Professional Documents

Culture Documents

Anchor Design

Uploaded by

Anonymous BAzcBzWuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anchor Design

Uploaded by

Anonymous BAzcBzWuCopyright:

Available Formats

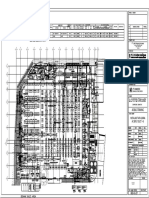

34-37_MEGA_A4.

qxd

25/11/05

9:56

Page 34

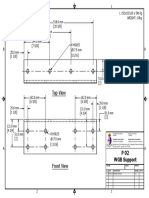

SPIT MEGA A4

1/4

Torque controlled expansion anchor, made of zinc

coated steel for use in cracked and non cracked

concrete

L

df

d0

Tinst

tfix

hef

h0

hmin

APPLICATION

Safety critical loads

Overhead crane rails

Steel columns and walkways

Wall plates

Safety rails

MATERIAL

Screw / threaded rod:

Grade 8.8, EN 20898-1

Cone: 1.0765 steel EN 10087

Expansion sleeve:

1.5530 steel EN 10083-3

Distance sleeve:

TS 37 a BK, NF A 49341

Washer: S 420 ml, EN 20898-2

Hexagonal nut:

Strength grade 8, EN 20898-2

Gavanised 5 m

Technical data

SPIT MEGA Z Min. Max. thick Min thick thread

anchor of part to of base

depth be fixed material

(mm)

(mm)

(mm)

(mm)

hef

tfix

hmin

d

V8-12/10

10

V8-12/20

20

V8-12/35

35

E8-12/10

60

10

120

8

E8-12/20

20

E8-12/35

35

E8-12/55

55

E8-12/95

95

V10-15/20

20

V10-15/45

45

E10-15/20

70

20

140

10

E10-15/45

45

E10-15/65

65

E10-15/100

100

V12-18/25

25

V12-18/45

45

E12-18/25

80

25

160

12

E12-18/45

45

E12-18/65

65

E12-18/105

105

V16-24/25

25

E16-24/25

100

25

200

16

E16-24/45

45

E16-24/95

95

V16P-24/25

25

E16P-24/20 125

20

250

16

E16P-24/70

70

Drilling

depth

drill

bit

clearance

(mm)

hO

(mm)

dO

(mm)

df

80

12

14

90

15

17

105

18

20

124

24

26

150

24

26

Total

Max.

Code

anchor tighten

lenth torque

(mm)

(Nm)

L

Tinst

80

053340

90

053260

105

053560

89

23

053350

99

053370

114

053380

134

053390

174

053310

110

053280

125

053570

114

46

053420

139

053430

159

053440

194

053320

120

053300

140

053580

132

80

053470

152

053480

172

053490

212

053330

140

052650

154

120 052860

174

052870

224

052880

165

052680

174

120 052680

224

052680

INSTALLATION

Anchor mechanical properties

Threaded part

fuk (N/mm2) Min. tensile strength

fyk(N/mm2) Yield strength

As (mm2)

Stressed cross-section

Wel (mm3) Elastic section modulus

M0Rk,s (Nm) Characteristic bending moment

M (Nm)

Recommended bending moment

34

M8

M10

M12

M16

800

640

36,6

31,23

30

17,1

800

640

58

62,3

60

34,2

800

640

84,3

109,17

105

59,9

800

640

157

277,47

266

152,2

34-37_MEGA_A4.qxd

25/11/05

9:56

Page 35

SPIT MEGA A4

2/4

The loads specified on this page allow judging the products performances, but cannot be used for the designing.

The data given in the pages CC method have to be applied.

Ultimate (NRu,m, VRu,m) / characteristic loads (NRk, VRk) in kN

Mean Ultimate loads are derived from test results in admissible service conditions, and characteristic loads are statistically determined.

