t = 0 or C(0,1)

will stay at cell 1 and no swapping will occur. The process

then proceeds to cell 2 where P(0,2) is compared with Pl

to decide whether C(0,2) will swap position with C(0,3). If

P(0,2) is again larger than Pl, C(0,2) will not swap position

with C(0,3). The process will then proceed to cell 3.

If in the rst instance, P(0,1) is smaller than Pl, then

C(0,1) will swap position with C(0,2). The process then

proceeds to cell 3 where P(0,3) is compared with Pl to

decide whether C(0,3) will swap position with C(0,4). If

P(0,3) is again smaller than Pl, C(0,3) will swap position

with C(0,4). The process will continue at cell 5. If at the

end of the sequence, there is only one cell remaining,

the probability P(0,nt) will not be compared with the

limiting value, Pl. Since the tracer is already in the last

cell adjacent to the wall, no swapping will occur. This

`decision-making process can start at either side of the bed.

In summary, at any time t, C(t,1) can either be C(t Dt,1)

or C(t Dt,2), depending on the values of P(t Dt,1)

and

Pl. Similarly, C(t,2) can either be C(t Dt,1), C(t Dt,2)

or C(t Dt,3), depending on the values

of P(t Dt,1),

P(t Dt,2) and Pl. For cell n = nt , C(t,nt) can either

be

C(t Dt,nt 1) or C(t Dt,nt). In general, C(t,n) can

be C(t

C(t Dt,n) or C(t Dt,n + 1),

either

Dt,n 1),

for 1 < n < nt . This process is essentially

a `random

walk

procedure.

A spreadsheet program based on the aforementioned

procedure has been set up. Each cell of the spreadsheet

represents a cell of the solid bed. The probability value

for each cell, P(t,n), is produced by the spreadsheet

random number generation tool. It returns an evenly distributed random number greater than or equal to 0 and less

than 1. A new random number is returned every time the

worksheet is calculated. The frequency distributions of

the solid tracers across the bed can be obtained after

performing the calculation for several time intervals, Dt

and after a certain number of tests, N. This calculation is

then repeated several times for a range of Pl. The distribution curves, except for the two tracers which started in

the cells immediately adjacent to the side walls (tracers

m = 1 and m = nt = 10), resemble normal distribution

Trans IChemE, Vol 78, Part B, January 2000

curves where the majority of the tracers reside at their

original position.

The spread of the computed distribution is represented

by its standard deviation, s. Figure 7 shows the standard

deviation s computed for the tracer particles over a range

of values of Pl. If the probability to swap is higher, the

solids are more likely to spread as they travel to other cells,

as indicated by the increasing horizontal scatter of the data

at higher values of Pl. Since tracers at the centre of a grate

tend to spread more in comparison to those near to the

wall, more than one standard deviation can be obtained

from each assumed probability of swapping, Pl. A relationship between the probability of swapping, Pl, and standard

deviation, s, can be expressed in mathematical form by

tting a curve through the data.

Multiple regression analysis1 was carried out to determine the best tting line of the simulated data. This line

must pass through the origin since there is no chance for

the tracers to disperse if the probability of swapping is equal

to 0. The least squares curve of points (s1,Pl1), (s2,Pl2),,

(sN,PlN) is found to be of the form:

Pl = 0.04638s 2

(1)

The 95% condence limits for the coefcient in equation

(1) were found to be 0.04638 6 0.0108. The computation

of the standard deviation is somewhat in error due to

grouping of data into classes and this error is adjusted

using Sheppards correction1.

Figure 5. Division of solid bed in the transverse (y) direction.

GOH et al.

24

Figure 6. Local swap procedure in the transverse standard deviation.

By inserting the mean value of experimentally obtained

s into equation (1), the probability for the solid tracers to

swap positions in the experiment, Pl, was obtained. This

value of Pl is then fed into the mixing model to predict the

standard deviation for each tracer distribution.

Figure 8 compares the experimentally obtained and the

computed standard deviations of the tracers. It also shows

the variation of s with respect to distance from one of the

side walls; which was used as a reference wall in this

analysis. It is evident from Figure 8 that there is a

reasonably good agreement between the experimental and

the computed data. The mean of the computed standard

deviations was found to be 2.1; a value which lies within

the 95% condence bands of the best tting curve as

shown in Figure 9. This suggests that the movement of the

tracer particles in the y-direction can be accurately predicted

using this technique.

