Professional Documents

Culture Documents

Sewerage Code of Australia: Second Edition

Uploaded by

abhijithavalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sewerage Code of Australia: Second Edition

Uploaded by

abhijithavalCopyright:

Available Formats

Sewerage Code of Australia

Part 2: Products and Materials

Second Edition

Version 2.3

WSA 022002-2.3

122

CONTENTS

10 PRODUCTS AND MATERIALS OVERVIEW

10.1 PURPOSE

10.2 SCOPE

10.3 RESPONSIBILITIES

10.3.1 Water Agency

10.3.2 Designer

10.3.3 Constructor

10.3.4 Purchaser

10.4 PRODUCT AND MATERIAL STANDARDS AND SPECIFICATIONS

10.4.1 Product standards

10.4.2 Purchase specifications

10.4.3 Purchase specificationsAlternatives

10.5 QUALITY ASSURANCE

10.5.1 Default requirement

10.5.2 Additional information on quality assurance

10.5.3 Innovative products and materials

10.6 SELECTION GUIDE FOR PIPELINE SYSTEMS

10.7 ADDITIONAL PRODUCT AND MATERIAL INFORMATION

APPENDIX F QUALITY ASSURANCE OF PRODUCTS AND MATERIALS

F1 GENERAL

F2 QUALITY ASSURANCE OPTIONS

F2.1 ISO 9000 quality management system certification

F2.2 Product certification

F2.2.1 Product certification Type 1

F2.2.2 Product certification Type 3

F2.2.3 Product certification Type 5

F2.3 Suppliers declaration of conformance

F2.4 Second party verification

F3 FACTORS INFLUENCING SELECTION OF QUALITY ASSURANCE OPTIONS

F3.1 General factors

F3.2 Likelihood of manufacturing non-conformance

F3.3 Likelihood of failure of pipeline system from a product non-conformance

F3.4 Consequences of failure

F3.5 Product specification

F3.6 Project magnitude / management

F3.7 Innovative products

F4 SELECTING THE QUALITY ASSURANCE OPTION

F4.1 General factors

F4.2 Product certification

F4.2.1 General

F4.2.2 Type 1

F4.2.3 Type 3

F4.2.4 Type 5

F4.3 ISO 9000 quality management system certification

F4.4 Suppliers declaration of conformance

F4.5 Second party verification

123

123

123

123

123

123

124

124

124

124

124

125

125

125

125

125

126

126

140

140

140

140

140

141

141

141

142

142

142

142

142

143

143

143

143

143

143

143

144

144

144

144

144

145

145

145

TABLES

TABLE 10.1 PRINCIPAL GRAVITY SEWER PIPELINE SYSTEMS

TABLE 10.2 PRINCIPAL SEWERAGE GRAVITY PIPELINE SYSTEMS - PRECAUTIONS,

LIMITATIONS ADVANTAGES AND DISADVANTAGES

TABLE 10.3 PRINCIPAL SEWERAGE PRESSURE PIPELINE SYSTEMS

TABLE 10.4 PRINCIPAL SEWERAGE PRESSURE PIPELINE SYSTEMS PRECAUTIONS, LIMITATIONS ADVANTAGES AND DISADVANTAGES

COPYRIGHT

127

128

135

136

123

WSA 022002-2.3

10 PRODUCTS AND MATERIALS OVERVIEW

10.1 PURPOSE

Water Agencies typically expect sewerage infrastructure to have a life of at least 100

years. This requirement reflects community expectations of Agencies operational and

financial performance. The performance of a sewer system significantly depends on the

attributes of the materials and products used in its construction. The appropriate selection

of pipeline system products and materials is paramount to achieving life expectancies.

NOTE: The term products and materials will simply be referred to as products from this point

forward since it could be argued that materials are in fact a subset of products.

Unless otherwise specified by the Water Agency, products should comply with recognised

national or industry standards. The involvement of third party certification bodies to

independently verify conformance is stipulated for many products.

The purpose of Part 2 is to:

(a)

provide information and recommendations concerning products to assist policymakers, planners, Designers, Constructors, manufacturers, suppliers and third party

certification bodies;

(b)

nominate default product standards; and

(c)

provide default purchase specifications for products.

Product and Material Information and Guidance and Purchase Specifications can be found

on the WSAA website at www.wsaa.asn.au.

This edition of WSA 02 does not include a "Product Atlas". For products that

have been formally appraised by WSAA, the website provides details of the

appraisal. The website does not provide a listing of approved products and

suppliers. Individual Agencies may operate their own product approval or

authorisation system.

10.2 SCOPE

This Part provides information, standards and purchase specifications for products

commonly used in sewer construction and listed on the WSAA website www.wsaa.asn.au.

Products may be added or deleted as the need arises. The WSAA website should be

accessed to ensure that current information is used.

10.3 RESPONSIBILITIES

10.3.1 Water Agency

Each Water Agency should be responsible for:

(a)

Accepting or excluding products listed in this Part as being suitable for use in its area

of responsibility.

(b)

Nominating variations to the default purchase specifications and quality assurance

requirements.

10.3.2 Designer

Except where a project or Agency agreement or specification states otherwise, the

Designer should be deemed responsible for selecting the most appropriate / suitable

products. In some cases, products may have to be authorised by the Water Agency.

Product requirements, including attributes such as protective coating, pressure and/or

stiffness class, joint type etc should be stated in the Design Drawings and/or Specification.

COPYRIGHT

WSA 022002-2.3

124

10.3.3 Constructor

Constructors should use only such products that are nominated in the Specification and

Design Drawings.

10.3.4 Purchaser

Unless otherwise specified by the Water Agency, the default purchase specifications listed

on the WSAA website (Refer to Clause 10.4.2) should be used for specifying product

requirements.

The purchaser should be responsible for obtaining the suppliers declaration that products

conform to purchase specifications.

The Constructor is frequently the purchaser of products.

Where third party certification is specified, the accredited certification body is

deemed to be responsible for licensing the manufacturer to use the

certification bodys mark and ensuring correct use of the mark

The supplier may or may not be the manufacturer of the product.

10.4 PRODUCT AND MATERIAL STANDARDS AND SPECIFICATIONS

10.4.1 Product standards

A product standard is generally a document prepared by a standards body recognised

nationally, regionally or internationally such as Standards Australia, International

Organisation for Standardisation (ISO), European Committee for Standardisation (CEN) or

a water industry body such as PIPA, WRc (UK) or AWWA (USA). The standard typically

specifies product attributes such as dimensions, materials of construction, performance

requirements, production and factory quality control and product testing.

The product standard should be adopted as the technical specification for manufacture and

the reference for third-party certification of product conformance.

For most products used in the water industry, appropriate manufacturing standards exist.

These standards (including overseas standards) may be purchased from Standards

Australia.

If, at any time, a suitable product standard is not available to meet WSAA members needs,

WSAA may prepare and publish a product standard. This generally will be an interim

solution, pending publication of a suitable Australian standard. WSAA product standards

are listed on the WSAA website.

Examples of product standards are AS 2638.2Gate valves for waterworks purposes

Resilient seated; AS/NZS 1477PVC pipes and fittings for pressure applications;

BS EN 545Ductile iron pipes, fittings, accessories and their joints for water pipelines

Requirements and test methods; WSA 103Butterfly valves.

In some cases more than one product standard is deemed by this Code to be suitable for

use e.g. for ductile iron pipe, AS/NZS 2280 or BS EN 545 due to the availability of

acceptable products from overseas. Each Water Agency should be responsible for

nominating which options are acceptable for use.

10.4.2 Purchase specifications

Purchase specifications are the means for purchasers to specify their requirements to

suppliers. In most cases, the purchase specification references a relevant product standard

and nominates quality assurance requirements. The purchaser should nominate options

allowed by the product standard e.g. protective coatings, pressure class, stiffness class,

joint type etc.

COPYRIGHT

125

WSA 022002-2.3

WSAA purchase specifications are listed on the WSAA website.

