Professional Documents

Culture Documents

Paper A 3

Uploaded by

thanatitosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paper A 3

Uploaded by

thanatitosCopyright:

Available Formats

Proceedings of the 16th International Symposium on High Voltage Engineering

c 2009 SAIEE, Innes House, Johannesburg

Copyright

ISBN 978-0-620-44584-9

INVESTIGATION OF THE EFFECTS OF A LIGHTNING IMPULSE

WAVEFORM EXCEEDING 600 KV ON THE DIELECTRIC STRENGTH

OF SF6GAS AND INSULATION OIL

Hiroshi Koyama1, Toshihiro Hoshino1, Masahiro Hanai 1

Shigemitsu Okabe2, Toshihiro Tsuboi2, Jun Takami2

1

Toshiba Corporation, Japan

2

Tokyo Electric Power Company, Japan

*Email: hiroshi.koyama@toshiba.co.jp

Abstract: The waveform of the lightning impulse voltage of transmission and distribution

apparatus has been prescribed as the standard lightning impulse that has a front time [1.2 s

30] and a time to half-value [50 s20] [1]. In recent years, however, it has become difficult

to apply such a standard waveform due to the increased use of higher capacitance equipment.

Although confined to within the allowable range in accordance with currently applicable standards,

tests are performed for waveforms that have a large overshoot in some cases. According to

existing standards, a problem has been noted that evaluations of voltage values vary significantly

in a discontinuous depending on whether the frequency of a vibrational component near the peak

value of the waveform is higher or lower than 0.5 MHz. Many examinations are currently in

progress on how to evaluate oscillatory waveforms of lightning impulse voltage [2][3][4]. We

investigated the extent to which dielectric breakdowns differ for SF6 gas gap and oil gap using

electrodes that have a large area and cubic volume depending on differences in the waveform of

negative-polarity impulse voltage. The test results reveal that the difference in lightning impulse

voltage has an impact, to a certain degree, on dielectric breakdown depending on differences in

front time and overshoot rate.

1.

conductor was laid out around a columnar, central

conductor, in a pressure vessel. The central conductor

and the grounded conductor were made of aluminum.

The diameter of the central conductor of the test

electrode for applying the voltage was 120 mm, and the

grounded, cylindrical conductor was 270 mm in inner

diameter and 1000 mm in length. Consequently, the

area of this high-voltage conductor, on which the

electric field is effectively applied, was approximately

3770 cm2. This test electrode is classified as a largescale electrode. The gas pressure for the test was set to

0.45 MPa.

INTRODUCTION

In recent years, increasing numbers of transmission and

distribution apparatus with rated voltages exceeding

1000 kV have been developed, resulting in higher

capacitance equipment. As a result, it has become

difficult to apply the prescribed waveform by

employing an impulse voltage generator owned by

transmission and distribution apparatus manufacturers.

Consequently, we must cope with this methodological

issue either using oscillatory waves by adjusting rise

time or using non-oscillatory waves by delaying rise

time.

1000

As the test voltage was originally intended to guarantee

the insulation performance of transmission and

distribution apparatus, the lightning impulse voltage,

which is deemed to be an equivalent test voltage, must

have the same dielectric breakdown characteristics.

Similar examinations in the past were performed for

transmission and distribution apparatus with a rated

voltage range of only 200 kV or less. [2][3][4] Here,

we report on the extent of differences found in the

dielectric breakdown voltage regarding SF6 gas and oil

in the voltage range above 600 kV, depending on

differences in the waveform of lightning impulse

voltage.

2.

120

270

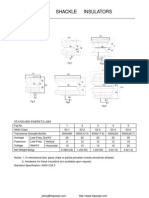

Figure 1: Structure of coaxial cylindrical electrode

used for tests in SF6 gas.

