Professional Documents

Culture Documents

Mankenberg Vacuum Valve

Uploaded by

Anibal QuezadaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mankenberg Vacuum Valve

Uploaded by

Anibal QuezadaCopyright:

Available Formats

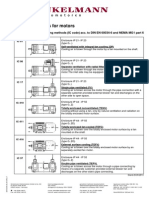

Pressure Control Valves

Vacuum Breakers,

Vacuum Control Valves

Vacuum breaker with setting scale

body CrNi-steel, stainless steel

spring cap brass, stainless steel

flange steel, stainless steel

PN...... 6 - 40

p2........ 0.05 - 0.95 bar diff. pressure

Kvs...... 1.5 - 388 m3/h

VV 36

VV 34

35

DN...... 20 - 250

G......... 3/4A - 2 1/2A

T.......... 300 C

Vacuum breaker without setting scale

stainless steel

PN...... 6 - 40

p2........ 0.05 - 0.1 bar diff. pressure

Kvs...... 1.2 - 25 m3/h

G......... 1/2A - 2 1/2A

T..........300 C

Vacuum Breaker

VV 59

all stainless steel SST 316 construction

PN...... 16

G......... 3/4A

p2........ 0,1 bar diff.-pressure

T..........40 C

Kvs...... 6 m3/h

VV 652

Vacuum control valve

Sheet no. VV/14.1.081.1 - issue 06.02.2008

please send us your operating data and a description of the application

Special versions on request. All the pressure has always been indicated as overpressure. We reserve the right to alter technical specifications without notice.

WIR REGELN DAS SCHON

FIRMLY IN CONTROL

Mankenberg GmbH Spenglerstrae 99 D-23556 Lbeck Tel. +49-451-8 79 75 0 Fax +49-451-8 79 75 99 gm@mankenberg.de www.mankenberg.de

Know How Vacuum valves

Vacuum breakers protect vessels and pipelines against vacuum. A vacuum can build up

when a system is being drained, when it cools down or when a pump fails.

Vacuum control valves are pressure reducing or overflow valves which control pressures

below 1 bara

Vacuum control valves:

See Kow How pressure reducing valves and overflow valves.

Vacuum breakers:

Operation

Vacuum breakers protect installations, vessels etc. against

vacuum. They are normally closed. If the pressure inside a

tank or vessel drops below atmospheric pressure by more

than the set differential pressure, the valve opens causing the

system to be vented until the set pressure difference has been

established again. Vacuum breakers remain closed when the

pressure rises above atmospheric; therefore they do not offer

protection against excessive pressure.

spring cap.

Protecting the vacuum breaker

As the suction orifices are open to atmosphere, they should be

adequately protected against the ingress of dust, dirt or insects. If there is a danger of freezing the vacuum breaker

should by fitted with a heating-jacket.

Setting the valve

The performance curves shown in the flow capacity diagram

relate to fully open valves. To obtain these values under partial

load conditions, the operating pressures on the scales of valve

types 34 and 35 should always be set 0.05 bar below the

pressures given in the diagram. The reason for this is the

spring force which increases as the flow and cone movement

increase.

Selecting valve type and nominal diameter

Vacuum breakers should be selected according to the pressu- Maintenance

re difference between the atmospheric pressure and the pres- Vacuum breakers should be cleaned and serviced regularly.

sure inside the vessel or pipeline, not according to the vacuum Depending on the ambient operating conditions, the valve

or absolute pressure in the vessel or pipeline. All specifica- spindle should regularly be checked for freedom of movement.

tions given in data sheets or tables or on the scales of valves The service intervals should be specified in a maintenance

etc., relate to this differential pressure. Another factor which schedule.

must be taken into account when selecting a vacuum valve is

the suction capacity. For very small differential pressures

Valves free of oil and grease or silicone

vacuum control valves can be used as vacuum breakers.

Please pay attention to order an fit only spares free of oil and

Sheet no. VV/13.1.041.1 - issue 26.04.2004

grease resp. free of silicone.

Vacuum breaker capacity table

Please use the capacity table to select your vacuum breaker.

