Professional Documents

Culture Documents

FInal Tunnel-2 Report

Uploaded by

p_ignatiusOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FInal Tunnel-2 Report

Uploaded by

p_ignatiusCopyright:

Available Formats

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

5.0 Numerical Analysis

5.0.1 Introduction of Phase2

An essential part of the design of tunnel is the prediction of the response of rocks / rock masses, in terms of

stresses and displacements, which can be well understood by Numerical Methods.

Phase2 is a 2-dimensional windows based program, very popular for the analysis of underground / surface

excavation in rock mass or soil. The program is used for a wide range of geotechnical engineering projects

including complex tunneling problems in weak rock, stress analysis, tunnel design, slope stability, support

design and groundwater seepage analysis etc. Complex multi staged models can easily be created and

analyzed quickly. The program is user friendly, easy to operate and easy to understand. Some of the basic

features are:

Elasto-Plastic Analysis,

Constant or Gravity Field Stress,

Staged Model,

Plain Strain or Axisymmetric Analysis,

Support analysis (Rock Bolts, Steel Ribs, Lattice Girders Shotcrete / Concrete Liner etc.),

Multiple materials,

Load splitting,

Slope stability analysis,

Ground water seepage analysis etc.

There are three basic components in Phase2 program - Model, Compute and

Interpret. Model is the pre-processing module used for entering and editing

the model boundaries, support, in-situ stresses, boundary conditions,

material properties and creating the finite element mesh. Model, Compute

and Interpret will each run as standalone programs. They also interact with

each other as illustrated in the schematic diagram on the right side.

Compute and interpret can both be started from within the model.

Compute must be run on a file before results can be analyzed with interpret (red

arrow).

Model can be started from interpret.

5.0.2 Input parameters for Phase2

In phase2, field stress can be constant or gravity stress. The gravity field stress option is used to define a

gravity stress field which varies linearly with depth from a user-specified ground surface elevation. Gravity

field stress is typically used for surface or near surface at shallow depth elevations and the areas where

there is the effect of topography in the stress magnitudes and directions.

AA/HD/1544

24

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Material parameters such as Unconfined Compressive Strength of intact rock ( ci), Hoek-Brown constant

(mi), Geological strength index (GSI), Youngs Modulus of intact rock (Ei), Poissons ratio (), Density of the

rock mass () are the material property inputs in Phase2.

5.0.3 Interpretation of the results

The principal stresses can be displayed. The major and minor principal stresses and angle with horizontal at

any point can be read and the results can be compared with the gravity stress. The strength factor contours

of the rock mass around the tunnel are also displayed. With elastic analysis if the strength factor is greater

than one everywhere around the tunnel, the result will be the same even if Plastic Analysis is done. Hence

there is no necessity of plastic analysis if the strength factor is less than one. The contours of vertical,

horizontal and total displacements can be displayed around the tunnel with values marked. The values can

be compared with the results obtained from analytical/semi-analytical methods and measurements of tunnel

convergence in field.

AA/HD/1544

25

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

5.1.0

Tunnels- 2 Design Report

Mid Tunnel Section

5.1.0.1 Continuum Modeling

In the Continuum modeling technique rock joints are taken into consideration implicitly, i.e. the rock mass

quality is described by strength and deformability parameters through a failure criterion. Mohr-Coulomb and

Hoek-Brown failure criteria are utilized in the analysis.

5.1.0.2 Finite

Element

Mesh,

Boundary

Conditions

and

Construction

Sequence

To eliminate the influence of the applied boundary conditions, the finite element mesh is extended up to the

ground surface and in the lateral direction up to two times the tunnel width. The mesh is of 3272 elements

and 6803 nodes. The gradation factor, ratio of the average length of discretization on excavation boundary to

the length of discretization on the external boundary is 0.2, i.e., the average length of the element on the

external boundary is 20 times the length of the element on the excavation boundary.

AA/HD/1544

26

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig 6: Model showing the extent and boundary conditions adopted for the external boundary

The modeling starts with generation of the initial stress field, followed by a four stage Excavation process.

Fig.7: Model with stages of sequential excavation

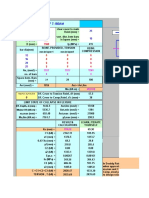

Table 11: Mesh and Discretization Parameters

Mesh type

Graded

Element type

6 Noded triangles

Gradation factor

0.2

Default number of nodes on all excavations

110

5.1.0.3 Estimation of In-situ Stresses:

Different in-situ horizontal stress conditions are taken into consideration using stress ratio, k=0.5, 1.0, 1.5

and 2.0. The vertical in-situ stress distribution is considered as the result of weight of the overburden, ( v =

H).

5.1.0.4 Estimation of rock mass parameters:

AA/HD/1544

27

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Middle section @ km: 107.645, using data of BH No.5 is used for analysis. The effect of variability and

uncertainty sourced from the complex and variable nature of rock mass cannot be considered by

deterministic approaches using single or mean value. Therefore an effort is made to estimate the required

rock mass properties to construct a reliable FEM-model. Mohr Coulomb (MC) & Hoek- Brown (HB) Failure

criterion are used in the analysis.

Table 12: Uniaxial Compressive Strength (UCS) of intact rock samples of BH5 at km: 107.645

Depth

UCS(Mpa)

E(Mpa)

(kN/m3)

58.0-59.0

82

46463

2.95

62.5-63.8

183

28932

3.01

67.0-68.0

70

65872

3.06

71.5-72.5

75

71484

3.02

75.5-76.5

35

88223

2.81

80.5-81.5

130

109647

2.99

Mean

96

68437

2.97

Std. dev.

47.75

UCS values on rock core samples from the borehole are highly distributed. Value of standard deviation of the

data is 47.75% of the mean value. Statistical analysis is therefore required to justify a single value for use.