For the oil gap tests, as shown in Figure 2, the

aluminum electrode, whose surface was prepared to be

smooth, was used in the composition of flat-plate

versus flat-plate. The curvature radius of R75 was

adopted to prevent dielectric breakdown at this curved

portion of the electrode end. As the gap length was 40

mm between the two flat-plates and the diameter of the

flat-plate electrodes was 1000 mm, the cubic volume of

the test electrode, on which 90% of the maximum

electric field is applied, was calculated to be 3.1104

cm3. As a result, the cubic volume of the model

EXPERIMENTAL SETUP

For SF6 gas gap tests, the electrode had a coaxial

cylindrical structure, which is almost the same as that

of an actual gas insulated switchgear (GIS). As shown

in Figure 1, tests were performed after having installed

a coaxial electrode, on which a grounded, cylindrical

Pg. 1

Paper A-3

Proceedings of the 16th International Symposium on High Voltage Engineering

c 2009 SAIEE, Innes House, Johannesburg

Copyright

ISBN 978-0-620-44584-9

electrode was almost equal to one-fourth of the cubic

volume of a 500 kV actual transformer, on which 90%

of the maximum electric field is applied at a point on

the main insulation among winding wires.

of 0%, reflecting restrictions of the testing apparatus.

The waveforms with an overshoot were made to agree

with almost a 50% area of the wave tail portion of the

standard waveform.

For the SF6 gas gap tests, a negative-polarity lightning

impulse with a low breakdown voltage under quaisuniform electric field gap was used. We pursued the

breakdown characteristics with the voltage up-anddown method for a total of 20 breakdowns. The voltage

step was set to approximately 5% of the applied

voltage. In view of the possibility of being affected by

ions floating in the gas, a five-minute time interval was

kept between applying voltages. The tests were

performed after replacing the original gas with a new

SF6 gas under each experimental condition.

1000

40

For the oil gap tests, every test was started after the

testing apparatus was left for more than 24 hours next

to the electrode setting, making a vacuum and oil

filling. The applied voltage was a negative-polarity

lightning impulse voltage, which had the same negative

polarity as in the case of the gas gap. The voltage step

was set to approximately 5% of the applied voltage. A

pump was installed in the oil tank so that particle could

be homogenized in the insulation oil by circulating the

insulation oil between the electrodes once a dielectric

breakdown occurred. Tests under the five conditions

above were performed continuously for several days

without replacing the oil.

Figure 2: Structures of flat-plate electrodes used for

tests in oil.

Figure 3 shows the appearance of the testing apparatus

on which respective electrodes are installed. The SF6

gas gap tests were performed on testing apparatus

equipped with a composite bushing, which is located at

the center of the figure. The oil gap tests were

performed using testing apparatus equipped with an oil

bushing that has a large high-voltage shield at the left

in the figure. The lightning impulse voltage was

produced and applied by the impulse voltage generator

at 6 MV in rated voltage, and the applied voltage was

measured by a voltage divider.

3.

Impulse voltage generator

Voltage divider

RESULTS OF EXPERIMENT

In this paper, the overshoot rate () is defined by the

equation (1) below, as a waveform shown in Figure 4.

U

Ue

Recorded curve

Ump

Base curve

Oil gap testing vessel

Residual curve

0

SF6 gas gap testing bus

Figure 4: Recorded and base curve showing overshoot

and residual curve.

(Ue-Ump)

=

(1).

Ue

Figure 3: Appearance of testing apparatus.

2.1.

Test procedure and test conditions

3.1.

Waveforms of applied lightning impulse voltage were

tested under five conditions for the two test types. The

SF6 gas gap tests were performed for one basic case

with a front time of 1.2 s and an overshoot rate of 0%,

two cases with a front time of 1.2 s and varied

overshoot rates of 10% and 20%, and two cases with a

varied front time of 2.4 s and 4.8 s and an overshoot

rate of 0%. The oil gap tests were performed for three

cases with a front time of 1.4 s and a varied overshoot

rates of 2%, 10%, and 20% and two cases with varied

front times of 2.4 s and 4.8 s and an overshoot rate

SF6 gas gap

Table 1 summarizes the results of dielectric breakdown

characteristics obtained with front time (Tf) and

overshoot rate () as the parameters for the SF6 gas

gap. Figures 5 and 6 show the changes in a 50%

breakdown voltage (U50) and average breakdown time

(Ave. BDT) for the respective parameters. The error

bars in the Figures refer to the standard deviation (v)

obtained from test data. v values of not more than 5%

in these SF6 gas gap tests were lower than the applied

voltage step except for one case.

