Professional Documents

Culture Documents

F 35BstoreSeparationAnalysis Focal Point Spring 2011

Uploaded by

amenendezamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F 35BstoreSeparationAnalysis Focal Point Spring 2011

Uploaded by

amenendezamCopyright:

Available Formats

Volume 15 Issue 1 Spring 2011

Store Separations for F-35s Analyzed Using Grids Made With Gridgen

By Jae M. Lee and Alfred Piranian, Naval Air Systems Command,

and John Martel, Capt. Darrell Crowe, and Magdi Rizk, Air Force

SEEK EAGLE Office

of CFD-based trajectory analyses for stores separating in jet flow

environments.

F-35 pilots need the ability to jettison stores in the event of emergencies during takeoff (such as a cold catapult stroke or power

plant problems), and emergencies in landing configuration (such

as during Short Take-Off and Vertical Landing - STOVL mode

approach). No wind tunnel data have been obtained for store

separation in the STOVL mode, with landing gear extended and

vectored thrust from the lift fan propulsion system, as shown in

Figure 1. A collaborative team consisting of Naval Air Systems

Command (NAVAIR), Air Force Seek Eagle Office (AFSEO), and

Lockheed Martin store separation engineers was formed to

conduct computational fluid dynamics (CFD)-based trajectory

analyses to support issuance of flight clearance limits related to

F-35 emergency jettison in those flight conditions. This article,

taken from AIAA paper 2010-510 Store Separations in Jet

Flow Environments, describes challenging aspects and results

The Beggar CFD code was selected for this task because the code

has been tailored exclusively for store separation applications and

validated against flight test data for more than 20 years. The

philosophy behind Beggar is to use a Chimera, or overlapped,

grid system so that the components of a problem may be gridded independently of each other and then assembled to form

the complete system of computational grids. By automating the

Chimera assembly process and incorporating an algorithm to

solve the rigid-body equations of motion, the code has become

a user-friendly platform ideal for store separation calculations.

Figure 1: F-35B in STOVL Mode

(Continues on page 2)

http://www.pointwise.com/focalpt/

Focal-Point-Spring-2011.pdf

Toll Free 800-4PTWISE

www.pointwise.com

Pointwise FocalPoint Spring 2011

Store Separations for F-35s Analyzed Using Grids Made With Gridgen

(Continued from page 1)

and transferred both integrated CFD grids and Beggar input files

to the AFSEO CFD team to use their computing resources.

Gridgen was used to generate CFD grids for configurations of

interest. The NAVAIR, AFSEO, and Lockheed Martin engineers

were well aware of the challenging complexities associated with

STOVL aircraft configuration/control.

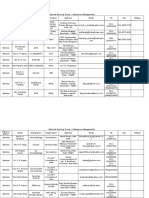

All of these grids, plus grids for any stores to be carried are assembled in a build-up procedure highlighted in Figure 2. Grid

quality for the individual components was validated through

comparisons with data to provide confidence in the results from

the integrated system grids. Results from CFD computations on

the complete configuration compare favorably to wind tunnel

tests of store trajectories.

When this project was started a year ago, a Lockheed Martin

CFD engineer already had worked on CFD validation of the F35B propulsion system (main nozzle, roll nozzle, and lift fan).

High resolution grids for the propulsion system had been built

to capture jet flow characteristics better and Lockheed Martin

had already validated their solutions against a thrust-based criterion. The computed thrust had 99 percent accuracy against

measured wind tunnel test data. The CFD grids for the propulsion system were transferred to NAVAIR and converted to a

Beggar format.

The joint team consisting of NAVAIR, AFSEO, and Lockheed

Martin engineers has worked together successfully to take a CFD

approach to support issuance of flight clearances that provides

for STOVL emergency jettison of stores. The CFD models were

validated and applied to a couple of STOVL conditions. The CFD

analyses showed that STOVL emergency store ejection looks safe

and benign for configurations and conditions investigated.

