Professional Documents

Culture Documents

An2178 01

Uploaded by

slyryeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An2178 01

Uploaded by

slyryeCopyright:

Available Formats

Application Note AN2178

Yet Another PSoC-Based Oscilloscope

Powered by Design4Fun

Author: Andrea Giacosi

Associated Project: Yes

Associated Part Family: CY8C26443 and CY8C27443

PSoC Designer Version: 4.1

Associated Application Notes:

Abstract

This Application Note describes how to realize a “just for fun” oscilloscope with a PSoC™ and some

additional components. The project has two parts: the PSoC hardware and firmware and a Microsoft.Net

front-end application. The oscilloscope hardware is connected to the host PC through an RS232 interface to

exchange data and commands. The RS232 communication protocol is specified in a separate document to

let readers who want to design their own hardware/firmware or their own front-end application to do so.

Introduction The firmware reads samples from the ADC and

Figure 1 shows a block diagram of the system sends data to the host PC through the UART. A

structure. A resistor network is used to feed the MAX232 driver is used to translate from TTL to

PSoC with a differential signal in the desired RS232.

range. The differential signal is driven to an

instrumental amplifier, which amplifies the input The firmware also implements some of the

signal according to the value specified by the commands described in:

oscilloscope firmware. The amplifier is built using

two PSoC analog continuous time (CT) blocks “OscilloscopeCommunicationDescription.pdf.”

(AMP_CH1 NON_INV, INV).

Note that this document covers the reserved time

The low part of the resistor network is connected base commands for further extensions using the

to the output of two 6-bit voltage output digital-to- faster ADC.

analog converters (ADC), built using two analog

switched capacitor (SC) blocks (VOFF_INV,

VOFF_NINV). The two voltages are selected by

the firmware to shift the input voltages of the

instrumental amplifier into the desired range.

With a 1:10 resistor ratio and a usable input

range less than 4V (when the power supply is 5V

DC), the maximum differential input signal is +/-

25V. The common mode that can be

“compensated” by the offset generator has the

same magnitude.

10/8/2004 Revision A -1-

AN2178

differential

output

Divide 12 bit

0

by 10 0 0 Amplifier incremental

Differential ADC

input 0 0

Instrumental

Amplifier

Oscilloscope RS-232 to

FW UART driver Host

Offset [PSOC CPU] PC

Offset Generator

Adjust

0 0

signals

0 0

0

PSOC

Figure 1. System Block Diagram

PSoC Project In this project the 12-bit incremental ADC is used

The implementation of the PSoC blocks and the sample frequency was set to 180 sps.

described is straightforward. Standard library Users can employ a faster ADC, for example, the

blocks are used. A 5V power supply voltage is 8-bit sigma-delta ADC, if a higher sample rate is

selected. The CPU frequency is set to 12 MHz. required. The UART speed can be increased to

24V1 and 24V2 divisors are 8 and 10, 115200 bps without any problems.

respectively, to achieve 3 MHz and 300 kHz

frequencies. A UART is configured as 38400 bps Placement of the different blocks is shown in

8N1. Figure 2.

Figure 2. PSoC Block Placement

Pin names, sources and types are shown in Figure 3.

10/8/2004 Revision A -2-

AN2178

A B

Figure 3. Pin Names and Sources (A) and Types (B)

Circuit Realization Figure 5 shows the breadboard with the basic

A schematic for the project is shown in the functional blocks highlighted.

Appendix.

Figure 4 shows the breadboard built to support

the code-debugging phase. The PSoC ICE-4000

debugger is used instead of the final chip in order

to speed-up code debugging. The ICE is also

used to power the system, which eliminates the

power section from the breadboard.

Figure 5. Breadboard Functional Blocks

Figure 4. Breadboard

10/8/2004 Revision A -3-

AN2178

Figure 6 shows a board working with a 6V DC Client Application

supply voltage. A simple .Net Windows application, developed

using C+, is included with this Application Note.

To access RS232, the application uses a

VB.NET class written by Corrado Cavalli and

freely available for download on the Internet.

The ScopeEngine class implements the

IScopeEngine interface used by the main class,

Scope, to retrieve data to be viewed and to send

commands to the PSoC board. Commands for

the Scope class are shown in Figure 7.