Pg. 2

Paper A-3

Proceedings of the 16th International Symposium on High Voltage Engineering

c 2009 SAIEE, Innes House, Johannesburg

Copyright

ISBN 978-0-620-44584-9

It was found that U50 values generally tend to decline

in proportion to the increase of Tf values. U50 values

remained almost constant regardless of changes of

value, so there was little impact due to the difference in

. Ave. BDT values were near the peak value for the

standard waveform with the front time of 1.2 s.

However, as Tf values increase, dielectric breakdowns

tend to occur at the wave tail portion. Dielectric

breakdowns occurred near the peak value for most

waveforms with an overshoot.

The error bars in these Figures refer to the v obtained

from test data. The v values in these oil gap tests were

5%-16%, which is considerably higher than those for

the SF6 gas gap. These v values of not less than 5% in

these tests were higher than the applied voltage step.

Although the U50 values tend to increase slightly

proportionately as either Tf values or values increase,

the gradient was smaller than in the SF6 gas cases. Ave.

BDT values tend to increase as Tf values increase for

most waveforms without an overshoot. Dielectric

breakdowns occurred at portions near the peak value

up to the wave tail. Most dielectric breakdowns

occurred near the wave tail portion after having passed

the peak value for most waveforms with an overshoot.

No significant relationship was found between Ave.

BDT and values.

Table 1: Dielectric breakdown characteristics

regarding the waveform parameters for SF6 gas.

Base curve

Longer front time

With overshoot

Tf [s]

1.2

2.4

4.8

1.2

1.2

'[%]

10

20

U50[kV]

1432

1408

1357

1435

1431

v[kV]

51

27

75

49

Ave.BDT[s]

2.3

7.3

11.6

1.5

1.4

SF6 gas

[kV]

1500

1.4

2.4

4.8

1.4

1.4

'[%]

10

20

U50[kV]

657

670

671

661

683

v[kV]

40

80

109

39

105

Ave.BDT[s]

5.6

5.9

7.3

4.4

5.2

1200

1100

1000

900

Ave.BDT

1300

With overshoot

Tf [s]

10

1400

Longer front time

Base curve

[s]

12

1600

Oil

[kV]

900

[s]

8

2

800

U50

6

[s]

Tf

Ave. BDT

Figure 5: Changes in U50 and Ave. BDT with regard to

front time.

700

Ave.BDT

800

U 50

U50

Table 2: Dielectric breakdown characteristics

regarding the waveform parameters for oil.

600

2

500

SF6 gas

[kV]

[s]

10

1400

1300

1200

1100

6

[s]

Tf

Ave. BDT

Figure 7: Changes in U50 and Ave. BDT with regard to

front time.

Oil

[kV]

1000

U50

Ave.BDT

1500

[s]

900

800

900

800

5

U50

10

15

'

Ave. BDT

20

[]

700

Ave.BDT

U50

U50

12

1600

600

Figure 6: Changes in U50 and Ave. BDT with regard to

overshoot rate.

2

500

3.2.

Oil gap

10

15

'

Table 2 summarizes the results of dielectric breakdown

characteristics obtained with Tf and as parameters

for the oil gap. Figures 7 and 8 show the changes in U50

and Ave. BDT regarding the respective parameters.

U50

20

0

[]

Ave. BDT

Figure 8: Changes in U50 and Ave. BDT with regard to

overshoot rate.

Pg. 3

Paper A-3

Proceedings of the 16th International Symposium on High Voltage Engineering

c 2009 SAIEE, Innes House, Johannesburg

Copyright

4.

DISCUSSION

4.1.