Anchor size

SHEAR

M8

M10

M12

Non cracked concrete (C20/25)

hef

60

NRu,m

25

NRk

21

70

32

24

80

40

33

Cracked concrete (C20/25)

hef

NRu,m

NRk

70

35

27

80

42

31

60

24

18

M16

Anchor size

M10

M12

M16

100

74,5

56,9

125

91,7

71,7

Cracked and non cracked concrete (C20/25)

47,2

62,2

Type V VRu,m

VRk

40,6

50,3

Type E VRu,m

34,7

46,3

VRk

29,4

37,5

92,8

72,9

65,8

53,7

135

98

121

75,5

100

65,3

42

125

71

53,9

M16

M8

Mechanical anchors

TENSILE

Design Loads (NRd, VRd) for one anchor without edge or spacing influence in kN

N Rd =

N Rk *

Mc

VRd =

VRk *

Ms

*Derived from test results

TENSILE

Anchor size

SHEAR

M8

Non cracked concrete (C20/25)

hef

60

NRd

14,0

M10

M12

M16

M16

Anchor size

M8

M10

M12

M16

48,6

43,0

65,3

60,4

Cracked and non cracked concrete (C20/25)

70

13,3

80

18,3

100

37,9

125

47,8

Cracked concrete (C20/25)

hef

60

70

80

NRd

12,0

15,0

17,2

Mc = 1,5 for M8-M16 and Mc = 1,8 for M10-M12

100

28,0

125

35,9

Type V

Type E

VRd

VRd

27,1

23,5

33,5

30,0

Ms = 1,5 for Type V and Ms = 1,25 for Type E

Recommended loads (Nrec, Vrec) for one anchor without edge or spacing influence in kN

N Rec =

N Rk *

M . F

VRec =

VRk *

M . F

*Derived from test results

TENSILE

SHEAR

M16

Anchor size

M12

M16

100

27,1

125

34,1

46,7

43,1

Cracked concrete (C20/25)

hef

60

70

80

100

NRec

8,6

10,7

12,3

20,0

F = 1,4 ; Mc = 1,5 for M8-M16 and Mc = 1,8 for M10-M12

Cracked and non cracked concrete (C20/25)

Type V VRec

19,3

24,0

34,7

Type E VRec

16,8

21,4

30,7

F = 1,4 ; Ms = 1,5 for Type V and Ms = 1,25 for Type E

125

25,7

Anchor size

M8

Non cracked concrete (C20/25)

hef

60

NRec

10,0

M10

70

9,5

M12

80

13,1

M16

M8

M10

35

34-37_MEGA_A4.qxd

25/11/05

9:56

Page 36

SPIT MEGA A4

3/4

SPIT CC- Method

TENSILE in kN

N

SHEAR in kN

V

Pull-out resistance

N Rd,p = N

N0Rd,p

Anchor size

O

Rd , p

M8

Non cracked concrete

hef

N0Rd,p (C20/25)

O

VRd,c = VRd

,c .fb .f ,V .S C ,V

.fb

Design pull-out resistance

M10 M12 M16 M16

100

-

125

40,0

Cracked concrete

hef

60

70

80

N0Rd,p (C20/25)

5,0

6,7

13,9

Mc = 1,5 for M8-M16 and Mc = 1,8 for M10-M12

100

-

125

-

60

10,7

70

11,1

Design concrete edge resistance

at minimum edge distance (Cmin)

M8

M10 M12 M16

N Rd,c = N ORd ,c .fb .s .c, N

N0Rd,c

Anchor size

M8

Design cone resistance

M10 M12 M16 M16

Non cracked concrete

hef

N0Rd,c (C20/25)

60

15,6

70

16,4

80

20,0

Cracked concrete

hef

60

70

80

N0Rd,c (C20/25)

11,2

11,7

14,3

Mc = 1,5 for M8-M16 and Mc = 1,8 for M10-M12

Non cracked concrete

hef

Cmin

Smin

V0Rd,c (C20/25)

Cracked concrete

hef

Cmin

Smin

V0Rd,c (C20/25)

Mc = 1,5

Concrete cone resistance

100

33,6

100

24,0

60

75

70

6,4

70

95

80

10,1

80

108

90

13,4

100

150

110

25,0

60

75

70

4,6

70

95

80

7,2

80

108

90

9,5

100

150

110

17,8

Steel resistance

125

47,0

125

33,5

VRd,s

Anchor size

Steel design shear resistance

M8

M10 M12 M16

Non cracked concrete

Type V VRd,s

Type E VRd,s

Cracked concrete

Type V VRd,s

Type E VRd,s

Ms = 1,25

Steel resistance

NRd,s

Anchor size

NRd,s

Ms = 1,5

V0Rd,c

Anchor size

80

16,7

Concrete edge resistance

22,0

16,8

28,0

25,6

38,7

36

89,5

47,2

22,0

12,8

28,0

19,2

38,7

36

89,5

47,2

Steel design tensile resistance

M8

M10 M12 M16

19,3

30,7

44,7

83,7

NRd = min(NRd,p ; NRd,c ; NRd,s)