The table applies to valve types 34, 35 and 36. On the left side Please consult our engineer if extreme operating conditiyou will find the nominal diameter; at the top (horizontally) you ons apply or whenever you are in doubt.

find the differential pressure given in bar at which the valve

opens.

Notes on Safety, operating instruction etc. MUST be

followed.

Full opening at set pressure

For applications which require a vacuum breaker to open fully

at the set pressure (to prevent a further rise in vacuum), our

weight-loaded vacuum breakers type 43 or 44 should be used.

Seat leakage

In their standard form vacuum breakers are supplied with a

metallic cone seal which requires less maintenance than a soft

seal. For more stringent leakage specifications these valves

can be supplied with soft seals. As vacuum breakers may remain in closed position for longer periods, a soft seal tends to

stick to the valve seat. The correct functioning of such valves

can therefore be guaranteed only if they are serviced frequently and carefully. Also the soft elastomer seal limits the

maximum possible operating temperature.

Protecting your system

If toxic or hazardous media are used measures must be taken

to ensure that in the case of cone failure the hazardous medium can be drained in a controlled and safe manner. In such a

case we reccomend our type 33 with closed valve body and

WIR REGELN DAS SCHON

FIRMLY IN CONTROL

Mankenberg GmbH Spenglerstrae 99 D-23556 Lbeck Tel. +49-451-8 79 75 0 Fax +49-451-8 79 75 99 gm@mankenberg.de www.mankenberg.de

Selection Vacuum Breaker

Vacuum Breakers

Selection

PN

16

16

6

6

16

6

40

40

40

40

40

40

T

C

300

300

300

300

300

300

Differential pressure

bar (adjustable)

0.05 - 0.95

0.05 - 0.5

0.05 - 0.95

0.05 - 0.1

0.05 - 0.95

0.05 - 0.95

Kvs-Value

m3/h

1.5

107

1.5

1.2

1.5

1.5

-

Connection

screwed

70

388

25

25

388

25

Notes

flanged DN V

20 - 100 Vlspring cap with setting scale

125 - 250 Vlspring cap with setting scale

3/4 - 2 1/2

spring cap with setting scale

1/2 - 2 1/2

open design, without scale

25 - 250 Vlweight loaded

3/4 - 2 1/2

Vweight loaded

Type

34

34

35

36

43

44

Vacuum Breakers 34, 35, 36, 43 and 44

Flow Rate [m3/h]

nominal

Differential Pressure (Set Pressure) [bar]

diameter

= 0.47

0.4

0.3

0.2

Sheet no. VV/11.1.061.1 - issue 12.06.2006

G 1/2

0.1

0.05

12

G 3/4

41

37

32

26

18

10

G1

71

66

57

46

33

18

G 1 1/4

127

117

102

82

58

32

G 1 1/2

199

183

158

129

91

50

G2

348

320

278

227

160

87

G 2 1/2

551

507

439

359

254

139

DN 20

41

37

32

26

18

10

DN 25

71

66

57

46

33

18

DN 32

127

117

102

82

58

32

DN 40

199

183

158

129

91

50

DN 50

348

320

278

227

160

87

DN 65

551

507

439

359

254

139

DN 80

891

819

710

580

410

225

DN 100

1514

1393

1207

986

697

382

DN 125

2316

2129

1846

1507

1065

584

DN 150

3664

3369

2921

2385

1686

923

DN 200

5768

5303

4597

3753

2654

1453

DN 250

8387

7711

6685

5458

3859

2114

The specified flow rate refer to a full open valve.

To get these flow rates the scale setting for type 34 and 35

must be 0.05 bar lower then the . p tabular values.

Type 36 is fully adjusted.

Special designs on request.

The pressure has always been indicated as overpressure.

Mankenberg reserves the right, to alter or improve the designs or specifications of the products described herein without notice.