Consideration about the test voltage factor

k(f)

one side in an imbalanced state. According to the study,

at least five minutes are considered to be necessary to

restore the ion distribution before application of

lightning impulse voltage after such application. [5]

The center frequency of the vibrational component at

the overshoot portion of the voltage waveform, to

which voltage was applied in the tests, was calculated

to be 270 kHz and 280 kHz by the FFT method in the

SF6 gas gap tests. Figure 9 plots the test results

together with the proposed voltage factor curve. The

test voltage factor k(f) was almost 1.0 and deviated

slightly from the proposed voltage factor curve, both of

which are the same as those obtained for the

conventional peak value without using the voltage

factor k(f). As the test voltage factor k(f) remained at

almost 1.0 in the SF6 gas gap tests, it proved that the

occurrence of dielectric breakdowns is mostly

determined by the peak value up to around 270 kHz for

the frequency of the vibrational component. There is

concern that this could not be sufficiently verified as

the voltage step was higher than the v value in the

tests.

The voltage waveform standardized

Figures 10 and 11 plot the voltage waveform

standardized by the peak voltage against the

breakdown time to which the maximum voltage was

applied. It reveals that the number of breakdowns

increases after having passed the peak value point as

the Tf increases. In addition, it was also confirmed that

breakdowns occurred in the range of more than 80% of

the peak voltage at both wave crest and wave tail with

regard to breakdown time. As a result, a voltage level

of less than 80% does not contribute to the occurrence

of dielectric breakdowns.

The center frequency of the vibrational component at a

voltage waveform with an overshoot was calculated to

be 270 kHz and 245 kHz by the FFT method for the oil

gap tests. For the oil gap, the test voltage factor k(f)

tends to decline as the overshoot rate increases, as

represented, for example, by 0.91 in the center

frequency of the vibrational component when the

value is 10% and 0.81 when the value is 20%

approaches 270 kHz. There is concern that withstand

voltage performance cannot be sufficiently verified in

insulation tests.

The voltage waveform standardized

0.2

0.1

0

0.1

(f)

SF6 gas gap

10

[MHz]

100

Oil gap

Figure 9: Test voltage factor.

4.2.

4.2.1

1000

0.8

800

0.6

600

0.4

400

0.2

200

10

2.4s/0%

2.4s/BDT

0

20

[s

4.8s/0%

4.8s/BDT

Consideration about dielectric breakdown

characteristics

SF6 gas gap

1.6

1600

1.4

1400

1.2

1200

1000

0.8

800

0.6

600

0.4

400

0.2

200

At least five minutes were taken as the interval

between applying voltages because the application of

lightning impulse voltage would cause ions in the gas

to be drawn to the electrode, where they would be

neutralized and converted into SF6 molecules due to the

effects of electric potential of difference, which is

produced by the lightning impulse voltage, or drawn to

10

Time

1.2s/0%

0%/BDT

1.2s/10%

10%/BDT

BDV [kV]

k(f)

1

(1+2.2f 2)

0.01

1200

For waveforms with an overshoot, dielectric

breakdown occurs near the peak value in most cases. In

the case of Tf at 1.2 s with an overshoot, breakdowns

were concentrated intensively on the crest portion. The

test result in this case was different from the cases of

the Tf with 2.4 s and 4.8 s.

0.6

0.001

1.2

Figure 10: The voltage waveform standardized and

changes in BDT with regard to front time.

0.7

0.3

1400

Time

0.8

k(f)

1.4

1.2s/0%

1.2s/BDT

0.4

1600

0.9

0.5

1.6

BDV [kV]

ISBN 978-0-620-44584-9

0

20

[s

1.2s/20%

20%/BDT

Figure 11: The voltage waveform standardized and

changes in BDT with regard to overshoot rate.