The CFD grids for geometrically complex nose and main landing

gear were built by AFSEO CFD engineers using Gridgen and had

30 million grid points, the weapon bay itself had 30 million grid

points to have a direct eddy simulation (DES) quality grid. NAVAIR

engineers integrated the CFD grids from different sources to attain the desired configurations, set up input files for Beggar runs,

Freestream

validation for stores

Figure 2: Build-up and validation processes

Trajectory

validation

Main nozzle

Propulsion system

validation

Lift fan

Landing

gears

Lift fan

Rollnozzle

You might also like

- Master Thesis Aircraft DesignDocument5 pagesMaster Thesis Aircraft Designfjmayw0n100% (2)

- The JSF Stovl Performance Process From Small-Scale Database To Flight Test Demonstration 2002 - 6002Document25 pagesThe JSF Stovl Performance Process From Small-Scale Database To Flight Test Demonstration 2002 - 6002SpazSinbad100% (1)

- Mustang - General InformationDocument8 pagesMustang - General InformationfranciscogpdaNo ratings yet

- MAE 4350 - Lab 4 AerodynamicsDocument45 pagesMAE 4350 - Lab 4 AerodynamicsjonolioNo ratings yet

- Modern Solutions For Ground Vibration Testing of Large AircraftDocument8 pagesModern Solutions For Ground Vibration Testing of Large Aircraftuamiranda3518No ratings yet

- Stability and Control of Stovl Aircraft PDFDocument10 pagesStability and Control of Stovl Aircraft PDFChegrani AhmedNo ratings yet

- (FAA) Eb-105 Vertiport Design Industry - DraftDocument48 pages(FAA) Eb-105 Vertiport Design Industry - Draftdkfk9854No ratings yet

- Simulation Platform For Quadricopter Using MatlabSimulink and X-PlaneDocument5 pagesSimulation Platform For Quadricopter Using MatlabSimulink and X-PlaneFox NekNo ratings yet

- Avionics Question and AnswersDocument4 pagesAvionics Question and AnswersJosin Jose100% (1)

- Eucass2017 204Document16 pagesEucass2017 204joseph.mangan1892No ratings yet

- Modelling Design PrototypingDocument10 pagesModelling Design PrototypingYasin CnkciNo ratings yet

- Aircraft Drag and Thrust Analysis (Airdata) Publishable Synthesis ReportDocument59 pagesAircraft Drag and Thrust Analysis (Airdata) Publishable Synthesis ReportAlexandru MoldovanNo ratings yet

- Simulation Platform For Quadricopter: Using Matlab/Simulink and X-PlaneDocument5 pagesSimulation Platform For Quadricopter: Using Matlab/Simulink and X-PlaneajmalshahbazNo ratings yet

- LOAN Low Observable Axisymmetric Nozzle F-35 - Air - Vehicle - Technology - Overview pp4Document4 pagesLOAN Low Observable Axisymmetric Nozzle F-35 - Air - Vehicle - Technology - Overview pp4Ahmed HamoudaNo ratings yet

- 2002 FLT Simulation ReviewDocument44 pages2002 FLT Simulation ReviewKannan PerumalNo ratings yet

- Flight Control Laws Carefree Handling Clearance of A Highly Manoeuvrable Aircraft Using Multi-Strategy Adaptive Global OptimizationDocument15 pagesFlight Control Laws Carefree Handling Clearance of A Highly Manoeuvrable Aircraft Using Multi-Strategy Adaptive Global OptimizationBlaze123xNo ratings yet

- Reverse Engineering and Aerodynamic Analysis of A Flying Wing UAV ATSChandranDocument13 pagesReverse Engineering and Aerodynamic Analysis of A Flying Wing UAV ATSChandrancsulbstudent1No ratings yet

- Bright 2021 IOP Conf. Ser.: Mater. Sci. Eng. 1012 012019Document12 pagesBright 2021 IOP Conf. Ser.: Mater. Sci. Eng. 1012 012019Prince BadhanNo ratings yet