WIR REGELN DAS SCHON

FIRMLY IN CONTROL

Mankenberg GmbH Spenglerstrae 99 D-23556 Lbeck Tel. +49-451-8 79 75 0 Fax +49-451-8 79 75 99 gm@mankenberg.de www.mankenberg.de

VV 34, 35, 36

Pressure Control Valves

Vacuum breaker, Vacuum ventilating valves,

Vacuum limiting valves

Technical Data

Connection

VV 34 DN 20 - 250

VV 35 G 3/4A - 2 1/2A

VV 36 G 1/2A - 2 1/2A

Nominal Pressure PN 6 - 40

Setting Range

0.05 - max. 0.95 bar

differential pressure

(see table below)

1.2 - 388 m3/h

Kvs-value

VV 34

VV 35

Description

Vacuum breakers also called vacuum venting valves or vacuum limiters - are valves which allow air to be aspirated once a

set vacuum or pressure difference to atmosphere is reached.

These valves are installed on pipelines, vessels, machines and

equipment and are used, for instance, for venting tanks, limiting

the vacuum in vacuum systems and protecting steam installations.

Under normal operating conditions the valve is kept closed by a

pre-loaded spring and the internal vacuum acting on the valve

cone. If the vacuum drops below the value set by means of the

spring, the valve is opened by the atmospheric pressure and air

enters the system. With increasing air flow the cone stroke and

spring force increase. The pressure difference increases accordingly.

VV 36

The VV 34 and VV 35 vacuum breakers have a tension spring

and a bonnet complete with scale for setting the breaking pressure.

Vacuum breaker VV 36 is an open version without bonnet or

setting scale made entirely of stainless steel.

For control duties vacuum breakers may be used only to a limited degree. For such duties we recommend using the diaphragm-controlled vacuum control valve VV 33.

Sheet no. VV 34/2.1.081.1 - issue 06.02.2008

STANDARD EQUIPMENT

VV 34 and 35 with brass bonnet and setting scale

VV 36 all stainless steel construction (CrNiMo steel)

OPTIONS

VV 34 and 35 all stainless steel construction (CrNiMo steel)

Special connections: ANSI or DIN flanges,

other connections on request

Special versions on request

Operating instructions, Know How and Safety instructions must

be observed.

The pressure has always been indicated as overpressure.

We reserve the right to alter technical specifications without notice.

Kvs-values [m3/h]

nom. dia.

DN

G..A

1/2

20

3/4

25

1

Kvs-value

m3/h

1.2

1.5

3.2

Kvs-values [m3/h]

32

40

1 1/4 1 1/2

6

50

2

65

2 1/2

16

25

nom. dia.

DN

80

100

125

150

200

250

Kvs-value

m /h

41

70

107

169

266

388

Adjustable Differential Pressure [bar]

Type

p bar

K DN 100

0.05-0.95

34

GDN 125

0.05-0.5

35

36

0.05-0.95

0.05-0.1

WIR REGELN DAS SCHON

FIRMLY IN CONTROL

Mankenberg GmbH Spenglerstrae 99 D-23556 Lbeck Tel. +49-451-8 79 75 0 Fax +49-451-8 79 75 99 gm@mankenberg.de www.mankenberg.de

VV 34, 35, 36

Pressure Control Valves

Vacuum breaker, Vacuum ventilating valves,

Vacuum limiting valves

Materials

Type

Body

Flange

Bonnet

Cone

Valve Seal

VV 34

VV 34

CrNi-steel optional CrNiMo-steel

steel optional CrNiMo-steel

Ms optional CrNiMo-steel

CrNiMo-steel

CrNiMo-steel

Materials

Type

Body

VV 35

CrNi-steel optional CrNiMo-steel

Bonnet

Cone

Valve Seal

Ms optional CrNiMo-steel

CrNiMo-steel

CrNiMo-steel

VV 35

Materials

Type

Body

VV 36

CrNiMo-steel

Cone

Valve Seal

CrNiMo-steel

CrNiMo-steel

Dimensions [mm] VV 34

nominal diameter

size 20 25 32 40

A

50

65

80

100 125 150 200 250

250 280 350 350 380 530 600 650 700 860 1140 1390

VV 36

Weights [kg] VV 34

nominal diameter DN

20

25

32

40

2

2.2 4.2 4.2

50

5.2

65

9.7

80 100 125

10.5 11.5 20

150

25

200

34

250

44

Dimensions (mm) VV 35

size

A

nominal diameter G...A

3/4

1

1 1/4

250

280

350

1 1/2

350

2

380

2 1/2

530

Weights [kg] VV 35

1 1/4

1.8

1 1/2

2.3

2

2.5

2 1/2

6

Dimensions [mm] VV 36

size

A

nominal diameter G...A

1/2

3/4

1

120

120

130

1 1/4

140

1 1/2

150

2

150

2 1/2

180

Weights [kg] VV 36

nominal diameter G...A

1/2

3/4

1

0.5

0.6

0.8

1 1/4

1

1 1/2

1.2

2

1.5

2 1/2

2

Special designs on request.