Pg. 4

Paper A-3

Proceedings of the 16th International Symposium on High Voltage Engineering

c 2009 SAIEE, Innes House, Johannesburg

Copyright

Figures 13 and 14 plot standardized voltage waveform

against breakdown time. Breakdown time tends to

decrease proportionately as voltage increases. The

plotted points present the ever-decreasing v-t

characteristic. We may consider that this tendency in

the data is attributable to a v value that was higher

than the voltage step value in the tests. The voltage

step value for the oil gap was appropriate. There were

only a few waveforms that accompanied a considerably

delayed dielectric breakdown in the case of a longer

front time, unlike the case of the SF6 gas gap. The oil

gap values are smaller than those of the SF6 gas gap in

terms of Ave. BDT.

We may consider that the breakdown voltage did not

present any large change because the waveform before

achieving the near peak value may be regarded to be

almost the same as the previous one despite the change

of values. It may become necessary to examine the

effects of overshoot by verifying whether a breakdown

occurs at the wave tail portion after reducing the

voltage step of the applied voltage to less than the v

value.

The voltage waveform stand ardized

Next, we examined the relationship of waveform area

with breakdown voltage for a certain voltage level and

peak value. Figure 12 plots projections of breakdown

voltage for the respective measured voltage waveforms,

both of which were then converted into areas with the

front time as the parameter for conversion between the

peak value and a 95% portion and between the peak

value and a 97% portion, on the basis of the standard

waveform. The error bar in the Figure refers to v

obtained from test data. According to calculations

based on conversion into area, breakdown voltage

values tend to decline as front time increases. As

breakdown voltage values tend to decline

proportionately as front time increases also for the

measured values, the relationship between Tf and U50

can be explained, to a certain degree, by the area rules.

1.6

800

1.4

700

1.2

600

500

0.8

400

0.6

300

0.4

200

0.2

100

[kV]

1.4s/0%

1.4s/BDT

1600

2.4s/0%

2.4s/BDT

[s]

4.8s/0%

4.8s/BDT

Figure 13: The voltage waveform standardized and

changes in BDT with regard to front time.

1500

1400

1300

For waveforms with an overshoot, the breakdown time

tends to increase and follow the area rules as overshoot

rate increases, similar to the case of a longer front time.

The plotted points present ever-decreasing v-t

characteristics. Most of the dielectric breakdowns for

the oil gap occurred at the wave tail portion after

having passed the peak value point.

1200

1100

1000

900

0

Front time

[s]

The voltage waveform standardized

Measured values

97% calculated values on standard impulse

95% calculated values on standard impulse

Figure 12: Relationship between waveform area and

breakdown voltage.

Oil gap

The most influential factor in the dielectric breakdown

of insulation oil is the existence of particle in the oil.

Consequently, any increase/decrease of particles in the

course of tests may change the breakdown voltage. If

insulation oil undergoes a dielectric breakdown, it is

decomposed by the heat of the arc, which is determined

by the product of the current and the voltage caused by

the breakdown, and produces carbon. If the resulting

carbon floats in insulation oil filled between the

electrodes as a kind of particle, the likelihood of

affecting breakdown voltage becomes high.

1.6

800

1.4

700

1.2

600

500

0.8

400

0.6

300

0.4

200

0.2

100

10

20

Time

1.4s/2%

2%/BDT

1.4s/10%

10%/BDT

BDV [kV]

BDV

20

Time

1700

4.2.2

10

BDV [kV]

ISBN 978-0-620-44584-9

[s]

1.4s/20%

20%/BDT

Figure 14: The voltage waveform standardized and

changes in BDT with regard to overshoot rate.

Pg. 5

Paper A-3

Proceedings of the 16th International Symposium on High Voltage Engineering

c 2009 SAIEE, Innes House, Johannesburg

Copyright

ISBN 978-0-620-44584-9

We examined the relationship of waveform area up to

the peak value with breakdown voltage in a similar

way to the cases of the SF6 gas gap. Figure 15 plots

projections of the breakdown voltage for the respective

measured voltage waveforms, both of which were then

converted into areas with front time as the parameter

for conversion between peak value and 90% portion

and between peak value and 80% portion, on the basis

of the standard waveform. The error bar in the Figure

refers to v obtained from test data. According to

calculations based on conversion into area, the

breakdown voltage values tend to decline as the front

time increases. The breakdown voltage values tend to

rise slightly proportionately as front time increases for

the measured values, but such variations remained

confined to within a predicted variability.

sufficiently verified for the waveforms with an

overshoot because the voltage factor k(f) tends to

vary due to differences in overshoot rate at almost

the same vibrational frequency.