VRd = min(VRd,c ; VRd,s)

N = NSd / NRd 1

V = VSd / VRd 1

N1,5 + V1,5 1

fB INFLUENCE OF CONCRETE

Concrete class

C25/30

C30/37

C35/45

36

fB

1,1

1,22

1,34

Concrete class

C40/50

C45/55

C50/60

f,V INFLUENCE OF SHEAR LOADING DIRECTION

fB

1,41

1,48

1,55

Angle []

0 to 55

60

70

80

90 to 180

f,V

1

1,1

1,2

1,5

2

90

180

34-37_MEGA_A4.qxd

25/11/05

9:56

Page 37

SPIT MEGA A4

4/4

SPIT CC- Method

s INFLUENCE OF SPACING FOR CONCRETE CONE RESISTANCE IN TENSILE LOAD

70

80

90

110

150

180

210

240

270

300

S = 0, 5 +

Reduction factor s

Cracked and non-cracked concrete

M8

M10 M12 M16

0,69

0,72

0,69

0,75

0,71

0,69

0,81

0,76

0,73

0,68

0,92

0,86

0,81

0,75

1,00

0,93

0,88

0,80

1,00

0,94

0,85

1,00

0,90

0,95

1,00

s

6.hef

Smin < S < Scr,N

Scr,N = 3.hef

S must be used for each spacing

influenced the anchors group.

Mechanical anchors

SPACING S

c,N INFLUENCE OF EDGE FOR CONCRETE CONE RESISTANCE IN TENSILE LOAD

N

EDGE C

c, N = 0, 26 + 0, 48.

c

hef

Cmin < C < Ccr,N

Ccr,N = 1,5.hef

c,N must be used for each distance

influenced the anchors group.

Reduction factor c,N

Cracked and non-cracked concrete

M8

M10 M12 M16

0,86

0,94

0,84

1,00

0,91

0,83

0,98

0,89

1,00

0,92

0,79

0,98

0,84

1,00

0,98

1,00

75

85

95

105

110

120

150

187,5

s-c,V INFLUENCE OF SPACING AND EDGE DISTANCE FOR CONCRETE EDGE RESISTANCE IN SHEAR LOAD

For single anchor fastening

Factor s-c,V

Cracked and non-cracked concrete

C

Cmin

1,0

1,2

1,4

1,6

1,8

2,0

2,2

2,4

2,6

2,8

3,0

3,2

s-c,V

1,00

1,31

1,66

2,02

2,41

2,83

3,26

3,72

4,19

4,69

5,20

5,72

h>1,5.c

s c,V =

c

cmin

For 2 anchors fastening

cmin

s

h>1,5.c

s c,V =

3.c + s

c

.

6.cmin cmin

s1

s2

s3

sn-1

C

Cmin 1,0

Cmin

1,0

1,5

2,0

2,5

3,0

3,5

4,0

4,5

5,0

5,5

6,0

0,67

0,75

0,83

0,92

1,00

Factor s-c,V

Cracked and non-cracked concrete

1,2

1,4

1,6

1,8

2,0

2,2

2,4

2,6

2,8

3,0

3,2

0,84

0,93

1,02

1,11

1,20

1,30

1,03

1,12

1,22

1,32

1,42

1,52

1,62

1,22

1,33

1,43

1,54

1,64

1,75

1,86

1,96

1,43

1,54

1,65

1,77

1,88

1,99

2,10

2,21

2,33

1,65

1,77

1,89

2,00

2,12

2,24

2,36

2,47

2,59

2,71

2,83

1,88

2,00

2,12

2,25

2,37

2,50

2,62

2,74

2,87

2,99

3,11

2,12

2,25

2,38

2,50

2,63

2,76

2,89

3,02

3,15

3,28

3,41

2,36

2,50

2,63

2,77

2,90

3,04

3,17

3,31

3,44

3,71

3,71

2,62

2,76

2,90

3,04

3,18

3,32

3,46

3,60

3,74

4,02

4,02

2,89

3,03

3,18

3,32

3,46

3,61

3,75

3,90

4,04

4,33

4,33

3,16

3,31

3,46

3,61

3,76

3,91

4,05

4,20

4,35

4,65

4,65

For other case of fastenings

s c,V =

3.c + s1 + s2 + s3 + ... + sn 1

c

.