Given that specifications are liable to change, users should regularly review the revision

status of specifications. The WSAA website contains a list of recent additions or variations

to specifications.

10.4.3 Purchase specificationsAlternatives

In some cases, typically for products of overseas origin, more than one product standard

has been deemed by WSAA to be applicable to a product type. A matching alternative

purchase specification (i.e. additional to the default) is listed on the website e.g. for ductile

iron pipes and fittings, alternative specification WSA 201 references EN 545.

Each Water Agency shall be responsible for nominating which alternative specification(s)

are acceptable.

Where more than one purchase specification is listed for a product (e.g. ductile iron), the

default specification shall be deemed to apply, unless otherwise specified by the Water

Agency.

WSAA product standards and purchase specifications are published by the

Water Services Association of Australia Inc. on the understanding that:

The Water Services Association of Australia Inc. and individual contributors are

not responsible for the results of any action taken on the basis of information in

the WSAA product standards and/or purchase specifications, nor any errors or

omissions.

The Water Services Association of Australia Inc. and individual contributors

disclaim all and any liability to any person in respect of anything, and the

consequences of anything, done or omitted to be done by a person in reliance

upon the whole or any part of a WSAA product standard or purchase

specification.

It should also be noted that WSAA product specifications have no reference to

any contractual requirements or general terms and conditions that may be

required by purchasers. Such contract details are the responsibility of the

individual purchaser.

10.5 QUALITY ASSURANCE

10.5.1 Default requirement

Unless otherwise specified by the Water Agency, the default quality assurance option

nominated in the product purchase specification should apply. Where third party

certification is specified, the certification body (CB) should be accredited by JAS-ANZ or by

an equivalent overseas accreditation body.

When placing an order, the purchaser should ensure that the supplier is aware of the

specified quality assurance requirement.

10.5.2 Additional information on quality assurance

Additional information concerning material and product quality assurance is given in

Appendix F.

10.5.3 Innovative products and materials

Innovative products are deemed to be those for which a recorded history of successful

performance under a range of Australian installation and operating conditions is not

available and for which a default or alternative specification is not included in this Code.

Depending on the outcomes of a product appraisal, such products may be recommended

COPYRIGHT

WSA 022002-2.3

126

for provisional acceptance. Nevertheless, each Water Agency is responsible for authorising

innovative or non-standard products.

It is intended that the WSAA product appraisal process facilitate information

sharing and ultimate standardisation of innovative products.

The WSAA website displays reports of products which have been assessed by

the WSAA appraisal process as being suitable for use. Following satisfactory

appraisal, a purchase specification may be published on the website and the

product is thus no longer deemed to be innovative. Products assessed as

unsuitable for use are not published in the public domain, but referred to the

applicant for further action.

Disclaimer

The WSAA product appraisal process involves assessment of product

attributes and expected performance when installed in accordance with the

manufacturers or other nominated recommendations. Reasonable measures

are taken by the WSAA network to assess suitability for use in conditions

commonly encountered in Australia. However, responsibility for use of

appraised products and materials is the individual agencies, users or

specifiers.

To view the current disclaimer of liability for product appraisal refer to the

WSAA website.

10.6 SELECTION GUIDE FOR PIPELINE SYSTEMS

Tables 10.1 and 10.2 provide general information on availability of sizes, jointing and fitting

options and comparisons of principal pipeline options. The objective of this comparison is

to assist specifiers make informed decisions on material selection. Life cycle costing as per

AS/NZS 4536 should be considered as part of the decision making process. More detailed

information on products is provided on the WSAA website.

When in doubt, specialist advice should be obtained, including from the pipe manufacturer.

10.7 ADDITIONAL PRODUCT AND MATERIAL INFORMATION

Additional information on product attributes, uses, benefits and limitations is given on the

WSAA website. The information is not intended for use in a contractual sense but serves

as a guide to specifiers, Designers, Constructors and other interested parties.

Information will be updated in line with market developments and as further feedback on

product performance is received.

COPYRIGHT

127

WSA 022002-2.3

TABLE 10. 1

PRINCIPAL GRAVITY SEWER PIPELINE SYSTEMS

Informative

PIPE

CONVENTIONA

L

PIPE SIZES

TYPICAL PIPE

CLASSES

JOINTING

METHODS

FITTINGS

DN

Crushing strengths

DN 150 34 kN/m

VC

150, 225, 300,

400, 450, 500,

600, 700, 800,

1000

DN 200-250

Classes 160, 200

DN 300-350

Classes 120, 160, 200

DN 400-500

Classes 120, 160

Rubber ring seal

Polypropylene

couplings with

rubber lip seal

VC bends, junctions,

connectors and

adaptors

DN 600-1000

Classes 95, 120

PVC

Reinforced

concrete

(PVC lined)

GRP

100, 150, 225,

300, 375, 450

600, 750, 900,

1050, 1200,

1350, 1500,

1800, 2100

300, 375, 450,

525, 600, 675,

750, 900,

1000, 1200

SN 6 or 10 for DN 100

SN 4 or 8 for other sizes

Class 3

Class 4

PE

Solvent cement

weld

SN 5000

SN 10000

Rubber ring seal

GRP couplings

with rubber lip

seal

MHs, saddles for

slope and square

junctions, connectors

and other

configurations

available

SN 15000

SN 8

SN 10

Electrofusion fittings

DN 110 DN 450

Electrofusion

Butt fusion

SN 16

PVC bends, junctions,

connectors and

adaptors

Fittings not readily

available

Pipes with inlets,

bends and specials

manufactured to order

Stiffness classes

Stiffness classes

110, 125, 160,

180, 225, 280,

315, 450, 630

Rubber ring seal

PE plain end for butt

fusion and

electrofusion

Flanged fittings

Mechanical fittings

ABS

AS 3518

300,

400,

575,

750,

350, 375,

450, 500,

600, 650,

850

Stiffness and equivalent

pressure class

SN 6 ( PN 6.6)

SN 8 ( PN 7.3)

Rubber ring seal

Solvent cement

weld

SN 10 ( PN 7.8)

DI

Cement

mortar

lined

100,

225,

375,

600,

150, 200,

250, 300,

450, 500,

750

Pipe wall thickness

classes

Flanged fittings

Fabricated fittings for

larger diameters

Rubber ring seal

Ductile iron cement

mortar lined (DICL)

Flanged

Fusion bonded

polymer encapsulated

ductile iron

K9

K12 - flanged and

special structural design

Limited range of

fittings

NOTE: For special applications in large diameters, steel pipe lined with PE or high alumina cement

may be suitable.

COPYRIGHT

WSA 022002-2.3

128

TABLE 10.2

PRINCIPAL SEWERAGE GRAVITY PIPELINE SYSTEMS

PRECAUTIONS, LIMITATIONS ADVANTAGES AND DISADVANTAGES

All pipelines may be damaged, rendered structurally unsound or have inadequate joint performance due to incorrect

installation practices

All pipes and fittings may be damaged prior to installation by inappropriate transportation, storage and handling practices

GENERAL

PRECAUTIONS

All pipelines should be constructed by trained and certified pipelayers with a system of documentation for quality control of

installation in place

All pipelines can be adversely affected in both the short and long term by third party damage to the pipe or corrosion

protection system

All pipes require verification of the internal diameter for hydraulic designthe nominal size does not necessarily represent

accurately the internal diameter

Larger diameter flexible pipelines require knowledge of the soil properties along the route of the pipeline and at the intended

depth of the pipeline for accurate structural design

GENERAL

LIMITATIONS

All pipelines require detailed site investigation and special designs for installations in contaminated land and sites where the

ground is subject to significant movement or subsidence

All pipes and fittings may be damaged by inappropriate cleaning practices and maintenance equipment

All pipeline systems have components that can be damaged by illegal discharges of trade waste

Plastic pipes are resistant to H2 S gas attack, impervious to groundwater and resistant to corrosion by almost all chemicals

found in sewage except some specific organic compounds

Thermoplastic pipes allow handling of much longer lengths and larger sizes than VC and GRP pipes, and are easier to cut