(3) The dielectric breakdown voltage does not change

so much with a longer front time for waveforms

without an overshoot compared to similar ones

with an overshoot. As a result, we may consider

that changing in front time may be effective only

for apparatus with higher capacitance.

6.

[1] IEC 60060-1 High-voltage test techniques, Part

1 : General definitions and test requirements,

(1989)

[2] S.Berlijn, F.Granacho, P.Simon, E.Gockenbach,

P.Werle, K.Hackemack and M. Watts, :Digital

Measurement of Parameters Using for Lightning

Impulse Tests for High Voltage Equipment, Final

Report, Contract PL-951210-SMT4-CT96-2132

(1999)

[3] P.Simon,

F.Grauacho,

S.M.Berlijn

and

E.Gockenbach, Determining the Test Voltage

Factor Function for the Evaluation of Lightning

Impulse with Oscillation and/or an Overshoot,

IEEE Trans. on Power Delivery, Vol.21, No.2,

pp.560-566 (2006)

[4] P.Simon, Research of the Characteristic

Parameters of the Behaviour of Dielectric Media

under Non Standard Lightning Impulses in High

Voltage, Politechnical University of Madrid

(2006)

[5] N.Wiegart, K.Niemeyer, F.Pinnekarp, W.Boeck,

J.Kindersberger, R.Morrow, W.Zangel, M,Zwicky,

L.Gallimberti, and S.A.Boggs: Inhomogeneous

Field Breakdown in GIS The Predication of

Breakdown Probabilities and Voltage , Part1:

Overview of a Theory for Inhomogeneous Field

Breakdown in SF6, Part 2: Ion Density and

Statistical Time Lag, Part 3: Discharge

Development in SF6 and Computer Model of

Breakdown, IEEE Trans. on Power Delivery,

Vol.3, No.3, pp923-946(1988)

[kV]

1000

900

BDV

800

700

600

500

400

300

0

Front time

6

[s]

Measured values

90% calculated values on standard impulse

80% calculated values on standard impulse

Figure 15: Relationship between waveform area and

breakdown voltage.

5.

REFERENCES

CONCLUSION

The following points have been proven by tests using

an electrode system that has a large area and cubic

volume assuming that an actual equipment is used.

(1) In the SF6 gas gap under quasi-uniform electric

field, occurrence of a dielectric breakdown of the

waveforms with an overshoot is determined by the

peak value. Consequently, if the new proposed

voltage factor k(f) is used, an excessive test

voltage may be applied. However, a voltage step

higher than the v value may have had an impact

on test results. About the waveforms of a longer

front time, a dielectric breakdown voltage tends to

lower than the standard waveforms and the

breakdown time is delayed behind the peak time.

(2) It is difficult to precisely evaluate the physical

characteristics of dielectric breakdown given

considerable variations in the breakdown voltage

in the oil gap. Yet, there is concern that withstand

voltage performance may not have been

Pg. 6

Paper A-3

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Chapter 4: Soil Test and SurveyDocument17 pagesChapter 4: Soil Test and SurveyOpaw Kho100% (1)

- MV Design Guide StandardsDocument9 pagesMV Design Guide StandardsCristina FerrarNo ratings yet

- Cable Sizing ImportantDocument6 pagesCable Sizing ImportantSreekanth RaveendranNo ratings yet

- GR 8 Learning Module in ScienceDocument6 pagesGR 8 Learning Module in ScienceMaribel100% (1)

- Busbar Sizing For SubstationDocument22 pagesBusbar Sizing For SubstationHasala Dharmawardena100% (6)

