Professional Documents

Culture Documents

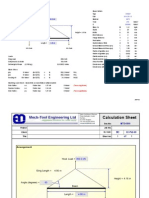

Spreader Beam - Asme

Uploaded by

Aris PurniawanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spreader Beam - Asme

Uploaded by

Aris PurniawanCopyright:

Available Formats

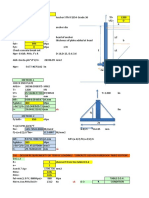

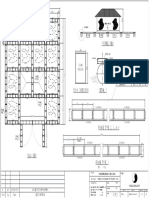

SPREADER BEAM - ASME

W24x94

1

2

3

4

5

6

7

8

9

10

11

12

W [lb]

Nd

65,000

3

Material

SA-36 Material

36,000

29,000,000

Dimensions

180

2,700

12,155

24.31

4.533

0.875

7.9319

1.98

13

14

15

16

L

[in]

I [in^4]

C

[in]

d

[in]

b

[in]

t

[in]

Af [in^2]

ry [in]

17

18

Compact Section :

19

Bending Stress

20

21

22

23

24

25

26

27

28

Fy [psi]

E [psi]

Checked

Fb

[psi] =

M [lb/in] =

S

[psi] =

Check "S" =

Wmax [lb] =

1.1*Fy/Nd

W*L/4

M*c/I

S < Fb

4*Fb*I/(c*L)

Gusset Bracing

Lp1

Lp2

Lp

[in] = 0.67*E/(Fy*d/Af)

[in] = 1.76*ry*sqrt(E/Fy)

[in] = Min(Lp1, Lp2)

SPREADER BEAM - ASME

: Weight of Load (berat beban)

: Design Factor

: Yeild Strenght

: Modulus Elasticity

: Length of Beam

: Moment of inertia

: Distance to Neutral Axis

: Depth of Section

: Width of Compression Flange

: Thickness of compression flange

: Area of Compression Flange

: Minor Axis Radius of Gyration

b/t < 0.38 x sqrt(E/Fy)

( Allowable bending stress )

( Bending moment )

( Actual bending stress )

(Maximum spacing between gussets)

< 10.79

Acceptable

13,200

2,925,000

13,168

Acceptable

65.16

176

99

99

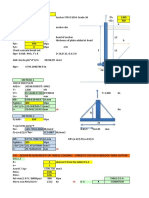

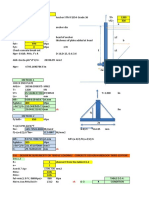

Lug with Pinned Connection

65,000

3

W [lb] : Weight of Load (berat beban)

Nd : Design Factor

Material

SA-36 Material

36,000

Fy [psi] : Yeild Strenght

58,000

Fu [psi] : Tensile Strenght

29,000,000

E [psi] : Modulus Elasticity

Dimensions

3

10

1

5

0.625

Dh

w

t

R

Leg

[in] : Hole Diameter

[in] : Width of Lug

[in] : Tickness of Lug

[in] : Outer Radius

[in] : Weld Leg Height

Tensile Stress

Ft

[psi] =

A [in^2] =

St

[psi] =

Check "St" =

Fy/Nd

t*(w - Dh)

w/A

St < Ft

( Allowable Tensile stress )

( Area in Tension )

( Tensile stress )

Shear Strenght Through Pinhole

Av [in^2] = 2*(R-(Dh/2)*cos(radians(45)))*t (Total Area for 2 Shaear plan )

Pv

[lb] = 0.7*Fu/(1.2*Nd)*Av (Double plane shear strength )

Check "Pv" = W < Pv

Shear Stress ini Weld

Exx [psi] =

Fv [psi] =

Aw [in^2] =

Fw

[lb] =

Check "Fw" =

(Tensile Strenght filler metal )

0.6*Exx/(1.2*Nd)

(Allowable weld shear stress )

(2*w+2*t) * (0.707*Leg (Area of the weld )

Fv*Aw

(Allowable weld load )

