Professional Documents

Culture Documents

Comparison Chart Modular Steel Tanks and GRP

Uploaded by

jenshid0 ratings0% found this document useful (0 votes)

296 views2 pagesPioneer tanks have several advantages over GRP/pressed steel tanks:

1) Pioneer tanks use a cylindrical design and self-supporting roof trusses which distribute weight evenly, while rectangular GRP tanks experience greater stresses at corners and require bracing.

2) Pioneer tanks have a flexible liner separating the water from the steel structure to prevent corrosion and leakage, while water is in permanent contact with nuts, bolts and bracing in GRP tanks.

3) Pioneer tanks only require a simple reinforced concrete ring foundation which is cheaper than the full concrete slab needed for GRP tanks.

Original Description:

Advantages of Modular Steel Tanks over GRP Panel Tanks

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPioneer tanks have several advantages over GRP/pressed steel tanks:

1) Pioneer tanks use a cylindrical design and self-supporting roof trusses which distribute weight evenly, while rectangular GRP tanks experience greater stresses at corners and require bracing.

2) Pioneer tanks have a flexible liner separating the water from the steel structure to prevent corrosion and leakage, while water is in permanent contact with nuts, bolts and bracing in GRP tanks.

3) Pioneer tanks only require a simple reinforced concrete ring foundation which is cheaper than the full concrete slab needed for GRP tanks.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

296 views2 pagesComparison Chart Modular Steel Tanks and GRP

Uploaded by

jenshidPioneer tanks have several advantages over GRP/pressed steel tanks:

1) Pioneer tanks use a cylindrical design and self-supporting roof trusses which distribute weight evenly, while rectangular GRP tanks experience greater stresses at corners and require bracing.

2) Pioneer tanks have a flexible liner separating the water from the steel structure to prevent corrosion and leakage, while water is in permanent contact with nuts, bolts and bracing in GRP tanks.

3) Pioneer tanks only require a simple reinforced concrete ring foundation which is cheaper than the full concrete slab needed for GRP tanks.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

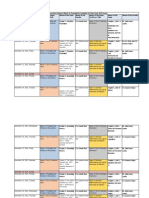

Comparison chart Pioneer Water Tanks & GRP/ Pressed Steel tanks

Pioneer Cylindrical Zincalume Water Tanks

Cylindrical design ensuring the weight of the

water is evenly distributed. There are no weak

points or areas subjected to greater structural

stresses from the hydrostatic load. The roof is

self supporting using HDG Roof Trusses there

are no Supporting columns or internal bracing

Pioneer tanks are lined internally using a

Heavy Duty, reinforced PVC water-tight liner

membrane system. All Pioneer liners are food

grade, custom factory manufactured & pretested. Liners are suited for storage of potable

water, salt water, grey and black water.

Pioneer tanks are designed for installation

onto a Reinforced Concrete Ring Beam

Foundation filled internally with clean

compacted sand. A ring beam foundation is

relatively simple & fast to construct at a

fraction of the cost of a GRP foundation 80%

cost saving compared to an equal capacity

GRP / Pressed Steel tank foundation.

Pioneer tanks are designed to last more than

25 years. Using a liner ensures there is no

contact between the steel structure and the

stored water.

Pioneer tanks use a unique V- Lock, corrugated

steel wall for rigidity. The internal liner and

tank shell are designed to move independently

of one another to with-stand earth movement

All Pioneer tank components are readily

replaceable at minimal cost. Pioneer tanks are

easily dismantled for relocation / installation.

Pioneer tank liners are flexible providing very

strong structural and waterproofing

capabilities in tanks up to 10 metres high with

no leakage or structural issues.

10 year warranty no maintenance required.

Pioneer tanks are designed to perform in

excess of 25 year and parts are easily replaced

at minimal cost beyond warranty

GRP / Pressed Steel Water Tanks

Rectangular or square shaped tanks

experience greater stresses / loading at the

corners. Accordingly, these tanks require

substantial internal or external bracing

support to prevent structural failure when

filled with water.

