Professional Documents

Culture Documents

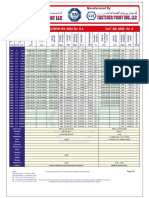

Tap Selection Chart

Uploaded by

Anonymous Q1frWgetsEOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tap Selection Chart

Uploaded by

Anonymous Q1frWgetsECopyright:

Available Formats

SPIRAL POINT

Bright

TiN

SPIRAL FLUTE

O

35

TiCN/ Bright

TiALN

TiN

SPIRAL FLUTE

O

15

TiCN/ Bright

TiALN

TiN

STRAIGHT

FLUTE

CAST IRON

TAP

A

C

D

TiCN/

Bright

TiALN Bright Bright Bright

TiN

FLUTELESS

TiCN/ Bright

TiALN

TiN

GUIDANCE CHART

FOR TAP SELECTION

AND APPLICATION

First Choice

Second Choice

APPLICATION

TENSILE

HARDNESS STRENGTH

2

HB

N/mm

MATERIAL

Steel

CUTTING

SPEED M/Min.

TYPE OF

COOLANT

TiN/

BRIGHT

TiCN

Low alloy Steel, Structural Steel

<200

<700

20

40

Sulfo- or chlorinated oil

Plain Carbon Steel, Alloy Steel & Steels

<250

<850

15

32

Sulfo- or chlorinated oil

<250

<850

12

Sulfo- or chlorinated oil

Through Hole

Blind Hole

Through or Blind Hole

with Good machinability

Stainless

Free Machining Stainless Steel

Steels

Austenitic Ferritic AISI 304,316,321

Cast Iron

Grey cast Iron

<150

<700

15

20

Dry, air jet or soluble oil

Malleable Cast Iron

<200

<700

15

Soluble oil or chemical-type coolant

Copper &

Soft

<100

<350

12

20

Light base oil

Its Alloys

Hard

<200

<700

25

40

Light base oil

Brass

Short Chipping

<200

<700

30

45

Soluble oil, light duty oil

Long Chipping

<200

<700

20

40

Soluble oil, light duty oil

Short Chipping

<300

<700

--

Soluble oil, light duty oil

Long Chipping

<200

<700

20

30

Soluble oil, light duty oil

Short Chipping Si<10%

<120

<400

20

35

Water soluble or oil/chemical especially for aluminum

Magnesium Short Chipping Si>10%

<120

<400

15

30

Water soluble or oil/chemical especially for aluminum

Long Chipping unalloyed

<100

<350

16

30

Oil specially recommended for magnesium

Medium Chipping Si <0.5%

<150

<500

30

50

Oil specially recommended for magnesium

20

40

Soluble oil

Bronze

Aluminum

Zinc alloys

1. Material to be machined

Type of hole

2. Hole type in which tapping is to be done

Use above chart for tap selection

BLIND HOLE

THROUGH HOLE

(For Ex :- For Short chipping brass)

How to find the

right tap ?

L <3D

L < 1 - 1/2 D

L <3D

Fig.T1

Fig.T2

Fig.B1

Fig.B2

(For Ex.:- "M" metric type of thread)

5. General Tap dimensions required

(For Ex.:- IS 6175 - III )

Select the hole type as given below

6. For Thread Forming Tap :

(For Ex. :- Blind hole)

(a) For Fig.T1 & B1- Use Fluteless Tap

Use above chart for tap selection

(For Ex. :- For short chipping brass)

select the hole type as given below

L < 1 - 1/2 D

4. Thread type required

(For Ex. :- blind hole)

3. Thread depth to be produced

Select the hole type as given below

(For Ex. :- blind hole with L < 3D)

(For Ex.:- L < 1 - 1/2 D)

(b) For Fig.T2 & B2- Use Fluteless Oil Groove.

