Professional Documents

Culture Documents

PT6A Engine Testing

Uploaded by

JerichoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PT6A Engine Testing

Uploaded by

JerichoCopyright:

Available Formats

PT6A SERIES ENGINE TESTING

PREPARED BY : JOKO ISMIYANTO

PT. NUSANTARA TURBIN & PROPULSI

2013

PT6A SERIES ENGINE TESTING

TABLE OF CONTENT

1. ENGINE TEST FLOW CHART

. 3

2. TEST REQUIREMENT AND PROCEDURE MATRIX

.. 5

3. LIST OF PT6A PARAMETER AND SYMBOL

.. 6

4. TEST PROCEDURE SEQUENCE

.. 7

5. ENGINE TEST OPERATING CONDITION LIMIT

.. 9

6. ENGINE MOTORING, STARTING AND SHUT DOWN

.. 10

7. RUN IN PROCEDURE

.. 12

8. ACCESSORIES GEARBOX (AGB) VIBRATION SURVEY

.. 13

9. REDUCTION GEARBOX (RGB) VIBRATION CHECK

.. 15

10. ACCELERATION AND BODIE CHECK

.. 16

11. TT5 TRIM DETERMINATION

.. 21

12. ACCEPTANCE CHECK (PERFORMANCE)

.. 26

13. CONTROL SETTING : MAXIMUM NG ADJUSTMENT

.. 56

14. CONTROL SETTING : MINIMUM FUEL FLOW CHECK

.. 60

15. POST TEST RUN CHECK

.. 64

16. UNUSUAL OIL CONDITION

.. 66

PT6A series engine testing

ENGINE TEST PROCESS FLOW CHART

START

INSPEKSI VISUAL DAN

CEK KELENGKAPAN

DOKUMEN

QI TC17-002

ENGINE &

DOKUMEN

KOMPLIT

TIDAK

KONTAK

PPC

YA

PREPARASI ENGINE &

FASILITAS

QI TC17-002 dan

OVERHAUL MANUAL

CHECK ENGINE & FASILITAS TEST :

CEK KEWAJARAN NILAI ZERO

READING PARAMETER

CEK SISTEM PROTEKSI

CEK FUNGSI KONTROL DYNO

QI TC17-002 dan

OVERHAUL MANUAL

FASILITAS

TEST

NORMAL

TIDAK

KONTAK

FUNGSI

ETS

YA

TEST ENGINE

QI TC17-002 dan

OVERHAUL MANUAL

EVALUASI

HASIL TEST

QI TC17-002 dan

OVERHAUL MANUAL

PT6A series engine testing

ENGINE TEST PROCESS FLOW CHART

A

BELLMOUTH & EXHAUST

CHECK

QI TC17-002 dan

OVERHAUL MANUAL

DE-PREPARASI ENGINE

QI TC17-002 dan

OVERHAUL MANUAL

LENGKAPI DOKUMEN

TEST

QI TC17-002 dan

OVERHAUL MANUAL

KONTAK PPC

FINISH

PT6A series engine testing

TEST REQUIREMENT & PROCEDURE MATRIX

PARAGRA

F NO.

1

2

3

4

5

7

8

9

10A

10D

10E

10G

10H

10I

10J

11A

PROCEDURE

GAS

POWER

ENGINE GENERATO SECTIO

R

N

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

General

Consumable material

Special tools

Fixtures, equipment and supplier tools

Engine test equipment

Symbols

Preparation for test

Engine motoring, starting & shut down

LIMITS

Preliminary check

AGB vibration survey

Acceleration and Bodie check

TT5 trim determination

Acceptance check / performance check

Acceptance Value

Control setting : Minimum Governor check

Control setting : Propeller Governor maximum

11B speed

X

X

Control setting : Underspeed fuel governing

11C check

X

X

11D Control setting : Maximum NG adjustment

X

X

11E Control setting : Minimum Fuel Flow Check

X

X

12

Post test run check

X

X

13

Unusual oil condition

X

14

Preservation

X

X

15

Removal of test equipment

X

X

X

18

Final check

X

X

X

19

Power section run in

X

Note : The vibration survey requirement applies only to engine being tested following

overhaul or repair requiring balancing of the compressor rotor assembly

PT6A series engine testing

LIST OF PT6A PARAMETER AND SYMBOL

During static condition / engine not running / zero reading ,

the normal reading for parameters are listed below:

SYMBOLS

PARAMETER NAME

COMPUTER

OHM

DYNOSP

WFPPH

NGPER

Wf

NG

NFPER

NF

TT11

TT12

TT13

TT14

TT1A

TT5

TT71

TT72

TT73

TT74

TT75

TT76

TT77

TT78

TT7A

TFUEL

TOILIN

TOILSC

PBARO

PS1

PS3

PGEAR

MOP

POILSC

TORQ2

TORQ2S

DELP

VBGEA

TORQ1

THETA

THETAR

DELTA

Ng

Nf

Tt1

Tt5

Tt7

Tf

Pam

Psn

Ps3

Prgb

Pam

P

TH

RTH

DEL

Dyno speed

Fuel flow

Gas generator speed in percent

Gas generator speed in radian per minute

Power turbine speed in percent

Power turbine speed in radian per minute

Engine inlet temperature no 1

Engine inlet temperature no 2

Engine inlet temperature no 3

Engine inlet temperature no 4

Engine inlet temperature average

Interturbine temperature

Engine exhaust nozzle temperature no. 1

Engine exhaust nozzle temperature no. 2

Engine exhaust nozzle temperature no. 3

Engine exhaust nozzle temperature no. 4

Engine exhaust nozzle temperature no. 5

Engine exhaust nozzle temperature no. 6

Engine exhaust nozzle temperature no. 7

Engine exhaust nozzle temperature no. 8

Engine exhaust nozzle temperature average

Fuel temperature

Oil temperature

Scavenge Oil temperature

Ambient Barometric Pressure

Test cell static pressure

Compressure discharge static pressure

Reduction Gearbox Static Pressure

Main Oil Pressure

Scavenge Oil pressure

Engine Torquemeter Pressure

Engine Torquemeter Static Pressure

Delta TORQ2 - TORQ2S

Gearbox vibration

Dyno torque

THETA

THETA (AKAR THETA)

