Professional Documents

Culture Documents

LNG 1 1 e 13 150dpi19 4577

Uploaded by

Mark J.L. ChenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LNG 1 1 e 13 150dpi19 4577

Uploaded by

Mark J.L. ChenCopyright:

Available Formats

Linde Engineering

LNG Technology.

Contents.

3 Introduction

4 Pretreatment and separation of natural gas

5 LNG plant block scheme

6 Single mixed refrigerant liquefaction process: LIMUM1

7 References

LNG plant in Kollsnes, Norway

LNG plant in Kwinana, Australia

8 Single mixed refrigerant liquefaction process: LIMUM3

9 References

MFC and LIMUM

are registered trademarks of Linde AG

LNG plants in China

LNG plant in Stavanger, Norway

LNG plant in Bintulu, Malaysia

10 MFC process (mixed-fluid cascade)

11 LNG plant in Hammerfest, Norway

12 Coil-wound heat exchanger

14 Plate-fin heat exchanger

16 Contact

Introduction.

Natural gas is a mixture of gases containing primarily hydrocarbon gases. It is colorless and odorless in its pure form.

It is the cleanest fossil fuel with the lowest carbon dioxide

emissions. Natural gas is an important fuel source as well as

a major feedstock for fertilizers and petrochemicals.

For economic transportation over great distances natural gas

can be cooled and liquefied occupying only 1/600th of its

normal volume in gaseous form at a temperature of around

-162C. Linde Engineering has a strong history in the LNG

industry having developed, built and started-up over 20 LNG

plants world-wide since 1967.

Linde Engineerings natural gas liquefaction processes can

cover LNG plants ranging from 40 thousand to more than

10 million tons per year.

Pretreatment and separation

of natural gas.

Pretreatment of natural gas

Prior to liquefaction natural gas often has to be

pretreated. Such pretreatment typically consists

of mercury removal, gas sweetening and drying.

Depending on the downstream processing steps

and the concentration of the sour gas components, it may be necessary to remove H2S and

CO2 from the natural gas. Scrubbing processes

such as MDEA, are offered for this application.

Should only minor amounts of sour gas be present, they can be removed by adsorption along

with the removal of water. Mercury guard beds

are recommended to protect people and equipment.

Separation of natural gas

Cryogenic processes represent the most economical solutions to reject or to recover natural gas

components.

NGL, LPG, condensate or the pure components

methane, ethane, propane and butane often

have higher sales value compared to the pipeline gas itself. Therefore they are frequently extracted and fractionated in tailor made processing plants according to the specific requirements

of the regional market. NGL and LPG are ideal

feedstocks for steam crackers producing olefins.

Removal of nitrogen leads to reduced transportation volumes and an increased heating value.

Furthermore it is sometimes required for the

usage as fuel gas feeding gas turbines. The gas

turbines are installed to provide the required

electrical or mechanical power of the LNG plants.

C3+ recovery plant in Kollsnes, Norway

(Photo courtesy of STATOIL)

Helium recovery is often combined with nitrogen removal. High purity helium is produced by

the combination of cryogenic and pressure

swing adsorption process steps.

All manner of processes for the pretreatment

and separation of natural gas as well as the

extraction of NGL, LPG, nitrogen and helium

are offered by the Engineering Division.

LNG plant block scheme.

A typical LNG plant is comprised of the

following units:

LNG metering stations

Sometimes in addition the following units

are required:

Feed gas compression, in case the natural

gas pressure is low

CO2 removal, mostly by a wash process and

drying H2O removal by an adsorber (CO2 and

H2O would otherwise freeze and cause clogging in the downstream liquefaction equipment)

Natural gas liquefaction

Refrigeration system and

refrigerant make-up unit

LNG storage

LNG loading stations

Sour

gas

Exhaust

gas

hot

oil

Feed gas

compression

Refrigerant

make-up unit

flue

gas

Gas turbine

NG purification

CO2 removal

Fire fighting

NG purification

dryer

Utilities

liquid refr.

dry

NG

vap. refr.