The same technique can be applied to the x and z

directions and be validated against experimental data

obtained from the particle tracking experiments in the

respective directions. The integration of the mixing model

in these directions will provide a three-dimensional mixing

model which can predict the mixing process on the grate

and be incorporated to a mathematical model for incinerator waste bed combustion simulation.

considered to consist of four components: moisture, volatile,

xed carbon and ash. During incineration, moisture, volatiles

and xed carbon are removed from the solid matter by the

drying, pyrolysis and gasication processes, respectively. A

physical representation of the change of bed volume which is

mathematically linked to these three processes has been

established in the step change model2.

The conservation equations of the solid phase components are expressed as:

s Yi

+ = (s ns Yi ) = = (Ds = (s Yi ) + Si

(2)

t

where = u = u x /x + u z /z for a two-dimensional simulation. The general expression for the energy equation of

the solid phase may be written as:

s Hs

+ = (s ns Hs ) = = (ls = Ts ) + = qr + Qs

t

(3)

MODELLING OF INCINERATOR

BED COMBUSTION

The physical volume of the municipal waste reduces

by 90% and the mass by 70% during combustion. A suitable

bed model must therefore permit simulation of the reduction in the bed volume. In general, the solid waste can be

Figure 7. Probability of swapping versus computed standard deviation.

Trans IChemE, Vol 78, Part B, January 2000

INCINERATOR BED COMBUSTION

25

Figure 8. Variation of standard deviation (s) with distance from one of the side walls ( y).

Figure 9. Comparison of the experimental result with the calculated value from the mixing model.

where qr denotes the radiative heat ux, and the source term

Qs represents the overall effects of heat transfer between

gas and solid and heats of reaction of the various processes

occurring during solid incineration.

The solid velocity in the vertical direction for any control

volume j in the bed (ns)z( j ), depends on the rate of volume

reduction of the bed and can be written as:

1 V

(ns )z ( j) = (ns )z ( j 1) +

(4)

Az ( j ) t j

where

V VB VC VD VA

+

+

+

(5)

=

t

t

t

t

t

and B is the initial waste material, C is the dried solids, D is

the dried and pyrolysed solids and A is the dried, pyrolysed

and gasied solid (ash). The time differential equations

representing the changes in volume of each material are

given as follows2:

VB

(RP)2

(6)

=

2 v 2B (1 B )

t

VC (RP )2 [1 (1 F2 )v 2B ]

(RP )3

(7)

=

3 v3C (1 C )

t

2 v2B (1 C )

VD (RP )3 [1 (1 F3 )v 3C ]

(RP )5

(8)

=

5 v5D (1 D )

t

3 v 3C (1 D )

VA

(RP )5 v 4D

(9)

=

t

5 v 5D (1 A )

Trans IChemE, Vol 78, Part B, January 2000

The steady-state travelling grate combustion problem may

be simplied by using an unsteady-state static bed if it is

assumed that the refuse is supplied to the moving grate at a

constant rate, and there is no movement of bed material

relative to the grate. Predicted variations with respect to

time, t, using the unsteady-state static bed model can be

used to predict variations with distance, x, from the point

of refuse input in the steady-state moving bed model by

using x = nx t, where nx is the local steady velocity of the

grate movement. Any variations of the conditions above

the bed and the rate of underfeed air input with respect to x

for the locally steady-state moving bed can be modelled

Figure 10. Typical gas temperature prole from unsteady state xed bed

model.

26

GOH et al.

Figure 11. Contour plot of predicted solid temperature.

as variations with respect to time in the unsteady-state static

bed using t = x/nx . An example of the typical temperature

prole of the gas phase predicted by the mathematical

model is shown in Figure 10. This prole was obtained

assuming a constant freeboard temperature and that combustion of gaseous volatiles liberated during pyrolysis

occurs above the bed. Similar temperature proles were

obtained during experiments with a batch reactor (see

Figure 14). The slopes of the temperature rise in Figure 14

are not as steep as those seen in Figure 10. This indicates

that a fraction of the volatiles liberated during pyrolysis

burn within the bed causing a more gradual temperature

rise.

