Professional Documents

Culture Documents

Asian Granito India LTD

Uploaded by

Sharukh Khan0 ratings0% found this document useful (0 votes)

51 views2 pagesAsian granito

Original Title

Asian Granito India Ltd

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAsian granito

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

51 views2 pagesAsian Granito India LTD

Uploaded by

Sharukh KhanAsian granito

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

1. Asian Granito India Ltd.

2. Euro Ceramics Ltd.

3. Kajaria Ceramics Ltd.

4. Murudeshwar Ceramics Ltd.

5. Nitco Ltd.

6. Orient Bell Ltd.

7. Regency Ceramics Ltd.

8. Restile Ceramics Ltd.

9. Somany Ceramics Ltd.

Private Companies:

1. Regent Granito (India) Ltd.

2. Romano Tiles Pvt. Ltd.

3. Varmora Granito Pvt. Ltd.

Overall picture of the Industry.

Ceramic tiles as a product segment has grown to a sizeable chunk today at approximately 680 Millions Square

meters production per annum. However, the potential seems to be great, particularly as the housing sector, retail, IT

& BPO sectors have been witnessing an unprecedented boom in recent times.

The key drivers for the ceramic tiles in India are the boom in housing sector coupled by government policies fuelling

strong growth in housing sector. The retail boom in the Indian economy has also influenced the demand for higher

end products. Overall the bullish growth estimates in the Indian economy has significantly influenced the growth of

the Indian Ceramic tile industry.

The main product segments are the Wall tile, Floor tile, Vitrified tile and Industrial tile segments. The market shares

(in value terms) are 20%, 23% 50%, and 7% respectively for Wall, Floor, Vitrified, and Industrial tiles. The tiles are

available in a wide variety of designs, textures and surface effects. They cater to tastes as varied from rustics to

contemporary marble designs in super glossy mirror finishes.

Both, traditional methods of manufacturing (tunnel ) and the latest single fast firing methods are deployed in

manufacturing. Some of the latest trends in manufacturing methods can be seen in India.

The industry also enjoys the unique distinction of being highly indigenous with an abundance of raw materials,

technical skills, infrastructural facilities despite being fairly capital intensive. A total of over 5,50,000 people are

employed in the sector. Out of this, 50,000 people are directly employed and 5,00,000 are indirectly associated. The

potential is huge considering the per capita consumption of ceramic tiles in India. Currently it is at 0.50 square meters

per person in comparison to over 2 square meters per person for like countries like China, Brazil and Malaysia

Where we stand and what we must do?

As a foreign exchange earner or a global player, Indian Tile industry has captured the attention of the world in the

ceramic tiles segment. To compete internationally, our plants must be geared up to large units currently operating in

China and Turkey are driven by economies of scale. These will also help us in lowering our cost of production

significantly. Also, infrastructural support is a key factor that determines the speed of growth. Better infrastructure will

bring in better growth in terms of consistency and sustenance. Freight, supply of power and gas remains the key

cost-related issues impacting the industry. Availability, consistent supply and reasonable rates are extremely

important for the growth of the ceramic tile industry.

Also, the prevailing anomalies pertaining to Basic Customs Duty on import of ceramic tiles from China and raw

materials imported from abroad need to be corrected to prevent dumping of tiles from China. Rural thrust should be

enhanced by favorable excise duty and MRP structure

You might also like

- Porter's Five Forces Analysis of Cement IndustryDocument8 pagesPorter's Five Forces Analysis of Cement Industryjanvii rayani100% (2)

- Internship Report Part2Document40 pagesInternship Report Part2ayshwarya sudheer100% (1)

- Cement Industry in IndiaDocument19 pagesCement Industry in IndiaShobhit Chandak100% (14)

- Plywood Industry ProfileDocument28 pagesPlywood Industry ProfileRheinhart PahilaNo ratings yet

- Channel of DistributionDocument122 pagesChannel of Distributioncursorkkd100% (1)

- Week 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student HandoutDocument3 pagesWeek 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student Handoutdwkwhdq dwdNo ratings yet