The pressure has always been indicated as overpressure.

Mankenberg reserves the right, to alter or improve the designs or specifications of the products described herein without notice.

WIR REGELN DAS SCHON

FIRMLY IN CONTROL

Mankenberg GmbH Spenglerstrae 99 D-23556 Lbeck Tel. +49-451-8 79 75 0 Fax +49-451-8 79 75 99 gm@mankenberg.de www.mankenberg.de

Sheet no. VV34/3.1.81.1 - issue 06.02.2008

nominal diameter G...A

3/4

1

1

1

VV 59

Pressure Control Valves

Vacuum breaker, Vacuum ventilating valves, Vacuum limiting valves

up to 40 C

Technical Data

Connection

Nominal Pressure

Set Pressure

Kvs Value

G 3/4A

PN 16

0,1 bar fixed adjusted

6 m3/h

Description

Vacuum breakers also called vacuum venting valves or vacuum limiters - are valves which allow air to be aspirated once a

set vacuum or pressure difference to atmosphere is reached.

These valves are installed on pipelines, vessels, machines and

equipment and are used, for instance, for venting tanks, limiting

the vacuum in vacuum systems and protecting steam installations.

Under normal operating conditions the valve is kept closed by a

pre-loaded spring and the internal vacuum acting on the valve

cone. If the vacuum drops below the value set by means of the

spring, the valve is opened by the atmospheric pressure and air

enters the system. With increasing air flow the cone stroke and

spring force increase. The pressure difference increases accordingly.

Due to the large dimensioned seat diameter VV 59 achieves an

outstanding high flow rate. This vacuum breaker is manufactured

from deep-drawn stainless steel featuring excellent corrosion

resistance. The valve cone is fitted with a soft seal.

Top and bottom sections of the valve body are connected by a

clamp ring and two bolts. Servicing/maintenance is easy and does

not call for special tooling.

For control duties vacuum breakers may be used only to a limited degree. For such duties we recommend using the diaphragm-controlled vacuum control valve VV 33.

STANDARD EQUIPMENT

Sheet no. VV 59/2.1.072.1 - issue 12.11.2007

All stainless steel construction

Removeable protection cap made of stainless steel

Quick-release body clamp ring

OPTIONS

Special connections on request

Special versions on request

Operating instructions, Know How and Safety instructions must

be observed.

The pressure has always been indicated as overpressure.

Kvs Value [m3/h]

6

We reserve the right to alter technical specifications without notice.

WIR REGELN DAS SCHON

FIRMLY IN CONTROL

Mankenberg GmbH Spenglerstrae 99 D-23556 Lbeck Tel. +49-451-8 79 75 0 Fax +49-451-8 79 75 99 gm@mankenberg.de www.mankenberg.de

VV 59

Pressure Control Valves

Vacuum breaker, Vacuum ventilating valves, Vacuum limiting valves

up to 40 C

Materials

Body

stainless steel

Protection Cap

Body Seal

stainless steel

EPDM

Cone

Spring

ball made of NBR

stainless steel

Dimensions [mm]

nominal diameter

size

G 3/4A

148

136/110

Weight [kg]

nominal diameter

G 3/4A

1,5

Sheet no. VV59/3.1.072.1 - issue 12.11.2007

Special designs on request.

The pressure has always been indicated as overpressure.

Mankenberg reserves the right, to alter or improve the designs or specifications of the products described herein without notice.