DELTA (PBARO (inHg)/29.921)

NORMAL VALUE @ ZERO

READING

VALUE

UNIT

0

0

0

rpm

pph

%

0

0

0

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

70 - 87

13.3 - 13.5

rpm

%

rpm

deg f

deg f

deg f

deg f

deg f

deg f

deg f

deg f

deg f

deg f

deg f

deg f

deg f

deg f

deg f

deg f

deg f

deg f

psia

same with pbaro

0

0

0

0

0

0

TORQ2 - TORQ2S

0

0

0.92 - 1.053

1.01 - 1.03

0.905 - 0.918

psia

psig

psig

psig

psig

psig

psig

psig

G's

ft lbs

PT6A series engine testing

IF ASSUMED THAT ENGINE TREATED AS OVERHAUL AND COMPRESSOR ROTOR HAVE

BEEN BALANCING, THEN TEST PROCEDURE SEQUENCE IS:

START

ENGINE MOTORING,

STARTING & SHUTDOWN

RUN-IN PROCEDURE

1.

2.

3.

PRELIMINARY CHECK :

OBTAIN NF/RTH = 33000 RPM

PERFORM 2 FEATHERING OPERATION

OIL PRESSURE CHECK

AGB VIBRATION SURVEY

RGB VIBRATION CHECK

ACCELERATION & BODIE

CHECK

TT5 TRIM

DETERMINATION

A

7

PT6A series engine testing

IF ASSUMED THAT ENGINE TREATED AS OVERHAUL AND COMPRESSOR ROTOR HAVE

BEEN BALANCING, THEN TEST PROCEDURE SEQUENCE IS:

A

ACCEPTANCE CHECK /

PERFORMANCE

MINIMUM GOVERNOR

CHECK

PROPELLER GOVERNOR

MAXIMUM SPEED

UNDERSPEED FUEL

GOVERNING CHECK

MAXIMUM NG

ADJUSTMENT

MINIMUM FUEL FLOW

CHECK

POST TEST RUN CHECK

PRESERVATION

FINISH

8

PT6A series engine testing

ENGINE TEST OPERATING CONDITION LIMIT

LIMIT

PT6A-21

PT6A-27/28 PT6A-25

38,100

38,100

38,100

Steady State

(101.7%)

(101.7%)

(101.7%)

NG (rpm)

38,500

38,500

38,500

Acceleration

(102.75%)

(102.75%) (102.75%)

34,200

34,200

34,200

Steady State

(103.6%)

(102.9%)

(103.6%)

NF (rpm)

36,300

36300

36,300

Acceleration*

(110%)

(109.2%)

(110%)

Start

1350

1440

1350

TT5 (deg F) Steady State (trimmed)

1283

1380

1283

Steady State (untrimmed)

1325

1400

1325

Steady State

92

125

94

delP (inHg)

Acceleration*

94

127

94

NOTE : Rundown time on the compressor from ground-idle must not be < 20 seconds

*2 second time limit

PARAMETE

R

MAXIMUM OPERATING

CONDITION

SUPPLEMENTARY LIMITATION

PARAMETER

Fuel pressure @ engine inlet all time including transient

Oil temperature for all running except transient

Scavenge oil b ack pressure @ engine outlet

Maximum permitted difference between individual inlet temp.

indication

Maximum permitted difference between average Tt7 thermocouple

reading between each exhaust nozzle assembly

Maximum permitted difference between thermocouple within a

given nozzle

Maximum operating vibration limit

Maximum acceptance vibration limit

LIMIT

5 - 20 psig

140 - 160 deg F

20 - 50 psig

8:F

60:F

100:F

100 G's

70 G's

PT6A series engine testing

ENGINE MOTORING, STARTING & SHUT DOWN

WET MOTORING RUN

IF FIRE CONDITIONS OCCURS WITHIN ENGINE DURING

MOTORING RUN , IMMEDIATELY CLOSE FUEL SHUTOFF VALVE

AND CONTINUE MOTORING ENGINE

ALLOW SUFFICIENT STARTER COOLING PERIOD BETWEEN

MOTORING CYCLES AND ENGINE START; REFER TO STARTER

MANUFACTURERS LIMITS AND RECOMMENDATIONS.

DRY MOTORING RUN

This procedure is used to remove internally trapped fuel and fuel vapor, or if

there is evidence of fire within the engine. Air passing through the engine

serves to purge fuel/fuel vapor from the combustion section, power turbine and

exhaust system.

ENGINE STARTING

ALLOW SUFFICIENT STARTER COOLING PERIOD BETWEEN

MOTORING CYCLES AND ENGINE START; REFER TO STARTER

MANUFACTURERS LIMITS AND RECOMMENDATIONS.

THE ENGINE MUST START AND REACH IDLE WITHIN 35 SECONDS OF INITIATION OF THE START.