«interface»

IScopeEngine «interface»

IScopePlot

+setTimeBase(in timeBase : int) : bool

+setVoltageGain(in ch : int, in gain : int) : bool +scanModeAddPoint(in newVal : int)

+setScanOrBurstMode(in mode : bool) : bool +replaceModeSetPoints(in newValues : int[])

+setVoltageOffset(in ch : int, in offset : int) : bool +setLinkStatus(in status : int)

+shutdown()

ScopeEngine

-serial : Rs232

-reader : Thread

-plotter : IScopePlot

Scope

-bReaderRun : bool

-samples : int[] +scanModeAddPoint(in newVal : int)

-samplesPointer : int +replaceModeSetPoints(in newValues : int[])

-bTriggerEdgeRising : bool +setLinkStatus(in status : int)

-bTriggerSingleAuto : bool +Scope()

-bContinuousScan : bool -redraw(in sender : object, in e : PaintEventArgs)

-READ_TIMEOUT_MS : int #Dispose(in disposing : bool)

-SAMPLE_BURST_SIZE : int -InitializeComponent()

-Main()

+setTimeBase()

-Scope_Load(in sender : object, in e : EventArgs)

+setVoltageGain()

-timeBaseTB_Scroll(in sender : object, in e : EventArgs)

+setScanOrBurstMode()

-voltageGainCH1_Scroll(in sender : object, in e : EventArgs)

+setVoltageOffset()

-holtRunBt_Click(in sender : object, in e : EventArgs)

+shutdown()

-scanTriggerMode_CheckedChanged(in sender : object, in e : EventArgs)

+ScopeEngine()

-voltageOffsetCH1_Scroll(in sender : object, in e : EventArgs)

-makeTriggerModeOptions()

-ch1OffsetIncr_Click(in sender : object, in e : EventArgs)

-OnDataReceived()

Figure 6. 6V-Powered Example Board -dataReaderLoop()

-ch1OffsetDecr_Click(in sender : object, in e : EventArgs)

-sendCmd()

Firmware Overview Figure 7. Scope and ScopeEngine commands.

The firmware architecture is very simple. After all

Figure 8 shows a screenshot of the front-end

the devices are initialized, the system enters in

application.

the main loop where commands are received

from the UART and processed as soon as they

are received.

Global variables are used to keep the

configuration persistent for the oscilloscope

required by the host system.

When a continuous sample mode is selected, as

soon as a new sample is available, it is sent to

the host through the UART. If the trigger is ON,

data is transmitted en mass to the host only after

128 data bits have been sampled. Data are

saved in the sample’s array.

All commands are a single byte and are decoded

Figure 8. Front-End Application

by a simple switch. Offset and gain commands

directly change the gain of the instrumental

amplifier and the output of the DAC. Future Improvements

o The second channel will be

The trigger mode, selected by the host system, is implemented.

saved in a bit-field variable, which is checked o All the missing commands will be

with each loop of the main loop where the added to the firmware, especially the

sampling is performed. basic trigger functionalities.

o A voltmeter form will be created.

o A “calibration” XML file will be added to

the client side to calibrate the actual

speed and gain of the channel.

10/8/2004 Revision A -4-

AN2178

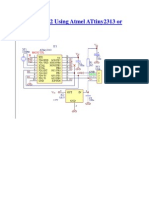

Appendix

VCC

VCC

20 28 1 16

P2[0] VCC C1+ VCC

8 C5 3

P2[1] 1u

C1-

21 27 4

CH1+ P2[2] P0[6] C2+ C2

7 5 2 1u

P2[3] C2- V+

R2 22 15 6

CH1- P2[4] P1[7] C4 V-

9M 1u

6 13

P2[5] P1[6]

23 16 11 14

P2[6] P1[5] T1IN T1OUT C3 C1

5 12 10 7 1u 1u

P2[7] P1[4] T2IN T2OUT

R1 R3 17 12 13

9M 1M

P1[3] R1OUT R1IN Tx

24 11 9 8

P0[0] P1[2] R2OUT R1IN Rx

4 18

P0[1] P1[1] GND

2 10 VCC 15

P0[5] P1[0] GND

R4 3

1M

P0[3]

25 19 R5 MAX232

P0[2] XRES

26 1k

P0[4]

19

XRES

9

SMP

R6

14 1k

VSS

CY8C27443

Figure 9. Device Schematic

About the Author

Name: Andrea Giacosi

Title: Electronic Engineer

Background: Real-Time Software

Contact: giacosi@libero.it

Cypress MicroSystems, Inc.

nd

2700 162 Street SW, Building D

Lynnwood, WA 98037

Phone: 800.669.0557

Fax: 425.787.4641

http://www.cypress.com/ / http://www.cypress.com/support/mysupport.cfm

Copyright © 2004 Cypress MicroSystems, Inc. All rights reserved.