Vitrified clay pipes are resistant to H2 S gas attack and resistant to corrosion by almost all chemicals found in sewage

GENERAL

ADVANTAGES

Rubber ring jointed pipes are easily jointed and tolerate some joint deflection

All pipes can be used as slip liners inside microtunnelled/jacked encasing pipe

GRP, reinforced concrete and VC pipes can be supplied in designs for pipe jacking in microtunnelling installations

Rigid pipes have one or more pipe classes that have sufficient ring strength to not rely on side support for achieving structural

adequacy

Metallic pipes are easy to trace and, when fully welded, are impermeable to organic contaminants and gases

COPYRIGHT

129

WSA 022002-2.3

TABLE 10.2 (continued)

Informative

Flexible pipes may be susceptible to deflection after placement and compaction of embedment and fill

Plastic pipes may be susceptible to permeation and degradation by certain organic contaminants in soils

Plastic pipes and plastic coating or sleeving on metal pipes may be susceptible to degradation by certain organic contaminants

in soils

GENERAL

DISADVANTAGES

Plastic pipelines are sensitive to point loading

Rubber rings may be susceptible to degradation by certain organic contaminants in soils

Flexible pipes rely on support from embedment and adjacent native soil to achieve structural adequacy in buried installations

(except for some shallow installations without live loadings)

Non-black plastic pipes and fittings and plastic pipe coatings suffer UV degradation on prolonged exposure to direct sunlight

(generally 12 to 24 months depending on Australian locality)

PIPE

SYSTEM

TYPE

SPECIFIC ADVANTAGES

SPECIFIC DISADVANTAGES

NOT SUITABLE

SPECIAL APPLICATIONS

Fittings in riser structures prone

to failure if not appropriately

designed and supported

Fittings generally not available

off shelf

Can be solvent cement or

rubber ring jointed

ABS

Solid wall

Longer lengths

Solvent welding of large

diameter pipes requires

specialised training and

equipment

Beam strength may be

insufficient if pipe barrel is not

offered continuous support (load

dependent)

New product with limited

performance history

COPYRIGHT

Aggressive groundwater and

tidal zones

Above-ground

pipelines except

within conduits

Watercourse crossings as a

syphon

Crossing under railways or

major roadways within an

encasing pipe

130

WSA 022002-2.3

TABLE 10.2 (continued)

Informative

PIPE

SYSTEM

TYPE

SPECIFIC

ADVANTAGES

SPECIFIC DISADVANTAGES

NOT SUITABLE

SPECIAL APPLICATIONS

Generally not used except

for special applications

requiring high strength

Above ground pipelines

except marine

environments, e.g.

aqueduct crossings, steep

slopes not allowing burial system designed not to

generate or receive H 2 S

Normal Portland cement not

resistant to H2 S gas attack

and sulphuric acid resulting

from H2 S

Ductile

Iron (DI)

Cement

mortar lined

High ring, beam and

shear strength

High ring stiffness

High alumina cement has

improved performance over

Portland cement

PE sleeving is required and

must be carefully applied and

repaired when damaged

especially by third-parties

Glass

reinforced

plastic

(GRP)

Centrifugally

cast

Available as micro

tunnelling and jacking

pipe

UV resistant (Special

product)

Fittings generally not available

off shelf

Poorly supportive native

soils

Damaged sections require

cutting out or repair using

couplings or clamps; in-situ

repair using epoxy patching

not advisable as methods not

proven

Ground subject to high

differential movement

Low beam and shear strength

Uncertainties in

geotechnical analysis to

determine if flexible pipe

structurally suitable

Where control of

construction practices is

not adequate to ensure

quality of embedment for

flexible pipes

Above ground where

vandalism possible

COPYRIGHT

Aggressive groundwater

and tidal zones

Trenchless technology

applications

131

WSA 022002-2.3

TABLE 10.2 (continued)

Informative

PIPE

SYSTEM

TYPE

SPECIFIC ADVANTAGES

Can easily be curved to

eliminate need for bends

Suitable for directional

drilling, e.g. water course

crossings for syphons

Polyethylene

(PE)

Solid

wall

PE 80B

Available joint welding

provides higher confidence

in achieving long-term

leak-free system

Available in long coiled

lengths for fewer joints

Resistant to failure from

differential settlement or

pipe longitudinal flexibility

accommodates large

differential ground

settlement

SPECIFIC DISADVANTAGES

NOT SUITABLE

Fusion jointing requires skilled

installers and special equipment

Aggressive groundwater and

tidal zones

Black pipe limits detectability of

defects by CCTV inspection

Soils with differential

movement

Out-of-trench jointing may be

necessary

Currently available fittings do not

cover all the specific

configurations required of

reticulation sewers

Fusion repair is difficult to

successfully achieve due to high

cleanliness/dryness

requirements and heating

controls

Requires much thicker wall than

PVC-U solid wall pipe to achieve

equivalent stiffness

COPYRIGHT

SPECIAL APPLICATIONS

Reticulation systems

except for special

applications

Poorly supportive

native soils

Trenchless technology

applications

Watercourse crossings as a

syphon

Crossing under railways or

major roadways within an

encasing pipe

132

WSA 022002-2.3

TABLE 10.2 (continued)

Informative

PIPE

SYSTEM

TYPE

SPECIFIC ADVANTAGES

Comprehensive range of

fittings

SPECIFIC DISADVANTAGES

NOT SUITABLE

SPECIAL APPLICATIONS

Fittings in riser structures prone

to failure if not appropriately

designed and supported

Fully integrated MSs available

Solid wall

Can be solvent jointed

Beam strength may be

insufficient if pipe barrel is not

offered continuous support (load

dependent)

Longer lengths than VC

Aggressive groundwater

and tidal zones

As for solid wall PVC plus:

PVCU

Sandwich

construction

As for solid wall PVC plus:

Lighter than solid wall PVC for

the same ring stiffness

New product with little

performance history

Longer lengths than VC

As for solid wall PVC plus:

Fully integrated MSs available

Profiled wall

Lighter than solid wall PVC for

the same ring stiffness

Longer lengths than VC

Some specialised fittings not

available

Cannot be solvent cement

jointed

3 m lengths in sizes DN 225 and

DN 300 cf 6 m in PVC solid wall

COPYRIGHT

Above-ground

pipelines except

within conduits

Crossing under railways or

major roadways within an

encasing pipe

133

WSA 022002-2.3

TABLE 10.2 (continued)

Informative

PIPE

SYSTEM

TYPE

SPECIFIC ADVANTAGES

SPECIFIC DISADVANTAGES

NOT SUITABLE

SPECIAL APPLICATIONS

Above-ground pipelines

Trenchless technology

applications

Reinforced

concrete

(RC)

High beam and ring crushing

strength

Thermoplastic lined

Available as micro tunnelling

and jacking pipe

Field welding of PVC liner at pipe

joints is required to ensure

integrity of liner for resistance to

H 2 S gas attack

Fittings not readily available

Retrospective installation of

fittings/ repair complicated

Where soils

containing acid

sulphates are

encountered or

aggressive

groundwater or tidal

zones are relevant,

the limits of AS 4058

apply

As an alternative to large

diameter flexible pipes where:

Native ground modulus

inadequate to provide

structural support

Inadequate geotechnical data

available

Inadequate control over

embedment placement and

compaction

Likely third party interference

to the pipe surround

COPYRIGHT

134

WSA 022002-2.3

TABLE 10.2 (continued)

Informative

PIPE

SYSTEM

TYPE

SPECIFIC ADVANTAGES

SPECIFIC DISADVANTAGES

NOT SUITABLE

SPECIAL

APPLICATIONS

Not totally impervious to groundwater

Low shear strength

Comprehensive range of fittings

High ring strength

Embedment requirements less

stringent than for plastic pipes

Standard

Vitrified

clay

(VC)

Less imported embedment

required

Disturbance of pipe side

support does not substantially

impair structural performance

unlike flexible pipe

Available as micro tunnelling

and jacking pipe

Beam strength may be insufficient if

pipe barrel is not offered continuous

support (load dependent)