- Apm p5 Course NotesDocument267 pagesApm p5 Course NotesMusumbulwe Sue MambweNo ratings yet

- A Project Report On Ceramic Tile IndustryDocument44 pagesA Project Report On Ceramic Tile IndustryRavi KiranNo ratings yet

- MCL OrganizationDocument30 pagesMCL OrganizationDeekshith KumarNo ratings yet

- Ceramic Tiles Industry in IndiaDocument9 pagesCeramic Tiles Industry in Indiaaltaf_catsNo ratings yet

- Sai RamDocument43 pagesSai Ramnirmala periasamyNo ratings yet

- Highlights of Ceramics IndustryDocument5 pagesHighlights of Ceramics IndustryVaibhav P ShahNo ratings yet

- A Summer Training Report On Cramic TileDocument25 pagesA Summer Training Report On Cramic TileVivek Arya0% (1)

- Consumer Awareness About Sai Ram CeramicsDocument13 pagesConsumer Awareness About Sai Ram Ceramicsnirmala periasamyNo ratings yet

- Introduction of Ceramic Tile IndustryDocument72 pagesIntroduction of Ceramic Tile IndustryYogesh RathiNo ratings yet

- Plywood IndustryDocument13 pagesPlywood Industryhardik.patel096486100% (1)

- Global Scenerio: Industry ProfileDocument6 pagesGlobal Scenerio: Industry Profilegreshma jayakumarNo ratings yet

- Fiber Cement Market AnalysisDocument5 pagesFiber Cement Market Analysismenilik chanyalew NigatuNo ratings yet

- Sanitaryware IndustryDocument4 pagesSanitaryware IndustrySunil BajaadNo ratings yet

- Industry Profile: History of Ceramic TilesDocument32 pagesIndustry Profile: History of Ceramic TilesstudioustiaNo ratings yet

- A Project On Dealers Perception On Kajaria Ceramics CoimbatoreDocument47 pagesA Project On Dealers Perception On Kajaria Ceramics CoimbatoreMohamed SanferNo ratings yet

- As Per The Requirement of Clause 49 of The Listing Agreement The Management Discussion& Analysis Report Is As Under: Industry Structure & DevelopmentDocument5 pagesAs Per The Requirement of Clause 49 of The Listing Agreement The Management Discussion& Analysis Report Is As Under: Industry Structure & DevelopmentSandeep ThakurNo ratings yet

- Ceramic Tiles IndustryDocument5 pagesCeramic Tiles IndustryAlisha AliNo ratings yet

- Ceramic Tiles IndustryDocument6 pagesCeramic Tiles IndustryHiren JoshiNo ratings yet

- Economics Assignment KunalKathuriaDocument5 pagesEconomics Assignment KunalKathuriaKunal KathuriaNo ratings yet

- Feature RoofingDocument3 pagesFeature RoofingLavina KinnyNo ratings yet

- Indian Cement Industry: Price: Rs500Document3 pagesIndian Cement Industry: Price: Rs500pooja singhNo ratings yet

- ChettinadDocument52 pagesChettinadVinodh KumarNo ratings yet

- Analysis of Ceramic IndustryDocument66 pagesAnalysis of Ceramic IndustryShefali Singh67% (6)

- Literature Review of Indian Cement IndustryDocument8 pagesLiterature Review of Indian Cement Industryc5pgcqzv100% (1)

- Ritik Goud Mm2 ProjectDocument5 pagesRitik Goud Mm2 ProjectCHINMAY KEKRE Student, Jaipuria IndoreNo ratings yet

- TAPMI School of Business: Manipal University, JaipurDocument26 pagesTAPMI School of Business: Manipal University, Jaipurvivek guptaNo ratings yet

- Spartek Ceramic India LimitedDocument22 pagesSpartek Ceramic India LimitedBhumika VajaNo ratings yet