PSoC™, Programmable System-on-Chip™, and PSoC Designer™ are trademarks of Cypress MicroSystems, Inc.

All other trademarks or registered trademarks referenced herein are the property of their respective owners.

The information contained herein is subject to change without notice. Made in the U.S.A.

10/8/2004 Revision A -5-

You might also like

- PIC Introduction PDFDocument46 pagesPIC Introduction PDFPeeyush Kp100% (1)

- Aoc 2436saDocument45 pagesAoc 2436saatomo33100% (1)

- DS3231 Extremely Accurate I C-Integrated RTC/TCXO/Crystal: General Description Benefits and FeaturesDocument20 pagesDS3231 Extremely Accurate I C-Integrated RTC/TCXO/Crystal: General Description Benefits and Featuresalfian100% (1)

- Make The Smartpic Serial Programmer: Feature ArticleDocument5 pagesMake The Smartpic Serial Programmer: Feature Articlersanchez-100% (1)

- Introduction I2c and SPIDocument14 pagesIntroduction I2c and SPIHaris Jeelani100% (1)

- SPI Master Core Specification: Author: Simon SrotDocument14 pagesSPI Master Core Specification: Author: Simon SrotManoj Kumar100% (1)

- Embeddded Pic 18f Starter KitDocument3 pagesEmbeddded Pic 18f Starter KitEmblitz Rajajinagar100% (1)

- AVR Hardware Design ConsiderationsDocument14 pagesAVR Hardware Design ConsiderationsAmarnath M Damodaran100% (1)

- USB to RS232 Converter Using Atmel MicrocontrollersDocument4 pagesUSB to RS232 Converter Using Atmel Microcontrollersmikcomi100% (1)

- Nec Ir For PicDocument14 pagesNec Ir For Picsudhakar5472100% (1)

- Moving Up To ARMDocument128 pagesMoving Up To ARMlilianfis100% (1)

- HBridgeMotorControl With PICDocument11 pagesHBridgeMotorControl With PICcoceicr100% (3)

- Hobby Servo Motor Control Via PIC Pulse Width Modulation: Nathan Markey April 4, 2003Document7 pagesHobby Servo Motor Control Via PIC Pulse Width Modulation: Nathan Markey April 4, 2003Luciana Gutierrez Salazar100% (1)

- Interfacing an HD44780 LCD to a C8051F120 MicrocontrollerDocument23 pagesInterfacing an HD44780 LCD to a C8051F120 Microcontrollerahimpli100% (2)

- I2C-Master Core SpecificationDocument17 pagesI2C-Master Core Specificationvarunmr100% (1)

- CCP ModuleDocument11 pagesCCP ModuleAltaaf Mulani100% (1)

- Open Core SpiDocument13 pagesOpen Core SpiBhanu Pratap Singh100% (1)

- USB Chip - Choices Jul2000Document5 pagesUSB Chip - Choices Jul2000Jameskrazy100% (1)

- JHD12864Document15 pagesJHD12864dravife100% (1)

- PT2314Document4 pagesPT2314Yamir Sandoval100% (1)

- Pic Usb - v2Document23 pagesPic Usb - v2Andres Echeverry100% (1)

- Avr Isp Usb AioDocument1 pageAvr Isp Usb Aiospy004100% (1)

- Jeu D'instructions Des Microcontrôleurs PICDocument17 pagesJeu D'instructions Des Microcontrôleurs PICzabderrezzak100% (1)

- Instructions Assembler DirectivespptDocument22 pagesInstructions Assembler DirectivespptAntra Gurain100% (1)

- Bascom and AVR, RS-232Document10 pagesBascom and AVR, RS-232akbar100% (1)

- Invertor LCD OZ9601SDocument1 pageInvertor LCD OZ9601SRenatoMaia100% (1)

- Section 7.2 - I2CNewMarch27Document32 pagesSection 7.2 - I2CNewMarch27Andy Wo100% (1)

- Self Balancing Robot Circuit DiagramDocument1 pageSelf Balancing Robot Circuit DiagramCalin Popescu100% (1)

- CD4063 CD4040 CD4001 CD4069 CD40110 circuit : 8-BIT BINARY-TO-DECIMAL CONVERTERDocument1 pageCD4063 CD4040 CD4001 CD4069 CD40110 circuit : 8-BIT BINARY-TO-DECIMAL CONVERTERDrNikhil Agrawal100% (1)

- LCD HandshakingDocument19 pagesLCD HandshakingNvskinId100% (1)