fuel gas

fuel gas

hot oil

purified

NG

Boil-off gas

(fuel gas)

compression

Refrigeration

system

lean

solvent

rich

NG

solvent

Solvent

regeneration

Natural gas

Waste heat

recovery

hot oil

hot oil

Hot oil

system

hot oil

Waste

water

Condensate stabilisation

Fractionation

N2 removal

NG

liquefaction

Flare

LNG

LNG

storage

LNG

LNG loading

station

container

LNG loading

jetty

LNG loading

station truck

LNG

LNG meters

LNG

LNG

LNG meters

Single mixed refrigerant liquefaction process:

LIMUM1

LIMUM1 (Linde multi-stage mixed refrigerant process applying platefin heat exchanger)

The LP MR (mixed refrigerant) is compressed in a two stage centrifugal

compressor and partially condensed against cooling water or air

Both phases of the compressed MR are jointly fed to a brazed aluminium

plate-fin heat exchanger, are fully liquefied and subcooled

After expansion in a J-T valve the MR if fully vaporized under low pressure providing refrigeration for natural gas liquefaction and fractionation, if required.

Basic single flow LNG process

for less than 0.5 mtpa LNG

NG

Fractionator

N2

NGL

LNG

LP MR

HP MR

References.

LNG plant in Kollsnes, Norway

Capacity

Customer

Start-up

40,000 tpa

Naturgass Vest, now Gasnor

2003

LNG is distributed by trucks and by small LNG

transport ships to satellite stations. One innovative feature of this project is the use of LNG as

fuel in ferry boats along the Norwegian coast.

There are many advantages replacing diesel

with LNG. The exhaust gas of the engines is

clean and free of solid particles. NOx and CO2

emissions are reduced. The engines and therefore the ferries have a reduced noise level.

LNG plant in Kwinana, Australia

Capacity

Customer

Start-up

62,500 tpa

Westfarmers Gas Limited

2008

LNG is produced from pipeline gas and is then

distributed by truck to various customers, such

as peak shaving power stations. Here the LNG

replaces diesel and other fuels, which are less

environmentally acceptable.

Single mixed refrigerant liquefaction process:

LIMUM3

LIMUM3 (Linde multi-stage mixed refrigerant process applying coilwound heat exchanger)

The LP MR (mixed refrigerant) is compressed in a two stage centrifugal

compressor and partially condensed against cooling water or air

The heavy, liquid MR fraction os used in a coil-wound heat exchanger

to pre-cool natural gas and to condense the light, gaseous MR fraction

partially

The resulting, intermediately boiling MR fraction serves as liquefaction

refrigerant, while the remaining light ends MR fraction sub-cools the

liquefied natural gas

Advanced single flow LNG process

for 0.2 to 1.0 mtpa LNG

LNG

Fractionator

N2

NGL

NG

LP MR

HP MR

References.

LNG plants in China

Capacity

Customer

Start-up

430,000 tpa

Xin Jiang Guanghui

2004

Capacity

Customer

Start-up

430,000 tpa

Xin Jiang Ji Munai Guanghui

2013

Capacity

Customer

Start-up

300,000 tpa

Huineng Coal Chemical Co. Ltd.

2013

Capacity

Customer

Start-up

350,000 tpa

Siehuang Tonghei Engery &

Technology Dev. Co. Ltd.

2014

All of these LNG plants are highly flexible and

excel due to their robustness. As special feature

the plant in Jimunai has a nitrogen removal column integrated into the liquefaction process.

This is an economically attractive concept for

nitrogen rich feed gases. LNG is transported by

trucks to a large number of satellite stations.

This LNG scheme creates new gas markets and

provides a great improvement in the tight energy supply situation in China.

LNG plant in Stavanger, Norway

Capacity

Customer

Start-up

300,000 tpa

Lyse Gass AS

2010

Due to the high feed gas pressure and based

on the Linde proprietary LIMUM process this

LNG plant achieves an outstanding energy efficiency. The plant supplies LNG to both the local

industry and AGA, an affiliate of the Linde Gas

division. The AGA quota of the produced LNG

is first shipped to an import terminal in Nynshamn, Sweden, which was built as well by Linde

Engineering.

LNG plant in Bintulu, Malaysia

Capacity

Customer

Start-up

650,000 tpa

MLNG

2014

The plant is the worlds largest re-liquefaction

plant for N2 rich boil-off gases from MLNGs LNG

complex in Bintulu, Malaysia.