Figure 11 shows the temperature contours of the solid

material in the bed, modelled on a sloping grate with the

refuse being fed from left to right, predicted using

the steady-state travelling bed model. The temperature of

the solid material in the bed gives an indication of the

process that is occurring within the bed; drying (between

the wet bulb temperature and the vaporization temperature), pyrolysis (approximately 540 K) and gasication

(above 600 K). The locations of the processes as indicated

in the gure show close similarity to the combustion model

proposed by Kuo et al.3. Typically, the solid waste on the

travelling grate is initially heated and loses most of its

free moisture by the time its temperature reaches 373 K. The

drying zone in the bed as indicated in Figure 11 corresponds

to the region where the mass fraction of the moisture content in the bed is decreasing in Figure 12. In Figure 11, as

the bed temperature increases further, the waste pyrolyses

at about 540 K and then ignites at approximately 600 K.

The waste eventually burns vigorously until either the

oxygen surrounding the solid is consumed, or the solid is

fully devolatilized leaving a carbonaceous char. The residual charred or partially charred element may undergo

further pyrolysis, be gasied by CO2 or H2O to yield CO

and H2, or be oxidized by O2 to form CO2.

MEASUREMENTS OF WASTE BED COMBUSTION

A good dynamic mathematical model of the incineration

process requires a combined knowledge of the physical

characteristics of the grate movements and chemical characteristics of the waste combustion on the grate. Combustion

Figure 12. Contour plot of predicted moisture concentration.

Trans IChemE, Vol 78, Part B, January 2000

INCINERATOR BED COMBUSTION

27

Figure 13. Schematic diagram of the xed bed reactor.

and kinetics data that are required for the bed modelling

programme have been obtained from an experimental

laboratory xed bed reactor built to study the combustion

of municipal solid waste, as illustrated in Figure 13. The rig

consists of a cylindrical chamber of 1.5 m length and 20 mm

internal diameter. The combustion pot was designed to hold

samples of simulated waste up to 0.5 m in height from the

grate (about 2 to 3 kg). Preheated primary air is introduced

through a distributor plate (i.e., the grate) at the bottom of

the chamber. The bed is ignited at the surface and the

process fronts advance from the top of the bed to the grate.

The chamber is mounted on a weighing scale to permit the

burning rates to be determined. Temperatures and gas

composition measurements at xed positions above the

grate are also made. An example of the temperature

measurements obtained during a typical preliminary

combustion experiment are shown in Figure 14. As the

thermocouples are located at xed positions within the fuel

bed, the approach of a reaction front to each position is

shown by the sharp increase in the temperature measured.

The corresponding change in the solid mass in the bed is

as illustrated in Figure 15.

The gas composition in the reactor at 430 mm above the

grate is as illustrated in Figure 16. The time for the increase

in CO (to above the range of the gas analyser) and CO2

concentrations and the reduction in O2 concentration in this

position correspond to the time for the bed temperature

rise as depicted in Figure 9. This notable change is the

ignition front and is due to the ignition of the gaseous

volatiles that are liberated during the pyrolysis process.

Figure 16 also shows that concentration of NOx in this

position is also seen to gradually increase to a maximum

value of approximately 150 ppm before reducing to about

100 ppm. The NOx concentration increases because the

gases coming up to the sampling point contain NOx that

is formed during devolatization of the waste. As the layer

of char close to the surface of the bed passes below the

sampling point, the concentration of NOx decreases slightly.

Trans IChemE, Vol 78, Part B, January 2000

This decrease in NOx concentration can be attributed to

the reduction of NOx in the char layer where CO and NOx

can react to form CO2 and N2 using the carbon in char

as catalyst for the reaction4.

Experimental investigations on the xed bed reactor

must be complemented by studies on a full-scale incinerator

plant. In addition, development work on a suitable mathematical model for incinerator bed combustion is far from

ideal without comparisons with experimental data and

measurements from a full-scale plant to conrm the validity

of the approach used in the model. Conventional measuring

techniques only allow full scale plant data to be obtained

from xed positions in the plant, mainly in the freeboard

region and not inside the burning bed. In-situ instantaneous

measurements of temperature, radiation and gas composition inside a burning bed in a full-scale incinerator plant

are therefore difcult and often restricted for many

reasonssize and integrity of the affordable measuring

instrument, safe access, etc.

The requirement for accurate solid bed combustion

data for the bed model validation, particularly within the

solid waste in large incinerator plants, has initiated the

Figure 14. Gas temperatures above the grate.

GOH et al.

28

Figure 15. Change in bed mass with time.

as it can be introduced into the incinerator with the waste

feed and tumbles along with the burning waste material.