Sealant is used for water- proofing and is

sandwiched between each panel section then

pressed together with the bolting system of

tank. These areas are more leakage prone.

Water is permanently in contact with the nuts,

bolts & steel bracing.

GRP tanks require an expensive full concrete

slab with rows of concrete footings to support

the tank base. GRP tank foundations are

expensive. Water-proofing Joint integrity

between the panels is often compromised as a

result of any imprecise foundation works.

GRP tanks require a considerable amount of

internal steel bracing which directly contacts

the stored water. Bracing frequently corrodes

over time often leading to structural failure.

Non flexible structure any ground movement

often results in leakages from the joints.

Repairs are complicated and in some cases

cannot be resolved.

Problems with GRP / Pressed Steel tanks are

generally time consuming and often difficult to

resolve.

Tank floor and walls are limited in flexibility.

The maximum height of GRP structures is

4 metres. At this height, greater stresses are

placed on the tank floor and walls. GRP tanks

require periodic bolt tightening and

maintenance for leakage issues

10 year warranty. Tanks often require

maintenance works within this time.

Pioneer Tank

GRP Tank

You might also like

- Adjustment and Impulse Control DisordersDocument19 pagesAdjustment and Impulse Control DisordersArchana50% (4)

- Reinforced Concrete Reservoir AssignmentDocument7 pagesReinforced Concrete Reservoir AssignmentKuza AnasNo ratings yet

- Vedic Astrology OverviewDocument1 pageVedic Astrology Overviewhuman999100% (8)

- Astm-A3: Licensed by Information Handling Services Licensed by Information Handling ServicesDocument4 pagesAstm-A3: Licensed by Information Handling Services Licensed by Information Handling ServicesTran van VuongNo ratings yet

- Welded Steel Water Tanks: Steel Plated Structures (Lecture Notes) Fourth Year Civil 2006-2007Document20 pagesWelded Steel Water Tanks: Steel Plated Structures (Lecture Notes) Fourth Year Civil 2006-2007MazenMowafyNo ratings yet

- Hydraulic Tube-Bundle-Extractor Removes Bundles QuicklyDocument4 pagesHydraulic Tube-Bundle-Extractor Removes Bundles Quicklynyr1981_942955963100% (1)

- Welcome To The Institute For Timber Construction-South Africa Itc-SaDocument75 pagesWelcome To The Institute For Timber Construction-South Africa Itc-SaMclyb GumbieNo ratings yet

- Hoist LoadsDocument44 pagesHoist Loadslords3No ratings yet

- Method to Stabilize Suspended Decks in Double Walled Storage TanksDocument68 pagesMethod to Stabilize Suspended Decks in Double Walled Storage TanksBambang NiryonoNo ratings yet

- MechanismDocument17 pagesMechanismm_er100No ratings yet

- FCV Series Fixed Cone Valves from WWW.VSIVALVE.COMDocument11 pagesFCV Series Fixed Cone Valves from WWW.VSIVALVE.COMRofi Trianto SNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Hee-Gyung KongNo ratings yet

- Grouts & AnchorsDocument6 pagesGrouts & Anchorseng_osamahazaymehNo ratings yet

- 3000 Brochure PDFDocument24 pages3000 Brochure PDFFarooque ShaikhNo ratings yet

- ASCE 7-10 MEP Seismic & Wind ProvisionsDocument55 pagesASCE 7-10 MEP Seismic & Wind ProvisionsMe MeNo ratings yet

- Astm A572 1979 PDFDocument5 pagesAstm A572 1979 PDFzepol2000No ratings yet

- Dynamic Analysis of Steel Silo Using Wind Load As Per Indian Standard IJERTV8IS110206Document4 pagesDynamic Analysis of Steel Silo Using Wind Load As Per Indian Standard IJERTV8IS110206AliNo ratings yet

- PBM Sanitary Ball ValvesDocument40 pagesPBM Sanitary Ball ValvesAnonymous bTvqZMftNo ratings yet