10

MFC process (mixed-fluid cascade).

The MFC process is highly efficient due to the use of the three mixed

refrigerant cycles.

The process is comprised of:

Plate-fin heat exchangers for natural gas precooling

CWHEs (coil-wound heat exchangers) for natural gas liquefaction and

LNG subcooling

Three separate mixed refrigerant cycles, each with different compositions, which result in minimum compressor shaft power requirement

Three cold suction centrifugal compressors

> 10 mtpa LNG can be produced in a single train.

MFC (mixed-fluid cascade) process

for 3 to 12 mtpa LNG

NG

LNG

SMR

LMR

LMR

SMR

11

LNG plant in Hammerfest, Norway.

Capacity

Customer

Start-up

4.3 mtpa

(million tons per annum)

Statoil

2007

This is Europes first and the worlds northernmost LNG baseload plant. The MFC (mixed fluid

cascade) process together with the low cooling

water temperature at the site are the basis for

the extremely low specific power consumption

of the plant (less than 250 kWh/t).

This LNG project has another distinguishing feature: the entire LNG baseload plant was preassembled in various shipyards in Europe and

transported to its operating location on HLVs

(heavy lift vessels). The process plant itself was

installed on a barge in a shipyard, transported

by HLV and finally grounded in a prepared dock

at the site.

12

Coil-wound heat exchanger.

The ample choice of usable alloys including aluminium and stainless

steel allow coil-wound heat exchangers to be used for a wide range of

applications in cold as well as warm applications. The coil-wound heat

exchanger is the core equipment in large base-load LNG plants.

The Engineering Division has numerous references for coil-wound heat

exchangers designed and manufactured in its own workshops.

Benefits

Providing a large heating surface per shell

Tolerant against thermal shocks due to its robust design

Manufacturing of coil-wound heat exchanger

in Linde workshop

13

Refrigerant inlet

Manhole

Baffle plate

Pre-distributor

Tube bundle pigtail

Mandrel

Distributor

Lifting trunnion

Hand hole

Bonnet

Transition joint

Bundle outlet nozzle

Drain

Vent

Shroud

Tube bundle with alternating winding direction

Platform stubs

Insulation support ring

Vessel shell

Vacuum ring

2 multi nozzle

Temperature detector junction box

Bundle inlet nozzle

Tube sheet

Refrigerant outlet

Skirt

The coil-wound heat exchanger

is the core equipment in large baseload

LNG plants.

14

Plate-fin heat exchanger.

The vacuum brazed aluminium plate-fin heat exchangers are key components in many cryogenic process plants. They are the preferred heat exchangers in small LNG plants.

Benefits

Compactness, saving installation space and investment costs

Many process streams can be handled in a single unit, thus avoiding

expensive interconnecting piping of different units

Low equipment weight

Aluminium plate-fin heat exchangers assembled

in Linde workshop

15

Stub pipe

Distributor fin

Header tank

Heat transfer fin

Partition plate

Side bar

Cover plate

Scheme of an aluminium plate-fin

heat exchanger

The vacuum brazed aluminium plate-fin

heat exchangers are key components in many

cryogenic process plants. They are the preferred heat exchangers in small LNG plants.

Designing processes constructing plants.

Lindes Engineering Division continuously develops extensive process engineering know-how for the planning,

project management and construction of turnkey industrial plants.

The range of products comprises:

Petrochemical plants

LNG and natural gas processing plants

Synthesis gas plants

Hydrogen plants

Gas processing plants

Adsorption plants

Air separation plants

Cryogenic plants

Biotechnology plants

Furnaces for petrochemical plants and refineries

The Engineering Division

and its subsidiaries manufacture:

Packaged units, coldboxes

Coil-wound heat exchangers

Plate-fin heat exchangers

Cryogenic standard tanks

Air-heated vaporizers

Spiral-welded aluminium pipes

More than 4,000 plants worldwide document the leading position of the Engineering Division in international

plant construction.

Linde Impianti Italia S.L.R.