High protrusion of socket requires

more careful preparation of bedding

to prevent a pipe length just being

supported at the socket

No longitudinal pipe barrel flexibility

to accommodate any loss of pipe

bedding continuity

Even minor cracks can lead to

penetration and chokes by

aggressive root systems

Above-ground pipelines

In the vicinity of trees with

aggressive root systems

Fittings in riser structures more

prone to failure than thermoplastic

fittings

Short pipe lengths in

mine subsidence areas

Highly susceptible to root intrusion

through rubber ring joints, likely due

to pipe permeability causing damp

external surfaces

As for standard VC plus:

Calcined

Almost totally impervious to

groundwater

Lighter than standard VC

As for standard VC plus:

Glazed

Totally impervious to

groundwater

As for standard VC except:

Susceptibility to root intrusion

through rubber ring joints is

uncertain and requires further

investigation

COPYRIGHT

Aggressive

groundwater and tidal

zones

Above-ground pipelines

135

WSA 022002-2.3

TABLE 10.3

PRINCIPAL SEWERAGE PRESSURE PIPELINE SYSTEMS

Informative

PIPE

CONVENTIONAL

PIPE SIZES

DN

DI

Cement

mortar

lined

100,

225,

375,

600,

150, 200,

250, 300,

450, 500,

750

TYPICAL PIPE

CLASSES

Rubber ring

seal

Ductile iron cement

lined (DICL)

K9

Restrained

joints

DN 100-300

Fusion bonded

polymeric

encapsulated ductile

iron

Series 1 (Metric)

Pressure classes

100, 150, 200,

250, 300, 375, 450

PN 9, PN 12,

PN 15

Unplasticised

Oriented

Modified

Series 2DI

compatible

100, 150, 200,

250, 300, 375, 450

Cement

mortar

lined

Steel

PE

coated

and

lined

100 2500

Pressure classes

Classes available

to meet all design

requirements

SN5000

SN10000

Glass reinforced

plastic (GRP)

Flanged

Fusion bonded

polymer encapsulated

ductile iron

Rubber ring

seal

Pressure classes

Sleeved ductile iron

cement lined

Post-formed PVC-U

or PVC-M bends

PN 9, PN 12,

PN 16

Stiffness classes

300, 375, 450,

525, 600, 675,

750, 900, 1000,

1200

FITTINGS

Pipe wall

thickness class

K12 - flanged pipe

PVC

JOINTING

METHODS

Rubber ringseal DN 300

1600

Welded

Steel with same

coating and lining as

pipe

Flanged

Tape wrapped SCL

GRP couplings

with rubber lip

seal

Fusion bonded

polymeric

encapsulated ductile

iron

Mechanical

couplings

PN 10, PN 12.5,

PN 16

PE sleeved DICL

Fusion bonded

polyethylene coated

SCL

Tape wrapped SCL

Fabricated GRP to

match pipe class

Polyethylene

(PE)

(solid wall)

Pressure classes

Mechanical

PN 10, PN 12.5,

PN 16

Electrofusion

63, 110, 125, 160,

180, 225, 280,

315, 450, 630

Butt fusion

Compression fittings,

couplings for DN 63

Electrofusion fittings

DN 110 DN 450

PE plain end for butt

fusion and

electrofusion

Flanged fittings

Mechanical fittings

COPYRIGHT

WSA 022002-2.3

136

TABLE 10.4

PRINCIPAL SEWERAGE PRESSURE PIPELINE SYSTEMS

PRECAUTIONS, LIMITATIONS ADVANTAGES AND DISADVANTAGES

All pipelines may be damaged, rendered structurally unsound or have inadequate joint performance due to inappropriate

installation practices

All pipes and fittings may be damaged prior to installation by inappropriate transport, storage and handling practices

All pipelines should be constructed by trained and certified pipelayers with a system of documentation for quality control of

installation in place

GENERAL

PRECAUTIONS

All pipelines can be adversely affected in both the short and long term by third party damage to the pipe or corrosion protection

system

All pipeline systems may be damaged by illegal discharges of trade waste

All pipes require verification of the internal diameter for hydraulic designthe nominal size does not necessarily represent

accurately the internal diameter

All large diameter (DN 450) pipelines require a geotechnical investigation of the soil properties along the route and at the

intended depth of the pipeline

A risk assessment may be needed before locating pipelines in some locations, e.g. freeways, highways and major roads

GENERAL

LIMITATIONS

All pipelines require detailed site investigation and special designs for installations in contaminated land and sites where the

ground is subject to significant movement or subsidence

Electrically continuous pipelines constructed adjacent to electricity transmission lines >66kV shall comply with AS/NZS 4853

Plastic pipes are resistant to H2 S gas attack, corrosion resistant, relatively lightweight and easy to cut

GENERAL

ADVANTAGES

Metal pipes are easy to trace, do not require fatigue analysis and, when fully welded, are impermeable to organic contaminants

and gases

Rubber ring jointed pipes are easily jointed and tolerate some joint deflection

COPYRIGHT

137

WSA 022002-2.3

TABLE 10.4 (continued)

Informative

Plastic pipes may be susceptible to permeation by certain organic contaminants

Plastic pipes and plastic coating or sleeving on metal pipes may be susceptible to degradation by certain organic contaminants

Plastic pipelines require a detectable tracer tape for ease of location, although when installed with ductile iron fittings limited

traceability may be achieved

Plastic pipelines require de-rating at elevated temperatures and may require de-rating in certain surge and fatigue situations

GENERAL

DISADVANTAGES

Plastic pipelines are sensitive to point loading

Rubber ring jointed pipes may permit permeation through the joints in ground contaminated with organic compounds

Flexible pipes rely on support from embedment and adjacent native soil to achieve structural adequacy in buried installations

(except for some shallow installations without live loadings)

Metal pipes are susceptible to corrosion if their internal or external or both corrosion protection systems are damaged or fail

Non-black plastic pipes and fittings and plastic pipe coatings and sleeving suffer UV degradation on prolonged exposure to

direct sunlight (generally 12 to 24 months depending on Australian locality)

PIPE

SYSTEM

TYPE

SPECIFIC ADVANTAGES

Fatigue analysis not normally

required

High mechanical strength and

toughness

Ductile

iron (DI)

Cement

mortar lined

(DICL)

Ease of jointing

UV resistant/vandal proof

impact resistant

Well-established methods of

repair

Restrained joint systems

available

SPECIFIC

DISADVANTAGES

Standard Portland cement

mortars not resistant to H2 S

gas attack at any high points

or discharge points in the

main. High alumina cement

has improved resistance

PE sleeving is required and

must be carefully applied

and repaired when

damaged, especially by

third-parties

COPYRIGHT

NOT SUITABLE

SPECIAL APPLICATIONS

State/Territory roads and main

thoroughfares

Railway crossings to AS 4799

Anaerobic

conditions or tidal

zones

Above-ground pipelines

In poor ground conditions where

high risk of subsidence

Non-tidal creek and culvert

crossings

Aqueducts and non-tidal bridge

crossings

138

WSA 022002-2.3

TABLE 10.4 (continued)

Informative

PIPE

SYSTEM

TYPE

SPECIFIC ADVANTAGES

Alternative installation

techniques possible e.g. sliplining

UV resistant (Special product)

GRP

Centrifugally

cast

Custom-made specially

configured GRP pressure

fittings can be manufactured

to order

Suitable for use without

additional corrosion protection

in areas where stray electrical

currents occur

SPECIFIC

DISADVANTAGES

Low impact resistance and

ease of damage of

thermoset resin makes GRP

susceptible to damage

during transportation and

installation, in above-ground

installations or when

damaged from nearby

excavation

NOT SUITABLE

Above ground

locations subject to

interference

SPECIAL APPLICATIONS

Aggressive groundwater,

anaerobic conditions and tidal

zones

Retrospective installation of

fittings/ repair complicated

Can easily be curved

PE

PE 80B and

PE 100

Alternative installation

techniques possible e.g. pipe

cracking and slip lining

Fusion jointing requires

skilled installers and special

equipment

Can be welded to form a

system that will resist end

load

Out-of-trench jointing may

be necessary

DN 125 available in coiled

lengths for fewer joints

Retrospective installation of

fittings/repair complicated

COPYRIGHT

Above ground

locations subject to

interference

Butt welding in

trenches

Aggressive groundwater,

anaerobic conditions and tidal

zones

139

WSA 022002-2.3

TABLE 10.4 (continued)