By using statistical analysis it is possible to determine the percentage of values in the data set that exceeds

a certain value. 90% of UCS values measured are exceeding 35 Mpa and that value will be used as input

parameter in the FEM-model.

Fig. 8: Normal distribution of UCS data

The mean value of 96.0 Mpa may also be used but in that case the rock mass in 50% of cases be less

favorable than the parameter used in the design and would be hard to justify. It will however be used here for

comparison purpose. Fig. 9 shows the correlation between UCS and E.

AA/HD/1544

28

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig.9: Correlation between UCS and E

Fig. 10: Linear correlation between Q and RMR

Residual friction angle, r = tan-1(Jr/Ja) is worked out to be 56 o with field measured values of J r =1.5 and Ja =

1.So no change is made as regards to the friction angle of rock mass, though the borehole data indicated

friction angle mean =56o and 10% = 44o. The stiffness modulus E10% should be around 88.871 Gpa according

to figure 9.

Table 13: The values of cohesion and friction

C(Mpa)

2.25

1.45

0.45

AA/HD/1544

29

(Degrees)

49.83

57.02

61.05

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

The following table shows the values considered for Numerical Analysis.

Table 14: Selected Rock Mass Parameters for Numerical Analysis

Confidence Limits

90%

50%

Units

Input values of Mohr Coulomb failure Criterion

Cohesion,C

0.350

1.506

Mpa

Friction Angle,

44.00

56.00

Degree

Tensile Strength,T

0.300

0.920

Mpa

Modulus of Elasticity,Ei

88.87

68.440

Gpa

Modulus of Deformation,Ed

35.19

30.850

Gpa

Geological Strength Index,GSI

64.00

75.00

Intact Rock Constant,mi

29.00

29.00

Disturbance factor,D

0.00

0.00

Uniaxial compressive strength,UCS

35.00

96.00

Mpa

Modulus of Elasticity,Ei

14.88

40.80

Gpa

Modulus of Deformation,Ed

9.072

33.307

Gpa

Parameter,mb

7.900

11.892

Parameter,s

0.018

0.062

Parameter,a

0.502

0.501

Unit weight,

2.870

2.970

Poisson's Ratio,

0.130

0.440

Input values of Hoek Brown failure Criterion

kN/cum

5.1.0.5 Stability assessment of tunnels:

Design of effective ground support takes into account the mode of instability so that the support components

can be designed to work efficiently for the anticipated instability mode.

There are three main tunnel instability mechanisms:

Shear Yielding of rock mass is quite common in poor quality rock masses. A plastic zone is formed

around the tunnel and, depending upon the ratio of rock mass strength to in-situ stress, this may

stabilize, or it may continue to expand until the tunnel collapses. The two main mechanisms that

can produce this type of instability are swelling and squeezing conditions. Fig. 11a illustrates, Shear

failure in a plastic zone around tunnels in weak rock

STRUCTURALLY CONTROLLED KINEMATIC INSTABILITY appears in jointed rock masses under

low in-situ stress conditions. Gravity driven wedge instability is typically the dominant instability

mode of the type. The failure involves gravity fall of wedges formed by intersecting geological

AA/HD/1544

30

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

features. Fig. 11b illustrates Gravity driven wedge instability along pre-existing geological structures

in blocky ground under low in-situ stress conditions

BRITTLE ROCK FAILURE initiates as a result of the propagation of tensile cracks from defects in

highly stressed massive hard rock. These cracks generally propagate along the maximum principal

stress trajectories, resulting in thin splinters or slabs. Depending upon the ratio of intact rock

strength to in-situ stress, spalling may be limited to small plate-sized slabs, or it may develop into a

massive violent failure or rock burst. Fig. 11c illustrates Stress driven brittle failure tends to

dominate in massive brittle rock under high in-situ stress conditions

Fig. 11: Potential Modes of Failure

5.1.1

Elastic Analysis

5.1.1.1 Interpretation of the results:

Different output parameters after the simulation through different stages of excavation in elastic mode are

shown in Fig.12 below.

5.1.1.2 Principal Stresses:

In Phase2, 1 corresponds to the in plane major principal stress and 3 in plane minor principal stress. The

elastic stress redistribution around the excavation suggests that 1 increases and 3 decreases in the rock

mass surrounding the tunnel.

AA/HD/1544

31

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

5.1.1.3 Major Principal Stress:

Predominant failure modes of the tunnel for different stress ratios (k) are predicted based on the limiting

ratio of tangential stress (1) to UCS of intact rock.

Fig. 12: Tunnel instability and brittle failure

AA/HD/1544

32

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Table 15: Computation of the ratio of Maximum principal stress to uniaxial compressive strength of intact

rock

As the stress ratio increases from 0.5 to 2, the failure mode in crown and walls ranges from falling or sliding

of block wedges to localized brittle failure of intact rocks and movement of blocks. The maximum principal

stress being compressive is located in the side wall for k values of 0.5 and 1.0 and in the crown for k values

of 1.5 and 2.0.

5.1.1.4 Strength Factor:

It is defined as the ratio of strength of rock mass to the induced stress. Strength Factor greater than 1.0

indicates that the material strength is greater than the induced stress. A strength factor less than one means

the material will fail, and plastic analysis is necessary.

The tangential stresses in the walls decrease as the stress ratio k varied from 0.5 to 2.0 resulting in

improved strength factor values.

The tangential stresses in the roof/crown increase as the stress ratio k varied from 0.5 to 2.0 resulting in

decreased strength factor values even though higher horizontal stress provides sufficient constraint and

stability of the roof.