- Control System Design of An Vtol Fixed-Wing AircraftDocument4 pagesControl System Design of An Vtol Fixed-Wing AircraftkhoamaiNo ratings yet

- ICAS2022 0367 PaperDocument13 pagesICAS2022 0367 Papersanskar.maddiNo ratings yet

- AM 2036 (10 May 2004) - Normes - Fem - GlobalDocument68 pagesAM 2036 (10 May 2004) - Normes - Fem - Globalja_mufc_scribd100% (5)

- Development of A Modular, Generic Helicopter Flight Dynamics Model For Real-Time SimulationsDocument18 pagesDevelopment of A Modular, Generic Helicopter Flight Dynamics Model For Real-Time Simulationslord-sothNo ratings yet

- Tejas / Light Combat Aircraft (LCA)Document4 pagesTejas / Light Combat Aircraft (LCA)Naveen Kumar SgNo ratings yet

- BICOPTERDocument22 pagesBICOPTERManideep Ananthula100% (4)

- USAF Streamlines Training Bids: Wicat Adds Boeing To Training Device PortfolioDocument1 pageUSAF Streamlines Training Bids: Wicat Adds Boeing To Training Device Portfoliodagger21No ratings yet

- A 2d Aerodynamic Study On Morphing of The Naca 241Document10 pagesA 2d Aerodynamic Study On Morphing of The Naca 241henryNo ratings yet

- Analysis of Vertical Take Off Landing Aircraft Using CFD IJERTV3IS090267Document15 pagesAnalysis of Vertical Take Off Landing Aircraft Using CFD IJERTV3IS090267Prasanna NaikNo ratings yet

- Conceptual Design and Analysis of Flying Wing DroneDocument3 pagesConceptual Design and Analysis of Flying Wing Dronesunshimmer6No ratings yet

- Aerodynamics 2Document17 pagesAerodynamics 2Charm YakuzaNo ratings yet

- 1st Univmichigan FTR Dbvf-2021Document22 pages1st Univmichigan FTR Dbvf-2021sohaibumer2001No ratings yet

- Multirotor Sizing Methodology With Flight Time EstimationDocument23 pagesMultirotor Sizing Methodology With Flight Time EstimationJose Antonio Siñani VilteNo ratings yet

- CAAC Special Emphasis Items (SEI) For Small Airplane: Flight Subject DescriptionDocument52 pagesCAAC Special Emphasis Items (SEI) For Small Airplane: Flight Subject DescriptionbenNo ratings yet

- Eurofighter Aero Design MatlDocument11 pagesEurofighter Aero Design MatlSayantan Datta GuptaNo ratings yet

- A Landing Radio Altimeter For Small AircraftDocument5 pagesA Landing Radio Altimeter For Small AircraftscitemplarNo ratings yet

- Flightgear Simulink v1Document3 pagesFlightgear Simulink v1Daniel WieseNo ratings yet

- Sub Scale Flight TestingDocument10 pagesSub Scale Flight TestingRajeuv GovindanNo ratings yet

- Designing 3-DOF Hardware-In-The-Loop Test Platform Controlling Multirotor VehiclesDocument6 pagesDesigning 3-DOF Hardware-In-The-Loop Test Platform Controlling Multirotor VehiclesDawit GetchoNo ratings yet

- Amsafe Hawk MK2 Arrestor Barrier Engagement AnalysisDocument15 pagesAmsafe Hawk MK2 Arrestor Barrier Engagement AnalysisAltairEnlightenNo ratings yet

- Quadcopter Research PaperDocument5 pagesQuadcopter Research Papergmannevnd100% (1)

- 341 751 1 PBDocument12 pages341 751 1 PBhebervaldoNo ratings yet

- VertiportdimensionDocument31 pagesVertiportdimensionmvsakthiNo ratings yet

- Aircraft Control Surfaces CalculationDocument16 pagesAircraft Control Surfaces Calculationlove2me20040% (1)