3.n.cmin

cmin

h>1,5.c

37

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Dynabolt Zinc Coated Steel Design GuideDocument4 pagesDynabolt Zinc Coated Steel Design GuideMuhammad SarajevoNo ratings yet

- 2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Document9 pages2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Difa LiuNo ratings yet

- Spit DynaboltDocument4 pagesSpit DynaboltMadePNo ratings yet

- HIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, MixerDocument11 pagesHIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, Mixerlael00No ratings yet

- Stainless StudsDocument4 pagesStainless StudsNestramiNo ratings yet

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Document12 pagesHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuNo ratings yet

- HVZ Adhesive Anchor: Basic Loading Data (For A Single Anchor) : HAS - (E-) TZDocument10 pagesHVZ Adhesive Anchor: Basic Loading Data (For A Single Anchor) : HAS - (E-) TZBogdanBNo ratings yet

- Chumbador HiltDocument14 pagesChumbador HiltSamanta FigueredoNo ratings yet

- Technical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315Document9 pagesTechnical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315dcarunchioNo ratings yet

- PEC Cals - 5433-300-2ADocument12 pagesPEC Cals - 5433-300-2AUsman MuhammadNo ratings yet

- Hilti HVZ 1Document13 pagesHilti HVZ 1Mihnea-Bogdan NicolaescuNo ratings yet

- 44 - HVZ Adhesive AnchorDocument14 pages44 - HVZ Adhesive AnchorHuan VoNo ratings yet

- Heavy-Duty Anchor TA M: TAM Approved ForDocument3 pagesHeavy-Duty Anchor TA M: TAM Approved ForGökhan GülhanNo ratings yet

- Hilti Manual For BoltDocument11 pagesHilti Manual For Boltcsengineer20% (1)

- ESA CNDocument2 pagesESA CNblble82No ratings yet

- HSV-R2 Stud Anchor: Concrete (Non-Cracked)Document8 pagesHSV-R2 Stud Anchor: Concrete (Non-Cracked)Ambreen FatimaNo ratings yet

- DIamond Walraven New CatalogueDocument225 pagesDIamond Walraven New Cataloguegk80823No ratings yet

- HSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHDocument10 pagesHSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHAlexandru OlaruNo ratings yet

- Design Calculation: Season 2 - Mechanical and Chemical Anchor CalculationDocument23 pagesDesign Calculation: Season 2 - Mechanical and Chemical Anchor CalculationNaveenNo ratings yet

- Anchor Fastening Technology ManualDocument152 pagesAnchor Fastening Technology ManualfdsafsadfNo ratings yet

- HSA Stud AnchorDocument11 pagesHSA Stud AnchorWin ThanNo ratings yet

- DEFNUT - Nituri TubulareDocument28 pagesDEFNUT - Nituri Tubularepaula09No ratings yet

- HHD - S.Technical - Information - ASSET - DOC - 2331274Document2 pagesHHD - S.Technical - Information - ASSET - DOC - 2331274Hoa Ly TrắngNo ratings yet

- Hilti - Calculo Manual de Re500Document41 pagesHilti - Calculo Manual de Re500James ClaytonNo ratings yet

- Hilti CatalogueDocument194 pagesHilti CatalogueFeleki AttilaNo ratings yet

- Declaratie de Conformitate Ancore MTH PDFDocument3 pagesDeclaratie de Conformitate Ancore MTH PDFFerencz ZsoltNo ratings yet

- Bolt StandardDocument42 pagesBolt StandardSHIVASHANKARNo ratings yet

- Fijaciones Químicas 2012 PDFDocument0 pagesFijaciones Químicas 2012 PDFMarcelo AlbeNo ratings yet