AA/HD/1544

33

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Fig. 13: Strength factor Contours for MC-90

Fig. 14: Strength factor Contours for MC-50

AA/HD/1544

34

Tunnels- 2 Design Report

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Fig. 15: Strength factor Contours for HB-90

Fig. 16: Strength factor Contours for HB-50

AA/HD/1544

35

Tunnels- 2 Design Report

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Table 16: Extent of zone (meters) of Strength Factor below 1.0

MC-90

Strength Factor(Extent of Zone in meter

less than 1)

k

0.5

1

1.5

2

Crown

0

0.904 1.066 1.29

Left wall

1.047 0.902 0.904 0.979

Right wall

0.991 0.918 0.822 0.963

Invert

2.174 3.764 5.038 6.071

MC-50

> 1 for all values of k

HB-90

Crown

Left wall

Right wall

Invert

HB-50

0

0

0

1.028

0

0

0

1.451

0.162

0.145

0.32

3.026

0.254

0.184

0.389

3.685

> 1 for all values of k

5.1.1.5 Minor Principal Stress induced failure (3<0):

The iso-line depicts the region with tensile stresses in the rock exceeding the tensile strength of the rock

mass. Tensile strength is estimated using the Mohr-Coulomb strength relationship, using the formula,

Tensile Strength (t) = (2c * Cos ) / (1+ Sin)

Table 17 shows the values of tensile strength adopted in the model using the formula. The maximum

principal stress in tension due to the de-confinement of rock mass in the tunnel floor is lower than the tensile

strength of the rock and hence a flat invert is considered to be adequate.

Table 17: Tensile strength as per Mohr Coulomb failure criteria

AA/HD/1544

MC 90

0.350

44.0

0.30

MC 50

1.506

56.0

0.92

36

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 17: Minor principal Stress Contours (<0, Grey Iso-lines) for MC-90

Fig. 18: Minor principal Stress Contours (<0, Grey Iso-lines) for MC-50

AA/HD/1544

37

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Tensile strength of the rock mass as per Hoek Brown failure criteria is

Tensile Strength (t) = s * ci / mb

Table 18: Tensile strength as per Hoek Brown failure criteria

s

mb

ci

HB 90

0.0180

8.017

35

0.08

HB 50

0.0621

11.875

96

0.50

Th

e region, in which the tensile strength of rock is exceeded, is significant in HB 90 model and a curved invert

can be considered, based on ground conditions met with.

Fig. 19: Minor principal Stress Contours (<0, Black Iso-lines) for HB-90

Table 19: Extent of tensile stress zone in meters

Extent of Minor principal Stress induced failure (3<0) in meter

Invert

AA/HD/1544

MC-90

MC-50

HB-90

HB-50

0.5

1.230

1.268

1.097

1.147

1.470

1.551

1.409

1.475

1.5

2.903

2.969

2.889

2.889

3.415

3.276

3.481

3.402

38

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 20: Minor principal Stress Contours (<0, Black Iso-lines) for HB-50

5.1.1.6 Critical Shear Strain

The maximum shear strain should be smaller than the critical shear strain ( c). If the maximum shear strain

is larger than the critical shear strain, tunnel support must be installed immediately so as to keep the

maximum shear strain less than the critical shear strain.

Where is the poisons ratio of the material and c is the critical strain defined as the ratio of uniaxial

compressive strength to the modulus of elasticity of rock mass.

Table 20: Permissible Shear Strain computation for different models

Model

MC 90

MC 50

HB 90

HB 50

AA/HD/1544

ci(Mpa)

35

96

35

96

Permissible Shear Strain ()

cm(Mpa)

Em(Mpa)

cm/Em

3.45

35190

9.81E-05

15.68

30850

5.08E-04

3.45

9072.6

3.80E-04

15.68

33307

4.71E-04

39

(1+m)

1.13

1.13

1.44

1.44

cm/Em (1+m)

1.11E-04

5.74E-04

5.48E-04

6.78E-04

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig.21: Maximum shear strain distribution for MC-90 exceeding permissible values

Fig. 22: Maximum shear strain distribution for HB-90 exceeding permissible values

With increasing stress ratio (k) the need for tunnel support is anticipated in models MC 90 and HB 90. Shear

strain is within limits for model MC 50 and HB 50.

AA/HD/1544

40

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

5.1.1.7

Tunnels- 2 Design Report

Principal Stress Cone

The location and thickness of the natural roof arch can be determined by the concept of invert principal

stress cone developed in the numerical modeling. The stress trajectories are displayed in Fig. 23.

Fig. 23: Development and application of concept of principal stress cone

Notations used:

k

= Stress Ratio

= Height of rock load in meter

Preqd

= Required Maximum support pressure in MPa calculated as the product of Unit weight of rock

and the height of rock load in m.

AA/HD/1544

41

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 24: Maximum height of rock load for MC-90

End anchored 25 rock bolts 4.5 m long at 2 m x 2 m spacing, and shotcrete, 50 mm thickness, M25 grade

yield support pressures of 0.051 Mpa and 0.06 Mpa resply., for all values of k.

Table 21: Support pressures using bolts and shotcrete to resist the rock load for MC-90

Support Pressure reqd

(Mpa)

Mode

l

MC 90

AA/HD/1544

Preqd

0.5

1

1.5

2

3.827

2.567

1.871

1.535

0.11

0.07

0.05

0.04

42

Support Pressure (Mpa)

End Anchored

Shotcret

bolts

e

0.025

0.025

0.025

0.025

0.12

0.06

0.06

0.06

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 25: Maximum height of rock load for MC-50

Table 22: Support pressure requirements using bolts and shotcrete to resist the rock load for MC-50

Maximum Support Pressure Calculation

Model

Preqd

End Anchored bolts

Shotcrete

MC 50

0.5

3.848

0.11

0.051

0.06

1.873

0.06

0.051

0.06

1.5

1.778

0.05

0.051

0.06

1.791

0.05

0.051

0.06

AA/HD/1544

43

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 26: Maximum height of rock load for HB-90

End anchored 25 rock bolts of 4.5 m length at a spacing of 2 m x 2 m and a shotcrete of M30 grade with

thickness of 100mm resulted in a support pressure of 0.051 Mpa and 0.14 Mpa for k=0.5.For all other values

of k, a shotcrete of M25 grade with thickness of 50mm is found adequate with a support pressure of 0.06

Mpa.

