Professional Documents

Culture Documents

Effect of Reservoir Heterogeneity On SAGD

Uploaded by

Anonymous PO7VwbBnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Reservoir Heterogeneity On SAGD

Uploaded by

Anonymous PO7VwbBnCopyright:

Available Formats

EFFECTS OF RESERVOIR HETEROGENEITIES ON HEAVY

OIL RECOVERY BY STEAM-ASSISTED GRAVITY DRAINAGE

G. YANG R.M. BUTLER

this article begins on the next page

JCPT92-08-03 HEAVY OIL Effects of reservoir heterogeneities on heavy oil recovery by steam-assisted gravity drainage GUIHUA YANG and R.M. BUTLER University of Calgary Calgary, Alberta ABSTRACT Previous studies of the SAGD process have been based on homogeneous reservoir models. In this paper, new @riments are described which simulate heterogeneous @ervoirs. These include reservoirs with thin shale @ers and reservoirs containing horizontal layers of different permeabilities

The restdts show that a short horizontal barrier does not affect the general performance greatly. A long

horizontat barrier dec@ the production rate but, in some configurations, not nearly as much as might be @cted. It is observed that faster production is found when a higher permeabitity layer is above a lower permeability layer than when the conditions are reversed Introduction The production of heavy oils by gravity drainage to a horizontal well with the continuous injection of steam above follows from the existing steam stimulation and steam flooding practices. The process has been recognized as steam-assisted gravity drainage (SAGD).

Rapid development in this area is being encouraged by

improved horizontal wefl drilling technology which allows more favourable economics. Butler et al.(2,3,4) carried out early experimental and the- oretical stuches on tlm area. Their theoretical prechctions agreed well with the homogeneous reservoir model experiments.

No reservoir is completely homogeneous, and the degrees of het- erogeneity can vary significantly, even within the same field. It is necessary that pre@ary experiments be performed to study the effects of reservoir heterogeneities.

The research work presented here is limited to two types of reser- voirs which are

considered to be representative and close to the real field conditions: (1) reservoirs with thin shale layers, (2) reservoirs containing horizontal layers of different pen-neabuities.

Laboratory studies were conducted using a visual reservoir model saturated with Cold Lake bitumen. The steam injection pressure employed was 153 kPa. Two different weff configurations have been investigated. The first consisted of a vertical circulation steam in- jector which was perforated new the top of the fo@on with b ced at the bottom; the second employed a s@ar umen produ

't- configuration to the first, but with steam introduced slightly above the production well at the base of the formation. Photographs were taken at specified time intervals and the tem@erature profile was recorded continuously to provide a means for comparisons and even- tually for selecting an optimal wefl con@ation for different reser- voir conditions. Experimental _ The two-dimensional re@oir model is that which has been described by llutler et al.(') only with minor modifications. The schematic experimental set-up is illustrated in Figure 1. The model was scaled to the field conditions

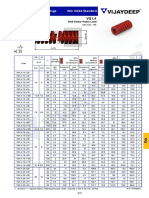

by using the method described by Butler et al.(2). The scaling parameters are shown in Table 1. One hour for ihe model is equivalent to 1.5 years in the field. The vertical circulating steain injector(l) was employed to initiate the communication between the injmfion and production wela. The in- jection well location was adjusted verticay to allow for different steam injection locations. Figures 2a and 2b show how this vertical steam injector works.

The porous materials used in the reservoir model were 2 nim and 3 nim glass beads. hi order to obtain a uiiforrrdy random pack- ing of

the porous pack, the reservoir model was secured on a vibrat- ing table. For two layer reservoirs with either 2 n-im or 3 n-im glass beads as the top layer, enough shaking time had to be allowed for stable consolidation of the first layer before adding the second porous mediwn through three fitting openings along the upper edge of the model. A straight horizontal interface between the two lay- ers was achiened through slow patient operation. To simulate the thin shale layer in the formation, 0.4 cm thick, reinforced, phenol- ic resin dividei- was sealed inside the model. However, because

the plastic has a thermal conductivity wl-dch is about 20% of that for typical shales, its resistance to heat conduction is equivalent to that of a shale la@er as thick as 2 m.