WIR REGELN DAS SCHON

FIRMLY IN CONTROL

Mankenberg GmbH Spenglerstrae 99 D-23556 Lbeck Tel. +49-451-8 79 75 0 Fax +49-451-8 79 75 99 gm@mankenberg.de www.mankenberg.de

You might also like

- SPM Full Bore Emergency Unloading Valve Manual PDFDocument9 pagesSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Proportional Electro-Hydraulic ControlsDocument31 pagesProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Convertidor Neumatico Y695ADocument8 pagesConvertidor Neumatico Y695AALBERTONo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Pm512 en MainDocument8 pagesPm512 en MainDusan GordicNo ratings yet

- Float Valves for Tanks and PipelinesDocument28 pagesFloat Valves for Tanks and PipelinescartarNo ratings yet

- Pressure relief devices for power transformersDocument8 pagesPressure relief devices for power transformersnagpurwale2011No ratings yet

- VCLDocument5 pagesVCLoutlander2008No ratings yet

- Convertidor Mechanical S108KDocument8 pagesConvertidor Mechanical S108KALBERTONo ratings yet

- Pressure Vacuum BleedersDocument4 pagesPressure Vacuum BleedersGustavo AlcaNo ratings yet

- Standard Pressure Testing ProcedureDocument10 pagesStandard Pressure Testing ProcedureAbdulbasit JunaidNo ratings yet

- PRDDocument30 pagesPRDMostafa MohmmedNo ratings yet

- 3-5400 Safety Relief Valves ManualDocument16 pages3-5400 Safety Relief Valves ManualPrashant ChauhanNo ratings yet

- Crankcase Pressure RegulatorsDocument11 pagesCrankcase Pressure Regulatorsdoni.ekosaputroNo ratings yet

- Pressure Test ProcedureDocument11 pagesPressure Test ProcedureRolando Nicanor0% (1)

- Armas 800 SeriesDocument44 pagesArmas 800 SeriesAlexisVillaNo ratings yet

- TescomDocument16 pagesTescomrafaareNo ratings yet

- HansenDocument4 pagesHansenBruna MacedoNo ratings yet

- Pressure Test ProceduresDocument10 pagesPressure Test ProceduresBibin VijayakumarNo ratings yet

- RVC 05 PDFDocument6 pagesRVC 05 PDFengp3077No ratings yet

- Selection GuideDocument12 pagesSelection GuideMiguel Angel VasquezNo ratings yet

- Direct Acting Excess Pressure ValvesDocument8 pagesDirect Acting Excess Pressure ValvescartarNo ratings yet

- E 55L 60Document2 pagesE 55L 60Gustavo Acosta MorenoNo ratings yet

- Viking Series 90 Operating & Maintenance Instructions: FiltersDocument15 pagesViking Series 90 Operating & Maintenance Instructions: FiltersninatenaNo ratings yet

- Inbal - Deluge Valve Pressure Control 03 - 13 CR01Document4 pagesInbal - Deluge Valve Pressure Control 03 - 13 CR01gustavosalvatoNo ratings yet

- Pressue CompensatorDocument2 pagesPressue CompensatorMahmud MaherNo ratings yet

- HANDBOOK Blanket Gas Regulators PDFDocument8 pagesHANDBOOK Blanket Gas Regulators PDFfrankz89No ratings yet

- Cocon QDocument4 pagesCocon QbayunsNo ratings yet

- ManualsDocument34 pagesManualsTreeNo ratings yet

- Vane Gaz Honeywell PDFDocument16 pagesVane Gaz Honeywell PDFdorckyNo ratings yet

- Ball Valves and Rotary Actors GuideDocument12 pagesBall Valves and Rotary Actors GuideAdvokat HadziTonicNo ratings yet

- 846 00 GB 0310Document8 pages846 00 GB 0310AlienshowNo ratings yet

- Wabco 9753034730 REGULADOR DE PRECION GOBERNADOR PDFDocument5 pagesWabco 9753034730 REGULADOR DE PRECION GOBERNADOR PDFOmar GarciaNo ratings yet

- 143i WillDocument4 pages143i WillMohamad FaruqiNo ratings yet

- Sporlan Adlse-2Document12 pagesSporlan Adlse-2Serrefriair Garcia RefriNo ratings yet

- Differential Pressure DetectorsDocument4 pagesDifferential Pressure Detectorskdp_806212786No ratings yet