- Aeronautical Engineer Designer Mass Properties in Wichita KS Resume Don ThachDocument3 pagesAeronautical Engineer Designer Mass Properties in Wichita KS Resume Don ThachDonThachNo ratings yet

- HILSDocument8 pagesHILSsakthi ambroseNo ratings yet

- ATA-100 JASC CodesDocument72 pagesATA-100 JASC CodesaerostressNo ratings yet

- Aircraft Crash AnalysisDocument100 pagesAircraft Crash AnalysisSrinivas RallabandiNo ratings yet

- Testing of The V-22 Flight Control SystemDocument16 pagesTesting of The V-22 Flight Control SystemliuhkNo ratings yet

- UAV Autopilot Controllers Test PlatformDocument6 pagesUAV Autopilot Controllers Test Platformtinymovies2002No ratings yet

- FlightGear Preconfigured 6DoF AnimationDocument3 pagesFlightGear Preconfigured 6DoF AnimationEmmanuelNo ratings yet

- Flight Control Simulation Testbed For Missile and Unmanned Aircraft Vehicle - IJSE 2008Document6 pagesFlight Control Simulation Testbed For Missile and Unmanned Aircraft Vehicle - IJSE 2008Nadia mjahadNo ratings yet

- High Level Architecture Based Simulation For Aircraft Carrier Deck Operations PDFDocument5 pagesHigh Level Architecture Based Simulation For Aircraft Carrier Deck Operations PDFjwpaprk1No ratings yet

- V Tail MAV ReportDocument46 pagesV Tail MAV ReportRodriguez ArthursNo ratings yet

- Ahs 2006 Harding Ah64d MclawsDocument15 pagesAhs 2006 Harding Ah64d MclawsversineNo ratings yet

- Extended Abstract 83675Document10 pagesExtended Abstract 83675Hoàng ThiếtNo ratings yet

- 11553-Article Text-20503-1-10-20211118Document7 pages11553-Article Text-20503-1-10-20211118Vignesan MechNo ratings yet

- Research Article: Minimization of Ground Vibration Test Configurations For F-16 Aircraft by Subtractive ModificationDocument20 pagesResearch Article: Minimization of Ground Vibration Test Configurations For F-16 Aircraft by Subtractive Modificationgfsdg dfgNo ratings yet

- Computational Fluid Dynamic Simulation (CFD) and Experimental Study On Wing-External Store Aerodynamic Interference of A Subsonic Fighter AircraftDocument6 pagesComputational Fluid Dynamic Simulation (CFD) and Experimental Study On Wing-External Store Aerodynamic Interference of A Subsonic Fighter AircraftsirakNo ratings yet

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- Airplane Flying Handbook: FAA-H-8083-3C (2024)From EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Rating: 4 out of 5 stars4/5 (12)

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Archaeological Investigations at The JupDocument15 pagesArchaeological Investigations at The JupamenendezamNo ratings yet

- How To Cook Filet Mignon To Absolute PerfectionDocument10 pagesHow To Cook Filet Mignon To Absolute PerfectionamenendezamNo ratings yet

- HawkEye 360 Mission Space 021121Document4 pagesHawkEye 360 Mission Space 021121amenendezamNo ratings yet

- 2021-Bluetooth Market UpdateDocument30 pages2021-Bluetooth Market UpdateamenendezamNo ratings yet

- Former RAF Upper Heyford, Cherwell Oxfordshire: A Reassessment of The FL Ying Fi Eld Conservation AreaDocument52 pagesFormer RAF Upper Heyford, Cherwell Oxfordshire: A Reassessment of The FL Ying Fi Eld Conservation AreaamenendezamNo ratings yet

- MRN-How Bluetooth Technology Is Enabling Safe Return StrategiesDocument19 pagesMRN-How Bluetooth Technology Is Enabling Safe Return StrategiesamenendezamNo ratings yet