Table 23: Support pressure requirements using bolts and shotcrete to resist the rock load for HB-90

Maximum Support Pressure Calculation

Model

Preqd

End Anchored bolts

Shotcrete

HB 90

0.5

5.927

0.17

0.051

0.14

2.567

0.07

0.051

0.06

1.5

1.871

0.05

0.051

0.06

1.535

0.04

0.051

0.06

AA/HD/1544

44

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 27: Maximum height of rock load for HB-50

Table 24: Support pressure requirements using bolts and shotcrete to resist the rock load for HB-50

Maximum Support Pressure Calculation

Model

Preqd

End Anchored bolts

Shotcrete

HB 50

0.5

2.822

0.08

0.051

0.06

2.129

0.06

0.051

0.06

1.5

2.106

0.06

0.051

0.06

1.132

0.03

0.051

0.06

Equations used for estimating the support pressure of shotcrete and rockbolts

AA/HD/1544

45

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

(Ref: https://www.rocscience.com/documents/pdfs/rocnews/winter2012/Rock-Support-Interaction-Analysisfor-Tunnels-Hoek.pdf)

AA/HD/1544

46

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

5.1.1.8 Deviatoric Stress:

The difference in the major and minor principal stress referred as deviatoric stress directly relates to the

maximum shear stress. It controls the degree of distortion, allowing for a material to deform in one direction

more than the other (i.e. in the direction of smaller stress.). In effect, this allows fracturing, rupture and

shearing of the rock to occur. The deviatoric stress should be less than UCS of rock mass ( cm =ci1.5/60). If

the deviatoric stress is high, plastic analysis is required.

Table 25: Extent of zone greater than UCS of rock mass

Extent of Degree of Distortion in meter

k

Crown

Walls

Invert

MC-90

0.5

0.00

3.287

0.000

ci =35

1.0

2.032

2.797

0.000

cm =3.45

1.5

4.569

2.531

10.545

2.0

9.445

2.214

full

HB-90

0.5

0.00

3.367

0.000

ci =35

1.0

2.074

2.791

0.00

cm =3.45

1.5

4.676

2.491

10.667

2.0

9.208

2.287

full

MC-50

HB-50

0 for all values of k

0 for all values of k

Fig. 28: Deviatoric stress distribution (more than UCS of rock mass)

AA/HD/1544

47

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

5.1.2

Tunnels- 2 Design Report

Plastic Analysis:

5.1.2.1 Yielded Elements:

The depth of the shear (x) and tensile (o) failure zones in the surrounding rock without any support is an

important factor to be considered in the design of required support system.

Fig. 29: Plastic Zones around the tunnel for MC 90

Table 26: Extent of yield zone around tunnels for MC 90 Model.

Extent of zone in m

Shear zone

MC 90

AA/HD/1544

k = 0.5

k=1

k = 1.5

k=2

Crown

0.0

1.85

1.84

3.73

Walls

2.0

1.90

1.86

2.85

Invert

2.2

3.45

5.20

5.50

Tension zone

k = 0.5

k=1

k = 1.5

k=2

Crown

0.00

0.60

0.78

0.66

Walls

0.80

0.90

0.86

0.87

Invert

1.22

1.34

2.68

2.52

48

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 30: Plastic Zones around the tunnel for HB 90

5.1.2.2

Depth of Spalling:

The concentration of compressive stress in sidewalls for k values of 0.5 and 1 is not to the level of intact rock

strength and may not lead to spalling.

Fig. 31: Major Principal stress concentration for k = 0.50 & 1.0

AA/HD/1544

49

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

The concentration of compressive stress is shifted to crown and invert for k values of 1.5 and 2. The

potential for spalling may also depend on the joint pattern. The rock bolt length is so chosen to extend

beyond the zone of stress concentration.

Fig. 32: Major Principal stress concentration for k = 1.5 & 2.0

5.1.2.3 Support System:

Each support component in a support system is intended to perform one of the three functions illustrated in

figure 33.

Reinforce the rock mass to strengthen it and control bulking.

Retain broken rock to prevent key block failure and unraveling.

Hold key blocks and securely tie back the retaining element(s) to stable ground.

While each support element may simultaneously provide more than one of these functions, it is convenient

to consider each function separately:

The goal of reinforcing the rock mass is to strengthen it, thus enabling the rock mass to

support itself. Reinforcing mechanisms generally restrict and control the bulking of the rock mass,

thus ensuring that inter block friction and rock mass cohesion are fully exploited. Typically,

reinforcing behave as stiff support elements or ductile or yielding elements

While retaining the broken rock at the excavation surface is required for safety reasons, it may also

become essential under high stress conditions to avoid the development of progressive failure

process that lead to unraveling of the rock mass. Qualitative observations indicate that full aerial

coverage by retaining elements becomes increasingly important as the stress level increases.

The holding function is needed to tie the retaining elements of the support system back to stable

ground, to prevent gravity-driven falls of ground.

AA/HD/1544

50

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig 33: Three primary functions of support elements

The support system adopted for the Tunnel Section under consideration is shown in Fig. 34.

Fig. 34: Proposed support system

Tension bolts with resin point anchorage are used to apply a compressive force across layered rock strata.

Tension bolts are applied using fast setting resin as the point anchorage in conjunction with slow setting

cement as a corrosion protection for the free stress length. Bolt tension is applied after the fast setting resin

has cured but before the slow setting cement cures.

As seen in Fig. 35, the rock bolts had marginal reduction effect on the roof settlement once a natural roof

arch is formed, and after systematic rock bolting, the roof arch is more stable. A pretension of 10 ton is

applied to the rock bolts to prevent rock dilation of 1.0 m. The application of pre-tensioned bolts is intended

to provide stiffer support by reacting faster to the rock movement.