THE FIRST START OF THE DAY CAN SOMETIMES TAKE LONGER; THEREFORE, THE START TIME

MUST BE CORRECTED TO COMPENSATE FOR LONG TIME TO LIGHT. FOR TTL GREATER THAN 3

SECONDS: TTI MODIFIED = TTI RECORDED - (TTL 3 SECONDS). IF THIS REQUIREMENT IS NOT

ACHIEVED, check the FCU pneumatic system for leaks. If no leaks are found, replace the

FCU.

IF Tt5 OBSERVED EXCEEDS 1440F OR CONTINUOUS FLAME ISSUES

FROM EXHAUST, SHUT OFF START CONTROL LEVER IMMEDIATELY.

DO NOT ATTEMPT TO RELIGHT ON RUNDOWN; WAIT UNTIL THE

ENGINE COMES TO REST, THEN IMPLEMENT A DRY MOTORING CYCLE

TO COOL THE ENGINE

10

PT6A series engine testing

ENGINE MOTORING, STARTING & SHUT DOWN

SHUT DOWN

IF A FIRE OCCURS IN THE ENGINE AFTER SHUTDOWN, DO A DRY

MOTORING RUN IMMEDIATELY

For normal shut down, allow engine to run at ground idle for at least

one minute to stabilize at minimum running temperatures.

11

PT6A series engine testing

RUN-IN PROCEDURE

NOTE : This procedure is to be done after scheduled or unscheduled

overhaul/repair has been completed.

1)

Do a wet motoring run followed with a dry motoring run.

2)

Start the engine and run at ground-idle 19750 500 rpm Ng

(propeller testing) or rotate dynamometer controller to obtain 5000

rpm Nf or maximum available (dynamometer testing) for 5 minutes.

3)

Record Ng, Nf, Tt1, Tt5, del P, oil pressures and oil temperatures.

12

PT6A series engine testing

AGB VIBRATION SURVEY

NOTE: 1. The vibration survey requirement applies only to engines being tested

following overhaul or repair requiring balancing of the compressor rotor

assembly.

NOTE: 2. Do the vibration survey using the following procedures and the ACES

Operators Manual. Personnel must be familiar with the Analyzer prior to

performing these operations.

CAUTION: DO NOT EXCEED ENGINE OPERATING LIMITS. ENGINE

OPERATING LIMITS SUPERSEDE ANY INSTRUCTION IN ACES

ANALYZER PROCEDURE.

ACCELERATION SURVEY

1)

Select Acceleration Survey from the menu on the analyzer.

2)

Set power control lever to GROUND-IDLE.

3)

Set propeller control lever to 33000 rpm Nf.

4)

Ng Sweep:

a)

Press Enter on the analyzer to start recording.

b)

Accelerate slowly at a rate of 5000 rpm/min from GROUND-IDLE

to max available Ng without exceeding any operating limits.

Reduce to GROUND-IDLE.

c)

Press Enter on the analyzer to stop recording.

13

PT6A series engine testing

AGB VIBRATION SURVEY

SHUTDOWN SURVEY

1)

Select shutdown Survey from the menu on the analyzer.

2)

Press Enter on the ACES Analyzer to start recording. Shut down

engine from idle.

3)

End vibration survey after engine reaches 0 rpm and a sync error

appears on the ACES Analyzer; then press Enter on the ACES

Analyzer to stop recording.

1ENg VIBRATION ACCEPTANCE LIMIT

a.

From the plots produced above, ensure that 1ENg vibration level

does not exceed the following limits:

GROUND-IDLE to max Ng ; 0.5 cm/sec

Shutdown from GROUND-IDLE to 5000 rpm Ng; 0.5 cm/sec

14

PT6A series engine testing

RGB VIBRATION CHECK

NG SWEEP

1)

Set Nf to 33000 +100/-0 rpm.

2)

Carry out a slow acceleration (4,000 rpm/min.) from ground idle to

maximum attainable Ng, do not exceed any operating limit.

3)

Carry out a slow deceleration (4,000 rpm/min.) from maximum

attainable Ng to ground idle.

4)

Record Ng, Nf, torque and vibrations at the highest vibration peak

from steps (2) and (3).

NF SWEEP

1)

Set Nf to 33000 +100/-0 rpm.

2)

Increase power to a torque of 80 3 in. Hg

3)

Carry out a slow deceleration (4,000 rpm/min.) from 33000 +100/-0

rpm to 24,500 rpm. Engine torque must be kept at 80 3 in. Hg

during deceleration.

4)

Carry out a slow acceleration (4,000 rpm/min.) from 24,500 rpm to

33000 +100/-0 rpm. Engine torque must be kept at 80 3 in. Hg

during acceleration.

5)

Record Ng, Nf, torque and vibrations at the highest vibration peak

from steps(3) and (4).

15

PT6A series engine testing

ACCELERATION & BODIE CHECK

ACCELERATION CHECK

1)

If engine response is sluggish, or acceleration rate is too slow, check

P3 and fuel system pneumatic control tubes and connectors for

leakage or obstruction, before any fuel control adjustments are

made

2)

Position power control lever maximum stop on console to limit

torque to 86.3 in.Hg.(PT6A-21 engines) or 108.6 in.Hg. (PT6A-27/-28

engines) or maximum obtainable without exceeding engine

operating limits. Lock stop on console.

3)

Rotate dynamometer controller to give 32000 rpm Nf (97% for

PT6A-25, 96% for PT6A-27/28).

4)

Record Ng, Nf, Tt1 and P.

5)

Decrease power control lever to flight-idle 23600 100 rpm Ng.

6)

Slam accelerate from flight-idle to T.O. timed to 97.5% of take-off

Ng. Slam decelerate to ground-idle (19750 500).

NOTE: The time taken to move power control lever in checks (5) through

(6) must not exceed 1.0 second, engine should respond smoothly during

acceleration and deceleration.