The unit thus experiences the same high temperature conditions as the waste material, whilst measuring and recording

the temperatures, gas composition and heat uxes in the

burning bed. At the end of the process, the capsule can be

recovered at the incinerator exit, and the data stored in

its memory unit can be downloaded to a computer. The

recorded data or process variables can then be saved to

a common delimited le, or copied to another existing

commercial package such as a spreadsheet, statistical

package or a word processor. The electronic instrument

within the capsule can be reused by refurbishing its

protective casing and the whole measuring procedure can

be repeated several times so that the mean and standard

deviation of the measured process variables can be determined. Thus, data on the statistical variability can be

obtained through random motion of the unit with the waste

and not through standard measurements from a xed

point in the plant, e.g. a boiler ue.

The size of the instrument must be optimized to exploit

fully the thermal properties of the insulating material and

geometrical design. To reduce the heating rate to the core

of the instrument, the ratio of the exposed surface area

per unit volume must be minimized. For a simple thermal

insulation system, the heating rate by conduction to the

unit, q, assuming quasi-steady state, is given by:

q = 2 lp(To

Ti )

Figure 16. Gas concentration at 430 mm above the grate.

development and construction of a prototype measuring

instrument. This prototype instrument consists of a family

of built-in electronic sensors and a recording memory unit

or a mini chip installed in a refractory bre or ablating

resin capsule about 12 to 15 cm in diameter and length. It

can record a variety of measurementstemperature (using

thermocouples), radiative ux (using a thin sapphire rod

as a bre optic element), and gas composition (e.g. CO2,

CO, O2) (using a phosphoric acid based electrochemical

cell), for the duration of the test, e.g. one hour, depending

on the thermal properties of the capsule and unit design.

The instrument as shown in Figure 17 is uniquely different from the instruments currently commercially available

(ro

(hi ro ho ri )

2ri ro

+

ri ) ln(hi ro /ho ri ) (ho h1 )

(10)

where, ho, hi, ro and ri are the dimensions of the capsule

as depicted in Figure 17.

The operating time of the instrument in each test depends

on the rate at which heat is transferred to the core and the

maximum allowable operating temperature of the electronics within the unit. To increase the operating time while

simultaneously maintaining a low internal temperature, a

heat sink can be incorporated into the design. Preliminary

testing of the system in a furnace at more than 10008 C with

plaster material and water as the heat sink demonstrated

a working life of more than one hour as shown in Figure 18.

This is sufcient for measurements in an incinerator since

most incinerators operate with a residence time of about

one hour.

Figure 17. Schematic of the prototype heat resistant capsule.

Trans IChemE, Vol 78, Part B, January 2000

INCINERATOR BED COMBUSTION

Figure 18. Change in core temperature with time.

Figure 19. Onset of slag formation.

MEASUREMENTS AND MODELLING OF

SECONDARY JETS IN AN INCINERATOR

In present practice in incinerators, secondary air jets are

located above the bed to burn out hydrocarbons and carbon

monoxide. It is observed that slag tends to build up round

these jets, and in time the jets are often completely closed

off. The build-up of slag around the jets is a major problem

in the operation of incinerators. This slag can accumulate

to a thickness of about one metre with a weight of several

tonnes. The accumulation can reduce the availability of the

plant and it also gives a safety problem since injury can be

caused when the slag is removed by pneumatic drill during

maintenance operations. More importantly, the jets are

often located in a critical mixing region in the incinerator,

i.e. in the throat region between the furnace chamber and

the radiation shaft, and the thick slag layer alters the ow

dynamics in this critical region where secondary air or

recycled ue gases are introduced.

Slag is formed when molten y ash particles which

are entrained into the jet ow impinge near the mouth of

the nozzle. The angle of the turn of the entrained ow in

the vicinity of the jet mouth is particularly sharp. Some

of the particles will have sufcient inertia not to be dragged

along with the jet. The inertia of these particles will lead

to them impinging on the wall as shown in Figure 19.

Since some of the lower melting point particles can be

molten at this stage, they will stick rather than bounce

off, thus initiating the slag layer. Once the slag layer

begins accumulating, even particles that are not molten

or sticky are more likely to be captured5. The solid slag

will then gradually build up until the thermal resistance

of the layer is such that the surface is molten. Particles

with a higher melting point can then stick and the rate

of build-up can be expected to increase. Eventually, the

inertia of the particles causes the layer to build up until

the jet is closed off.