- F-35 AgcasDocument65 pagesF-35 AgcasamenendezamNo ratings yet

- Cuban Missile Crisis: Edward T. RussellDocument9 pagesCuban Missile Crisis: Edward T. RussellamenendezamNo ratings yet

- Datasheet F414 Enhanced PDFDocument2 pagesDatasheet F414 Enhanced PDFamenendezamNo ratings yet

- F414-GE-39E: Turbofan EngineDocument2 pagesF414-GE-39E: Turbofan Engineamenendezam100% (1)

- Air To Air Refuelling Atp 56 B Ajp 3 3 4 2 PDFDocument336 pagesAir To Air Refuelling Atp 56 B Ajp 3 3 4 2 PDFamenendezamNo ratings yet

- Revised Draft Port Master Plan Update 10 2020Document487 pagesRevised Draft Port Master Plan Update 10 2020amenendezam100% (1)

- Turbofan Engines: 22,000 LB Thrust ClassDocument2 pagesTurbofan Engines: 22,000 LB Thrust ClassamenendezamNo ratings yet

- 15 Automatic Ground Collision AvoidanceDocument43 pages15 Automatic Ground Collision AvoidanceamenendezamNo ratings yet

- Restoring American Seapower: Bryan Clark, Peter Haynes, Bryan Mcgrath, Craig Hooper, Jesse Sloman, and Tim WaltonDocument45 pagesRestoring American Seapower: Bryan Clark, Peter Haynes, Bryan Mcgrath, Craig Hooper, Jesse Sloman, and Tim WaltonamenendezamNo ratings yet

- Hypersonic Missiles Report 2019-2027Document8 pagesHypersonic Missiles Report 2019-2027amenendezam50% (2)

- Hacking UK TridentDocument38 pagesHacking UK TridentamenendezamNo ratings yet

- KALKANII Mobile Medium Range 3D Air Defense Radar 1472Document2 pagesKALKANII Mobile Medium Range 3D Air Defense Radar 1472amenendezamNo ratings yet

- 2019 Gresmes Internetui enDocument66 pages2019 Gresmes Internetui enamenendezamNo ratings yet

- The U.S. Army Selects New Submachine Gun PDFDocument9 pagesThe U.S. Army Selects New Submachine Gun PDFamenendezamNo ratings yet

- The Saga of Israel's MIG-29 FulcrumsDocument13 pagesThe Saga of Israel's MIG-29 Fulcrumsamenendezam100% (2)

- 2019 Index of Military StrengthDocument494 pages2019 Index of Military Strengthamenendezam100% (3)

- European Defence Agency - Annual Report 2018Document32 pagesEuropean Defence Agency - Annual Report 2018amenendezamNo ratings yet

- Afi11 214Document3 pagesAfi11 214amenendezamNo ratings yet

- ATP-56 (B) Prelims (USA) PDFDocument26 pagesATP-56 (B) Prelims (USA) PDFamenendezamNo ratings yet

- North Atlantic Treaty Organization (Nato) Security Briefing: Insert Classification LevelDocument4 pagesNorth Atlantic Treaty Organization (Nato) Security Briefing: Insert Classification LevelamenendezamNo ratings yet

- Eurofighter World 2016-07 PDFDocument27 pagesEurofighter World 2016-07 PDFamenendezamNo ratings yet

- AirWarVietnam - Making A MiG-Killer Technology and Signals Intelligence For Air-To-Air Combat in Vietnam - From Balloons To DronesDocument24 pagesAirWarVietnam - Making A MiG-Killer Technology and Signals Intelligence For Air-To-Air Combat in Vietnam - From Balloons To Dronesamenendezam100% (2)

- Goldwallet 2.1.1Document16 pagesGoldwallet 2.1.1yanuarNo ratings yet

- Ship-Like Target Design For Underwater Explosion Experiments PDFDocument92 pagesShip-Like Target Design For Underwater Explosion Experiments PDFFernando Raúl LADINONo ratings yet