Realizing tlie importance of proper production well control, a thermocouple was connected to the production well. The amount of steam let oiit through the production wefl was controlled in such a manner that the thermocouple reading was maintained at 96'C within + I'C. Results and Discussion Ten runs are described and a summary of the operating conditions for these experiments is shown in Table 2. Two mm glass

beads were used in i@he low permeability layer, and three mm glass beads in the high permeability layer. Cold Lake bitumen was used as the heavy crude in each of the experiments. The properties of the Cold Lake biturneii are shown in Table 3. Further analyses of this bitu- men have been described previously(5). Paper reviewed and accepted for publication by the Editorial Board

(of

The

Journal

of

Canadian

Petroleum

Technology. 37 Keywords: Heavy oil, Heterogeneities, Shale barrier, SAGD, Steam. October 1992, Volume 31, No. 8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ein Extensive ListDocument60 pagesEin Extensive ListRoberto Monterrosa100% (2)

- The Van Conversion Bible - The Ultimate Guide To Converting A CampervanDocument170 pagesThe Van Conversion Bible - The Ultimate Guide To Converting A CampervanPil100% (3)

- CHAPTER 4 - CONTINUUM HYPOTHESIS - 1994 - Continuum MechanicsDocument12 pagesCHAPTER 4 - CONTINUUM HYPOTHESIS - 1994 - Continuum MechanicsAnonymous PO7VwbBnNo ratings yet

- CHAPTER 6 - MOTION - 1994 - Continuum MechanicsDocument51 pagesCHAPTER 6 - MOTION - 1994 - Continuum MechanicsAnonymous PO7VwbBnNo ratings yet

- CHAPTER 3 - CALCULUS OF TENSORS - 1994 - Continuum MechanicsDocument46 pagesCHAPTER 3 - CALCULUS OF TENSORS - 1994 - Continuum MechanicsAnonymous PO7VwbBnNo ratings yet

- Lake and Hirasaki (1981) (SPE-8436-PA)Document10 pagesLake and Hirasaki (1981) (SPE-8436-PA)Anonymous PO7VwbBnNo ratings yet

- Entropy 19 00048Document18 pagesEntropy 19 00048Anonymous PO7VwbBnNo ratings yet

- Mark Et Al. (1992) PDFDocument13 pagesMark Et Al. (1992) PDFAnonymous PO7VwbBnNo ratings yet

- McMurray Formation GeologyDocument123 pagesMcMurray Formation GeologyAnonymous PO7VwbBnNo ratings yet

- Notes - Permeability and Darcy LawDocument5 pagesNotes - Permeability and Darcy LawAnonymous PO7VwbBnNo ratings yet

- McGarry (1983)Document10 pagesMcGarry (1983)Anonymous PO7VwbBnNo ratings yet

- Wong Sandler (1992)Document10 pagesWong Sandler (1992)Anonymous PO7VwbBnNo ratings yet

- Solvent DataDocument7 pagesSolvent DataAnonymous PO7VwbBnNo ratings yet

- Numerical Methods For Unconstrained Optimization and Nonlinear Equations Classics in Applied MathematicsDocument395 pagesNumerical Methods For Unconstrained Optimization and Nonlinear Equations Classics in Applied Mathematicsmohammad_albooyeh100% (9)

- Polyhouse Gerbera CultivationDocument5 pagesPolyhouse Gerbera CultivationArvindVPawar100% (2)

- Project Proposal - Articulation SessionsDocument8 pagesProject Proposal - Articulation SessionsJhay-are PogoyNo ratings yet

- Too Much Time in Social Media and Its Effects On The 2nd Year BSIT Students of USTPDocument48 pagesToo Much Time in Social Media and Its Effects On The 2nd Year BSIT Students of USTPLiam FabelaNo ratings yet