The ow eld around a high velocity jet penetrating a

low velocity cross ow has been experimentally investigated in a wind tunnel specially designed to minimize

the turbulent intensity at the main ow inlet. The ink dot

ow visualization technique6 was used to obtain visible

streak lines on acetate lms that reveal the surface ow

patterns.

Figure 20 shows the surface ow pattern of a 7 mm diameter nozzle with a jet momentum ux ratio of 65 where

the jet momentum ux ratio J, is dened as7:

J=

(u 2 )jet

(u 2 )flow

(11)

It is evident in Figure 20 that the uid from the main

ow around the jet is entrained towards the mouth of the jet.

To prevent the process of slag build-up, the ow eld

around the jet region must be reversed. This can be achieved

by tting a deector near the mouth of the jet to redirect

some of the ow parallel to the wall as depicted in Figure 21.

The purpose of the deector is to skim off the outer layer

of the jet and redirect it tangentially to the surface of the

wall.

Figure 20. Surface ow prole around a jet.

Trans IChemE, Vol 78, Part B, January 2000

29

GOH et al.

30

Figure 21. Annular deector to prevent slag formation.

Figure 22 shows a surface tracing of the same nozzle

and ow conditions, but with a deector attached. The

deector had an orice diameter of 0.9 jet diameters, and

a height of 0.6 jet diameters above the at plate. It can be

seen that the addition of the deector clearly alters the ow

eld. Under these ow conditions, the deector moves

the area of separation in front of the nozzle 1.9 jet diameters

away from the leading edge of the nozzle. There is now

an area around the nozzle swept out by redirected ow

due to the deector. The darkened area seen near the forward facing mouth of the nozzle is due to recirculation

of ow in this area, which prevents the ink from being

blown away from the mouth of the nozzle.

Computational Fluid Dynamics simulation under the

same conditions revealed the recirculation zone under

the deector as shown in Figure 23. The uid from the

cross ow containing molten particles is no longer being

entrained into the jet but is forced away by the ow from

the main jet, hence reducing the probability of particle

impingement near the mouth of the jet. This recirculation

is likely to depend on the height of the deector and hence

the deector distance from the nozzle must be optimized to

minimize the recirculation. Further design to improve and

optimize the deector design, and hot combustion experiments with simulated y ash, are currently under way.

CONCLUSIONS

Incineration is now accepted as the most environmentally friendly means of disposing of municipal solid

waste, and the design of incinerators must be optimized.

In the past, the design of incinerators has not been based

on fundamental understanding and modelling of the process, and empirical rules have had to be used. The topic

is now receiving increased attention from the engineering

research community, and the gap between fundamental

scientic principles and plant construction and operation

is now being bridged. Municipal waste incineration

research carried out at SUWIC is focused on improving

the design of municipal solid waste incinerators so that

future plants can be designed and operated in the most

effective manner possible.

Mixing is the key factor to ensure complete combustion

of solid waste in an incinerator burning bed. Existing grate

systems do not produce a uniform waste distribution,

resulting in channelling of ow through the bed and a

high excess air requirement. A mathematical mixing model,

based on the probability for a tracer particle to swap position with an adjacent tracer on a travelling grate, has been

developed. In parallel with the model development, the

grate mixing process has been quantitatively determined

by a series of systematic particle movement experiments

on scaled models of three of the most common industrial

grates. Comparison between experimental and computed

data has shown good agreement. The grate mixing process

can be quantied and accurately modelled in a systematic

numerical procedure based on `swap probability. The

importance of the probability parameter is that it uniquely

characterizes the `random walk mixing and is essentially

independent of factors such as particle position and grate

length.

A comprehensive model of the burning bed of municipal

solid waste based on the key processes in a waste bed has

been developed in order to provide more accurate data than

presently available on the boundary conditions at the bed

surface. This information is required for use in the CFD

modelling of the gas phase. In the next stage, the mixing

mathematical model will be incorporated into the present

bed model to improve the prediction of the incinerator bed

combustion. The model developed for dynamic simulation

of a xed bed has been expanded for modelling the steady

state combustion process on a travelling grate incinerator.

The present analysis is limited in certain respects and

Figure 22. Flow prole with annular deector.

Trans IChemE, Vol 78, Part B, January 2000

INCINERATOR BED COMBUSTION

Figure 23. Velocity vector plot for ow eld prediction.

improvement to the bed combustion model requires

combustion data acquired from a laboratory-scale xed

bed reactor as well as full-scale incinerator plant. To acquire

high quality plant data, a prototype measuring instrument

is currently being developed. This instrument can be used

to collect the plant data within the burning solid waste bed

in the incinerator.