- 001-57294 AN57294 USB 101 An Introduction To Universal Serial Bus 2.0Document57 pages001-57294 AN57294 USB 101 An Introduction To Universal Serial Bus 2.0Arturo Picolin100% (1)

- Nex-Robotics 20x4 Serial LCD ModuleDocument9 pagesNex-Robotics 20x4 Serial LCD ModuleAshok Kumar100% (1)

- USB in A NutShellDocument35 pagesUSB in A NutShellSandro Jairzinho Carrascal Ayora100% (1)

- LCD162C# DatenblattDocument8 pagesLCD162C# Datenblattgeorgschmied100% (1)

- Datasheet lcd03 20x4 B PDFDocument8 pagesDatasheet lcd03 20x4 B PDFFrancis100% (1)

- NodeMCU ESP32 Development Board GuideDocument6 pagesNodeMCU ESP32 Development Board GuideFernando Piedade100% (1)

- By Marl Us: Lighting The Right To TheDocument7 pagesBy Marl Us: Lighting The Right To TheGiancarloRichardRivadeneyraMiranda100% (1)

- High Voltage Power Operational Amplifiers: Features DescriptionDocument6 pagesHigh Voltage Power Operational Amplifiers: Features DescriptionWaqas Ayub100% (1)

- History of The I2C BusDocument24 pagesHistory of The I2C BusManoj Kavedia100% (1)

- PIC PPT 13104022 (4th Year)Document41 pagesPIC PPT 13104022 (4th Year)Daman Deep Singh100% (1)

- Maxuino - Starter GuideDocument5 pagesMaxuino - Starter GuideArvind Singh100% (1)

- Agribot Project PresentationDocument21 pagesAgribot Project Presentationumaiya1990100% (1)

- User'S Manual: PIC-P26J50 Proto Development BoardDocument19 pagesUser'S Manual: PIC-P26J50 Proto Development Boardgiapy0000100% (1)

- Modbus Protocol UGDocument33 pagesModbus Protocol UGMuhammad Sa'ad100% (1)

- I2C Protocol in Fpga Using VHDL: Main Project Interim Report As A Partial Fullment of The CurriculumDocument18 pagesI2C Protocol in Fpga Using VHDL: Main Project Interim Report As A Partial Fullment of The CurriculumShuvra Saha100% (1)

- LCD - GDM1602BDocument10 pagesLCD - GDM1602BElanio Julio100% (1)

- RS485 5 Click Schematic v103Document1 pageRS485 5 Click Schematic v103Lauro Da Silva100% (1)

- Electronic Meters: Topic 4Document12 pagesElectronic Meters: Topic 4ltfadhil100% (1)

- An-960 RS 485 Incl Termination DetailsDocument12 pagesAn-960 RS 485 Incl Termination Detailsqafqgibsonq4543100% (1)

- Book PIC Microcontrollers-Chapter 5 CCP ModulesDocument17 pagesBook PIC Microcontrollers-Chapter 5 CCP ModulesHammamiSalah100% (1)

- U 0712076Document3 pagesU 0712076peter100% (1)

- Lpi Nano DockDocument2 pagesLpi Nano Dockmundomusicalmeria100% (1)

- LCD 8051 Ver1Document6 pagesLCD 8051 Ver1Nur Razanah Mohd Yasin100% (1)

- Lab 1 - MNM CompDocument4 pagesLab 1 - MNM CompAroosa BibiNo ratings yet

- Chapter 2 - DC Bias Point - 2018 - Analog Design and Simulation Using OrCAD Cap PDFDocument18 pagesChapter 2 - DC Bias Point - 2018 - Analog Design and Simulation Using OrCAD Cap PDFLuis Felipe Blanco CatalánNo ratings yet

- Analog To Digital Converter With Two-Digit Seven Segment DisplayDocument26 pagesAnalog To Digital Converter With Two-Digit Seven Segment DisplayChristian Mauricio Aldás SolísNo ratings yet

- Walter Dso ProjectDocument59 pagesWalter Dso Projectzte00000No ratings yet

- Design of 12-Bit DAC Using CMOS TechnologyDocument5 pagesDesign of 12-Bit DAC Using CMOS TechnologysanthoshNo ratings yet

- Lab2 MotorControl 08Document18 pagesLab2 MotorControl 08ĐạiDương100% (1)

- Exploring BeagleBone: Tools and Techniques for Building with Embedded LinuxFrom EverandExploring BeagleBone: Tools and Techniques for Building with Embedded LinuxRating: 4 out of 5 stars4/5 (2)