16

PT6A series engine testing

ACCELERATION & BODIE CHECK

NOTE: The time taken to move power control lever in checks (5) through

(6) must not exceed 1.0 second, engine should respond smoothly during

acceleration and deceleration.

7)

Acceleration time must fall within range specified

CAUTION: MAXIMUM ADJUSTMENT ON FCU ACCELERATION DOME TO

MEET ACCELERATION TIME IS THREE CLICKS CLOCKWISE OR

COUNTERCLOCKWISE.

8)

If necessary, adjust engine acceleration by rotating FCU acceleration

dome one detent at a time, using minimum number to obtain

satisfactory acceleration. Rotate dome clockwise to decrease (faster

acceleration) and counterclockwise to increase (slower acceleration)

acceleration time.

17

PT6A series engine testing

ACCELERATION & BODIE CHECK

9)

For example, the inlet screen temp. (TT1) during the day is 80: F,

then the acceleration time limits are :

low limit = 2.42 + 0.35 = 2.77 seconds

hi limit = 3.44 + 0.35 = 3.79 seconds

18

PT6A series engine testing

ACCELERATION & BODIE CHECK

BODIE CHECK

1)

Rotate FCU acceleration dome three detents clockwise to increase

fuel flow.

2)

Run engine for not less than one minute at maximum stop without

exceeding operation limit (Ref. step (2) preceding) to achieve

stabilization.

3)

Slam decelerate to 32000 Ng (85%), then without dwelling at lower

speed, slam accelerate to maximum stop. Repeat to 26000 Ng

(70%); again slam to maximum stop. Reduce Ng to GI.

4)

If engine is stall and surge free on completion of bodie checks, reset

acceleration dome to original position (three detents

counterclockwise).

5)

If engine stall or surge is experienced during checks, rotate

acceleration dome one detent counterclockwise and repeat bodie

check.

6)

If surge is still evident, check compressor bleed valve operation..

7)

If bleed valve is functioning correctly, the dome may be reset a

further twodetents, a bodie check being implemented after each

detent adjustment..

19

PT6A series engine testing

ACCELERATION & BODIE CHECK

BODIE CHECK continued

8)

When surge is eliminated, reset dome three detents counter

clockwise from surge-free setting.

9)

After satisfactory completion of bodie check following adjustment,

recheck acceleration time (Ref. steps (5) and (6) ACCELERATION

CHECK preceding).

10) Following acceptable acceleration and bodie checks, if scribe marks

do not align, remove seal and lockwire on FCU acceleration dome.

Holding adjusting screw with an Allen wrench, loosen adjuster

locknut. Turn dome to re-align scribe marks, then tighten locknut,

lockwire and seal. lockwire dome tab.

20

PT6A series engine testing

TT5 TRIM DETERMINATION

1)

Start engine, and advance power control and propeller control

levers (propeller testing) or rotate dynamometer controller until

engine is operating at observed power of 550 10 SHPCEG (PT6A-21

engines) or 680 10 SHPCEG (PT6A-27/-28 engines) or maximum

power obtainable without exceeding engine operating limits and at

an NFC equal to 33000 rpm but not to exceed 34200 rpm (NF

observed).

2)

Run engine for 5 minutes at this power setting to obtain

stabilization. Annotate log sheet; Tt5 Trim Determination and record

set of readings.

Nf, Ng, Pam or Baro, Psn or P1000, Ps3, p, SG, Tf, Tsg, Tt1, Tt5, Tt7

3)

Determine trim value from readings in step (2), preceding. Process

Data with Program PWC83020.

4)

With results obtained in step (3) preceding, calculate trim to

suppress TT5/TH to a value T5D/TH - 60 10 F (PT6A-21/-27/-28

engines) or T5D/TH - 65 5 F (PT6A-28 Piper engines only).

Tt5 Trim Determination (example):

TT5/TH = 1753R

T5D/TH = 1733R

T5D/TH - 60 = 1733 - 60 = 1673R

del T5/TH trim = 1753 1673 = 80

5)

Trim value obtained in step (a) preceding is for a 59F day. To trim

engine, this value should be denormalized as follows:

del T5/TH x TH = del T5.

21

PT6A series engine testing

TT5 TRIM DETERMINATION continued

6)

Select appropriate class of trim harness (P/N 3013604 or P/N

3031417) (Ref. Table703).

7)

Install selected trim harness (Ref. Final Assembly), and record class

in log sheet.

8)

Start engine and run at take-off power (Ref. step (1), preceding).

9)

After allowing for stabilization of readings, make sure that selected

trim reduces Tt5 by the required value. If you are using program

PWC83020, check the T5 trim check box and the output screen will

state if the trim is good or not. Should it be necessary, install

another class of trim and recheck.

22

PT6A series engine testing

TT5 TRIM DETERMINATION continued

TABLE 703, Trim Harness Classification

3031417

5% @ 70F Approx. Ohms

Approx. Range F

3013604

Class 10

3.75 to 3.95

-208 to -200

Class 11

3.95 to 4.20

-200 to -190

Class 12

4.20 to 4.45

-190 to -180

Class 13

4.45 to 4.75

-180 to -171

Class 14

4.75 to 5.10

-171 to -161

Class 15

5.10 to 5.50

-161 to -151

Class 16

5.50 to 5.90

-151 to -142

Class 17

5.90 to 6.40

-142 to -132

Class 18

6.40 to 6.90

-132 to -123

Class 19

6.90 to 7.66

-123 to -114

Class 20

-114 to -104

Class 25

-104 to - 91

Class 1

Class 30

10.5

- 91 to - 80

Class 2

Class 35

12

- 80 to - 71

Class 3

Class 40

14

- 71 to - 61

Class 5

Class 45

16

- 61 to - 51

Class 7

Class 50

19

- 48 to - 45

Class 10

Class 55

24

- 40 to - 35

Class 20

Class 60

30

- 34 to - 28

Class 30

Class 65

43

- 25 to - 20

Class 40

Class 70

72

- 15 to - 10

Class 50

Class 75

110

- 9 to - 6

Class 60

23

PT6A series engine testing

TT5 TRIM DETERMINATION continued

FLOW CHART OF TT5 TRIM DETERMINATION

START

1. Run engine to maximum power obtainable, NFC =

33000 rpm, don't exceed operating limit.