- Montavimo Technika Armaturos StrypamsDocument5 pagesMontavimo Technika Armaturos StrypamsHafidh BaequnieNo ratings yet

- 07 Assembly CS - ENDocument90 pages07 Assembly CS - ENandersson benito herreraNo ratings yet

- 07 Assembly HP - ENDocument67 pages07 Assembly HP - ENandersson benito herreraNo ratings yet

- 07 Assembly API - ENDocument55 pages07 Assembly API - ENandersson benito herreraNo ratings yet

- Anclaje HHD-SDocument2 pagesAnclaje HHD-SIngeniero Miguel VillarroelNo ratings yet

- 2013 87 - X-EnP Siding and Decking NailDocument8 pages2013 87 - X-EnP Siding and Decking NailDifa LiuNo ratings yet

- ELGES Alloy Steel Rod Ends: Corrosion-ResistantDocument8 pagesELGES Alloy Steel Rod Ends: Corrosion-Resistantdunareanu_marian8668No ratings yet

- CC936ADocument4 pagesCC936AKen Lau Boun KongNo ratings yet

- 07 Assembly CP - ENDocument104 pages07 Assembly CP - ENandersson benito herreraNo ratings yet

- WIT-PE 500 Design Manual RBDocument24 pagesWIT-PE 500 Design Manual RBMadusha TisseraNo ratings yet

- Dimensions, Sizes and Specification of DIN Flange & DIN Standard Flanges of Slip On Flanges, Blind Flanges, Welding FlangesDocument7 pagesDimensions, Sizes and Specification of DIN Flange & DIN Standard Flanges of Slip On Flanges, Blind Flanges, Welding FlangesSudhanshu67No ratings yet

- Product Catalogue.27214653 PDFDocument28 pagesProduct Catalogue.27214653 PDFJohny GharialNo ratings yet

- FTM '12 HKD Push-In AnchorDocument14 pagesFTM '12 HKD Push-In AnchorShankerNo ratings yet

- Shear Dowel: Shear Force Transmission in Expansion JointsDocument7 pagesShear Dowel: Shear Force Transmission in Expansion Jointsmoug_thNo ratings yet

- ConnectionsDocument205 pagesConnectionsbsitler100% (1)

- Bolt EqualentsDocument1 pageBolt EqualentsvkturkiNo ratings yet

- Earthing MaterialsDocument2 pagesEarthing MaterialsMohammed MustafaNo ratings yet

- Sadev Classic FXV enDocument15 pagesSadev Classic FXV enPeter DudasNo ratings yet

- (Xaydung360.Vn) 01 BoQ Interial Works The NASSIMDocument27 pages(Xaydung360.Vn) 01 BoQ Interial Works The NASSIMChâu TúNo ratings yet

- HVU Adhesive With HAS Rod: Basic Loading Data (For A Single Anchor) : HVU Capsule With HAS, HAS-EDocument5 pagesHVU Adhesive With HAS Rod: Basic Loading Data (For A Single Anchor) : HVU Capsule With HAS, HAS-EChristopher GarciaNo ratings yet

- 2014 HKD Push-In Anchor - Single Anchor ApplicationDocument3 pages2014 HKD Push-In Anchor - Single Anchor ApplicationDifa LiuNo ratings yet

- Tecfispa Vs Dop enDocument16 pagesTecfispa Vs Dop enThe DarkNo ratings yet

- 3 Hit-Hy150 HisnDocument9 pages3 Hit-Hy150 Hisndd160179No ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Guideline-on-Forensic-Engineering-Investigations - 0 4 PDFDocument1 pageGuideline-on-Forensic-Engineering-Investigations - 0 4 PDFAnonymous BAzcBzWuNo ratings yet

- BasementDocument1 pageBasementAnonymous BAzcBzWuNo ratings yet

- Plan Your Backyard Design: The Ultimate ChecklistDocument8 pagesPlan Your Backyard Design: The Ultimate ChecklistAnonymous BAzcBzWuNo ratings yet

- Your 12 Month Calendar: Grass Cutting & Lawn CareDocument3 pagesYour 12 Month Calendar: Grass Cutting & Lawn CareAnonymous BAzcBzWu100% (1)