- INBAL GeralDocument10 pagesINBAL GeralAlisson Gustavo KalilNo ratings yet

- TA-FUSION-C EN LowDocument16 pagesTA-FUSION-C EN LowTroi LauraNo ratings yet

- Guide to Valve Types, Uses, Maintenance and ControlDocument44 pagesGuide to Valve Types, Uses, Maintenance and Controlأحمد محمد قدريNo ratings yet

- PRS09 TC V PDFDocument4 pagesPRS09 TC V PDFengp3077No ratings yet

- 3-Way Dual Shut Off ValvesDocument1 page3-Way Dual Shut Off ValvesPete DechaNo ratings yet

- Dungs3 01Document8 pagesDungs3 01Andres ColladoNo ratings yet

- Valvulas de Seguridad Hansen PDFDocument4 pagesValvulas de Seguridad Hansen PDFLuis ReinoNo ratings yet

- Manual Valvula PCVDocument16 pagesManual Valvula PCVzamirgothNo ratings yet

- VCTDS-01042 Models Y1 BV-1 RA-Blanketing Regulator-EnDocument6 pagesVCTDS-01042 Models Y1 BV-1 RA-Blanketing Regulator-EnvipinNo ratings yet

- TankerDocument60 pagesTankerlopezdestructionNo ratings yet

- VXF41Document6 pagesVXF41Dukagjin RamqajNo ratings yet

- Supplemental Guide: Pressure Switch ProductsDocument12 pagesSupplemental Guide: Pressure Switch Productsing_vic1No ratings yet

- Sauter B6R Three-Way Valve With Female Thread, PN 16Document4 pagesSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991No ratings yet

- P11099-Fat ProcedureDocument5 pagesP11099-Fat ProcedureRicardoNo ratings yet

- Piezoresistive SensorDocument12 pagesPiezoresistive SensorAsghar AliNo ratings yet

- B&M Series 1000 SwitchesDocument12 pagesB&M Series 1000 SwitchesscribdkhatnNo ratings yet

- R431002626 AventicsH 3Controlair®ValveswithRollerDocument2 pagesR431002626 AventicsH 3Controlair®ValveswithRollerHamza ChenakerNo ratings yet

- Regulator de Presiune 41-23Document6 pagesRegulator de Presiune 41-23Cornel DumitruNo ratings yet

- Test Stand Technical ManualDocument51 pagesTest Stand Technical Manualewhf weGJO100% (1)

- Capacity RegulatorsDocument5 pagesCapacity Regulatorsdoni.ekosaputroNo ratings yet

- Boiler Mountings PDFDocument47 pagesBoiler Mountings PDFZohaib Alam100% (1)

- 0-WD910-EM610-00001 - RevB O&M Manual For WTS (Page 181)Document1 page0-WD910-EM610-00001 - RevB O&M Manual For WTS (Page 181)Anibal QuezadaNo ratings yet

- 107 sb3 12 5009 GN en 01 255455 v1Document4 pages107 sb3 12 5009 GN en 01 255455 v1Anibal QuezadaNo ratings yet

- Bearing Lift Oil Skid Assembly Manual (Pages 1,46-47,136-138, 141-143, 149)Document10 pagesBearing Lift Oil Skid Assembly Manual (Pages 1,46-47,136-138, 141-143, 149)Anibal QuezadaNo ratings yet

- 1&2-WD170-EE460-C0009 - Rev.F Control Valve List (Seiten 51-52)Document2 pages1&2-WD170-EE460-C0009 - Rev.F Control Valve List (Seiten 51-52)Anibal QuezadaNo ratings yet

- 9.steam Seal (Page 14) PDFDocument1 page9.steam Seal (Page 14) PDFAnibal QuezadaNo ratings yet

- 25 - 40 Spare Parts 2010 Pricing (Rev01)Document1 page25 - 40 Spare Parts 2010 Pricing (Rev01)Anibal QuezadaNo ratings yet

- Cooling Methods For Motors: Classification of The Cooling Methods (IC Code) Acc. To DIN EN 60034-6 and NEMA MG1 Part 6Document1 pageCooling Methods For Motors: Classification of The Cooling Methods (IC Code) Acc. To DIN EN 60034-6 and NEMA MG1 Part 6electworldNo ratings yet