2. Stabilize for 5 minutes.

3. Take fullset reading

install trim harness

TSG, SG, LHV, Ng, Nf, Pbaro,

Psn, P3, Tt5, Torq1, delP,

Wf,Tfuel, Tt1, Tt7

Input to and process

with Program Drp

PWC83020

1. Run engine to TAKEOFF or maximum power

obtainable, NFC = 33000 rpm, don't exceed

operating limit.

2. Make sure that selected trim reduces Tt5 by the

required value.

SELESAI

TT5TH AND T5DTH

NOTE :

TH = (Tt1+459.688)/518.688

example :

delT5TH = TT5TH - (T5DTH - 60)

delT5 = delT5TH x TH

TH = 1.05,

TT5TH = 1753 R,

T5DTH = 1733 R,

delT5TH = 1753 - (1733 - 60) = 80,

delT5 = 80 x 1.05 = 84,

lookup table 703, p/n : 3031417

trim class = class 30, -91 to -80

delT5

LOOKUP TABLE 703

TRIM

CLASS

24

PT6A series engine testing

TT5 TRIM DETERMINATION continued

EXAMPLE OF TT5 TRIM DETERMINATION

The data from left column above, taken from fullset @ takeoff. The data will process

with DRP program PWC83020.

The output from program are :

THETA

= (ENGINE INLET TEMP + 459.688)/518.688

= (85.93 + 459.688)/518.688 = 1.05

T5D/THETA

= 1723.8 deg R

CORR.TT5 (TT5/THETA) = 1752.4 deg R

With refer to flow chart, then :

(T5D/THETA ) - 60

= 1723.8 60 = 1663.8

DELTA TT5/ THETA TRIM = CORR.TT5 (TT5/THETA) (T5D/THETA) 60

= 1752.4 1663.8 = 88.6

DELTA TT5 DENORMALIZE = DELTA TT5/ THETA TRIM X THETA

= 88.6 X 1.05 = 93.03 = 93

LOOKUP TO TABLE 703 93 CLASS 25 OR CLASS 30

25

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

Before we move deeply to Acceptance Check, better if we have a good

understanding on several important parameter which were used for

determine the result of acceptance check .

The parameter which mentioned above are SHPCEG, NGC, WFC, SFC and

TT5C.

26

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

SHPCEG BLOCK DIAGRAM

TORQ3

(static torq press)

psig

del P

(torq2 - torq3 x 2.036)

SHP

(del P x NF / KONSTAN)

TORQ2

(torqmeter press)

psig

NF

(power turbine speed)

rpm

KONSTAN

PT6A-27 = 5272

PT6A-25 = 5183

SHPCEG

(SHP / DELTA / sqroot THETA)

PBAR

(ambient press)

psia

DELTA

(pbar / standard press)

standard press

(14.696 psi)

sq root THETA

(theta ^ 0.5)

THETA

(tt1 avg + 459.688) / 518.688

TT1 avg

(engine inlet temp)

deg F

TT5C or TT5TH BLOCK DIAGRAM

TT5 DEG R

(tt5 + 459.688)

TT5

(interturbine temp)

deg F

THETA

(tt1 avg + 459.688 / 518.688)

TT1 AVG

(engine inlet temp)

deg F

TT5C or TT5TH

(TT5 DEG R / THETA )

27

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

WFC BLOCK DIAGRAM

CORR SPGRAV

(spgrav-1.2875)/(ftsamp+1164)x(tfuel-ftsamf)+spgrav

FTSAMP

(fuel sample temp)

deg F

SPGRAV

(fuel spec. gravity)

psig

TFUEL

(fuel temp)

deg F

WFGPM

(fuel flow)

gpm

WFPPH

(wfgpm x 499.68 x corr spgrav)

WFC

(wfpph / DELTA x sqroot THETA)

PBAR

(ambient press)

psia

DELTA

(pbar / standard press)

standard press

(14.696 psi)

sq root THETA

(theta ^ 0.5)

THETA

(tt1 avg + 459.688) / 518.688

TT1 avg

(engine inlet temp)

deg F

SFCC BLOCK DIAGRAM

SHPCEG

(corr shp engine)

hp

WFC

(corr WF)

pph

SFCC

(shpceg / wfc)

28

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

NGC BLOCK DIAGRAM

sq root THETA

(theta ^ 0.5)

THETA

(tt1 avg + 459.688) / 518.688

TT1 avg

(engine inlet temp)

deg F

NGC

(ng / sqroot THETA)

NG

rpm

(gas producer speed)

TT7C BLOCK DIAGRAM

THETA

(tt1 avg + 459.688) / 518.688

TT1 avg

(engine inlet temp)

deg F

TT7 AVG

(engine exhaust nozzle temp)

deg F

TT7AC

(TT7A DEG R / THETA)

TT7A DEG R

(tt7 avg + 459.688)

PS3C BLOCK DIAGRAM

PBAR

(ambient press)

psia

DELTA

(pbar / standard press)

PS3C

(PS3 / DELTA )

standard press

(14.696 psi)

PS3

(compressor discharge press)

psig

29

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

PROCEDURE

CAUTION : DO NOT EXCEED ENGINE OPERATING LIMITS

1)

Run to following powers at Nf/RTH equal to 33000 rpm, but not to

exceed 34200 rpm (observed).