Rome, Italy

Phone +39.066.5613-1

Fax

+39.066.5613-200

impiantiitalia@linde-le.com

Linde Engineering Dresden GmbH

Dresden, Germany

Phone +49.351.250-30

Fax

+49.351.250-4800

ledd@linde-le.com

Linde Kryotechnik AG

Pfungen, Switzerland

Phone +41.52.3040-555

Fax

+41.52.3040-550

kryotechnik@linde-le.com

SELAS-LINDE GmbH

Pullach, Germany

Phone +49.89.7447-470

Fax

+49.89.7447-4717

selaslinde@linde-le.com

Bertrams Heatec AG

Pratteln, Switzerland

Phone +41.61.467-7525

Fax

+41.61.467-7500

bertramsheatec@linde-le.com

Cryostar SAS

Hsingue, France

Phone +33.389.70-2727

Fax

+33.389.70-2777

info@cryostar.com

CRYO AB

Gothenburg, Sweden

Phone +46.3164-6800

Fax

+46.3164-2220

cryo@linde-le.com

Linde CryoPlants, Ltd.

Aldershot, United Kingdom

Phone +44.1252.3313-51

Fax

+44.1252.3430-62

lindecryoplants@linde-le.com

Linde Process Plants, Inc.

Tulsa, OK, U.S.A.

Phone +1.918.4771-200

Fax

+1.918.4771-100

lpp@linde-le.com

Linde Engineering

North America, Inc.

Blue Bell, PA, U.S.A.

Phone +1.610.834-0300

Fax

+1.610.834-0473

lena@linde-le.com

Hydro-Chem

Holly Springs, GA, U.S.A.

Phone +1.770.345-2222

Fax

+1.770.345-2778

hydrochem@linde-le.com

Linde Engenharia do Brasil Ltda.

So Paulo, Brazil

Phone +55.21.3545-2255

Fax

+55.21.3545-2257

braziloffice@linde-le.com

Linde Process Plants (Pty), Ltd.

Johannesburg, South Africa

Phone +27.11.490-0513

Fax

+27.11.490-0412

southafrica@linde-le.com

Moscow Rep. Office

Moscow, Russia

Phone +7.495.642-6242

Fax

+7.495.642-6243

moscowoffice@linde-le.com

Linde Engineering RUS, OOO

Samara, Russia

Phone +7.846.331-3355

lerus@linde-le.com

Linde Arabian Contracting Co., Ltd.

Al-Khobar, Kingdom of Saudi Arabia

Phone +966.3.887-1191

Fax

+966.3.887-0133

lac@linde-le.com

Linde Arabian Contracting Co., Ltd.

Riyadh, Kingdom of Saudi Arabia

Phone +966.1.419-1193

Fax

+966.1.419-1384

lac@linde-le.com

Linde Engineering Middle East LLC

Abu Dhabi, United Arab Emirates

Phone +971.2.6981-400

Fax

+971.2.6981-499

leme@linde-le.com

Linde Engineering India Pvt., Ltd.

Vadodara, Gujarat, India

Phone +91.265.3056-789

Fax

+91.265.2461-757

india@linde-le.com

Linde AG

Engineering Division, Head office, Dr.-Carl-von-Linde-Strasse 6-14, 82049 Pullach, Germany

Phone +49.89.7445-0, Fax +49.89.7445-4908, E-Mail: info@linde-le.com, www.linde-engineering.com

Linde Engineering Far East, Ltd.

Seoul, South Korea

Phone +82.2780-0954

Fax

+82.2780-0958

fareast@linde-le.com

Linde Engineering (Dalian)

Co., Ltd.

Dalian, P.R. of China

Phone +86.411.3953-8819

Fax

+86.411.3953-8899

led@linde-le.com

Linde Engineering (Hangzhou)

Co., Ltd.