- WADocument28 pagesWADota NgNo ratings yet

- Modern Steel Construction's monthly steel column answers welding questionsDocument2 pagesModern Steel Construction's monthly steel column answers welding questionshector diazNo ratings yet

- Palo Alto Firewall VirtualizationDocument394 pagesPalo Alto Firewall VirtualizationRyanb378No ratings yet

- Drop Forged Turnbuckles: Turnbuckles Meet ASTM Specification F1145-92 Type 1 Grade 1Document4 pagesDrop Forged Turnbuckles: Turnbuckles Meet ASTM Specification F1145-92 Type 1 Grade 1Vicces P. EstradaNo ratings yet

- (PDF) Teach Your Baby Math - Glenn DomanDocument200 pages(PDF) Teach Your Baby Math - Glenn Domansugapovex0% (1)

- Astm A285 1978Document5 pagesAstm A285 1978Juan Manuel Cruz MárquezNo ratings yet

- NPSH CalculationDocument1 pageNPSH Calculationjenshid100% (1)

- Pipe Reinforcement Calculation (ASME-B31.3)Document3 pagesPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Dev LengthDocument5 pagesDev LengthdghtghfgjhhjjhnNo ratings yet

- Strategicmanagement Finalpaper 2ndtrisem 1819Document25 pagesStrategicmanagement Finalpaper 2ndtrisem 1819Alyanna Parafina Uy100% (1)

- Seismic Analysis and Design of Steel Liquid Storage Tanks PDFDocument7 pagesSeismic Analysis and Design of Steel Liquid Storage Tanks PDFBala SutharshanNo ratings yet

- Corrosion Webinar Series - Coatings Maintenance Assessments PDFDocument37 pagesCorrosion Webinar Series - Coatings Maintenance Assessments PDFyaofuzhang100% (1)

- Tanks - BasicDocument15 pagesTanks - BasicDedy WindiyantoNo ratings yet

- Rules & Guidelines of Elliott WaveDocument12 pagesRules & Guidelines of Elliott WaveNd Reyes100% (2)

- Design of Large Diameter Microtunnelling Shafts in Soft GroDocument9 pagesDesign of Large Diameter Microtunnelling Shafts in Soft Grojenshid100% (2)

- RCC 1 PDFDocument8 pagesRCC 1 PDFNgọc TuyênNo ratings yet

- OSECDocument63 pagesOSECjenshid100% (1)

- Floating Roof DesinDocument5 pagesFloating Roof Desindimdaliak_985662241No ratings yet

- Galvanized Tank BrochureDocument5 pagesGalvanized Tank Brochurem4004No ratings yet

- Abeco Tanks - Manufacturers of Pressed Steel Water Storage TanksDocument12 pagesAbeco Tanks - Manufacturers of Pressed Steel Water Storage TankslmthunziNo ratings yet

- Horseley Bridge Tanks BrochureDocument12 pagesHorseley Bridge Tanks BrochureObinna OkaforNo ratings yet

- 2a. Specs For Valves - IADocument4 pages2a. Specs For Valves - IAPraveen KasrottaranNo ratings yet

- 400 Roof and Seal Selection and DesignDocument51 pages400 Roof and Seal Selection and DesignALI YILMAZNo ratings yet

- Elastic BucklingDocument33 pagesElastic BucklingIstvan WunderlichNo ratings yet

- Chapter06 TurnbucklesDocument14 pagesChapter06 TurnbucklesDylan RamasamyNo ratings yet

- Significant Changes in AWWA D100-11Document6 pagesSignificant Changes in AWWA D100-11Leslie Scott100% (4)

- Galvanized Steel Performance in SoilDocument2 pagesGalvanized Steel Performance in SoilHarish KrothapalliNo ratings yet

- Failure of A Black Liquor Tank in A Paper Mill PDFDocument3 pagesFailure of A Black Liquor Tank in A Paper Mill PDFHeru MaulanaNo ratings yet

- Duplex Ss in API, NSF and AwwaDocument16 pagesDuplex Ss in API, NSF and AwwajoseritoNo ratings yet

- Sprinkler ESFRDocument4 pagesSprinkler ESFRGustavo Torres CabañasNo ratings yet