2)

Record readings for each of the power setting points :

3)

PT6A-21 or PT6A -25 engines: :

4)

5)

a)

550 SHP/DELRTH or maximum power obtainable.

a)

495 SHP/DELRTH.

PT6A-27/28 engines: :

a)

680 SHP/DELRTH or maximum power obtainable.

a)

620 SHP/DELRTH.

From readings obtained in steps (3) or (4) preceding, process data with

program PWC83020. Plot the best straight line across the normalized

values of Wf, Tt5 and Ng against shp on engine performance graph.

(Ref. Fig. 711).

30

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

PROCEDURE

31

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

ACCEPTANCE VALUE

1)

Enter curve at 550 shp (PT6A-21 engines) or 680 shp (PT6A-27/-28

engines) and record corresponding values for SFC, Tt5 and Ng for takeoff power in corrected engine performance block.

2)

Check parameters determined in step (1) against required parameters

(Ref. Table 704).

32

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

ACCEPTANCE VALUE

33

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

ACCEPTANCE VALUE

34

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

ACCEPTANCE VALUE

35

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

ACCEPTANCE VALUE

36

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

ACCEPTANCE VALUE

37

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

ACCEPTANCE VALUE

38

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

ACCEPTANCE VALUE

39

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

ACCEPTANCE VALUE

40

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

ACCEPTANCE VALUE

41

PT6A series engine testing

ACCEPTANCE CHECK (PERFORMANCE)

ACCEPTANCE CHECK performance calculation example

42

PT6A series engine testing

43

PT6A series engine testing

44

PT6A series engine testing

45

PT6A series engine testing

46

PT6A series engine testing

47

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- PT6A Engine Testing PDFDocument47 pagesPT6A Engine Testing PDFMichael095100% (1)

- PT6A Engine Rigging Guide PDFDocument80 pagesPT6A Engine Rigging Guide PDFandres100% (1)

- PT6A 20 OverhaulDocument12 pagesPT6A 20 OverhaulAmry Azryl100% (4)

- PT6A-27 CAT 0699 r02Document526 pagesPT6A-27 CAT 0699 r02LUIS FERNANDO CARDENAS PINEDA88% (8)

- Student Manual NameDocument80 pagesStudent Manual NameJose Tigaci100% (2)

- P&W PT6 Engine SeriesDocument8 pagesP&W PT6 Engine SeriesJuanOñate50% (2)

- PT6A-27 Vs - 34 Overview (PWC)Document19 pagesPT6A-27 Vs - 34 Overview (PWC)Hari Papahx ZahfaZalwa100% (6)

- PT6A Engine Rigging GuideDocument80 pagesPT6A Engine Rigging Guideplhought100% (9)

- Pt6 114a ManualDocument2 pagesPt6 114a ManualAlexander Atoche Rodas25% (4)

- Training Pt6a 60 Series PDFDocument270 pagesTraining Pt6a 60 Series PDFBhaskerNegi88% (8)

- FCUDocument72 pagesFCUversine100% (8)

- PT6A 140 BlackhawkDocument19 pagesPT6A 140 BlackhawkJose Francisco Colina100% (2)

- 6 PT6 Engine Mode PDFDocument3 pages6 PT6 Engine Mode PDFIvan BastianiNo ratings yet

- Pt6a Engine Training OverwiewDocument20 pagesPt6a Engine Training OverwiewRafael Alves Dos Santos100% (1)

- pt6 114a Manual PDFDocument3 pagespt6 114a Manual PDFAlexander Atoche Rodas0% (6)

- 2 - PT6A Engine Rig PDFDocument80 pages2 - PT6A Engine Rig PDFDavid Nicolau Fernandez100% (1)

- Curso PT6A - Small SeriesDocument93 pagesCurso PT6A - Small Seriesfernandofrmorae1987100% (12)

- pt6 Engine TroubleshootingDocument11 pagespt6 Engine TroubleshootingDade Sobarna94% (18)

- PT6-6 and - 20 Maint ManualsDocument782 pagesPT6-6 and - 20 Maint ManualsMathew Brown89% (19)

- PT6A Reference GuideDocument34 pagesPT6A Reference Guide彭树超100% (1)

- 1002 R29Document13 pages1002 R29LUCASDOURADO18100% (1)

- Part 1 PDFDocument162 pagesPart 1 PDFAnthonyNColucci100% (1)

- PT6 Engine Models & Prop SpeedsDocument4 pagesPT6 Engine Models & Prop SpeedsHendra RaNi100% (2)

- Sil IndexDocument162 pagesSil IndexBenjamin Strickland100% (1)

- PT6 Training ManualDocument69 pagesPT6 Training ManualMassimo Derco89% (19)

- Student Manual Makila2A-2A1 Rev 0Document367 pagesStudent Manual Makila2A-2A1 Rev 0Henrique costa mello100% (2)

- TFE731-40 Turbofan Engine Publication Collection PDFDocument17 pagesTFE731-40 Turbofan Engine Publication Collection PDFYousefh Pineda100% (1)

- PT6 Training ManualDocument59 pagesPT6 Training ManualApa Tuh100% (2)

- FADEC - Full-Authority Digital Engine ControlDocument44 pagesFADEC - Full-Authority Digital Engine Controlabsalar100% (5)

- PT6 Training ManualDocument64 pagesPT6 Training ManualAnderson Guimarães100% (2)