(For Ex.:- L < 3 D)

7. For Blind Hole Tapping :

O

(a) For Fig.B1- Use 15 Spiral Flute

(For Ex.:- L < 1 - 1/2 D)

O

(b) For Fig.B2- Use 35 Spiral Flute

(For Ex.:- L < 3 D)

FLUTELESS OIL

GROOVE

TiCN/ Bright

TiALN

TiN

TiCN/

TiALN

You might also like

- Zinc PlatingDocument12 pagesZinc PlatingAtendra Singh100% (1)

- Haresh Steel Centre: Copper-Nickel Pipe, Fittings & FlangesDocument16 pagesHaresh Steel Centre: Copper-Nickel Pipe, Fittings & FlangesHaresh Steel CentreNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- QW 442 A Number PDFDocument1 pageQW 442 A Number PDFMadidj_2014No ratings yet

- Minerals and Metals in Ancient IndiaDocument2 pagesMinerals and Metals in Ancient IndiaSuneel KotteNo ratings yet

- Steel Grade Equivalency TableDocument2 pagesSteel Grade Equivalency TableBudy GedhaBlackNo ratings yet

- ERD Tin Product BrochureDocument10 pagesERD Tin Product BrochureLaura ElgarristaNo ratings yet

- Spirax Sarco Fig 33Document2 pagesSpirax Sarco Fig 33Jacobus CalvelageNo ratings yet

- PB Nozzles eDocument21 pagesPB Nozzles echipulinoNo ratings yet

- FT Ros enDocument14 pagesFT Ros enmarjan banooNo ratings yet

- Stainless Steel Welding by Weld RealityDocument50 pagesStainless Steel Welding by Weld RealitylightwinterdayNo ratings yet

- Gandhi TubesDocument6 pagesGandhi TubesmukeshkumarjNo ratings yet

- F7208HDocument15 pagesF7208HSopon SrirattanapiboonNo ratings yet

- 24.catalogue Breather-Cat-18-In-PowerDocument39 pages24.catalogue Breather-Cat-18-In-PowerAngel StragliatiNo ratings yet

- What Are ASTM GradesDocument4 pagesWhat Are ASTM Gradesmohan babuNo ratings yet

- Kitz UK Valves CataloqueDocument20 pagesKitz UK Valves CataloqueTaher YusufNo ratings yet

- NPA205 Black Rush TaeguTecDocument6 pagesNPA205 Black Rush TaeguTecpchakkrapaniNo ratings yet

- 13 BushingsDocument25 pages13 BushingsRolffoTelloNo ratings yet

- Emirates Aluminium Limited Green Carbon Plant and Butts CrushingDocument3 pagesEmirates Aluminium Limited Green Carbon Plant and Butts CrushingAnonymous FoHj39G8CNo ratings yet

- Dowel PinsDocument12 pagesDowel PinssugirinNo ratings yet

- Basic Steel Selection Based On BS 970 en SeriesDocument8 pagesBasic Steel Selection Based On BS 970 en SeriesAmarendra Pendse100% (1)

- Technical DataDocument17 pagesTechnical Datat_syamprasadNo ratings yet

- CapScrewA325 A490Document2 pagesCapScrewA325 A490sergiosilvahNo ratings yet

- Chevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceDocument1 pageChevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceAldeline Sungahid100% (1)

- Dimensions, Sizes and Specification of DIN Flange & DIN Standard Flanges of Slip On Flanges, Blind Flanges, Welding FlangesDocument7 pagesDimensions, Sizes and Specification of DIN Flange & DIN Standard Flanges of Slip On Flanges, Blind Flanges, Welding FlangesSudhanshu67No ratings yet

- Piping Material Specification-Rev0Document25 pagesPiping Material Specification-Rev0Mohsen Ardestani100% (4)

- Rectangular Hollow Section Cold Formed..BS en 102191997Document4 pagesRectangular Hollow Section Cold Formed..BS en 102191997Jagdish ChhuganiNo ratings yet

- Valves Pipe Fittings DimensionsDocument37 pagesValves Pipe Fittings DimensionstsoheilNo ratings yet

- STP CatalogueDocument37 pagesSTP CataloguemmkattaNo ratings yet

- DS DSL990 FR en Us 16831Document2 pagesDS DSL990 FR en Us 16831Rahul JadhavNo ratings yet

- Tool BitsDocument10 pagesTool BitsRamiro Duran ZambranoNo ratings yet

- Welding PresentationDocument48 pagesWelding Presentationedu_canete100% (2)