- Buckling Experiments - Experimental Methods in Buckling of Thin-Walled StructureDocument1,120 pagesBuckling Experiments - Experimental Methods in Buckling of Thin-Walled StructureEJOUMALENo ratings yet

- Wind Pressures and Buckling of Cylindrical Steel1Document17 pagesWind Pressures and Buckling of Cylindrical Steel1ARNOUXNo ratings yet

- Grouting Systems - 620Document6 pagesGrouting Systems - 620arunkumarNo ratings yet

- Size RangeDocument15 pagesSize RangelucidbaseNo ratings yet

- High-Strength Low-Alloy Structural Steel With 50 Ksi (345 Mpa) Minimum Yield Point To 4 In. (100 MM) ThickDocument2 pagesHigh-Strength Low-Alloy Structural Steel With 50 Ksi (345 Mpa) Minimum Yield Point To 4 In. (100 MM) ThickSadashiva sahooNo ratings yet

- Specification For The Use of Steel Tanks in The Water Industry PDFDocument15 pagesSpecification For The Use of Steel Tanks in The Water Industry PDFJorge Alberto Martinez OrtizNo ratings yet

- 09-Thai Cooling TowerDocument27 pages09-Thai Cooling TowerEnergy4You100% (1)

- Low Temperature and Cryogenic Ball ValvesDocument4 pagesLow Temperature and Cryogenic Ball Valves윤병택100% (1)

- NUGROUT HI SPEC cementitious groutDocument2 pagesNUGROUT HI SPEC cementitious groutPaul RuckNo ratings yet

- Petroleum Tanks BrochureDocument12 pagesPetroleum Tanks BrochureM.Sreeram SanjayNo ratings yet

- Cleanouts HandoutDocument2 pagesCleanouts HandoutGIANNA MARIE BALIBAGNo ratings yet

- Stainless Steel Laser Fused Universal Beams and ColumnsDocument8 pagesStainless Steel Laser Fused Universal Beams and ColumnsDushyantha JayawardenaNo ratings yet

- Corrosion Failure Analysis of Galvanized Steel Pipes in A Water Irrigation SystemDocument6 pagesCorrosion Failure Analysis of Galvanized Steel Pipes in A Water Irrigation SystemC_rovere100% (1)

- Cable Roofs HistoryDocument3 pagesCable Roofs HistorySparrow JackNo ratings yet

- Nord Lock Washers InfoDocument8 pagesNord Lock Washers InfoMaclean ArthurNo ratings yet

- 2010 Straub Couplings CatalogDocument24 pages2010 Straub Couplings CatalogpaulpopNo ratings yet

- There Is A Difference Between Tank MaterialsDocument3 pagesThere Is A Difference Between Tank MaterialsReza KhajeNo ratings yet

- Comprehensive Study On WaterstopsDocument18 pagesComprehensive Study On WaterstopsFrederick TanNo ratings yet

- Water BarsDocument13 pagesWater BarsVijay YadavNo ratings yet

- Water Bars BY VIJAY KUMARDocument13 pagesWater Bars BY VIJAY KUMARVijay YadavNo ratings yet

- 6 Reasons Bolted Tanks Are Better Than Other OptionsDocument2 pages6 Reasons Bolted Tanks Are Better Than Other OptionsAdelmo FilhoNo ratings yet

- UntitledDocument29 pagesUntitledprtasadNo ratings yet

- Mod 3 Lec 8Document16 pagesMod 3 Lec 8The Layman TheoryNo ratings yet

- Mobile Hypo Unit - GADocument1 pageMobile Hypo Unit - GAjenshidNo ratings yet

- VTS Clima introduces European air handling and fan coil unitsDocument9 pagesVTS Clima introduces European air handling and fan coil unitsjenshidNo ratings yet

- Verbals For TeleconferenceDocument1 pageVerbals For TeleconferencejenshidNo ratings yet

- Naadan RuchikalDocument10 pagesNaadan RuchikalBhadraj RamachandranNo ratings yet