- Guideline-on-Forensic-Engineering-Investigations - 0 2 PDFDocument1 pageGuideline-on-Forensic-Engineering-Investigations - 0 2 PDFAnonymous BAzcBzWuNo ratings yet

- Guideline-on-Forensic-Engineering-Investigations - 0 1 PDFDocument1 pageGuideline-on-Forensic-Engineering-Investigations - 0 1 PDFAnonymous BAzcBzWuNo ratings yet

- Guideline-on-Forensic-Engineering-Investigations - 0 1Document1 pageGuideline-on-Forensic-Engineering-Investigations - 0 1Anonymous BAzcBzWuNo ratings yet

- Chapter B: Using Reclamation's Concrete Maintenance and Repair SystemDocument1 pageChapter B: Using Reclamation's Concrete Maintenance and Repair SystemAnonymous BAzcBzWuNo ratings yet

- Guideline-on-Forensic-Engineering-Investigations - 0 2Document1 pageGuideline-on-Forensic-Engineering-Investigations - 0 2Anonymous BAzcBzWuNo ratings yet

- PEO Purpose For Guidelines: Interest Refers To The Safeguarding of Life, Health, PropertyDocument1 pagePEO Purpose For Guidelines: Interest Refers To The Safeguarding of Life, Health, PropertyAnonymous BAzcBzWuNo ratings yet

- Guideline-on-Forensic-Engineering-Investigations - 0 5Document1 pageGuideline-on-Forensic-Engineering-Investigations - 0 5Anonymous BAzcBzWuNo ratings yet

- Evaluate The Extent of DamageDocument1 pageEvaluate The Extent of DamageAnonymous BAzcBzWuNo ratings yet

- Chapter B: Using Reclamation's Concrete Maintenance and Repair SystemDocument1 pageChapter B: Using Reclamation's Concrete Maintenance and Repair SystemAnonymous BAzcBzWuNo ratings yet

- Maint. DeckDocument1 pageMaint. DeckAnonymous BAzcBzWuNo ratings yet

- BRE GuideDocument21 pagesBRE GuideAnonymous BAzcBzWu50% (4)

- B. Using Reclamation's Concrete Maintenance and Repair SystemDocument1 pageB. Using Reclamation's Concrete Maintenance and Repair SystemAnonymous BAzcBzWuNo ratings yet

- Tower 100Document1 pageTower 100Anonymous BAzcBzWuNo ratings yet

- Helical PiersDocument1 pageHelical PiersAnonymous BAzcBzWuNo ratings yet

- Final 2013Document1 pageFinal 2013Anonymous BAzcBzWuNo ratings yet

- Chapter A: Repair and Maintenance of ConcreteDocument1 pageChapter A: Repair and Maintenance of ConcreteAnonymous BAzcBzWuNo ratings yet

- Other Considerations: Fall Protection SolutionsDocument1 pageOther Considerations: Fall Protection SolutionsAnonymous BAzcBzWuNo ratings yet

- 1 Input Data: WWW - Hilti.caDocument7 pages1 Input Data: WWW - Hilti.caAnonymous BAzcBzWuNo ratings yet

- Storage Rooms UpdatedDocument3 pagesStorage Rooms UpdatedAnonymous BAzcBzWuNo ratings yet

- NMS Complete English TOC 1-11-18Document33 pagesNMS Complete English TOC 1-11-18Anonymous BAzcBzWuNo ratings yet

- AAMA WDMA CSA 101 I.S.2 A440-1c. Windows Doors and Skylights 12Document2 pagesAAMA WDMA CSA 101 I.S.2 A440-1c. Windows Doors and Skylights 12Anonymous BAzcBzWuNo ratings yet

- Presenters SummaryDocument4 pagesPresenters Summaryaloys NdzieNo ratings yet

- Shanmugam Mech deDocument3 pagesShanmugam Mech dekevinNo ratings yet

- Sheet3 - Composites - Fiber ReinforcedDocument3 pagesSheet3 - Composites - Fiber ReinforcedAbdalla Mohamed AbdallaNo ratings yet

- As Built Drawing: No Kontrak Area Servis Kode UnitDocument1 pageAs Built Drawing: No Kontrak Area Servis Kode UnitSaeful Malik GintingNo ratings yet