- SB1357Document10 pagesSB1357ive23100% (1)

- PT6A-27 HSI Check SheetDocument10 pagesPT6A-27 HSI Check SheetSantosh SahNo ratings yet

- MM Capítulo 09 - Fuel SystemDocument44 pagesMM Capítulo 09 - Fuel Systemoscar100% (1)

- JT15D Ata 74Document6 pagesJT15D Ata 74Egor85No ratings yet

- Echannel Tech Pub DownloadDocument12 pagesEchannel Tech Pub Downloadhoby christianNo ratings yet

- Gas Turbine EnginesDocument14 pagesGas Turbine Enginestomzee1100% (2)

- 100 Hour Inspection Kit pt6 100 100 Hour Inpection KitDocument1 page100 Hour Inspection Kit pt6 100 100 Hour Inpection KitLuz Analía Valdez CandiaNo ratings yet

- Tpe 331Document424 pagesTpe 331Lucio Menga75% (12)

- Service BulletinDocument14 pagesService Bulletinlocoboeing100% (1)

- PT6A Small Customer Training OptimizadoDocument221 pagesPT6A Small Customer Training Optimizadonestor ivan jerez francoNo ratings yet

- TFE 731 Chap 70Document18 pagesTFE 731 Chap 70Egor85100% (1)

- SB 1803 R2 Operating TBO & HSI FrequencyDocument22 pagesSB 1803 R2 Operating TBO & HSI FrequencyDade Sobarna100% (4)

- Powerplant King 350Document22 pagesPowerplant King 350stive100% (2)

- 15 PowerplantDocument26 pages15 PowerplantBlueSkyMaster100% (4)

- CF34-8E Control SystemDocument58 pagesCF34-8E Control Systemhalartgacm100% (7)

- JT15D Ata 73Document22 pagesJT15D Ata 73Egor85100% (1)

- Pt6t Gearbox PDFDocument117 pagesPt6t Gearbox PDF13421301508No ratings yet

- Engine PDFDocument0 pagesEngine PDFpie031No ratings yet

- CFM 56-3 Specific Operating InstructionsDocument7 pagesCFM 56-3 Specific Operating InstructionsHubert LindenthalerNo ratings yet

- Motor GE CJ610-1Document4 pagesMotor GE CJ610-1César Pérez Perrusquía75% (4)

- 1G FUEL SYSTEM (DOHC) - Service Adjustment ProceduresDocument40 pages1G FUEL SYSTEM (DOHC) - Service Adjustment ProceduresAgus Prasetyanto100% (1)

- Powerroc T50 Start Up and Drilling Setting ProcedureDocument7 pagesPowerroc T50 Start Up and Drilling Setting ProcedurerolandNo ratings yet

- Manual Mitsubishi Pajero 4x4 Engine CoolingDocument18 pagesManual Mitsubishi Pajero 4x4 Engine CoolingGIAN CARLO MAMANI GILES.100% (1)

- Manual de Servicio Chery QQDocument55 pagesManual de Servicio Chery QQJose Rengel100% (2)

- Customer: HVN Type: A330 Rev. Date: Oct 01/11 Manual: AMM Selected Effectivity: ALL 71-00-00-860-817-A - Engine Operation Limits and GuidelinesDocument7 pagesCustomer: HVN Type: A330 Rev. Date: Oct 01/11 Manual: AMM Selected Effectivity: ALL 71-00-00-860-817-A - Engine Operation Limits and GuidelinesLê Viết DũngNo ratings yet

- Lycoming IO 360Document18 pagesLycoming IO 360Dita FebrianaNo ratings yet

- 9322A010Document5 pages9322A010BaytolgaNo ratings yet

- Governor (Types I, II, IV, and V) - CheckDocument5 pagesGovernor (Types I, II, IV, and V) - CheckDaniel TekleNo ratings yet

- 3E220557ADocument1 page3E220557AJerichoNo ratings yet

- Dynamo BasicsDocument8 pagesDynamo Basicserrrr1No ratings yet

- Solenoid Output Valve ModuleDocument6 pagesSolenoid Output Valve ModuleJerichoNo ratings yet

- CLI Rdos SFKB: Hubungan Antara Hardware Dan Software AdapsDocument1 pageCLI Rdos SFKB: Hubungan Antara Hardware Dan Software AdapsJerichoNo ratings yet

- Adaps StructureDocument1 pageAdaps StructureJerichoNo ratings yet

- Machine Vib Measurement PresentationDocument148 pagesMachine Vib Measurement PresentationJerichoNo ratings yet

- Power Supply SystemDocument10 pagesPower Supply SystemJerichoNo ratings yet

- Discrete OutputDocument3 pagesDiscrete OutputJerichoNo ratings yet

- Forex Trading TipsDocument30 pagesForex Trading TipsJericho50% (2)

- Forex Trading MachineDocument181 pagesForex Trading MachineJerichoNo ratings yet

- GFK 0898 FDocument420 pagesGFK 0898 FJerichoNo ratings yet

- Forex Trading TipsDocument30 pagesForex Trading TipsJericho50% (2)

- Calibration Procedure For Vibration Speed TrackingDocument2 pagesCalibration Procedure For Vibration Speed TrackingJerichoNo ratings yet

- Endevco Setup Jt8d ConfigDocument2 pagesEndevco Setup Jt8d ConfigpramasenjaNo ratings yet

- TCP-IP Ethernet Comm For 90Document195 pagesTCP-IP Ethernet Comm For 90JerichoNo ratings yet