W < Fw

Fu

Minimum Weld Throat:

throat_3-3 [in] = IF(R<=0.25,0.125,IF(R<0.5,0.188,(IF(R<0.75,0.25,0.313))))

IF(R<=0.25,0.125,IF(R<0.5,0.188,(IF(R<0.75,0.25,0.313))))

Check "Throat" = Leg*0.707>throat_3-3

ection

12,000

9,286

for 2 Shaear plan )

strength )

er metal )

ar stress )

5,0.25,0.313))))

5,0.313))))

7.879

88,854

58,000

9,667

9.721

93,972

=

=

0.313

You might also like

- Lifting Beam CalculationDocument2 pagesLifting Beam Calculationsalman1566No ratings yet

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- Spreader Bar Plus Free BodyDocument17 pagesSpreader Bar Plus Free BodyMichael HaiseNo ratings yet

- Sparta Spreader Bar CalculatorDocument1 pageSparta Spreader Bar CalculatorNalini MathuraNo ratings yet

- Lug Design R4, ASME BTH-1Document4 pagesLug Design R4, ASME BTH-1chuckhsu1248No ratings yet

- Lift Beam AnalysisDocument2 pagesLift Beam Analysishuangjl100% (2)

- Report SPeaDer BarDocument24 pagesReport SPeaDer BarMochammad Shokeh100% (2)

- Spreader Beam CalcDocument2 pagesSpreader Beam CalcBen100% (3)

- Spreader BarDocument5 pagesSpreader Barmramico100% (1)

- Sample Section Modulas CalculationDocument18 pagesSample Section Modulas CalculationShamik ChowdhuryNo ratings yet

- Lifting Beam Deign Staad 82187560 Design Calc 10T Spreader BeamDocument20 pagesLifting Beam Deign Staad 82187560 Design Calc 10T Spreader BeamJurie_sk360888% (8)

- Design of Pad Eye Using Check PlatesDocument3 pagesDesign of Pad Eye Using Check Plateshyoung65No ratings yet

- ASME SpreaderBar DWGDocument1 pageASME SpreaderBar DWGInspetor SoldagemNo ratings yet

- Spreader Beam BLOCK EDocument23 pagesSpreader Beam BLOCK Evaminos85% (13)

- Single Hook With Rectangle-Spreader Beam or Two Hooks 1aDocument2 pagesSingle Hook With Rectangle-Spreader Beam or Two Hooks 1ad_maziero100% (1)

- Mathcad - Spreader Bar FinalDocument4 pagesMathcad - Spreader Bar FinalOkondu Chiedu100% (3)

- Lifting LugsDocument2 pagesLifting LugsAdi Cahyoko82% (11)

- Lifting Beam CalculationDocument2 pagesLifting Beam Calculationராபர்ட் ஆன்றோ ரெனி100% (4)

- Vitec Equipments PVT LTD Filename: Spreader Beam CalculationDocument48 pagesVitec Equipments PVT LTD Filename: Spreader Beam CalculationDarshan PanchalNo ratings yet

- Lug Design (XLS)Document4 pagesLug Design (XLS)Bhartendu Patni100% (1)

- Spreader Bar3 - L.9 M-CertificationDocument10 pagesSpreader Bar3 - L.9 M-CertificationsiagiandobahNo ratings yet

- Spreader Beam DesignDocument3 pagesSpreader Beam DesignCHENo ratings yet

- Horizontal Lifting LugDocument1 pageHorizontal Lifting LugTushar MangratiNo ratings yet

- Spreader BeamDocument2 pagesSpreader Beamwisnu_bayusakti75% (4)

- Padeye Calculation For Anchor Block R0 20140722Document3 pagesPadeye Calculation For Anchor Block R0 20140722subucwiNo ratings yet

- 03 - Lifting Lug - 2nd Stage Separator (New)Document5 pages03 - Lifting Lug - 2nd Stage Separator (New)Alessio BarboneNo ratings yet

- Most Applications, F.S. 5.0) : Calculation ReferenceDocument5 pagesMost Applications, F.S. 5.0) : Calculation ReferenceParthibanNo ratings yet