The existence of high horizontal in-situ stress resulted in higher tunnel crown subsidence, floor uplift and

deformations. This may be explained by rock mass yielding, which is caused by differential principal stress.

AA/HD/1544

51

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Fig. 35: Total displacement of crown

Fig. 36: Total displacement of side wall

AA/HD/1544

52

Tunnels- 2 Design Report

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Table 27: Number of yielded elements in Elastic Perfectly plastic analysis

(Static Analysis/) Yielded elements

k

No sup

RB

SC

RB & SC

0.5

259

254

261

249

1.0

295

301

299

290

1.5

320

324

323

320

2.0

351

347

342

337

Redistribution of stresses is concentrated in the rock mass at a distance of 3.0 m from the tunnel boundary

which delineates the Plastic and Elastic zones. Pattern bolting and SFRS result in a near triaxial stress

condition.

Fig. 37: Principal stress Distribution near side wall from tunnel boundary for k=0.5

Fig. 38: Principal stress Distribution near side wall from tunnel boundary for k=1

AA/HD/1544

53

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 39: Principal stress Distribution near side wall from tunnel boundary for k=1.5

Fig. 40: Principal stress Distribution near side wall from tunnel boundary for k=2

Examination of the distribution of radial and tangential stresses indicates the function of the radial

reinforcement. It reduces the radial displacement (ur) and generates a higher magnitude of r in the fractured

zone, resulting in a higher gradient in the t distribution. The effect is to shift the plasticelastic transition

closer to the excavation boundary. Thus, both closure of the excavation and the depth of the zone of yielded

rock are reduced.

AA/HD/1544

54

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

5.1.3

Tunnels- 2 Design Report

Seismic Design

5.1.3.1 Pseudo-Static Analysis:

For most underground structures, the inertia of the surrounding rock is large, relative to the inertia of the

structure and therefore the seismic response of the tunnel is dominated by the response of the surrounding

rock mass. In phase2, seismic loading is based on pseudo-static approach, where the seismic force is

calculated as the product of the specified seismic coefficient, a dimensionless vector, and the amplitude of

the body force, which is the self weight of the finite element.

5.1.3.2 Seismic Coefficient Method:

The inertial forces due to earthquake are obtained by multiplying the rock load with the design coefficient

(0.08) which is expressed by the following equation (IS: 1893- 1984:Cl.3.4.2.3 (a))

Where

AA/HD/1544

55

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Selected Values in Blocks from Tables 2, 3 & 4 of IS: 1893:1984

AA/HD/1544

56

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 41: Mesh Generation for Seismic Analysis

Fig. 42: Stages of sequential excavation, support application and application of seismic load

AA/HD/1544

57

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

A large zone of tensile failure is seen in the upper left hand corner in all models, which can be attributed to

the effect of boundary conditions, when horizontal seismic loading is applied from left to right. .At the

external boundary, the material when pulled away by applied seismic force, creates a large tensile stress

due to the applied boundary conditions and their effect can be minimized by increasing the extent of the

external boundary, or by placing the an elastic material away from the tunnel.

Fig. 43: Tensile zone in Upper left corner due to earthquake loading

Table 28: Number of yielded elements in Elastic Perfectly plastic seismic analysis

Seismic

k

No sup

RB

SC

RB & SC

0.5

466

452

458

443

1.0

410

398

401

388

1.5

393

379

380

375

2.0

415

403

399

395

5.1.3.3 Interaction Diagrams of shotcrete and final lining:

Interaction diagrams are therefore useful to estimate if the tunnel lining is able to tolerate applied loading

from the rock mass. Results of analysis for static and seismic loading are presented in fig.44 to 51. Lining is

never loaded by the stress which is initially prevailed in the ground. Initial stress is reduced by deformation of

the ground that occurs during excavation. The Stress relaxation of the rock mass when considered

eliminates the data points outside the envelope.

AA/HD/1544

58

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 44: Interaction diagrams of of shotcrete for k=0.5 (Static case)

Fig. 45: Interaction diagrams of shotcrete for k=1.0 (Static case)

Fig. 46: Interaction diagrams of of shotcrete for k=1.5 (Static case)

AA/HD/1544

59

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 47: Interaction diagrams of shotcrete for k=2.0 (Static case)

Fig. 48: Interaction diagrams of final lining for k=0.5 (Seismic case) with M25 Grade concrete

Fig. 49: Interaction diagrams of final lining for k=1.0 (Seismic case) with M25 Grade concrete

AA/HD/1544

60

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 50: Interaction diagrams of final lining for k=1.5 (Seismic case) with M30 Grade concrete

Fig. 51: Interaction diagrams of final lining for k=2.0 (Seismic case) with M30 Grade concrete

5.1.3

Conclusions:

5.1.3.1 Numerical Analysis of twin tube tunnels using Phase 2 with poor rock mass properties is carried out.

In-situ stress ratio, k (H / v) varies along the length of tunnel due to variation in the

direction/magnitude of H and v with geology and topography. k= 0.5, 1.0, 1.5 and 2.0 are

considered for critical condition. In-situ vertical stress is due to gravity. Mohr- coulomb and Hoek

Brown failure criteria are utilized. Excavation of tunnels is by heading and bench method.

AA/HD/1544

61

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

5.1.3.2 ELASTIC Analysis:

A strength factor less than one in MC 90 and HB 90 models indicated that the material will fail and

plastic analysis is necessary.

As the stress ratio increases from 0.5 to 2.0, the failure mode in crown and walls range from falling

or sliding of block wedges to localized brittle failure of intact rocks and movement of blocks.

The tangential stresses in the walls decrease as the stress ratio k varied from 0.5 to 2.0 resulting in

improved strength factor values. In roof/crown it increase as k varied from0.5 to 2.0 resulting in

decreased strength factor values, even though higher horizontal stress provides sufficient constraint

and stability of the roof.

The region in which the tensile strength of rock is exceeded is significant in HB 90 model and can

be attributed to the use of a lower modulus of deformation value which stressed the use of a curved

invert.