- ADC816 m004405Document5 pagesADC816 m004405JerichoNo ratings yet

- Calibration Procedure For Vibration Speed TrackingDocument2 pagesCalibration Procedure For Vibration Speed TrackingJerichoNo ratings yet

- E1313A Users ManualDocument426 pagesE1313A Users ManualJerichoNo ratings yet

- Kerangka Hukum Negara Dalam Mengatur Agraria Dan Kehutanan Indonesia Mempertanyakan Sistem Ganda Kewenangan Atas Penguasaan TanahDocument17 pagesKerangka Hukum Negara Dalam Mengatur Agraria Dan Kehutanan Indonesia Mempertanyakan Sistem Ganda Kewenangan Atas Penguasaan TanahHerman Adriansyah AL Tjakraningrat83% (6)

- Action To Be Taken If Dyno Control Problem PersistDocument1 pageAction To Be Taken If Dyno Control Problem PersistJerichoNo ratings yet

- VxiDocument12 pagesVxiJerichoNo ratings yet

- Ethernet ConnectionDocument10 pagesEthernet ConnectionJerichoNo ratings yet

- Turbine Engine Design ConstructionDocument63 pagesTurbine Engine Design ConstructionJerichoNo ratings yet

- Recovery - Manual of Recovery StudioDocument229 pagesRecovery - Manual of Recovery StudiobobebostonNo ratings yet

- Kerangka Hukum Negara Dalam Mengatur Agraria Dan Kehutanan Indonesia Mempertanyakan Sistem Ganda Kewenangan Atas Penguasaan TanahDocument17 pagesKerangka Hukum Negara Dalam Mengatur Agraria Dan Kehutanan Indonesia Mempertanyakan Sistem Ganda Kewenangan Atas Penguasaan TanahHerman Adriansyah AL Tjakraningrat83% (6)

- Engineering Photovoltaic Systems 1 - 2010Document43 pagesEngineering Photovoltaic Systems 1 - 2010Joshua Pearce100% (9)

- Congress Day Two - Session 6 - Stephen Manda PDFDocument7 pagesCongress Day Two - Session 6 - Stephen Manda PDFHussein BoffuNo ratings yet

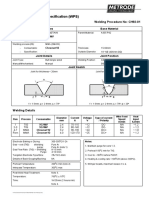

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- Bio BatteryDocument11 pagesBio BatteryGurubasamma LNo ratings yet

- EdExcel A Level Chemistry Unit 2 Paper Jan 2002Document9 pagesEdExcel A Level Chemistry Unit 2 Paper Jan 2002Ruwan BandaraNo ratings yet

- SIHI Uea CatalogueNew enDocument12 pagesSIHI Uea CatalogueNew enAlexander RivillasNo ratings yet

- Wiki Dye Sensitized Solar Cell-2Document12 pagesWiki Dye Sensitized Solar Cell-2singhadityaramNo ratings yet

- Emerging Trends in Electrical Engineering (22628)Document10 pagesEmerging Trends in Electrical Engineering (22628)Shreenath PujariNo ratings yet

- Mechanical SealDocument20 pagesMechanical Sealparchure123100% (3)

- Solar Project ReportDocument16 pagesSolar Project ReportGagan SharmaNo ratings yet

- 1-Adsorption Cooling System For Cold Storage Using Methanol Silicagel++++Document14 pages1-Adsorption Cooling System For Cold Storage Using Methanol Silicagel++++ali105No ratings yet

- Climatronic (AKL+AEH)Document8 pagesClimatronic (AKL+AEH)Istina GubitnikNo ratings yet

- Summer Internship ReportDocument19 pagesSummer Internship Reportmalikavita731No ratings yet

- EKHB Daikin Altherma Operation ManualDocument60 pagesEKHB Daikin Altherma Operation Manualangel_dos100% (1)

- PV System Energy Performance Evaluations SP7.6Document14 pagesPV System Energy Performance Evaluations SP7.6SohaibNo ratings yet

- 34 A Review of Power Quality ProblemsDocument10 pages34 A Review of Power Quality ProblemsVijay RajuNo ratings yet

- ChemistryDocument5 pagesChemistryapi-248750786No ratings yet

- 1.0 PT STP1 - BQDocument46 pages1.0 PT STP1 - BQdenny yusufNo ratings yet

- Compressed Gas Cylinders PowerPointDocument20 pagesCompressed Gas Cylinders PowerPointInspire KharianNo ratings yet

- CONTEMPORARY1Document13 pagesCONTEMPORARY1shienlyann.isanan15No ratings yet

- VCB SpecificationsDocument17 pagesVCB SpecificationsHarsh GuptaNo ratings yet

- Transformers - General InformationDocument4 pagesTransformers - General InformationGalco IndustrialNo ratings yet

- Variable Load Problems - KEYDocument1 pageVariable Load Problems - KEYChristian M. MortelNo ratings yet

- SSA 11 Kes Evoy - Workover Well KillDocument7 pagesSSA 11 Kes Evoy - Workover Well KillDavide Boreaneze100% (1)

- Obstruction Lighting GuideDocument64 pagesObstruction Lighting GuideJoseGarciaNo ratings yet

- Whitepaper Ground Potential Rise ExplainedDocument17 pagesWhitepaper Ground Potential Rise ExplainedHaresh RenkutlaNo ratings yet

- Module 5 Assignment: Creating Your Prototype WorksheetDocument3 pagesModule 5 Assignment: Creating Your Prototype WorksheetTARUN SHUKLANo ratings yet

- Water Turbine His To RZDocument6 pagesWater Turbine His To RZJosef LoLNo ratings yet

- 3 Hours / 70 Marks: Seat NoDocument3 pages3 Hours / 70 Marks: Seat NomeghrajkadamNo ratings yet