- Lifting LugDocument4 pagesLifting Lugsjkang0226100% (4)

- CEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveDocument5 pagesCEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveLaurentiu TeacaNo ratings yet

- Spreader Bar CalculationDocument1 pageSpreader Bar Calculationjirrsama100% (1)

- Lifting LugDocument2 pagesLifting LugKeyurNo ratings yet

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- 17 TonsDocument8 pages17 Tonsabuzahrau100% (3)

- Lifting Lug SampleDocument1 pageLifting Lug Sampleabdul marpaung0% (1)

- Report of Lifting Beam DesignDocument5 pagesReport of Lifting Beam Designnarutothunderjet216100% (1)

- Spreader Beam CalculationDocument2 pagesSpreader Beam Calculationhombre.muerto595977% (13)

- Flange Analysis - Traditional Method 14sep10Document1 pageFlange Analysis - Traditional Method 14sep10Lava SatNo ratings yet

- Skirt Support Analysis Per en 13445Document13 pagesSkirt Support Analysis Per en 13445karthik1amarNo ratings yet

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- Flat Plate - Roark & YoungDocument15 pagesFlat Plate - Roark & YoungPrasad Pingle0% (1)

- Steel StairDocument4 pagesSteel StairNikki RobertsNo ratings yet

- CONNECTIONDESIGNMANUALDocument34 pagesCONNECTIONDESIGNMANUALanon_97209652No ratings yet

- Connection Design ManualDocument34 pagesConnection Design ManualAlaa AssiNo ratings yet

- Pveng: Pressure Vessel Engineering LTDDocument5 pagesPveng: Pressure Vessel Engineering LTDBruno TrujilloNo ratings yet

- ASME Horizontal Vessel AnalysisDocument10 pagesASME Horizontal Vessel AnalysisSyedZainAliNo ratings yet

- Verifica Giunto Secondo AsmeDocument5 pagesVerifica Giunto Secondo AsmeFabio TemporiniNo ratings yet

- Edificios SMRF ACIDocument5 pagesEdificios SMRF ACIJorge AlbertoNo ratings yet

- 8BJXX7CICWDocument6 pages8BJXX7CICWAnonymous nfHBPXz178No ratings yet

- Foundation (Spread Footing) : 11215 1 UD F5 Inftr 1 SlabDocument24 pagesFoundation (Spread Footing) : 11215 1 UD F5 Inftr 1 SlabDhimas Surya NegaraNo ratings yet

- Bab I Perhitungan Panjang Batang: B B B B B B B B B S/D B 1,5 MDocument24 pagesBab I Perhitungan Panjang Batang: B B B B B B B B B S/D B 1,5 MUnyil Cuwiie MarunyilNo ratings yet

- Davit CalcDocument6 pagesDavit Calcrustamriyadi100% (1)

- 17 Asmeviii A-2 Reverse Integral FlangeDocument1 page17 Asmeviii A-2 Reverse Integral FlangepastylNo ratings yet

- 4-Strenthen by Steel JacketingDocument3 pages4-Strenthen by Steel JacketingBashdar AzadNo ratings yet

- Beam Design MylesDocument1,278 pagesBeam Design MylesRyanRuceMelvilleNo ratings yet

- Suppl Reinf 2018 11Document9 pagesSuppl Reinf 2018 11mehrdad khoeiNo ratings yet

- Ebf CBCDocument6 pagesEbf CBCNikki RobertsNo ratings yet

- SUPPL REINF Ver40Document9 pagesSUPPL REINF Ver40mehrdad khoeiNo ratings yet

- UntitledDocument8 pagesUntitledmehrdad khoeiNo ratings yet

- Baseplate Biaxial MZDocument26 pagesBaseplate Biaxial MZD SRINIVAS100% (1)

- R3642-Shwe Spool Numbering (New Format) - R3Document1 pageR3642-Shwe Spool Numbering (New Format) - R3Aris PurniawanNo ratings yet