- DC System SpecsDocument19 pagesDC System SpecsAboudouleNo ratings yet

- Wind TB GeneratorDocument26 pagesWind TB GeneratorbinhNo ratings yet

- Science Process Skills Examination 1ncv0kyDocument9 pagesScience Process Skills Examination 1ncv0kyInsar Damopolii TempoesekarangNo ratings yet

- X-Ray Photoelectron Spectroscopy (XPS) : Electron Spectroscopy For Chemical Analysis (ESCA)Document24 pagesX-Ray Photoelectron Spectroscopy (XPS) : Electron Spectroscopy For Chemical Analysis (ESCA)Jatin DarveNo ratings yet

- WG A325 Surge+Arrester Poster 20122Document2 pagesWG A325 Surge+Arrester Poster 20122sorry2qazNo ratings yet

- A770 A790 Ce Emi ReportDocument56 pagesA770 A790 Ce Emi ReportthanatitosNo ratings yet

- C13a002 FDocument1 pageC13a002 FthanatitosNo ratings yet

- SHIEMNESDocument1 pageSHIEMNESthanatitosNo ratings yet

- Current Transformers TheoryDocument6 pagesCurrent Transformers TheorykingkakingNo ratings yet

- Cruze HB 2015Document2 pagesCruze HB 2015thanatitosNo ratings yet

- TCI Protection FittingsDocument17 pagesTCI Protection FittingsthanatitosNo ratings yet

- Selecting the Right Dry-Type TransformerDocument2 pagesSelecting the Right Dry-Type Transformerbhargavram1987No ratings yet

- Capitulo 4Document7 pagesCapitulo 4thanatitosNo ratings yet

- Electrifying London Underground cable connects substations to placate London’s insatiable demand for powerDocument3 pagesElectrifying London Underground cable connects substations to placate London’s insatiable demand for powerkrdevauvceNo ratings yet

- Power Flow StudiesDocument11 pagesPower Flow Studiesoadipphone7031No ratings yet

- Power Factor CorrectionDocument9 pagesPower Factor CorrectionNiket Kumar MishraNo ratings yet

- A Practical Aproach To Harmonic Compensation in Power Systems Series Connection of Passive and AcDocument6 pagesA Practical Aproach To Harmonic Compensation in Power Systems Series Connection of Passive and ActhanatitosNo ratings yet

- Fault Recording System For Professional Fault Analysis Indactic 650Document16 pagesFault Recording System For Professional Fault Analysis Indactic 650thanatitosNo ratings yet

- Reconfiguration and Capacitor Placement For Loss Reduction of Distribution Systems by Ant Colony Search AlgorithmDocument9 pagesReconfiguration and Capacitor Placement For Loss Reduction of Distribution Systems by Ant Colony Search AlgorithmthanatitosNo ratings yet

- A Practical Aproach To Harmonic Compensation in Power Systems Series Connection of Passive and AcDocument6 pagesA Practical Aproach To Harmonic Compensation in Power Systems Series Connection of Passive and ActhanatitosNo ratings yet

- Digsilent DPL TutorialDocument62 pagesDigsilent DPL TutorialYuteeNo ratings yet

- Reconfiguration and Capacitor Placement For Loss Reduction of Distribution Systems by Ant Colony Search AlgorithmDocument9 pagesReconfiguration and Capacitor Placement For Loss Reduction of Distribution Systems by Ant Colony Search AlgorithmthanatitosNo ratings yet

- TCI Strain InsulatorsDocument3 pagesTCI Strain InsulatorsthanatitosNo ratings yet

- QuickInstallationGuide 15.1 MultiDocument31 pagesQuickInstallationGuide 15.1 MultithanatitosNo ratings yet

- Disc suspension porcelain insulators technical specificationsDocument13 pagesDisc suspension porcelain insulators technical specificationsthanatitosNo ratings yet

- Shackle Insulators: (ANSI Standard Type)Document2 pagesShackle Insulators: (ANSI Standard Type)thanatitosNo ratings yet

- Fault Recording System For Professional Fault Analysis Indactic 650Document16 pagesFault Recording System For Professional Fault Analysis Indactic 650thanatitosNo ratings yet