- Research For RRL 1Document1 pageResearch For RRL 1Raella MendezNo ratings yet

- Kafle Report 1Document71 pagesKafle Report 1arjun kafleNo ratings yet

- Hiru VCXDocument21 pagesHiru VCXYahya NiaziNo ratings yet

- Analysis of The Indian Cement IndustryDocument19 pagesAnalysis of The Indian Cement Industryashish sawantNo ratings yet

- Ceramics Home Decor in India: A New Business ApproachDocument17 pagesCeramics Home Decor in India: A New Business ApproachvidushiNo ratings yet

- The Cement Industry Is One of The Main Beneficiaries of The Infrastructure BoomDocument9 pagesThe Cement Industry Is One of The Main Beneficiaries of The Infrastructure BoomSyedFaisalHasanShahNo ratings yet

- Cement Industry: Factor EndowmentsDocument1 pageCement Industry: Factor Endowmentsgokul9rovNo ratings yet

- 6th Lesson To Investment ManagementDocument4 pages6th Lesson To Investment ManagementWynnie RondonNo ratings yet

- Indian Cement IndustryDocument7 pagesIndian Cement IndustrymayankNo ratings yet

- 07 Ultratech CementDocument16 pages07 Ultratech Cementkohinoor_roy5447No ratings yet

- Furniture IndustryDocument45 pagesFurniture IndustrySara Ghulam Muhammed Sheikha0% (2)

- 09 Chapter 2Document62 pages09 Chapter 2Chirag KothiyaNo ratings yet

- Sector Industry Profile For Attracting FDI: Ceramic Industry of BangladeshDocument19 pagesSector Industry Profile For Attracting FDI: Ceramic Industry of BangladeshYeamin HossainNo ratings yet

- Chapter - 1: DMS BITM, BallariDocument44 pagesChapter - 1: DMS BITM, BallariHarshil HundiaNo ratings yet

- Guruveda Marketing ProjectDocument44 pagesGuruveda Marketing ProjectPRIYAM XEROXNo ratings yet

- Kum.m.h.gardi School of It & ManagementDocument60 pagesKum.m.h.gardi School of It & ManagementJay PadhNo ratings yet

- Cement Industry in India PDFDocument19 pagesCement Industry in India PDFVrushabh ShelkarNo ratings yet

- Spartek Ceramics India Limited: N VenkiteswaranDocument16 pagesSpartek Ceramics India Limited: N VenkiteswaranchandnadasNo ratings yet

- Triology 89 IIMK Value Added GlassDocument11 pagesTriology 89 IIMK Value Added Glasstreddy249No ratings yet

- Ambuja Main FileDocument60 pagesAmbuja Main Filemicropoint2524No ratings yet

- A Study On Financial Analysis of Ultratech Cement Industry: Dr. C. Vadivel, K. Satya BhamaDocument3 pagesA Study On Financial Analysis of Ultratech Cement Industry: Dr. C. Vadivel, K. Satya BhamaSIVARANJANI PNo ratings yet

- Ceramic TilesDocument48 pagesCeramic TilesHarshil HundiaNo ratings yet

- Planning Comision SummaryDocument11 pagesPlanning Comision Summarykumud_nishadNo ratings yet

- Paper Presentation On Developing Supply Chain Management Stratergy For Indian Foundry SectorDocument14 pagesPaper Presentation On Developing Supply Chain Management Stratergy For Indian Foundry SectorGaurao WarungaseNo ratings yet

- Dot.compradors: Power and Policy in the Development of the Indian Software IndustryFrom EverandDot.compradors: Power and Policy in the Development of the Indian Software IndustryNo ratings yet

- Real Estate Investing: Building Wealth with Property Investments: Expert Advice for Professionals: A Series on Industry-Specific Guidance, #2From EverandReal Estate Investing: Building Wealth with Property Investments: Expert Advice for Professionals: A Series on Industry-Specific Guidance, #2No ratings yet

- The Biometric Industry Report - Forecasts and Analysis to 2006From EverandThe Biometric Industry Report - Forecasts and Analysis to 2006M LockieNo ratings yet