Informative

PIPE

SYSTEM

TYPE

Unplasticised

SPECIFIC ADVANTAGES

Oriented

Better fatigue resistance than PVCU and PVC-M

Available in long lengths (up to

12 m)

Modified

Available in long lengths (up to

13.5 m)

Custom-made specially configured

steel pressure fittings can be

manufactured to order

Steel

Can be welded to form a system

that will resist end loads

UV resistant/vandal proof/impact

resistant

Alternative installation techniques

possible e.g. slip lining

Cathodic protection can be applied

to provide enhanced external

corrosion protection

PE lined and

coated

SPECIAL APPLICATIONS

Use only DI fittings in pumped

mains to achieve full fatigue

resistance

12 m lengths should not be used

directly with DI fittings

Above ground

pipelines

Aggressive groundwater,

anaerobic conditions and

tidal zones

Better fracture toughness than

PVC-U

High mechanical strength and

toughness

Cement mortar

lined (SCL)

and PE coated

NOT SUITABLE

Well established methods of repair

Better fracture toughness than

PVC-U

PVC

SPECIFIC DISADVANTAGES

As for SCL plus:

Resistant to H2 S gas attack

Standard Portland cement

mortars not resistant to H2 S gas

attack at any high points or

discharge points in the main

High alumina cement has

improved resistance

Welded joints require skilled

installers and special equipment

Welded joints require

reinstatement of protection

systems on site

Special design required for

welded installations parallel and

adjacent to high voltage (>66 kV)

transmission lines

Cathodic protection requires

regular monitoring and

maintenance

As for SCL except for comment

on cement mortar linings

COPYRIGHT

State/Territory roads and

main thoroughfares

Railway crossings to

AS 4799

High-pressure mains

Above-ground pipelines

Aggressive groundwater,

anaerobic conditions and

tidal zones

Creek and culvert crossings

Aqueducts and bridge

crossings

Large diameter pipelines

140

WSA 022002-2.3

APPENDIX F

QUALITY ASSURANCE OF PRODUCTS

QUALITY ASSURANCE OPTIONS AND SELECTION

(Informative)

F1 GENERAL

The objective of product quality assurance is to reduce the likely consequences (and costs)

of non-conforming product; however, the cost of quality assurance should be balanced

against the tangible and other benefits arising from its adoption.

One or more of the following quality assurance options are stipulated in each purchase

specification referenced by this Code:

(a)

ISO 9000 management system certification.

(b)

Product certification (either Type 1, 3 or 5).

(c)

Second party verification.

(d)

Suppliers declaration of conformance.

This appendix provides information on applicability and limitations of the various quality

assurance options.

This Appendix does not address quality of installation or operation and maintenance,

upon which satisfactory performance of a conforming product depends.

F2 QUALITY ASSURANCE OPTIONS

F2.1 ISO 9000 quality management system certification

Although ISO 9001 or ISO 9002 management system certification may demonstrate that

there is systematic management of a part or whole of a supplier organisation, the scope

(breadth) and focus (depth) of the certification audit may be very general, particularly

where the organisation manufactures complex products or a diverse range of products.

Furthermore, an ISO 9000 management system certification audit does not necessarily

assess the compliance of a product to its specification.

On completion of a successful audit, the manufacturer is issued with a certificate that

includes a capability statement i.e. a general statement of the business activities covered

by the certification. A manufacturer may not apply a certification mark directly to a product,

but may do so on packaging.

F2.2 Product certification

A product certification audit specifically focuses on the products conformance to its

specification. Three types of product certification are referenced in this Code Types 1, 3

and 5. Depending on the type of product certification specified, the certification audit may

not include auditing of the manufacturing process(es). However, as a minimum in all cases,

product certification requires a type test to verify conformance. Product certification may

address some of the inadequacies of a generic ISO 9000 management system

certifications failure to specifically assess product or material conformance to

specification.

On completion of a successful audit, the Certification Body (CB) may licence the

manufacturer to apply the CB's mark to the product as evidence of independent verification

COPYRIGHT

141

WSA 022002-2.3

of conformance. The product certification certificate issued by the CB states the actual

specification to which the product has been declared to conform.

ISO lists various types of product certification that are differentiated by the scope, depth

and frequency of auditing and/or testing. Types 1, 3 or 5 are nominated by purchase

specifications referenced by this Code i.e.:

(a)

Type 1Type testing only (initial and thereafter at design change).

(b)

Type 3Type testing followed by subsequent audit testing of factory samples.

(c)

Type 5Type testing and on-going assessment / audit of the manufacturers

process controls.

Information on and comparison of these types is given below.

F2.2.1 Product certification Type 1

In Type 1 certification, the CB type tests or verifies that a satisfactory type test of a sample

of the product has been made. Tests for verifying critical performance attributes should be

stipulated in the product specification. Certification expires when there is a design change

(including materials and/or manufacturing method). Type 1 product certification is the

simplest and most limited form of independent certification of product conformance. There

is no follow-up testing or auditing by the certification body. Manufacturing quality control is

not considered.

The type test gives evidence only about a particular item made at a particular moment

in time. Alone, it gives no assurance that future items will be equivalent. Type testing

may verify a design and its capability to perform, subject to future items being

manufactured in an identical manner. Where possible, type testing should be

conducted by a NATA-accredited laboratory and reported on NATA-endorsed reports.

F2.2.2 Product certification Type 3

Type 3 is an extension of Type 1. There is periodic follow-up action by the certification

body to check, by audit testing of factory samples, that subsequent production conforms to

specification. In this Code, the frequency of audit testing is defined in the product purchase

specifications. Re-certification is required if there is a product design change.

F2.2.3 Product certification Type 5

Type 5 product certification is the most rigorous third party verification of a products

compliance with the specification to which it is manufactured. To achieve this level of

product certification, a manufacturer must have a suitable quality management system in

place and demonstrate to the satisfaction of the certification body that manufacturing

process controls, inspections and tests verify conformance to all significant aspects of the

product specification. Type testing, periodic testing of samples from the factory and

periodic auditing of factory quality control by the certification body is mandated. The CB

may require the manufacturer to have a full or part ISO 9000 management system.

Typically, Type 5 requires the CB to verify statistical manufacturing control or conduct

batch release testing.

COPYRIGHT

WSA 022002-2.3

142

F2.3 Suppliers declaration of conformance

Third party certification does not permit a manufacturer or supplier to abrogate its

obligations.

According to the International Organisation for Standardisation:

An assurance given by the seller to the buyer is the oldest and simplest form of the

general practice of certifying that a product is in accord with a specification or contract

[Reference: Certification Principles and Practice, published by International Organisation

for Standardisation (ISO), 1980].

Under the Trade Practices Act, a manufacturers promotion, or response to a purchasers

enquiry, must not give false or misleading information.

A suppliers declaration should state that the supplier has taken reasonable steps to

ensure that the product or material complies with the specification quoted in the order;

otherwise variations must be documented and provided to the purchaser. The supplier

may be the manufacturer or the retailer of the product, depending on the distribution chain

and purchase transaction.

F2.4 Second party verification

Second party verification of product, manufacturing process(es) and/or personnel

qualification involves the purchaser, or its agent, auditing the suppliers manufacturing

operations or inspecting finished product. This is generally in the form of an ISO 9000

management system audit or similar audit process. For complex products, a hold point in

manufacture may be specified whereby the purchaser audits or inspects the adequacy of

the manufacturing status prior to authorising continuation.