- MK4 - BEARINGS - AdvancedDocument52 pagesMK4 - BEARINGS - AdvancedWilmer Diaz TorresNo ratings yet

- DPWH Bldg. - Revised To 90percentDocument9 pagesDPWH Bldg. - Revised To 90percentJun Michael Artates VelascoNo ratings yet

- Demolish and Extension BoQ - Supply and Installation - 141019Document3 pagesDemolish and Extension BoQ - Supply and Installation - 141019Patrick SipatelaNo ratings yet

- SCG Decorative Wall Panel ModeenaDocument2 pagesSCG Decorative Wall Panel ModeenaJared Aaron CruzNo ratings yet

- Design Calculation For RC Ring BeamDocument19 pagesDesign Calculation For RC Ring BeamMahmoud FaroukNo ratings yet

- Beam Design ReportDocument29 pagesBeam Design Reportokechukwu1benjaminNo ratings yet

- Specification and Estimation Question BankDocument3 pagesSpecification and Estimation Question BankAsh Ravi100% (2)

- Soil Mechanics Lab ManualDocument39 pagesSoil Mechanics Lab ManualDharmaraaj RajalinggamNo ratings yet

- Huehoco Composite Materials Co., LTD. ANT D 4012 /A277-CN (W98)Document1 pageHuehoco Composite Materials Co., LTD. ANT D 4012 /A277-CN (W98)anbu2810wsNo ratings yet

- 2005-10-DIAVIK Mine A418 - Dike Techical Reference SheetDocument2 pages2005-10-DIAVIK Mine A418 - Dike Techical Reference SheetSalvatore MirandaNo ratings yet

- Girder-Slab System Design Guide v2.0 PDFDocument20 pagesGirder-Slab System Design Guide v2.0 PDFManoj GehlodNo ratings yet

- Air-Fuel-Ratio-Calculation For CarburettorDocument10 pagesAir-Fuel-Ratio-Calculation For Carburettorsumeetsharma27No ratings yet

- RCI Hand Out Chapter 4 - PPT - 4.2 One Way Ribbed SlabDocument46 pagesRCI Hand Out Chapter 4 - PPT - 4.2 One Way Ribbed SlabNathnael Jia100% (3)

- BS 1139-1.1-1990 Metal ScaffoldingDocument15 pagesBS 1139-1.1-1990 Metal ScaffoldingMuhamad HasbiNo ratings yet

- BILL NO 03 EarthworksDocument8 pagesBILL NO 03 Earthworksaz9No ratings yet

- Method of Statement List CP103 - 08sep2023Document1 pageMethod of Statement List CP103 - 08sep2023Kevin John PaglinawanNo ratings yet

- 02 Marine Multispecies Hatchery Complex Civil Detailed BOQ - 23.10.2019Document690 pages02 Marine Multispecies Hatchery Complex Civil Detailed BOQ - 23.10.2019samir bendreNo ratings yet

- Installation of Drilled Case MicropilesDocument13 pagesInstallation of Drilled Case MicropilesAntonio MorenoNo ratings yet

- API Inspection Categories Drilling RIG Equipment HoistingDocument5 pagesAPI Inspection Categories Drilling RIG Equipment Hoistingmalikpdj100% (6)

- Site Engineer Job - Huationg Contractor Pte LTD - 5337669 - JobStreetDocument5 pagesSite Engineer Job - Huationg Contractor Pte LTD - 5337669 - JobStreetBan YTNo ratings yet

- Concrete Industrial Ground Slabs: D. BeckettDocument38 pagesConcrete Industrial Ground Slabs: D. BeckettCarlo RabaiottiNo ratings yet

- Geto Aluminium Formwork User ManualDocument35 pagesGeto Aluminium Formwork User ManualbsudhareddyNo ratings yet

- Flow Past A Rotating CylinderDocument32 pagesFlow Past A Rotating CylinderSanjeet KumarNo ratings yet

- Geoelectric For GroundwaterDocument9 pagesGeoelectric For GroundwaterAbdurrahman WafiNo ratings yet

- G1 MergedDocument12 pagesG1 MergedJervin BragadoNo ratings yet

- Multiple Choice 7 Mechanical TestingDocument5 pagesMultiple Choice 7 Mechanical TestingChandra MohanNo ratings yet