- Chalk Point Fact SheetDocument1 pageChalk Point Fact SheetAnibal QuezadaNo ratings yet

- 2015-10-02 Voith Mom Enersur Uptooct-2015v1.0Document14 pages2015-10-02 Voith Mom Enersur Uptooct-2015v1.0Anibal QuezadaNo ratings yet

- Compressor Wash Skid Manual (Pages 1-14)Document14 pagesCompressor Wash Skid Manual (Pages 1-14)Anibal QuezadaNo ratings yet

- A Comparative Study of IEC 76 and ANSI C57.12 On TransformersDocument9 pagesA Comparative Study of IEC 76 and ANSI C57.12 On TransformersprasannamohandasNo ratings yet

- 0-WD170-EP442-C0001 - Rev.f - Manual Valve Datasheet & Drawings (Page 37)Document1 page0-WD170-EP442-C0001 - Rev.f - Manual Valve Datasheet & Drawings (Page 37)Anibal QuezadaNo ratings yet

- 0-WD992-ZZ100-00001 - RevAB Name Plate Drawing (Page 4)Document1 page0-WD992-ZZ100-00001 - RevAB Name Plate Drawing (Page 4)Anibal QuezadaNo ratings yet

- Bilfinger Investigates Compliance Violations in BrazilDocument1 pageBilfinger Investigates Compliance Violations in BrazilAnibal QuezadaNo ratings yet

- Multistage Vertical Inline Pumps PM1, PM3, PM5 Series: Specifications Information and Repair Parts ManualDocument12 pagesMultistage Vertical Inline Pumps PM1, PM3, PM5 Series: Specifications Information and Repair Parts ManualAnibal QuezadaNo ratings yet

- Bilfinger Investigates Compliance Violations in BrazilDocument1 pageBilfinger Investigates Compliance Violations in BrazilAnibal QuezadaNo ratings yet

- Log 1Document5 pagesLog 1Anibal QuezadaNo ratings yet

- Welding PositionsDocument116 pagesWelding PositionsASAPASAPASAPNo ratings yet

- Purchase Order Specification For Balancing Machine (Rev07)Document7 pagesPurchase Order Specification For Balancing Machine (Rev07)Anibal QuezadaNo ratings yet

- Technical Information Letters Rev03 (01OCT2014)Document6 pagesTechnical Information Letters Rev03 (01OCT2014)Anibal QuezadaNo ratings yet

- Bilfinger Investigates Compliance Violations in BrazilDocument1 pageBilfinger Investigates Compliance Violations in BrazilAnibal QuezadaNo ratings yet

- Log 3Document5 pagesLog 3Anibal QuezadaNo ratings yet

- LGE and KUs Executed Asset Purchase Agreement With Bluegrass Generation CompanyDocument313 pagesLGE and KUs Executed Asset Purchase Agreement With Bluegrass Generation CompanyAnibal Quezada0% (1)

- Spring Hanger & Piping Support InspectionDocument20 pagesSpring Hanger & Piping Support InspectionAnibal Quezada100% (3)

- ASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesDocument4 pagesASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesAnibal QuezadaNo ratings yet

- (HST) The BrainDocument19 pages(HST) The BrainAnibal QuezadaNo ratings yet

- Peaditrician All IndiaDocument66 pagesPeaditrician All IndiaGIRISH JOSHINo ratings yet

- PDI Quality Manual Rev 4 - 1.0 Table of ContentsDocument1 pagePDI Quality Manual Rev 4 - 1.0 Table of ContentslouieNo ratings yet

- Final ESIA On Construction Materials - Tamiru BultoDocument110 pagesFinal ESIA On Construction Materials - Tamiru BultoKayo Shankulie100% (1)

- Solution Manual For Safety Health and Environmental Concepts For The Process Industry 2nd EditionDocument8 pagesSolution Manual For Safety Health and Environmental Concepts For The Process Industry 2nd EditionRobert Hornback100% (34)

- Manual NSD70D EnglishDocument155 pagesManual NSD70D Englishnarvis1No ratings yet

- Practical Visual Inspection of WeldsDocument40 pagesPractical Visual Inspection of WeldsAmit Sharma100% (1)