- Construction Procedure For MicrotunnelllingDocument5 pagesConstruction Procedure For MicrotunnelllingjenshidNo ratings yet

- Design and Use of Check ValvesDocument10 pagesDesign and Use of Check Valvesjenshid0% (1)

- Theravada BuddhismDocument21 pagesTheravada BuddhismClarence John G. BelzaNo ratings yet

- VIACRYL VSC 6250w/65MP: Technical DatasheetDocument2 pagesVIACRYL VSC 6250w/65MP: Technical DatasheetPratik MehtaNo ratings yet

- Inbound 8511313797200267098Document10 pagesInbound 8511313797200267098phan42No ratings yet

- Good Evil EssayDocument2 pagesGood Evil EssayuniquebythemillionsNo ratings yet

- Eca Important QuestionsDocument3 pagesEca Important QuestionsSri KrishnaNo ratings yet

- ZO 503 Physiological Chemistry by Dr.S.S.KunjwalDocument22 pagesZO 503 Physiological Chemistry by Dr.S.S.KunjwalAbhishek Singh ChandelNo ratings yet

- CFC KIDS FOR CHRIST 2020 FINAL EXAMDocument13 pagesCFC KIDS FOR CHRIST 2020 FINAL EXAMKaisser John Pura AcuñaNo ratings yet

- No-Till For Micro Farms: The Deep-Mulch Method (Lean Micro Farm)Document20 pagesNo-Till For Micro Farms: The Deep-Mulch Method (Lean Micro Farm)Chelsea Green PublishingNo ratings yet

- Range of Muscle Work.Document54 pagesRange of Muscle Work.Salman KhanNo ratings yet

- Specification: F.V/Tim e 3min 5min 8min 10MIN 15MIN 20MIN 30MIN 60MIN 90MIN 1.60V 1.67V 1.70V 1.75V 1.80V 1.85VDocument2 pagesSpecification: F.V/Tim e 3min 5min 8min 10MIN 15MIN 20MIN 30MIN 60MIN 90MIN 1.60V 1.67V 1.70V 1.75V 1.80V 1.85VJavierNo ratings yet

- Goldenberg and Reddy (2017)Document10 pagesGoldenberg and Reddy (2017)Mariana ToniniNo ratings yet

- Bimbo Marketing ResearchDocument27 pagesBimbo Marketing Researcheman.konsouhNo ratings yet

- 1st ClassDocument18 pages1st Classchitl.23bi14075No ratings yet

- Final Exam IN Sample QuestionsDocument27 pagesFinal Exam IN Sample QuestionsJI TEN100% (1)

- French Ox Cheek Stew with MushroomsDocument2 pagesFrench Ox Cheek Stew with MushroomsMihai LeancăNo ratings yet

- 1.an Overview On Membrane Strategies For Rare Earths Extraction and Separation - 2017Document36 pages1.an Overview On Membrane Strategies For Rare Earths Extraction and Separation - 2017Vasile AlexandraNo ratings yet

- Bronchogenic CarcinomaDocument13 pagesBronchogenic Carcinomaloresita_rebongNo ratings yet

- Gender and Other Cross Cutting Issues Mental HealthDocument6 pagesGender and Other Cross Cutting Issues Mental HealthJamira Inoc SoboNo ratings yet

- Chapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsDocument10 pagesChapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsALANKRIT TRIPATHINo ratings yet

- Materials Science & Engineering A: Alena Kreitcberg, Vladimir Brailovski, Sylvain TurenneDocument10 pagesMaterials Science & Engineering A: Alena Kreitcberg, Vladimir Brailovski, Sylvain TurenneVikrant Saumitra mm20d401No ratings yet

- Genigraphics Poster Template 36x48aDocument1 pageGenigraphics Poster Template 36x48aMenrie Elle ArabosNo ratings yet

- Manage a micro business with BSB30315Document3 pagesManage a micro business with BSB30315Theo A W JacksonNo ratings yet

- IT Technician CVDocument3 pagesIT Technician CVRavi KumarNo ratings yet