F3 FACTORS INFLUENCING SELECTION OF QUALITY ASSURANCE OPTIONS

F3.1 General factors

In determining the default quality assurance requirement for a specific product, the

following issues are relevant:

(a)

Likelihood of manufacturing process causing a product non-conformance.

(b)

Likelihood of failure of the pipeline system from a product non-conformance.

(c)

Consequences of product failure.

(d)

The product specification.

(e)

Project magnitude / management.

(f)

Innovation

RISK = CONSEQUENCE OF FAILURE x LIKELIHOOD OF FAILURE

F3.2 Likelihood of manufacturing non-conformance

Variability of product quality and the reliability of quality assurance options are influenced

by the means of production.

Where the volume of production is high, sampling plans to AS 1199 or AS 2490 may be

used. Statistical sampling may not be applicable to low volume production processes or

jobbing fabrications, in which case focus on process and /or personnel qualification,

together with type testing, may be appropriate.

COPYRIGHT

143

WSA 022002-2.3

F3.3 Likelihood of failure of pipeline system from a product non-conformance

The likelihood of failure of a pipeline system from a product non-conformance depends on

the nature of the non-conformance. A non-conformance of a pipe to a specified internal

diameter would have little likelihood of causing to failure of a pipeline system. A nonconformance to a strength or stiffness requirement of a pipe could cause failure with low to

high consequence depending on how close the particular loading was to the failure limit for

the pipe / support selection i.e. standard stiffness small diameter PVC would have excess

loading capacity for most installations. A non-conformance to a specified external diameter

could affect joint sealing and may have a moderate to high likelihood of causing failure.

F3.4 Consequences of failure

A higher level of assurance of product compliance is required where the expected

detrimental consequences of failure resulting from any non-conformance are high. The

objective of quality assurance is to reduce the likelihood of non-conformance and

subsequent failure due to product design and/or manufacturing deficiency.

F3.5 Product specification

The product specification must be written such that it clearly specifies essential

performance requirements, attributes and test methods. These must be specified in a

manner that can be measured and objectively verified by the manufacturer and certification

body.

F3.6 Project magnitude / management

For contractual and other reasons, a major or special project may require specific quality

assurance provisions in lieu of the default quality assurance options stipulated in this

Codes product purchase specifications.

F3.7 Innovative products

This Code does not nominate specifications for innovative products, even though they may

have existing certification to a national or industry standard. For products undergoing trial

evaluations, a Water Agency may be prepared to accept or manage a (temporary) higher

level of risk.

Each agency should be responsible for stating its own quality assurance requirements

for innovative products.

F4 SELECTING THE QUALITY ASSURANCE OPTION

F4.1 General factors

Selection of the appropriate quality assurance option for products is made after

considering the factors outlined above.

All types of product certification require that the product specification unambiguously and

objectively define product attributes and performance measures.

The principal factors applying in selection of quality assurance options in accordance with

this Code are:

(a)

Likelihood of non-conformances from the manufacturing process; and

(b)

Consequence and likelihood of failure of the pipeline system.

An outline of the applicability of various options is given in Clause F4.2.

COPYRIGHT

144

WSA 022002-2.3

F4.2 Product certification

F4.2.1 General

Product certification is the preferred quality assurance option since the focus of the CB is

on directly verifying conformance of a particular product to its specification. In addition,

application of the CBs mark onto the product is objective evidence of the manufacturers

declaration of conformance.

F4.2.2 Type 1

Type 1 product certification should be nominated where:

(a)

the likelihood of the manufacturing process causing a non-conformance is low, e.g.

fully automated manufacturing and control, and manufacturing quantity is small;

and/or

(b)

the consequences of failure are low; and/or

(c)

the likelihood of failure is low.

Examples of products for which Type 1 product certification is applicable are nondetectable marking tapes and maintenance hole covers in non-trafficable areas.

For a product normally used in situations where failure would result in moderate

consequences of failure or where the likelihood of failure is moderate, Type 1 may be

specified in conjunction with an ISO 9000 quality management system certification if

Type 3 is not practicable.

F4.2.3 Type 3

Type 3 product certification should be nominated where:

(a)

the likelihood of manufacturing processes causing a non-conformance is moderate to

high and statistical sampling plans are not practicable e.g. a minor degree of manual

input to manufacturing; and/or

(b)

the consequences of failure are moderate; and/or

(c)

the likelihood of failure is moderate.

Examples of products for which Type 3 product certification is applicable are valve

chambers and maintenance hole covers in trafficable areas.

The frequency of CB surveillance audits should be increased to match an increase in the

likelihood of manufacturing non-conformances or increased risk of failure. Type 3 may be

specified in conjunction with an ISO 9000 quality management system certification if

Type 5 is not practicable.

F4.2.4 Type 5

Type 5 product certification should be nominated where:

(a)

the likelihood of manufacturing processes causing non-conformance on a large scale

and with consistent repetition is high, i.e. mass produced product; and /or

(b)

the consequences of failure are high; and/or

(c)

the likelihood of failure is high.

Examples of products for which Type 5 product certification is applicable are certain flow

control valves and buried pipes and fittings (excepting special low volume products).

For pipes made by batch processes or complex or speciality products, Types 1 or 3 plus

ISO 9000 quality management system certification may alternatively be specified.

Type 5 is specified where the risk of failure is high. It is commonly adopted for massproduced, critical products such as pipes, fittings and valves. However, it may not be

COPYRIGHT

145

WSA 022002-2.3

practicable for batch processes or complex or speciality products; for these, Types 1 or 3

plus ISO 9000 quality management system certification may be more appropriate.

F4.3 ISO 9000 quality management system certification

ISO 9000 quality management system certification is generally nominated where the

expected consequence and likelihood of non-conformance is moderate or, for high risk

products, where product certification is not practicable. This is typically where there may

be many design changes (e.g. concrete) or for low volume, speciality products (e.g.

fabricated GRP fittings) or where the specification does not adequately specify objective

performance criteria.

Where this Code mandates an ISO 9000 quality management system certification as a

means of assuring product quality, the scope of the certification is required to be focused

and relevant to the product. Typically this requires the certificate issued by the CB to

specifically state the product type or process by which the product is produced (e.g.

manufacture and supply of concrete, to AS 1379.)

An ISO 9000 management system certification generally does not reference a product

standard or specification; however, for the above example, reference to AS 1379 in the

scope is appropriate since AS 1379 is process oriented.

Given the process focus of the 2000 edition of ISO 9000, there is potential to improve

the relevance of a generic ISO 9000 management system to the certification to

products.

F4.4 Suppliers declaration of conformance

A suppliers declaration of conformance should be required for all products.

Purchasers are expected to seek the suppliers declaration that product supplied against a

purchase order complies with the nominated specification.

F4.5 Second party verification

A salient objective of third party (CBs) system or product certification is to minimise the

intervention of second parties (purchasers) in the suppliers production operations. Second

party auditing at the suppliers works may, however, be appropriate for low volume

fabricated items and may be used in conjunction with ISO 9000 management system

certification. This option may be an overriding option for the purchaser should product

quality problems be identified during the supply. The Water Agency or Designer may

determine the need for second party verification and specify this in the project contract

documentation.