- Causes & Prevention of Coronary Artery DiseaseDocument41 pagesCauses & Prevention of Coronary Artery DiseaseeenagpurcongNo ratings yet

- Cyclopropane, Ethynyl - (Cas 6746-94-7) MSDS: CyclopropylacetyleneDocument5 pagesCyclopropane, Ethynyl - (Cas 6746-94-7) MSDS: CyclopropylacetyleneMiMi JoyNo ratings yet

- Cottonhill - Red Collection PDFDocument33 pagesCottonhill - Red Collection PDFVioricaNo ratings yet

- Time ManagementDocument30 pagesTime ManagementVaibhav Vithoba NaikNo ratings yet

- Quality and Functionality of Excipients-Art (Alumnos-S) PDFDocument14 pagesQuality and Functionality of Excipients-Art (Alumnos-S) PDFLaura PerezNo ratings yet

- Post Harvest Value Chainof Carrot AReviewDocument12 pagesPost Harvest Value Chainof Carrot AReviewDave RoneNo ratings yet

- FW SuperLite Standard Range Catalogue 2012-13Document212 pagesFW SuperLite Standard Range Catalogue 2012-13majortayNo ratings yet

- Form-Ii (See Regulation 4) Postal Bill of Export - II (To Be Submitted in Duplicate)Document1 pageForm-Ii (See Regulation 4) Postal Bill of Export - II (To Be Submitted in Duplicate)mrthilagamNo ratings yet

- Palm Avenue ApartmentsDocument6 pagesPalm Avenue Apartmentsassistant_sccNo ratings yet

- Courses at NeevDocument10 pagesCourses at NeevDr Mohan SavadeNo ratings yet

- The Design of The 2016-17 Young Lives School Survey in EthiopiaDocument10 pagesThe Design of The 2016-17 Young Lives School Survey in EthiopiaFuadNo ratings yet

- Rockaway Times 11-21-19Document44 pagesRockaway Times 11-21-19Peter MahonNo ratings yet

- Is411 8Document1 pageIs411 8amoghimiNo ratings yet

- Hoja de Seguridad Magnafloc 155 (EN) PDFDocument6 pagesHoja de Seguridad Magnafloc 155 (EN) PDFIván Martínez-CostaNo ratings yet

- Grade 6 School Lesson on Propagating Trees and Fruit TreesDocument10 pagesGrade 6 School Lesson on Propagating Trees and Fruit TreesGhrazy Ganabol LeonardoNo ratings yet

- Mechanic CV TemplateDocument2 pagesMechanic CV Templateasmaa brkNo ratings yet

- Primary Healthcare Centre Literature StudyDocument32 pagesPrimary Healthcare Centre Literature StudyRohini Pradhan67% (6)

- Step by Step To The Perfect PedicureDocument6 pagesStep by Step To The Perfect PedicurepinkyNo ratings yet

- Procedure Title - Vickers Hardness Testing With The Mitutoyo MVK-H1 Microhardness TesterDocument12 pagesProcedure Title - Vickers Hardness Testing With The Mitutoyo MVK-H1 Microhardness TesterVitor100% (1)

- Thomas' SplintDocument2 pagesThomas' SplintCee SanchezNo ratings yet

- B Fire BehaviorDocument39 pagesB Fire BehaviorDon VitoNo ratings yet

- Marathon Electric Motors Price List for Motors and Fans Effective March 15, 2019Document24 pagesMarathon Electric Motors Price List for Motors and Fans Effective March 15, 2019Mohan BabuNo ratings yet

- Plant Nematology: A Briefly IntroductionDocument463 pagesPlant Nematology: A Briefly IntroductionRodrigo CarralNo ratings yet

- Soil Loss EstimationDocument77 pagesSoil Loss Estimationmys85No ratings yet

- The Voice of God: Experience A Life Changing Relationship with the LordFrom EverandThe Voice of God: Experience A Life Changing Relationship with the LordNo ratings yet

- From Raindrops to an Ocean: An Indian-American Oncologist Discovers Faith's Power From A PatientFrom EverandFrom Raindrops to an Ocean: An Indian-American Oncologist Discovers Faith's Power From A PatientRating: 1 out of 5 stars1/5 (1)