With increasing stress ratio (k) the need for immediate tunnel support is anticipated for stability in

models MC 90 and HB 90

For MC 90 and HB 90 models, the max. height of rock load above crown determined by the concept

of invert principal stress cone, is 3.848m for k=0.5. As k increases the rock load decreases. But MC

50 model indicates the height of rock load is 5.927m for k=0.5. End anchored 25dia rock bolts 4.5m

long at 2m x 2m spacing, and shotcrete, 50mm, M25 grade is adequate for the rock load except for

HB 90 model with k=0.5. Since this approach is based on empirical formulas,

The deviatoric stress (1-3) which directly relates to shear stress, controlling the degree of

distortion and fracturing, rupture and shearing of tunnel section, is more than UCS of rock mass, for

MC 90 and HB 90 models for k=0.5-2.0, indicating Plastic analysis is necessary.

5.1.3.3 PLASTIC Analysis:

The depth of the shear and tensile failure zones in the rock mass without any support is an

important factor in the design of required support system.

The extent of yielded zone in crown is 3.73m, walls 2.85 and invert 5.5m for k=2 and reduces with k

for MC 90 model. But plastic zone is limited to invert in HB-90model.

25dia rock bolts, resin end anchored + slow setting cement capsules, 4.5m long, shotcrete 50mm

thick and 200mm thick SFRS final lining is considered.

Redistribution of stresses is concentrated in the rock mass at a distance of 3m from the tunnel

boundary which delineate the plastic and elastic zones.

5.1.3.4 Seismic Design:

The tunnels are located in Zone III of seismic map of India. Tunnel section with Liner 1 of 50mm shotcrete

and Liner 2 of 200mm SFRS lining is analysed with Phase2 for its adequacy with and without seismic.

Interaction diagrams are generated. Thrust, Shear and Moments in tunnel section during different stages of

AA/HD/1544

62

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

construction are plotted on the interaction diagrams. Though some of the values are outside the diagram,

stress relaxation of the rock mass when considered eliminates the data points outside the envelope.

5.2

Portal Section

5.2.1

Estimation of rock mass parameters:

Portal section @ km: 107.845 and Borehole No.6 is used for the calculations. Mohr Coulomb Failure

criterion is used in the analysis. It is assumed similar rock conditions prevail at new north portal section after

shifting by 30 m.

Table 29 : Test results on intact rock samples of BH 6 at km: 107.845

Depth

UCS(Mpa)

E(Mpa)

(kN/m3)

17.0-18.0

102.70

42062

2.67

21.5-22.5

94.200

34673

2.66

26.0-27.0

115.30

45709

2.64

30.5-31.5

76.10

36119

2.68

35.0-36.0

116.50

38438

2.66

39.5-41.0

125.40

79032

2.74

Mean

105.00

46005.5

2.67

St dev

16.400

Value of standard deviation of the UCS data is 16.40 % of the mean value. 90% of UCS values measured

are exceeding 84.0 MPa and the value will be used as input parameter in the FEM-model. Fig. 52 shows the

correlation between UCS and E.

Fig. 52: Linear Correlation between UCS vs E

AA/HD/1544

63

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Measurements of cohesive strength in the same borehole indicates Cmean=4.14 MPa and C10%=2.5 MPa.

Fig. 53: Linear correlation between Q and RMR

Friction angle in the borehole indicates mean=70o and 10%=68o.is Residual friction angle, r = tan-1(Jr/Ja)

is worked out to be 36 o with Jr =1.5 and Ja = 2.0. So friction angle of rock mass equal to residual friction is

considered in the analysis. The stiffness modulus E10% is 33.0 GPa according correlation in Fig. 52.

Table 30: Test results of cohesion and friction of rock mass

C(Mpa)

(degrees)

3.80

71.36

2.76

68.91

5.85

67.61

After doing the Probabilistic Analysis, the following Rock Properties are considered for Numerical Modeling.

Table 31: Selected Rock Mass Properties for Numerical Analysis

Soil (Assumed)

Cohesive Strength,C

0.11

Mpa

Friction Angle,

16.00

Degree

Tensile Strength, T

0.00

Mpa

Modulus of Deformation, Ed

0.045

Gpa

Highly weathered Rock (Assumed)

Cohesive Strength, C

0.11

Mpa

Friction Angle,

35.00

Degree

Tensile Strength, T

0.00

Mpa

Modulus of Deformation, Ed

1.00

Gpa

Rock

AA/HD/1544

64

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Confidence Limit

90%

Tunnels- 2 Design Report

units

Input values of Mohr Coulomb failure Criterion

5.2.2

Cohesive Strength, C

2.50

Mpa

Friction Angle,

36.0

Degree

Tensile Strength, T

0.00

Mpa

Modulus of Elasticity, Ei

32.94

Gpa

Modulus of Deformation, Ed

1.32

Gpa

In-situ Rock Stress

Close to the ground surface k value is small due to weathering and hence k values of 0.35 and 0.50 are

considered for the analysis of portal section. Analysis with k=0.35 is reported since k=0.5 is not found critical.

Fig. 54: Model showing the extent and boundary conditions adopted for the external boundary

5.2.3

Elastic Perfectly Plastic Analysis

The direction of total displacement is semi horizontal parallel to the hill slope, as in near valley side model.

The deformation behavior in both tube tunnels indicates that the right wall and crown are in de-stressed

mode due to the excavation and there is stress concentration on the left wall. The intensity of distressed rock

in the tube tunnel roofs decrease as the tunnel advances into the hill.

AA/HD/1544

65

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 55: Displacement vectors and deformed excavation shapes at portal

The maximum principal stress in tension due to the de-confinement of rock mass in the tunnel floor is lower

than the tensile strength of the rock and hence a flat invert is considered to be adequate.