- Assessment of Learning 1 Quiz 1Document3 pagesAssessment of Learning 1 Quiz 1imalwaysmarked100% (4)

- Ds Lm5006 en Co 79839 Float Level SwitchDocument7 pagesDs Lm5006 en Co 79839 Float Level SwitchRiski AdiNo ratings yet

- BibliografieDocument2 pagesBibliografieMadalin AlexandruNo ratings yet

- Generator ProtectionDocument11 pagesGenerator Protectionyogeshsahu100% (2)

- Pads Hyperlynx DDR WizardDocument3 pagesPads Hyperlynx DDR Wizardkrishna_p_n_44510456No ratings yet

- NCP81243 Dual Output 3 & 2 Phase Controller With Single Intel Proprietary Interface For Desktop and Notebook CPU ApplicationsDocument26 pagesNCP81243 Dual Output 3 & 2 Phase Controller With Single Intel Proprietary Interface For Desktop and Notebook CPU ApplicationsAhmed Sherif CupoNo ratings yet

- Kumar Saurabh Resume (SAP IBP)Document6 pagesKumar Saurabh Resume (SAP IBP)SaurabhSinhaNo ratings yet

- C9 Game Guide For VIPsDocument62 pagesC9 Game Guide For VIPsChrystyanoNo ratings yet

- YAMAHA Blaster (Parts) PDFDocument65 pagesYAMAHA Blaster (Parts) PDFAlberto VegaNo ratings yet

- Computer Science Ram PresentationDocument11 pagesComputer Science Ram Presentationapi-268896185100% (3)

- Lesson13ToeIn ToeOut PDFDocument5 pagesLesson13ToeIn ToeOut PDFNurSafitriNo ratings yet

- Is Standard ListDocument11 pagesIs Standard ListSunil PulikkalNo ratings yet

- StatementDocument3 pagesStatementSachinBMetre87 SachinBMetreNo ratings yet

- Contact List For All NWGDocument22 pagesContact List For All NWGKarthickNo ratings yet

- Statistics - Frequency Table and GraphDocument9 pagesStatistics - Frequency Table and GraphTopheng D. SamaritaNo ratings yet

- MKDM Gyan KoshDocument17 pagesMKDM Gyan KoshSatwik PandaNo ratings yet

- Concrete Construction Article PDF - Site Casting Exposed Aggregate WallsDocument1 pageConcrete Construction Article PDF - Site Casting Exposed Aggregate WallssonofalexanderNo ratings yet

- New Centum VP Dcs With Network Io WhitepaperDocument4 pagesNew Centum VP Dcs With Network Io WhitepaperFarrukh MajeedNo ratings yet

- Tiger SharkDocument2 pagesTiger Sharkstefanpl94No ratings yet

- Solid Desiccant DehydrationDocument5 pagesSolid Desiccant Dehydrationca_minoNo ratings yet

- West Zone: South-West Zone: South Zone: Central Zone: North Zone: North West Zone: East ZoneDocument6 pagesWest Zone: South-West Zone: South Zone: Central Zone: North Zone: North West Zone: East ZoneKanupriyamNo ratings yet

- Manual Bombas Pozo e ImpulsionDocument112 pagesManual Bombas Pozo e ImpulsionFernando PuentesNo ratings yet

- Mode ReversionsDocument15 pagesMode ReversionsISHAANNo ratings yet

- Oracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0Document12 pagesOracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0ManifoldNo ratings yet

- C D C SDocument4 pagesC D C SandriNo ratings yet

- cm6800 48x8 NewDocument98 pagescm6800 48x8 Newvijayakumar3661No ratings yet

- Applsci 12 02711 v2Document31 pagesApplsci 12 02711 v2Chandra MouliNo ratings yet

- MT Company PresentationDocument30 pagesMT Company Presentationjose manuelNo ratings yet