Hangzhou, P.R. of China

Phone +86.571.8501-9222

Fax

+86.571.8501-9200

leh@linde-le.com

Beijing Rep. Office

Beijing, P.R. of China

Phone +86.10.6437-7014

Fax

+86.10.6437-6718

beijingoffice@linde-le.com

Linde Engineering Taiwan Branch

Taipei, Taiwan

Phone +886.2.2786-3131

Fax

+886.2.2652-5871

taiwanoffice@linde-le.com

LNG/1.1.e/13

Linde Engineering Schalchen Plant

Tacherting, Germany

Phone +49.8621.85-0

Fax

+49.8621.85-6620

schalchenplant@linde-le.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 2mins from Kyoto station☆big group - Kyōto-shi的公寓 出租Document1 page2mins from Kyoto station☆big group - Kyōto-shi的公寓 出租Mark J.L. ChenNo ratings yet

- Kyoto's Best RoomDocument1 pageKyoto's Best RoomMark J.L. ChenNo ratings yet

- Guest Izba Banya Podvorye DiminoDocument1 pageGuest Izba Banya Podvorye DiminoMark J.L. ChenNo ratings yet

- Enjoy Kyoto Miki HouseDocument1 pageEnjoy Kyoto Miki HouseMark J.L. ChenNo ratings yet

- Good Access To Kyoto Sta DowntownDocument1 pageGood Access To Kyoto Sta DowntownMark J.L. ChenNo ratings yet

- Stay As 5ppl1min To Kyoto sta+WIFIDocument1 pageStay As 5ppl1min To Kyoto sta+WIFIMark J.L. ChenNo ratings yet

- 月光荘. Moonlight GuesthouseDocument3 pages月光荘. Moonlight GuesthouseMark J.L. ChenNo ratings yet

- Luxurious Residence in Gion Kyoto - 京都的獨立屋 出租Document8 pagesLuxurious Residence in Gion Kyoto - 京都的獨立屋 出租Mark J.L. ChenNo ratings yet

- Toba Seaside Hotel in Ise-ShimaDocument3 pagesToba Seaside Hotel in Ise-ShimaMark J.L. ChenNo ratings yet

- Japan - The Best of AirbnbDocument4 pagesJapan - The Best of AirbnbMark J.L. ChenNo ratings yet

- Shokoku JiDocument3 pagesShokoku JiMark J.L. ChenNo ratings yet

- Modern MACHIYA With WoodDocument8 pagesModern MACHIYA With WoodMark J.L. ChenNo ratings yet

- LNG 1 1 e 13 150dpi19 4577Document16 pagesLNG 1 1 e 13 150dpi19 4577Mark J.L. Chen100% (1)

- Heat ExchangerDocument12 pagesHeat ExchangeremergingengineerNo ratings yet

- SCFMDocument1 pageSCFMMark J.L. ChenNo ratings yet

- MIT1 040s09 Lec22Document43 pagesMIT1 040s09 Lec22patilsachin70No ratings yet

- Gas TurbinesDocument1 pageGas TurbinesMark J.L. ChenNo ratings yet

- SPRUTT Clothes-Hanger - Yellow - IKEADocument3 pagesSPRUTT Clothes-Hanger - Yellow - IKEAMark J.L. ChenNo ratings yet

- Online Indian ExportDocument1 pageOnline Indian ExportMark J.L. ChenNo ratings yet

- 文件1Document2 pages文件1Mark J.L. ChenNo ratings yet

- Translate GoogleusercontentDocument1 pageTranslate GoogleusercontentMark J.L. ChenNo ratings yet

- 文件1Document2 pages文件1Mark J.L. ChenNo ratings yet

- Translate GoogleusercontentDocument1 pageTranslate GoogleusercontentMark J.L. ChenNo ratings yet

- Translate GoogleusercontentDocument1 pageTranslate GoogleusercontentMark J.L. ChenNo ratings yet

- Phone User GuideDocument295 pagesPhone User GuideEdward BettsNo ratings yet

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Electromagnetic Spectrum 1 QP PDFDocument13 pagesElectromagnetic Spectrum 1 QP PDFWai HponeNo ratings yet

- Epicor Software India Private Limited: Brief Details of Your Form-16 Are As UnderDocument9 pagesEpicor Software India Private Limited: Brief Details of Your Form-16 Are As UndersudhadkNo ratings yet

- Village Survey Form For Project Gaon-Setu (Village Questionnaire)Document4 pagesVillage Survey Form For Project Gaon-Setu (Village Questionnaire)Yash Kotadiya100% (2)