- SPD eRAN7.0 CSPC Feature Introduction-20140228-A-1.0Document25 pagesSPD eRAN7.0 CSPC Feature Introduction-20140228-A-1.0contact2vikasNo ratings yet

- The 9 Best Reasons To Choose ZultysDocument13 pagesThe 9 Best Reasons To Choose ZultysGreg EickeNo ratings yet

- How To Guide To Oauth and API SecurityDocument12 pagesHow To Guide To Oauth and API Securitysilviuleahu100% (1)

- Metabolic SyndromeDocument4 pagesMetabolic SyndromeNurayunie Abd HalimNo ratings yet

- Stps 20 H 100 CTDocument8 pagesStps 20 H 100 CTPablo Cruz ArchundiaNo ratings yet

- Multicomponent Distillation Shortcut MethodDocument5 pagesMulticomponent Distillation Shortcut MethodDiegoAndréVegaDávalosNo ratings yet

- Lab ManualDocument15 pagesLab ManualsamyukthabaswaNo ratings yet

- Advanced Machining User Guide PDFDocument250 pagesAdvanced Machining User Guide PDFDaniel González JuárezNo ratings yet

- Process Plant Layout and Piping DesignDocument4 pagesProcess Plant Layout and Piping Designktsnl100% (1)

- 3-Matic 14 - User Manual 15Document169 pages3-Matic 14 - User Manual 15Oliver RuizNo ratings yet

- Qrqs"1 Xl/Ijj1L Joi?Llt'Lll: Transport Bhawan, 1, Parliament Street New Delhi-110001Document2 pagesQrqs"1 Xl/Ijj1L Joi?Llt'Lll: Transport Bhawan, 1, Parliament Street New Delhi-110001PrakashKommukuriNo ratings yet

- LEBV4830Document371 pagesLEBV4830anton100% (1)

- International Economics 16Th Edition Thomas Pugel Test Bank Full Chapter PDFDocument45 pagesInternational Economics 16Th Edition Thomas Pugel Test Bank Full Chapter PDFRebeccaBartlettqfam100% (11)

- Memorandum of AgreementDocument6 pagesMemorandum of AgreementJomar JaymeNo ratings yet

- Fabric Technologist RoleDocument3 pagesFabric Technologist RoleAnup Kumar DeyNo ratings yet

- Solved Suppose That The Velocity of Circulation of Money Is VDocument1 pageSolved Suppose That The Velocity of Circulation of Money Is VM Bilal SaleemNo ratings yet

- Low Cost CompaniesDocument9 pagesLow Cost CompaniesIvan RodriguezNo ratings yet

- 1 48 Volt Parallel Battery System PSS-SOC - Step-By-Step VolvoDocument11 pages1 48 Volt Parallel Battery System PSS-SOC - Step-By-Step VolvoEyosyas NathanNo ratings yet

- Rectangular Wire Die Springs ISO-10243 Standard: Red Colour Heavy LoadDocument3 pagesRectangular Wire Die Springs ISO-10243 Standard: Red Colour Heavy LoadbashaNo ratings yet

- An Overview of The Geostatistical Analyst Toolbar and ToolboxDocument1 pageAn Overview of The Geostatistical Analyst Toolbar and ToolboxSumit SumanNo ratings yet

- Question: To What Extent Do You Agree or Disagree?Document5 pagesQuestion: To What Extent Do You Agree or Disagree?tien buiNo ratings yet

- Invidis Yearbook 2019Document51 pagesInvidis Yearbook 2019Luis SanchezNo ratings yet

- Tarlac - San Antonio - Business Permit - NewDocument2 pagesTarlac - San Antonio - Business Permit - Newarjhay llave100% (1)

- 1.2 Installation of SSH Keys On Linux-A Step-By Step GuideDocument3 pages1.2 Installation of SSH Keys On Linux-A Step-By Step GuideMada ChouchouNo ratings yet

- Valery 1178Document22 pagesValery 1178valerybikobo588No ratings yet