Fig. 56: Extent of Plastic Zone in tension(unsupported with Static)

AA/HD/1544

66

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 57: Extent of Plastic Zone in tension(Unsupported with Earthquake)

5.2.4

Design of Initial Support System

A top heading excavation with steel sets fully embedded in shotcrete to form a very strong structural shell on

enlarged footings (elephants feet) have been used. In addition to steel ribs, fully grouted rock bolt anchors

4.00 m long are installed at elephant foot location. The normal force in the footing of the lining, 0.4m wide, is

1.204 MN/m, resulting in stress of 3.10 Mpa, which is well below the sustainable stress of the rock mass.

Spilling is proposed to reduce the vertical stress ahead of the tunnel face to increase the stability.

Fig. 58: Extent of Plastic Zone in tension (supported with static)

AA/HD/1544

67

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 59: Extent of Plastic Zone in tension (supported with Earthquake)

The extent of plastic zones with support system is insignificantly small in without and with earthquake. The

interaction diagrams with primary support system of steel ribs and shotcrete are given below.

Fig. 60: Interaction diagrams of Steel rib embedded in shotcrete for k=0.35

AA/HD/1544

68

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

Fig. 61: Interaction diagrams of 50 mm Shotcrete for k=0.35

The moment-axial thrust capacity curves plotted in Figure 60 & 61 are calculated for a factor of safety of 1.0.

5.2.5 Design of Final lining

The final unreinforced final concrete lining is designed with a factor of safety of 2, in the portal section.

Fig. 62: Interaction diagrams of final lining 250 mm thick M 25 grade PCC for k=0.35

AA/HD/1544

69

Design Consultancy services for four-Laning of 'Goa/Karnataka Border - Kundapur

Section' of NH-17 from Km 93.700 to Km 283.300 in the State of Karnataka

Tunnels- 2 Design Report

The moment-axial thrust capacity diagram for a 250 mm thick lining of M25 grade, unreinforced concrete, is

plotted in Fig. 62. In the same figure, the induced moment-axial thrust combinations are also plotted. The

points all fall within the capacity envelope. Hence an unreinforced final concrete lining 250mm thick is

adequate in the portal.

5.2.6

Conclusions:

Mohr coulomb failure criteria is used in the analysis. Properties of rock mass of BH 6 are

considered with k = 0.35, since tunnel is at shallow depth below ground level.

Elastic Perfectly plastic analysis indicates direction of total displacement is parallel to the hill slope

and thereby stresses concentration is on hill side walls of both the tubes. Seismic condition is

included.

Interaction diagrams are generated for shotcerete, steel rib, and final concrete lining. Thrust, shear

and moments in tunnel section are within the interaction diagrams.

Excavation is by heading and bench with spiling umbrella. Initial support system is steel sets

W200x35.9, fully embedded in shotcrete. Steel ribs rest at bench on elephant foot footing. The final

lining is 250mm thick plain cement concrete M 25 grade.

AA/HD/1544

70

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Design of Rural Water Supply System Using Branch 3.0 - A Case Study For Nava-Shihora Region, IndiaDocument13 pagesDesign of Rural Water Supply System Using Branch 3.0 - A Case Study For Nava-Shihora Region, IndiaIAEME PublicationNo ratings yet

- Ground Floor: Hall 9'8" X12'6" Bed Room 7'10" X12'6" Kitchen 9'8" X12'6" Bed Room 9'3" X12'6"Document1 pageGround Floor: Hall 9'8" X12'6" Bed Room 7'10" X12'6" Kitchen 9'8" X12'6" Bed Room 9'3" X12'6"p_ignatiusNo ratings yet

- Flow and Stability of Al-Wand Earth Dam During Rapid Drawdown of Water in ReservoirDocument15 pagesFlow and Stability of Al-Wand Earth Dam During Rapid Drawdown of Water in Reservoirp_ignatiusNo ratings yet

- LOADING AND SLAB DESIGN DETAILS FOR KALESWARAM PUMP HOUSEDocument29 pagesLOADING AND SLAB DESIGN DETAILS FOR KALESWARAM PUMP HOUSEp_ignatiusNo ratings yet

- Design rectangular combined footingDocument45 pagesDesign rectangular combined footingifylasy100% (1)

- A New Construction Method For A Metro Station in BeijingDocument5 pagesA New Construction Method For A Metro Station in BeijingpabulumzengNo ratings yet

- DateDocument1 pageDatep_ignatiusNo ratings yet

- Water PressureDocument32 pagesWater Pressurep_ignatiusNo ratings yet

- Design of Raft FoundationDocument9 pagesDesign of Raft FoundationМилош ЈанићијевићNo ratings yet

- Sample Input Files For Nof and ofDocument2 pagesSample Input Files For Nof and ofp_ignatiusNo ratings yet

- Stability Assessment of Hydropower PDFDocument157 pagesStability Assessment of Hydropower PDFOgala OscarNo ratings yet

- Flow and Stability of Al-Wand Earth Dam During Rapid Drawdown of Water in ReservoirDocument15 pagesFlow and Stability of Al-Wand Earth Dam During Rapid Drawdown of Water in Reservoirp_ignatiusNo ratings yet

- SEISMIC BEHAVIOR OF PRECAST PIERS ON HIGH SPEED RAILWAY BRIDGESDocument361 pagesSEISMIC BEHAVIOR OF PRECAST PIERS ON HIGH SPEED RAILWAY BRIDGESp_ignatiusNo ratings yet

- Generate STAAD Design ParametersDocument48 pagesGenerate STAAD Design ParameterswxwmnstrNo ratings yet

- 2 Way Slab Design From Jahid Vai AIDCL ChangedDocument19 pages2 Way Slab Design From Jahid Vai AIDCL ChangedMagdy BakryNo ratings yet