- E12 Serial No. SMOE Contract NoDocument5 pagesE12 Serial No. SMOE Contract NoAris PurniawanNo ratings yet

- PDMS CommandDocument51 pagesPDMS CommandAris PurniawanNo ratings yet

- R3642-Shwe Spool Numbering (New Format) - R3Document1 pageR3642-Shwe Spool Numbering (New Format) - R3Aris PurniawanNo ratings yet

- R3642-Shwe Spool Numbering (New Format) - R3Document1 pageR3642-Shwe Spool Numbering (New Format) - R3Aris PurniawanNo ratings yet

- Asce 2 V 5001 K1ab VT BM1 U - 001 15030212 - 00Document1 pageAsce 2 V 5001 K1ab VT BM1 U - 001 15030212 - 00Aris PurniawanNo ratings yet

- Piping and Instrument DiagramsDocument34 pagesPiping and Instrument DiagramsSomayeh SarabadanNo ratings yet

- Floating Dock M.burhan REV.01 PDFDocument2 pagesFloating Dock M.burhan REV.01 PDFAris PurniawanNo ratings yet

- Profile: Basic SkillsDocument2 pagesProfile: Basic SkillsAris PurniawanNo ratings yet

- Site Office - TRUSS DETAIL PDFDocument1 pageSite Office - TRUSS DETAIL PDFAris PurniawanNo ratings yet

- Rubbish Bin PDFDocument1 pageRubbish Bin PDFAris PurniawanNo ratings yet

- VC Gas Pig LauncherDocument1 pageVC Gas Pig LauncherAris PurniawanNo ratings yet

- Yard Fabrication PlanDocument1 pageYard Fabrication PlanAris PurniawanNo ratings yet

- Office - PLAN VIEW PDFDocument1 pageOffice - PLAN VIEW PDFAris PurniawanNo ratings yet

- ProNest Programming Guide PDFDocument48 pagesProNest Programming Guide PDFBurhan ÇamNo ratings yet

- PID SymbolsDocument18 pagesPID SymbolsAnonymous f9EEXptHCNo ratings yet

- Smartplant Spoolgen: Automatic Isometrics For Fabrication & Erection Kim, Kyung Deck - Intergraph KoreaDocument31 pagesSmartplant Spoolgen: Automatic Isometrics For Fabrication & Erection Kim, Kyung Deck - Intergraph KoreaAris PurniawanNo ratings yet

- Welding PositionDocument6 pagesWelding Positionenels77No ratings yet

- Curriculum VitaeDocument1 pageCurriculum VitaeAris PurniawanNo ratings yet

- Sp3d Piping TutorialDocument24 pagesSp3d Piping TutorialirfanNo ratings yet

- Pipe (Parametric Fittings) : Pronest 2015 Optional ModuleDocument1 pagePipe (Parametric Fittings) : Pronest 2015 Optional ModuleAris PurniawanNo ratings yet

- 3D AssumptionDocument1 page3D AssumptionAris PurniawanNo ratings yet

- Lines PlanDocument2 pagesLines PlanAris PurniawanNo ratings yet

- Profile: Basic SkillsDocument2 pagesProfile: Basic SkillsAris PurniawanNo ratings yet

- Symbol of Weld PDFDocument28 pagesSymbol of Weld PDFSyarif IrwantoNo ratings yet

- IKL Project BslineDocument2 pagesIKL Project BslineAris PurniawanNo ratings yet

- TBBM 09 2 MEC DWG 001 A4 Rev 0 - General Arrangement Drawing Loading SkidDocument9 pagesTBBM 09 2 MEC DWG 001 A4 Rev 0 - General Arrangement Drawing Loading SkidAris PurniawanNo ratings yet

- CS Piping 2Document41 pagesCS Piping 2Aris PurniawanNo ratings yet

- Generic Plan Ems I2Document1 pageGeneric Plan Ems I2Dipak VaghelaNo ratings yet

- MS Project Tutorial PDFDocument36 pagesMS Project Tutorial PDFBilal Ahmed Barbhuiya100% (3)