- Metal Casting Metal Casting Metal Casting Metal Casting Design, Materials, Economics Design, Materials, Economics G GDocument42 pagesMetal Casting Metal Casting Metal Casting Metal Casting Design, Materials, Economics Design, Materials, Economics G Gzubairsajid_87No ratings yet

- Materials of ConstructionDocument2 pagesMaterials of ConstructionirsyadairNo ratings yet

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- TGX Series: Stainless Flux Cored Filler Rods No Back Purge NecessaryDocument2 pagesTGX Series: Stainless Flux Cored Filler Rods No Back Purge Necessarygazwang478No ratings yet

- Fresa Men ToDocument292 pagesFresa Men ToSandra CrisostomoNo ratings yet

- Steel Supply Sub-Grades To EC3Document22 pagesSteel Supply Sub-Grades To EC3Anonymous iS33V5No ratings yet

- OneSteel Valve Product CatalogueDocument40 pagesOneSteel Valve Product CatalogueEr Pupone de Naza100% (1)

- Aluminium Sheet Grade 65032 SuppliersDocument17 pagesAluminium Sheet Grade 65032 Supplierssanghvi overseas incNo ratings yet

- 77e5-B005 (Hydraulic Cylinder)Document4 pages77e5-B005 (Hydraulic Cylinder)Sandeep JoshiNo ratings yet

- Tatin CelikDocument52 pagesTatin Celikgoran073No ratings yet

- 3 05 A Welding Specification of Carbon Steel Alloy SteelDocument40 pages3 05 A Welding Specification of Carbon Steel Alloy SteelvancongthanhNo ratings yet

- Gating DesignDocument16 pagesGating DesignNisar HussainNo ratings yet

- Erw Steel PipesDocument2 pagesErw Steel PipesyogacruiseNo ratings yet

- ASTM Standards 1Document4 pagesASTM Standards 1balajiNo ratings yet

- Fig - 33 TI S60 03 ENDocument5 pagesFig - 33 TI S60 03 ENAditomo PutrantoNo ratings yet

- Flanges General - Pressure-Temperature Ratings ASTM and ASMEDocument5 pagesFlanges General - Pressure-Temperature Ratings ASTM and ASMEjacksonbello34No ratings yet

- What Are ASTM Grades: Chemical Requirements CompositionDocument4 pagesWhat Are ASTM Grades: Chemical Requirements CompositionAnonymous 6ZWS6IG2J9No ratings yet

- DAC Activity-1Document27 pagesDAC Activity-1Samaroha NandiNo ratings yet

- T 6061Document5 pagesT 6061Zoran DanilovNo ratings yet

- Catalogue-Tungaloy 03 Boring ToolholderDocument27 pagesCatalogue-Tungaloy 03 Boring ToolholderAlejandro Alex EnriquezNo ratings yet

- Valve DetailDocument5 pagesValve DetailRakesh RanjanNo ratings yet

- AssemblyDocument1 pageAssemblymotorola1994No ratings yet

- Astm International Bsi - British Standards Institute: 1387 (Bs en 10255:2004)Document13 pagesAstm International Bsi - British Standards Institute: 1387 (Bs en 10255:2004)Vishal MistryNo ratings yet

- 23.catalogue Breather-Cat-18-In-DisDocument37 pages23.catalogue Breather-Cat-18-In-DisNicolas GallegosNo ratings yet

- JIS Standard ValveDocument8 pagesJIS Standard ValveJong JavaNo ratings yet

- ASTM A178 Welded Steel Pipes PDFDocument7 pagesASTM A178 Welded Steel Pipes PDFHardyson ChenNo ratings yet

- A. Placing Order of Material: Tracking FileDocument2 pagesA. Placing Order of Material: Tracking FileAnonymous Q1frWgetsENo ratings yet

- File Label Sheet1Document3 pagesFile Label Sheet1Anonymous Q1frWgetsENo ratings yet

- KPI Dashboard - Revisited IIDocument4 pagesKPI Dashboard - Revisited IIRupee Rudolf Lucy Ha100% (1)