- Multispan LC 2046 Length Counter PDFDocument2 pagesMultispan LC 2046 Length Counter PDFvinod kumarNo ratings yet

- Address MappingDocument26 pagesAddress MappingLokesh KumarNo ratings yet

- ARUP Project UpdateDocument5 pagesARUP Project UpdateMark Erwin SalduaNo ratings yet

- Mat Boundary Spring Generator With KX Ky KZ KMX KMy KMZDocument3 pagesMat Boundary Spring Generator With KX Ky KZ KMX KMy KMZcesar rodriguezNo ratings yet

- Escario Vs NLRCDocument10 pagesEscario Vs NLRCnat_wmsu2010No ratings yet

- Shubham RBSEDocument13 pagesShubham RBSEShubham Singh RathoreNo ratings yet

- T1500Z / T2500Z: Coated Cermet Grades With Brilliant Coat For Steel TurningDocument16 pagesT1500Z / T2500Z: Coated Cermet Grades With Brilliant Coat For Steel TurninghosseinNo ratings yet

- Channel Tables1Document17 pagesChannel Tables1erajayagrawalNo ratings yet

- Selvan CVDocument4 pagesSelvan CVsuman_civilNo ratings yet

- Shahroz Khan CVDocument5 pagesShahroz Khan CVsid202pkNo ratings yet

- American AccentDocument40 pagesAmerican AccentTimir Naha67% (3)

- MSDS - Tuff-Krete HD - Part DDocument6 pagesMSDS - Tuff-Krete HD - Part DAl GuinitaranNo ratings yet

- Unit 2Document97 pagesUnit 2MOHAN RuttalaNo ratings yet

- Republic of The Philippines National Capital Judicial Region Regional Trial Court Manila, Branch 1Document4 pagesRepublic of The Philippines National Capital Judicial Region Regional Trial Court Manila, Branch 1brendamanganaanNo ratings yet

- Cs8792 Cns Unit 1Document35 pagesCs8792 Cns Unit 1Manikandan JNo ratings yet

- Recommended Practices For Developing An Industrial Control Systems Cybersecurity Incident Response CapabilityDocument49 pagesRecommended Practices For Developing An Industrial Control Systems Cybersecurity Incident Response CapabilityJohn DavisonNo ratings yet

- Digital LiteracyDocument19 pagesDigital Literacynagasms100% (1)

- General Field Definitions PlusDocument9 pagesGeneral Field Definitions PlusOscar Alberto ZambranoNo ratings yet

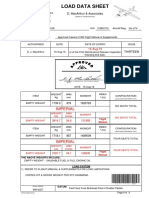

- Load Data Sheet: ImperialDocument3 pagesLoad Data Sheet: ImperialLaurean Cub BlankNo ratings yet

- Guide For Overseas Applicants IRELAND PDFDocument29 pagesGuide For Overseas Applicants IRELAND PDFJasonLeeNo ratings yet

- Government of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Document2 pagesGovernment of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Satyaki Prasad MaitiNo ratings yet

- CANELA Learning Activity - NSPE Code of EthicsDocument4 pagesCANELA Learning Activity - NSPE Code of EthicsChristian CanelaNo ratings yet

- Personal Best B1+ Unit 1 Reading TestDocument2 pagesPersonal Best B1+ Unit 1 Reading TestFy FyNo ratings yet

- Oem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Document43 pagesOem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Farhad FarajyanNo ratings yet

- Research Article: Finite Element Simulation of Medium-Range Blast Loading Using LS-DYNADocument10 pagesResearch Article: Finite Element Simulation of Medium-Range Blast Loading Using LS-DYNAAnonymous cgcKzFtXNo ratings yet

- Interruptions - 02.03.2023Document2 pagesInterruptions - 02.03.2023Jeff JeffNo ratings yet

- Agricultural Economics 1916Document932 pagesAgricultural Economics 1916OceanNo ratings yet

- PLT Lecture NotesDocument5 pagesPLT Lecture NotesRamzi AbdochNo ratings yet