- 6Document2 pages6Min Hsuan HsianNo ratings yet

- E61 DiagramDocument79 pagesE61 Diagramthanes1027No ratings yet

- Senior Project RiceberryDocument76 pagesSenior Project RiceberryIttisak PrommaNo ratings yet

- Maxillofacial Notes DR - Mahmoud RamadanDocument83 pagesMaxillofacial Notes DR - Mahmoud Ramadanaziz200775% (4)

- Leather & Polymer - Lec01.2k11Document11 pagesLeather & Polymer - Lec01.2k11Anik AlamNo ratings yet

- Indian Standard (First Revision) : Method of Chemical Analysis of Hydraulic CementDocument44 pagesIndian Standard (First Revision) : Method of Chemical Analysis of Hydraulic CementArijit dasguptaNo ratings yet

- Potato Storage and Processing Potato Storage and Processing: Lighting SolutionDocument4 pagesPotato Storage and Processing Potato Storage and Processing: Lighting SolutionSinisa SustavNo ratings yet

- NG Teng Fong Discharge DocumentsDocument14 pagesNG Teng Fong Discharge DocumentsAnonymous yGwMIPJRawNo ratings yet

- Adenoid HypertrophyDocument56 pagesAdenoid HypertrophyWidi Yuli HariantoNo ratings yet

- Study Notes On Isomers and Alkyl HalidesDocument3 pagesStudy Notes On Isomers and Alkyl HalidesChristian Josef AvelinoNo ratings yet

- BQ - Electrical Calibration Relay Bld803, NPBDocument2 pagesBQ - Electrical Calibration Relay Bld803, NPBKazuya KasumiNo ratings yet

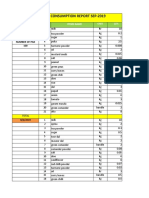

- Daily Staff Food Consumption Reports Sep-2019Document4 pagesDaily Staff Food Consumption Reports Sep-2019Manjit RawatNo ratings yet

- Pioneer PDP 5071 5070pu Arp 3354Document219 pagesPioneer PDP 5071 5070pu Arp 3354Dan Prewitt100% (1)

- The Emom Manual: 25 Kettlebell Conditioning WorkoutsDocument14 pagesThe Emom Manual: 25 Kettlebell Conditioning WorkoutsguilleNo ratings yet

- Feature: SFP Optical Module 1 .25G Double Optical Fiber 20kmDocument2 pagesFeature: SFP Optical Module 1 .25G Double Optical Fiber 20kmDaniel Eduardo RodriguezNo ratings yet

- Starkville Dispatch Eedition 9-10-20Document12 pagesStarkville Dispatch Eedition 9-10-20The DispatchNo ratings yet

- Case Study of Milk ProductionDocument46 pagesCase Study of Milk Productionmian21100% (2)

- Congenital Flexural Deformity in CalfDocument6 pagesCongenital Flexural Deformity in CalfBibek SutradharNo ratings yet

- Chemical Engineering Projects List For Final YearDocument2 pagesChemical Engineering Projects List For Final YearRajnikant Tiwari67% (6)

- TC 10 emDocument7 pagesTC 10 emDina LydaNo ratings yet

- S ELITE Nina Authors Certain Ivey This Reproduce Western Material Management Gupta Names Do OntarioDocument15 pagesS ELITE Nina Authors Certain Ivey This Reproduce Western Material Management Gupta Names Do Ontariocarlos menaNo ratings yet

- Far Eastern University - Manila Income Taxation TAX1101 Fringe Benefit TaxDocument10 pagesFar Eastern University - Manila Income Taxation TAX1101 Fringe Benefit TaxRyan Christian BalanquitNo ratings yet

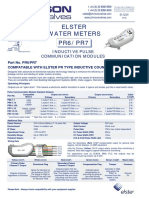

- Data Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleDocument1 pageData Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleThaynar BarbosaNo ratings yet

- Neopuff PDFDocument4 pagesNeopuff PDFoechimNo ratings yet

- Pantera 900Document3 pagesPantera 900Tuan Pham AnhNo ratings yet

- Method Statement (RC Slab)Document3 pagesMethod Statement (RC Slab)group2sd131486% (7)

- Benzil PDFDocument5 pagesBenzil PDFAijaz NawazNo ratings yet