Another key area to improve the incinerator plant efciency is to prevent the formation of slag. At present, slag

formation around the secondary air jets in the incinerator

poses a major operation problem. SUWICs research also

suggests that the formation of slag around secondary air

jets can be prevented by installing an annular deector

around the jets.

NOMENCLATURE

qo

Qs

ri

ro

(Rp)i

s

Si

Ti

Ts

Tg

To

t

u

ns

nx

V

VL

x

y

Yi

z

l

ls

s

i

Az

C(t,n)

Ds

F2

F3

hi

ho

Hs

j

J

m

M

n

nt

Pl

P(t,n)

qr

q

control volume cross-sectional area normal to z direction

tracer particle in cell n at time t

solid diffusion coefcient

fraction of the waste volume occupied by water which is replaced

by pores during drying

fraction of the waste volume occupied by volatile matter which

is replaced by pores during pyrolysis

capsule core height

capsule external height

solid sensible enthalpy

control volume

jet momentum ux ratio

tracer number

solid mass

cell number

total number of cells

swapping probability

random number generated for cell n at time t

radiative heat ux

conductive heat ux to capsule core

Trans IChemE, Vol 78, Part B, January 2000

viL

Dt

convective heat ux to ablating surface

source term for enthalpy balance equation

capsule core radius

capsule outer radius

rate of removal of component i, where i = 2, 3, 4, 5 or 6

standard deviation

source term for component mass balance equation

temperature of the internal surface

solid temperature

gas temperature

temperature of the external surface

time

uid velocity

solid velocity

moving grate velocity

total volume of solid

volume of solid material L, where L = A, B, C or D

axial direction

transverse direction

mass fraction of component i

direction normal to grate

thermal conductivity of the capsule material

solid effective thermal conductivity

uid density

solid density

density of component i

void fraction of material L

volume fraction of component i in material L

time increment

Subscripts

2

moisture

3

volatile matter

4

bound ash

5

xed carbon

6

free ash

A

dried, pyrolysed and gasied material

B

raw waste material

C

dried material

D

dried and pyrolysed material

31

GOH et al.

32

REFERENCES

1. Spiegel, M. R., 1972, Theory and Problems of Statistics, Shaums

Outline Series in Mathematics (McGraw-Hill Publishing Company)

Chapters 4, 13 and 14.

2. Goh, Y. R., Siddall, R. G., Nasserzadeh, V., Zakaria, R.,

Swithenbank, J., Lawrence, D., Garrod, N. and Jones, B., 1998,

Mathematical modelling of the waste incinerator burning bed, Journal

of the Institute of Energy, 71: 110118.

3. Kuo, T. J. and Essenhigh, R. H., 1970, Combustion and emission

phenomena in incinerators: development of physical and mathematical models of incinerators, Proc 1970 Nat Incinerator Conf

(ASME, New York), 261271.

4. Goel, S., Sarom, A. F. and Lu, J., 1996, A new approach to studying

pore diffusivity during char combustion at FBC conditions, 26th

Symposium (International) on Combustion (The Combustion Institute), 31273155.

5. Glen, N. F. and Howarth, J. H., 1988, Modelling refuse incineration

fouling, 2nd. UK National Conference on Heat Transfer (Glasgow,

IMechE).

6. Langston, L. S. and Boyle, M. T., 1982, New surface-streamline ow

visualisation technique, Journal of Fluid Mechanics, 125: 5357.

7. Ryu, C. K. and Choi, S., 1995, Design Consideration for the Cross Jet

Air Mixing in the Municipal Solid Waste Incinerators HTD 317-2,

American Society of Mechanical Engineers, Heat Transfer Division,

205212.

ACKNOWLEDGEMENT

The authors would like to thank the Engineering and Physical Sciences

Research Council (EPSRC), Kingseld Electronics Ltd., Shefeld Heat

and Power Ltd., Shefeld Municipal Solid Waste Incinerator Plant UK and

ABB Corporate Research (Switzerland) for their nancial and technical

contributions to this project.

ADDRESS

Correspondence concerning this paper should be addressed to

Dr Y. R. Goh, Department of Chemical and Process Engineering,

University of Shefeld, Mappin Street, Shefeld, S1 3JD, UK.

This paper was presented at the 2nd International Symposium on

Incineration and Flue Gas Treatment Technologies, organized by IChemE

and held at the University of Shefeld, UK, 46 July 1999.