COPYRIGHT

WSA 022002-2.3

146

NOTES

COPYRIGHT

You might also like

- WSA02 2002 Part0 2 3Document30 pagesWSA02 2002 Part0 2 3abhijithavalNo ratings yet

- Stormwater and DamsDocument116 pagesStormwater and DamsnathychidazNo ratings yet

- WASA CodeDocument34 pagesWASA CodeJaz SinghNo ratings yet

- Water Supply Code of AustraliaDocument69 pagesWater Supply Code of Australiahuman2955No ratings yet

- S406 Specifications For The Supply of Stone PDFDocument6 pagesS406 Specifications For The Supply of Stone PDFMfanelo MbanjwaNo ratings yet

- HD 2606Document29 pagesHD 2606alfaza3No ratings yet

- Gatic Access Covers Brochure WebDocument55 pagesGatic Access Covers Brochure WebTrong Tran100% (1)

- Sewerage Code of Australia: WSA 02-2002 Version 2.3Document2 pagesSewerage Code of Australia: WSA 02-2002 Version 2.3abhijithavalNo ratings yet

- The National Academies Press: Manual On Subsurface Investigations (2019)Document7 pagesThe National Academies Press: Manual On Subsurface Investigations (2019)Andres PuertaNo ratings yet

- AGRD04-17 Guide To Road Design Part 4 Intersections and Crossings General Ed2.1Document192 pagesAGRD04-17 Guide To Road Design Part 4 Intersections and Crossings General Ed2.1fbturaNo ratings yet

- TRH 22 Pavement Management SystemsDocument157 pagesTRH 22 Pavement Management Systemsannaselemela100% (1)

- Dokumen - Tips - Ream Guidelines For Road Drainage Design Volume 4Document100 pagesDokumen - Tips - Ream Guidelines For Road Drainage Design Volume 4nasNo ratings yet

- Arr Guide Book PDFDocument1,526 pagesArr Guide Book PDFrobliutpg.com.auNo ratings yet

- TRH 14 ManualDocument22 pagesTRH 14 ManualNelson KachaliNo ratings yet

- Specification For Base & Surface CoursesDocument62 pagesSpecification For Base & Surface Coursessri10888No ratings yet

- Technical NoteDocument3 pagesTechnical NotearulazzikriNo ratings yet

- TN27 Australian Standard For Precast BC and HeadwallDocument8 pagesTN27 Australian Standard For Precast BC and HeadwallgemotorresNo ratings yet

- Policy Design Guideline Standards For Single Carriageway National Roads - Draft May 2009Document13 pagesPolicy Design Guideline Standards For Single Carriageway National Roads - Draft May 2009sage.electconNo ratings yet

- Traffic Calming GuidelinesDocument24 pagesTraffic Calming GuidelinesRendani Vele100% (2)

- WSA 03 AnnexuresDocument8 pagesWSA 03 AnnexuresShahabShoaeeNo ratings yet

- Body Corporate Guidelines PDFDocument17 pagesBody Corporate Guidelines PDFmaNo ratings yet

- PW 344 2017 DPW Manual Volume 2-Annexures PDFDocument266 pagesPW 344 2017 DPW Manual Volume 2-Annexures PDFMichael BenhuraNo ratings yet

- Sika Crack Injection Method Statement v4 2021Document19 pagesSika Crack Injection Method Statement v4 2021Jamsheed Ap KadangodNo ratings yet

- SANS 3001 BSM3 Final DraftDocument13 pagesSANS 3001 BSM3 Final DraftMark D VillanuevaNo ratings yet

- MSCL Handling Instal Manual 2007Document34 pagesMSCL Handling Instal Manual 2007Jai SudholzNo ratings yet

- Specifications of The Application of Class Concrete Paving BlocksDocument10 pagesSpecifications of The Application of Class Concrete Paving BlockshonneyValadasNo ratings yet

- Cpaa Design Manual: Hydraulics of Precast Concrete ConduitsDocument65 pagesCpaa Design Manual: Hydraulics of Precast Concrete Conduitsrobliutpg.com.auNo ratings yet

- Highways Agency DMRB 0-1 - 1Document67 pagesHighways Agency DMRB 0-1 - 1Suraj De SilvaNo ratings yet

- Fully Book of Drawing May 16-2020 With Catch Water Drain PDFDocument17 pagesFully Book of Drawing May 16-2020 With Catch Water Drain PDFDaniel Pasy SelekaNo ratings yet

- Colto-Specifications 2009 PDFDocument2 pagesColto-Specifications 2009 PDFRoddy TeeNo ratings yet

- Sans 10400 DisabledDocument51 pagesSans 10400 Disabledsjoubert_törökNo ratings yet

- S406 Specifications For The Supply of StoneDocument6 pagesS406 Specifications For The Supply of StoneRui Lourenco100% (1)

- Rock FillDocument8 pagesRock FillMahmoud Mansour100% (1)

- DBKL ChecklistDocument4 pagesDBKL ChecklistJia Fei KuangNo ratings yet

- Dokumen - Tips Arahan Teknik Jalan 6 85 Guidelines For Presentation of Engineering DrawingDocument29 pagesDokumen - Tips Arahan Teknik Jalan 6 85 Guidelines For Presentation of Engineering Drawingiris engineeringNo ratings yet

- Sewer Geotechnical ReportDocument112 pagesSewer Geotechnical ReportAmir Reza Ahmadi MotlaghNo ratings yet

- Austroads Rural RoadDocument150 pagesAustroads Rural RoadBabulalSahu100% (2)

- SAPEM Chapter 1 2nd Edition 2014Document52 pagesSAPEM Chapter 1 2nd Edition 2014kjhkjh100% (1)

- PDFDocument5 pagesPDFLesego MatojaneNo ratings yet

- SAPEM Chapter 11 2nd Edition 2014 PDFDocument32 pagesSAPEM Chapter 11 2nd Edition 2014 PDFAlenNo ratings yet

- 2.4 Material Requirements: Code Description Summary of SpecificationDocument3 pages2.4 Material Requirements: Code Description Summary of Specificationsan aungNo ratings yet

- Infraset Product Catalogue (2014)Document55 pagesInfraset Product Catalogue (2014)Christian JordaanNo ratings yet

- Coto Chapter 20-Quality Assurance - DS Version Oct 2020Document56 pagesCoto Chapter 20-Quality Assurance - DS Version Oct 2020Spam Me here100% (1)

- RTA Guide To Signs and Markings Reference Lists - Version 2.2Document27 pagesRTA Guide To Signs and Markings Reference Lists - Version 2.2Anthony HibbertNo ratings yet

- Akta Air 1920Document20 pagesAkta Air 1920Dinar Ismail100% (1)

- Hydraulic Services DesignDocument10 pagesHydraulic Services DesignSeenivasan GovindarajNo ratings yet

- SAPEM Chapter 5 Jan2013Document39 pagesSAPEM Chapter 5 Jan2013Frans van der Merwe100% (3)

- V10 12d NZ - W02 Network EditorDocument15 pagesV10 12d NZ - W02 Network EditorrenandNo ratings yet

- Botswana Road Design Manual. - Hydrology and DrainageDocument88 pagesBotswana Road Design Manual. - Hydrology and DrainageBalarka100% (1)

- Di Pipe DrawingsDocument6 pagesDi Pipe DrawingsZatul Akmal ZamilNo ratings yet

- CP 97-1-2002 - PreviewDocument11 pagesCP 97-1-2002 - PreviewNyan Myint TunNo ratings yet

- SAPEM Chapter 3 Jan2013 PDFDocument100 pagesSAPEM Chapter 3 Jan2013 PDFKamukwema johnNo ratings yet

- Chapter 14 Post Construction Jan2013Document37 pagesChapter 14 Post Construction Jan2013Asim Amin100% (1)

- Guide On BQ Preparation (South Africa)Document21 pagesGuide On BQ Preparation (South Africa)hantu_limahNo ratings yet

- PVC-U Robineti VEEIV063 PDFDocument299 pagesPVC-U Robineti VEEIV063 PDFCrisTimNo ratings yet

- CAIS - Complete Manual - Rev 3 - 2023-03-30Document1,340 pagesCAIS - Complete Manual - Rev 3 - 2023-03-30Muhammad UmarNo ratings yet

- As 5100.3-2004 Bridge Design Foundations and Soil Supporting StructuresDocument8 pagesAs 5100.3-2004 Bridge Design Foundations and Soil Supporting StructuresSAI Global - APACNo ratings yet

- Wind Flow Characteristics and Their Effects On Low-Rise BuildingsDocument172 pagesWind Flow Characteristics and Their Effects On Low-Rise Buildingspepe colliNo ratings yet

- P08flexible Hose UlDocument9 pagesP08flexible Hose Ulyucai.chenNo ratings yet

- XINXING - WSAA CertificateDocument5 pagesXINXING - WSAA CertificateAbraham OrtizNo ratings yet