- Columna CirculDocument16 pagesColumna Circulp_ignatiusNo ratings yet

- Analysis of T-Beam: Nos in Layer 1 Nos in Layer2Document9 pagesAnalysis of T-Beam: Nos in Layer 1 Nos in Layer2p_ignatiusNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument21 pagesLarsen & Toubro Limited: ECC Division - EDRCp_ignatiusNo ratings yet

- FootingsDocument21 pagesFootingsManuel GONo ratings yet

- Creep&ShrinkageDocument9 pagesCreep&Shrinkagep_ignatiusNo ratings yet

- BANGDocument5 pagesBANGp_ignatiusNo ratings yet

- Guidelines For Numerical Modelling of Rock Support For MinesDocument26 pagesGuidelines For Numerical Modelling of Rock Support For MinesJose YucraNo ratings yet

- BangDocument2 pagesBangp_ignatiusNo ratings yet

- 8848313Document40 pages8848313p_ignatiusNo ratings yet

- Bearing Failure Modes of Rock Foundations With Consideration of Joint SpacingDocument11 pagesBearing Failure Modes of Rock Foundations With Consideration of Joint Spacingsurya prakashNo ratings yet

- BackgroundDocument2 pagesBackgroundp_ignatiusNo ratings yet

- Peak and Residual Strengths of Jointed Rock Masses and Their Determination For Engineering DesignDocument9 pagesPeak and Residual Strengths of Jointed Rock Masses and Their Determination For Engineering Designp_ignatiusNo ratings yet

- Kinematic AnalysisDocument26 pagesKinematic AnalysisrNo ratings yet

- Nternational Ournalof Esearch Cience& AnagementDocument8 pagesNternational Ournalof Esearch Cience& Anagementp_ignatiusNo ratings yet

- BIMDocument1 pageBIMp_ignatiusNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Worksheet MotionDocument3 pagesWorksheet MotioniskenderbeyNo ratings yet

- Universal Law of GravitationDocument13 pagesUniversal Law of GravitationDavid NgNo ratings yet

- Machine Elements - Lubrication and BearingsDocument13 pagesMachine Elements - Lubrication and BearingsShridhar ChinuuNo ratings yet

- FM & F Machines 2013 PDFDocument355 pagesFM & F Machines 2013 PDFChandan KumarNo ratings yet

- Sound Waves: Audible, Ultrasonic and Infrasonic WavesDocument3 pagesSound Waves: Audible, Ultrasonic and Infrasonic Wavesrakib hasanNo ratings yet

- Frisbee AerodynamicsDocument220 pagesFrisbee Aerodynamicstk36No ratings yet

- 2Document12 pages2Thabang Maphakisa0% (1)

- M.SC - Physics SyllabusDocument19 pagesM.SC - Physics SyllabusglopatNo ratings yet

- Lifting Design Using Rebars: Details of PanelDocument3 pagesLifting Design Using Rebars: Details of PanelAsaru Deen100% (2)

- Projectile Motion Lab Predicts Rocket DisplacementDocument4 pagesProjectile Motion Lab Predicts Rocket Displacementsyed.imam100% (1)

- Dme-2 byDocument81 pagesDme-2 byHauaisnNo ratings yet

- Calculate Design Beam Jib CraneDocument25 pagesCalculate Design Beam Jib Cranejafary100% (14)

- Prediction of Stress Distribution in Press-Fit Process of Interference Fit With A New Theoretical ModelDocument14 pagesPrediction of Stress Distribution in Press-Fit Process of Interference Fit With A New Theoretical ModelDragon EcuNo ratings yet

- Rotational Kinematics Worksheet PacketDocument12 pagesRotational Kinematics Worksheet PacketElias MaciasNo ratings yet

- ME 601 Stress Analysis Homework SolutionsDocument3 pagesME 601 Stress Analysis Homework SolutionsGowtham RajaduraiNo ratings yet

- May2018 Physics Paper 2 TZ1 HL MarkschemeDocument18 pagesMay2018 Physics Paper 2 TZ1 HL MarkschemeAnanya Aggarwal100% (2)

- .Document7 pages.Darshan Panchal100% (1)

- ch8 Steady Incompressible Flow in Pressure Conduits (Partb) PDFDocument66 pagesch8 Steady Incompressible Flow in Pressure Conduits (Partb) PDFnaefmubarak0% (1)

- J Ijpvp 2017 10 002Document19 pagesJ Ijpvp 2017 10 002Memo 1 1No ratings yet

- Man-Arian Flow Cad SoftwareDocument27 pagesMan-Arian Flow Cad Softwaresyahmi1337No ratings yet

- Module 9 Heat TransferDocument8 pagesModule 9 Heat TransferGreen BrainNo ratings yet

- Exercise Book StaticsDocument44 pagesExercise Book StaticsStephany AlonsoNo ratings yet

- Physics: Extbook For Class XLDocument193 pagesPhysics: Extbook For Class XLChaithanya Bharghava SNo ratings yet

- Teoria de Placas e Cascas AE-207Document7 pagesTeoria de Placas e Cascas AE-207Wallison SilvaNo ratings yet

- Effects of Earthquakes On Dams and Embankments By: Fifth RankineDocument22 pagesEffects of Earthquakes On Dams and Embankments By: Fifth RankineΚική ΚωστοπούλουNo ratings yet

- A Review of One-Dimensional Unsteady Friction Models For Transient Pipe FlowDocument11 pagesA Review of One-Dimensional Unsteady Friction Models For Transient Pipe FlowBhuvanaNo ratings yet

- Lateral resistance and bending moments in retaining wallsDocument8 pagesLateral resistance and bending moments in retaining wallsanumnedNo ratings yet

- Physics Lab 6Document7 pagesPhysics Lab 6Tahsin RahmannNo ratings yet

- Magnetic Properties & CharacteristicsDocument9 pagesMagnetic Properties & CharacteristicsRogelyn JosolNo ratings yet

- Backhoe Loader Finite Element AnalysisDocument55 pagesBackhoe Loader Finite Element AnalysisPrabhakar Purushothaman100% (2)