- Strain Clamp Specifications and Dimensions from Tucheng InternationalDocument8 pagesStrain Clamp Specifications and Dimensions from Tucheng InternationalthanatitosNo ratings yet

- TCI-Station Post InsulatorsDocument15 pagesTCI-Station Post InsulatorsnoonilovelyNo ratings yet

- Tài Liệu Livestream: A. B. C. DDocument3 pagesTài Liệu Livestream: A. B. C. Dphananhthu1301No ratings yet

- Class 4 Worksheet on Tenses, Conversion, Rights and Duties, MatterDocument7 pagesClass 4 Worksheet on Tenses, Conversion, Rights and Duties, MatterTech trixNo ratings yet

- CLIMATE CONSULTANT GLASS ARCHITECTUREDocument11 pagesCLIMATE CONSULTANT GLASS ARCHITECTUREAjith KumarNo ratings yet

- Prabharani Public SchoolDocument30 pagesPrabharani Public SchoolMainak RayNo ratings yet

- The Modern Periodic Table Chemistry PresentationDocument15 pagesThe Modern Periodic Table Chemistry PresentationShee YingNo ratings yet

- How To Determine BasicityDocument10 pagesHow To Determine Basicityccy9489No ratings yet

- A CLPE Booklist: Information BooksDocument13 pagesA CLPE Booklist: Information BooksChong Beng LimNo ratings yet

- Ev02007 4601 FRPDocument199 pagesEv02007 4601 FRPVincent UlleroNo ratings yet

- My Academic Voyage in Water Into The World of Heavy Metals: Professorial Inaugural LectureDocument31 pagesMy Academic Voyage in Water Into The World of Heavy Metals: Professorial Inaugural LectureAburufaida 1010No ratings yet

- CRIMINOLOGY Organic ChemistryDocument59 pagesCRIMINOLOGY Organic ChemistryLhadii RicaneNo ratings yet

- Lab4 MIN277Document29 pagesLab4 MIN277Jhordy Romero GabrielNo ratings yet

- Chap 3 BDocument32 pagesChap 3 BMike BelayNo ratings yet

- Geography Final Objective Life TimeDocument109 pagesGeography Final Objective Life Timegowrishankar nayanaNo ratings yet

- Mechanical Properties of Mortar Containing Waste PDocument10 pagesMechanical Properties of Mortar Containing Waste Pنوالدين محمد الطويرNo ratings yet

- HKUST CIVIL ENGINEERING FOUNDATION PROJECT REPORTDocument12 pagesHKUST CIVIL ENGINEERING FOUNDATION PROJECT REPORTJun KangNo ratings yet

- EcologyDocument50 pagesEcologyKipi Waruku BinisutiNo ratings yet

- Wqi Report Group 1Document10 pagesWqi Report Group 1Kimaii ZakiNo ratings yet

- Porosity Measurement Techniques and Applications in Petroleum EngineeringDocument26 pagesPorosity Measurement Techniques and Applications in Petroleum Engineeringrashed kabbaraNo ratings yet

- NPCIL's Role in Meeting India's Growing Energy NeedsDocument8 pagesNPCIL's Role in Meeting India's Growing Energy NeedsNikunjNo ratings yet

- Understanding Heat Transfer, Conduction, Convection and RadiationDocument24 pagesUnderstanding Heat Transfer, Conduction, Convection and RadiationIra MontillaNo ratings yet

- P 4 Assignment CritiqueDocument3 pagesP 4 Assignment CritiqueVĩ NguyễnNo ratings yet

- Negative Mass Exotic MatterDocument3 pagesNegative Mass Exotic MattertechzonesNo ratings yet

- Unit 1 Scientific Investigation - Chapter 1 Thinking Like A ScientistDocument2 pagesUnit 1 Scientific Investigation - Chapter 1 Thinking Like A ScientistKayla OsbornNo ratings yet

- OxygenDocument10 pagesOxygenFaheem HaiderNo ratings yet

- 2 7Document9 pages2 7Rifat032017No ratings yet