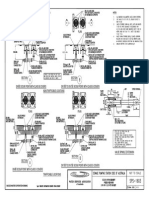

- SPS-1603 1 1Document1 pageSPS-1603 1 1abhijithavalNo ratings yet

- Pump Scour Elevation: NotesDocument1 pagePump Scour Elevation: NotesabhijithavalNo ratings yet

- Sewerage Code of Australia: WSA 02-2002 Version 2.3Document2 pagesSewerage Code of Australia: WSA 02-2002 Version 2.3abhijithavalNo ratings yet

- Product Details For Pressure Mains: For Dicl, PVC, GRP & Pe Pipes Pipe InstallationDocument1 pageProduct Details For Pressure Mains: For Dicl, PVC, GRP & Pe Pipes Pipe InstallationabhijithavalNo ratings yet

- Quantity (Litres/Second) : Pressure Main ConfigurationDocument1 pageQuantity (Litres/Second) : Pressure Main ConfigurationabhijithavalNo ratings yet

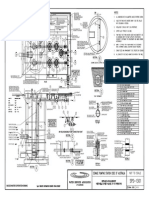

- Concrete Cover Detail: NotesDocument1 pageConcrete Cover Detail: NotesabhijithavalNo ratings yet

- SPS-1301 1 1Document1 pageSPS-1301 1 1abhijithavalNo ratings yet

- SPS-1302 1 1Document1 pageSPS-1302 1 1abhijithavalNo ratings yet

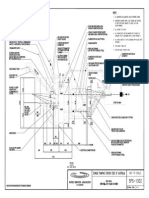

- Typical Cover Arrangement: Valve Chamber LegendDocument1 pageTypical Cover Arrangement: Valve Chamber LegendabhijithavalNo ratings yet

- Case 2 - Pressure Main With A High Point Case 1 - Always Rising Pressure MainDocument1 pageCase 2 - Pressure Main With A High Point Case 1 - Always Rising Pressure MainabhijithavalNo ratings yet

- Plan of Top Slab ElevationDocument1 pagePlan of Top Slab ElevationabhijithavalNo ratings yet

- SPS-1304 1 1Document1 pageSPS-1304 1 1abhijithavalNo ratings yet

- Locality Plan: Notes 1. 3. 4Document1 pageLocality Plan: Notes 1. 3. 4abhijithavalNo ratings yet

- Minor Cut Fill Fill: SO IL ILDocument1 pageMinor Cut Fill Fill: SO IL ILabhijithavalNo ratings yet

- Typical Site Plan Typical Layout For Pumping Station Sites Not Fronting Adjacent Roadway Alternative Typical Site PlanDocument1 pageTypical Site Plan Typical Layout For Pumping Station Sites Not Fronting Adjacent Roadway Alternative Typical Site PlanabhijithavalNo ratings yet

- Location Plan: C Ommerc IALDocument1 pageLocation Plan: C Ommerc IALabhijithavalNo ratings yet

- SPS-1203 1 1Document1 pageSPS-1203 1 1abhijithavalNo ratings yet

- Alternative Configurations: R 8 00 0 (M IN.)Document1 pageAlternative Configurations: R 8 00 0 (M IN.)abhijithavalNo ratings yet

- Based On Sydney Water Standard DrawingDocument1 pageBased On Sydney Water Standard DrawingabhijithavalNo ratings yet

- Anda Street Oxford Road: MA RT INDocument1 pageAnda Street Oxford Road: MA RT INabhijithavalNo ratings yet

- SPS-1103 1 1Document1 pageSPS-1103 1 1abhijithavalNo ratings yet

- Tales From The SSRDocument48 pagesTales From The SSRBrad GlasmanNo ratings yet

- A Brief History & Development of Banking in India and Its FutureDocument12 pagesA Brief History & Development of Banking in India and Its FutureMani KrishNo ratings yet

- Hospitals' EmailsDocument8 pagesHospitals' EmailsAkil eswarNo ratings yet

- Ict: Advantages & Disadvantages: Presentation PlanDocument11 pagesIct: Advantages & Disadvantages: Presentation PlanLe FleauNo ratings yet

- Microsoft 365 Migration Checklist For MSPs Dec2022Document15 pagesMicrosoft 365 Migration Checklist For MSPs Dec2022bhavesh_pathakNo ratings yet

- Universalism and Cultural Relativism in Social Work EthicsDocument16 pagesUniversalism and Cultural Relativism in Social Work EthicsEdu ArdoNo ratings yet

- Code of Ethics For Public School Teacher: A. ResponsibiltyDocument6 pagesCode of Ethics For Public School Teacher: A. ResponsibiltyVerdiebon Zabala Codoy ArtigasNo ratings yet

- MAKALAH Mice and EventDocument13 pagesMAKALAH Mice and EventJeni Wulandari SembiringNo ratings yet

- William SantiagoDocument5 pagesWilliam SantiagoSubhadip Das SarmaNo ratings yet

- Thesis Statement 1Document4 pagesThesis Statement 1Naomi Aira Gole CruzNo ratings yet

- Republic of The Philippines Department of Education Region Iv - A Calabarzon Schools Division Office of Rizal Rodriguez Sub - OfficeDocument6 pagesRepublic of The Philippines Department of Education Region Iv - A Calabarzon Schools Division Office of Rizal Rodriguez Sub - OfficeJonathan CalaguiNo ratings yet

- A Comparison of The Manual Electoral System and The Automated Electoral System in The PhilippinesDocument42 pagesA Comparison of The Manual Electoral System and The Automated Electoral System in The PhilippineschaynagirlNo ratings yet

- Iron Maiden - Can I Play With MadnessDocument9 pagesIron Maiden - Can I Play With MadnessJuliano Mendes de Oliveira NetoNo ratings yet

- Eternal Generation What Is Eternal Generation?Document2 pagesEternal Generation What Is Eternal Generation?Jake DavilaNo ratings yet

- Soal Soal ERPDocument31 pagesSoal Soal ERPAnggitNo ratings yet

- Principles of PR Measurement 0 PDFDocument15 pagesPrinciples of PR Measurement 0 PDFVisai_kitasNo ratings yet

- Fachhochschule Südwestfalen: We Create MomentumDocument45 pagesFachhochschule Südwestfalen: We Create MomentumSha EemNo ratings yet

- Soal Asking and Giving OpinionDocument2 pagesSoal Asking and Giving OpinionfitriaNo ratings yet

- BlompmDocument208 pagesBlompmswiftvishnulalNo ratings yet

- John Carroll University Magazine Winter 2008Document69 pagesJohn Carroll University Magazine Winter 2008johncarrolluniversityNo ratings yet

- The Kurdistan Worker's Party (PKK) in London-Countering Overseas Terrorist Financing andDocument28 pagesThe Kurdistan Worker's Party (PKK) in London-Countering Overseas Terrorist Financing andrıdvan bahadırNo ratings yet

- BPM at Hindustan Coca Cola Beverages - NMIMS, MumbaiDocument10 pagesBPM at Hindustan Coca Cola Beverages - NMIMS, MumbaiMojaNo ratings yet

- TrerwtsdsDocument167 pagesTrerwtsdsvinicius gomes duarteNo ratings yet

- Concept Note Digital Platform Workshop - en PDFDocument3 pagesConcept Note Digital Platform Workshop - en PDFgamal90No ratings yet

- Udom Selection 2013Document145 pagesUdom Selection 2013Kellen Hayden100% (1)

- TcasDocument7 pagesTcasimbaNo ratings yet

- Creating A Carwash Business PlanDocument7 pagesCreating A Carwash Business PlanChai Yeng LerNo ratings yet

- Walt DisneyDocument56 pagesWalt DisneyDaniela Denisse Anthawer Luna100% (6)

- Basic Features of Jaimini AstrologyDocument3 pagesBasic Features of Jaimini AstrologyVd Vivek SharmaNo ratings yet

- Case LawsDocument4 pagesCase LawsLalgin KurianNo ratings yet