- Exhibitors 2016Document25 pagesExhibitors 2016Anonymous Q1frWgetsENo ratings yet

- Bis Standards & Specifications (Master List)Document9 pagesBis Standards & Specifications (Master List)Anonymous Q1frWgetsENo ratings yet

- Valves Exhibitors ListDocument64 pagesValves Exhibitors ListAnonymous Q1frWgetsENo ratings yet

- Dubai Auto Fair Product IndexDocument59 pagesDubai Auto Fair Product IndexAnonymous Q1frWgetsENo ratings yet

- SuccessfulAuctionDetails11092020 PDFDocument4 pagesSuccessfulAuctionDetails11092020 PDFTapas PadhiNo ratings yet

- Equivalent Grades of Cast IronsDocument2 pagesEquivalent Grades of Cast IronsVinh Do Thanh100% (1)

- WSRC Ms 2001 00544Document25 pagesWSRC Ms 2001 00544arjun prajapatiNo ratings yet

- ASTM A563 - Portland BoltDocument5 pagesASTM A563 - Portland BoltamrNo ratings yet

- Schaffler DiagramDocument6 pagesSchaffler DiagramNikesh KoliNo ratings yet

- Mini Interruptores Termomagnéticos e Interruptores DiferencialesDocument52 pagesMini Interruptores Termomagnéticos e Interruptores DiferencialesJay SantanNo ratings yet

- Deca Catalogo GB e D PDFDocument88 pagesDeca Catalogo GB e D PDFJoséRoldánGarcíaNo ratings yet

- Chemical Composition of Solid Wire, WT.%:: C: AWS SFA 5.18 W P ER70S-2 H, F, Vu, Oh CDocument1 pageChemical Composition of Solid Wire, WT.%:: C: AWS SFA 5.18 W P ER70S-2 H, F, Vu, Oh CAshok RajNo ratings yet

- Astm A131Document7 pagesAstm A131Técnico XXXNo ratings yet

- Bracelets On Cartier® Official Website Cartier USDocument1 pageBracelets On Cartier® Official Website Cartier USAntea JukićNo ratings yet

- Tooling Materials&Heat TreatmentDocument13 pagesTooling Materials&Heat TreatmentVinod MadireddyNo ratings yet

- 1278 - Filler Rods For Gas WeldingDocument20 pages1278 - Filler Rods For Gas WeldingKaushik SenguptaNo ratings yet

- Sap 5Document22 pagesSap 5reza noviyantiNo ratings yet

- Market Survey: Construction & MaterialsDocument115 pagesMarket Survey: Construction & MaterialsRUSHALI SRIVASTAVANo ratings yet

- Global Overview of Ore-Based Metallics: Amm Dri & Mini-Mills Conference - November 2017Document30 pagesGlobal Overview of Ore-Based Metallics: Amm Dri & Mini-Mills Conference - November 2017NtlNo ratings yet

- DPR 1Document58 pagesDPR 1MITHUNNo ratings yet

- Finish - Chart Stainless SteelDocument3 pagesFinish - Chart Stainless SteelheshamNo ratings yet

- Pentrmeter SpecificationDocument30 pagesPentrmeter SpecificationJayeshNo ratings yet

- Delta FerriteDocument4 pagesDelta FerriteRavindra ErabattiNo ratings yet

- Parting ProcesssDocument8 pagesParting ProcesssAnwesh SatapathyNo ratings yet

- Insert Grades: A1 To A37Document38 pagesInsert Grades: A1 To A37sahil josephNo ratings yet

- Filler Metal Selection-SignedDocument14 pagesFiller Metal Selection-Signedamine bouizarNo ratings yet

- Grey CoatingDocument1 pageGrey CoatingazizNo ratings yet

- Bolt Standard BS 3692Document1 pageBolt Standard BS 3692Mai Xuan Truong0% (1)

- TKBG Hoa Hoc 9 Tap 1Document236 pagesTKBG Hoa Hoc 9 Tap 1Tạp Chí Hóa Học - www.hoahoc.orgNo ratings yet

- Study of Constituents of AlloysDocument17 pagesStudy of Constituents of AlloysPrakash Giri100% (2)