Trans IChemE, Vol 78, Part B, January 2000

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Actividad 3 - Compressed PDFDocument7 pagesActividad 3 - Compressed PDFLUIS LIBROSNo ratings yet

- Air Standard CyclesDocument45 pagesAir Standard CyclesVedant ChoudharyNo ratings yet

- Technical: CatalogueDocument120 pagesTechnical: CatalogueNikola VeleskiNo ratings yet

- Burners: Air-Steam Atomizing Oil BurnersDocument8 pagesBurners: Air-Steam Atomizing Oil BurnersAhmed GadNo ratings yet

- Effective Permeability: Reservoir Rock PropertiesDocument17 pagesEffective Permeability: Reservoir Rock PropertiesAnant BajpaiNo ratings yet

- H Chemistry All 2013Document36 pagesH Chemistry All 2013Ross TaylorNo ratings yet

- Air Pollution in UAEDocument8 pagesAir Pollution in UAEKanwal SanyaNo ratings yet

- CHPRCS01001 Prasad QuestionsDocument4 pagesCHPRCS01001 Prasad QuestionsAshish SrivastavaNo ratings yet

- Bureau of Fire Protection: Republic of The Philippines Department of The Interior and Local GovernmentDocument69 pagesBureau of Fire Protection: Republic of The Philippines Department of The Interior and Local Governmentdiona macasaquitNo ratings yet

- Chemistry Class 10 Gateway To Science (Sushmita Ma'amDocument224 pagesChemistry Class 10 Gateway To Science (Sushmita Ma'amdarth92vader100% (4)

- SDS AbilifyDocument41 pagesSDS AbilifyCH NarimaneNo ratings yet

- Air Cooler CleanerDocument19 pagesAir Cooler CleanerArdyas Wisnu BaskoroNo ratings yet

- Ldce 2022Document13 pagesLdce 2022Ramesh TammineniNo ratings yet

- Integrated Training Program / Phase B - Flare Protection Systems Page 1 of 33Document33 pagesIntegrated Training Program / Phase B - Flare Protection Systems Page 1 of 33metasoniko2014No ratings yet

- G3508 - 600kvaDocument7 pagesG3508 - 600kvaJim Patrick ChombaNo ratings yet

- Answers To End-Of-Chapter Questions: Chapter 11 Petrochemicals and PolymersDocument2 pagesAnswers To End-Of-Chapter Questions: Chapter 11 Petrochemicals and PolymersMP3 MusicNo ratings yet

- HSE - Catering Information Sheet No 10 Rev1 PDFDocument4 pagesHSE - Catering Information Sheet No 10 Rev1 PDFAdamNo ratings yet

- Determination of TOC in Water and Soil SamplesDocument25 pagesDetermination of TOC in Water and Soil SamplesDipmalya BasakNo ratings yet

- Grimório - Modelo - GURPSDocument2 pagesGrimório - Modelo - GURPSRicardo AlexandreNo ratings yet

- FIRE TECH. QuestionnaireDocument7 pagesFIRE TECH. QuestionnaireDioner Ray100% (3)

- Polaris InfoDocument4 pagesPolaris InfoSankuri RamNo ratings yet

- DSPA Product BrochureDocument4 pagesDSPA Product BrochureTri NguyenNo ratings yet

- FMDS0801Document18 pagesFMDS0801ALAN CARDOSONo ratings yet

- 6 - 10 - 2015 10 - 34 - 52 Am - 41200399Document51 pages6 - 10 - 2015 10 - 34 - 52 Am - 41200399Aashu chaudharyNo ratings yet

- Solid Rocket Propellant - An Overview - ScienceDirect TopicsDocument10 pagesSolid Rocket Propellant - An Overview - ScienceDirect TopicsTESFAMICHAELNo ratings yet

- Lesson V Automobile Engine, and The Four-Stroke CycleDocument5 pagesLesson V Automobile Engine, and The Four-Stroke CycleNicolas AntiguaNo ratings yet

- FM Print Plant SafetyDocument26 pagesFM Print Plant SafetyEvert AlexNo ratings yet

- Exothermic and Endothermic ReactionsDocument18 pagesExothermic and Endothermic ReactionsGolden TrioNo ratings yet

- Engineering Vol 69 1900-06-15Document35 pagesEngineering Vol 69 1900-06-15ian_newNo ratings yet