- Karbon MobilesDocument7 pagesKarbon Mobilessac_444kumarNo ratings yet

- Unit One - Supervise The Identification of Types of Information and Commonly Created Office RecordsDocument44 pagesUnit One - Supervise The Identification of Types of Information and Commonly Created Office RecordsArefayne EsheteNo ratings yet

- Alia ARC900 Paperless RecordersDocument4 pagesAlia ARC900 Paperless RecordersRexCrazyMindNo ratings yet

- The Complete Digital Workflow in Interdisciplinary Dentistry.Document17 pagesThe Complete Digital Workflow in Interdisciplinary Dentistry.floressam2000No ratings yet

- Dashboard Design LayoutDocument6 pagesDashboard Design Layoutluis anchayhua pradoNo ratings yet

- Get FileDocument548 pagesGet FileNiraj BhaktwartiNo ratings yet

- Ergonomics in Game Controllers and ConsolesDocument5 pagesErgonomics in Game Controllers and ConsolesAlex GregorieNo ratings yet

- Audiocodes Mediant Sbcs For Service ProvidersDocument9 pagesAudiocodes Mediant Sbcs For Service ProvidersrAVINo ratings yet

- Lecture 5 Principles of Parallel Algorithm DesignDocument30 pagesLecture 5 Principles of Parallel Algorithm Designnimranoor137No ratings yet

- ICT - Minimum Learning Competencies - Grade 9 and 10Document8 pagesICT - Minimum Learning Competencies - Grade 9 and 10kassahunNo ratings yet

- BC10 WebDocument576 pagesBC10 Webjiezhao080406No ratings yet

- SunSystems 5 Admin and User InterfaceDocument263 pagesSunSystems 5 Admin and User Interfaceskakach100% (1)

- 1.2 Cmri 1010Document2 pages1.2 Cmri 1010biglingambigNo ratings yet

- Cardinal Scale 205 Weight Indicator Installation and Technical ManualDocument58 pagesCardinal Scale 205 Weight Indicator Installation and Technical ManualKennyGabrielNo ratings yet

- PFB2N60/PFF2N60 DatasheetDocument7 pagesPFB2N60/PFF2N60 DatasheetCostel CojocaruNo ratings yet

- PF Lecture 4Document63 pagesPF Lecture 4yaseen ejazNo ratings yet

- Peak SolutionsDocument9 pagesPeak SolutionsAdeel AhmadNo ratings yet

- S120 Drive FCT Man 0718 en-USDocument1,074 pagesS120 Drive FCT Man 0718 en-USdinhvanquyenNo ratings yet

- CJV150 - CJV300 - CJV330 - Cutting Adjustment Guide D501067 Ver.2.0Document16 pagesCJV150 - CJV300 - CJV330 - Cutting Adjustment Guide D501067 Ver.2.0BrandonNo ratings yet

- SynopsisDocument12 pagesSynopsisTony HobbsNo ratings yet

- Analyzing The Effects of Social Media On The Hospitality IndustryDocument21 pagesAnalyzing The Effects of Social Media On The Hospitality IndustryHa Le HiepNo ratings yet

- CATALOG - Anti-Vandalism (En)Document16 pagesCATALOG - Anti-Vandalism (En)deceneu2005No ratings yet

- Checklist Mobile App Testing 0Document11 pagesChecklist Mobile App Testing 0Sana Khan100% (1)

- Low Coolant Level S85 TechnicalfileDocument2 pagesLow Coolant Level S85 TechnicalfileMd ShNo ratings yet

- A Review On Optimization of Bus Driver Scheduling-IJAERDV04I0373755Document5 pagesA Review On Optimization of Bus Driver Scheduling-IJAERDV04I0373755Editor IJAERDNo ratings yet

- Comptia Security Sy0 701 Exam Objectives (5 0)Document21 pagesComptia Security Sy0 701 Exam Objectives (5 0)Erick Camilo50% (4)

- Brocade ISL TrunkingDocument26 pagesBrocade ISL TrunkingMilton RaimundoNo ratings yet

- US23-0920-02 UniSlide Install Manual Rev D (12!16!2010)Document72 pagesUS23-0920-02 UniSlide Install Manual Rev D (12!16!2010)sq9memNo ratings yet

- The Translation of PunsDocument42 pagesThe Translation of Punsliani ghustivaNo ratings yet

- 22 Alex - Balashov Kamailio TriviaDocument24 pages22 Alex - Balashov Kamailio TriviaerminNo ratings yet