Professional Documents

Culture Documents

Lifecycle Assessment of Solar Thermal Collector

Uploaded by

Adnan Ahmed KidwaiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifecycle Assessment of Solar Thermal Collector

Uploaded by

Adnan Ahmed KidwaiCopyright:

Available Formats

Renewable Energy 30 (2005) 10311054

www.elsevier.com/locate/renene

Life cycle assessment of a solar thermal collector

Fulvio Ardente, Giorgio Beccali,

Maurizio Cellura*, Valerio Lo Brano

Dipartimento di Ricerche Energetiche ed Ambientali (DREAM),

Universita` di Palermo, Viale delle Scienze, 90128 Palermo, Italy

Received 9 March 2004; accepted 13 September 2004

Available online 23 November 2004

Abstract

The renewable energy sources are often presented as clean sources, not considering the

environmental impacts related to their manufacture. The production of the renewable plants, like

every production process, entails a consumption of energy and raw materials as well as the release of

pollutants. Furthermore, the impacts related to some life cycle phases (as maintenance or

installation) are sometimes neglected or not adequately investigated.

The energy and the environmental performances of one of the most common renewable

technologies have been studied: the solar thermal collector for sanitary warm water demand. A life

cycle assessment (LCA) has been performed following the international standards of series ISO

14040. The aim is to trace the products eco-profile that synthesises the main energy and

environmental impacts related to the whole products life cycle. The following phases have been

investigated: production and deliver of energy and raw materials, production process, installation,

maintenance, disposal and transports occurring during each step. The analysis is carried out on the

basis of data directly collected in an Italian factory.

q 2004 Elsevier Ltd. All rights reserved.

Keywords: Life cycle assessment (LCA); Renewable energy; Solar thermal collector

1. Introduction

All goods and services have an environmental impact along their life cycle. On this concept

the European countries have focused their attention, considering the improvement of

* Corresponding author. Tel.: C39 91 236 131; fax: C39 91 484 425.

E-mail address: mcellura@dream.unipa.it (M. Cellura).

0960-1481/$ - see front matter q 2004 Elsevier Ltd. All rights reserved.

doi:10.1016/j.renene.2004.09.009

1032

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

the eco-performances of products/services as a key point of the European environmental

programme [1]. In other words, global environmental problems can be met only if the use of

the energy and the raw materials per product unit will be reduced, i.e. eco-efficiency increased.

The need to strengthen the green market has been successively confirmed in another

official document named the green paper on Integrated Product Policy (IPP) [2]. Once a

product is put on the market, there is relatively little that can be done to improve its

environmental characteristics. The IPP approach seeks to reduce the environmental

impacts occurring throughout the entire life cycle of the product since the early stages

of product design and development. Furthermore, the diffusion of the green public

procurement should induce the producers to investigate the environmental impacts of

their production and to disseminate the environmental information adopting scientific data

format as the environmental product declaration (EPD) [3].

For IPP to be effective, life cycle thinking needs to become second nature for all those

who come into contact with products [4]. The cognitive process is at the basis of the

environmental performances improving. It is necessary to have detailed and reliable data

on which to base assessments regarding each life cycle step. Life cycle assessment (LCA)

represents an important support tool for IPP and the the best framework for assessing the

potential environmental impacts of products currently available [4]. To obtain reliable

results, data should be collected and managed following standardised procedures. The

international standards of series ISO 14040 represent a widespread accepted methodology

[57]. The best way to demonstrate the advantage of the life cycle thinking concept is by

demonstrating its practical application. The present paper focuses the attention upon one

of the most common renewable technologies: the solar thermal collectors for warm

sanitary water demand. Renewable energy sources are often presented as clean energy,

not considering the environmental impacts related to their manufacture. The production of

the renewable plants, like every production process, entails a consumption of energy and

natural resources as well as the release of pollutants [8].

Many authors have deeply investigated the benefits related to the employment of solar

systems [913] including studies regarding LCA of solar collectors and comparative

analyses of different collectors typologies [1419]. However, the studys assumptions or

data references are often not clearly shown. In addition, results are often presented as

aggregated indexes [1517] making difficult the comparison among different studies or the

dominance analysis of each life cycle step are difficult. Furthermore, some life cycle steps

(as, for example, installation or maintenance processes) are generally not investigated in

detail or are simply neglected. Some studies, in fact, consider the full LCA of a solar

collectors as too much expensive and time consuming [17] or suppose as significant only

the impacts related to materials processing and collectors assembling [18,19].

On the other hand, the principles of eco-design suggest to employ disaggregated

information to identify the steps with the greatest impacts and with the largest

improvements potentials [20,21]. The aims of this paper are:

to trace an eco-balance of an exemplary equipment, referring to a passive thermal. The

research refers to a passive thermal solar collector produced in Italy

to grant transparency of assumptions, system boundaries and data sources in order to

allow comparability to other studies

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

1033

to present results as much disaggregated as possible, in order to show the incidence of

each component and life cycle step and to avoid uncertainties related to weighting

processes and impacts assessment

The presented results are extracted from the case study CS2 performed within the

works of Task 27Subtask C of IEA (International Energy Agency) about Performance,

durability and sustainability of advanced windows and solar components for buildings.

Data regarding the production, the installation and maintenance phases have been directly

collected; thanks to the collaboration of an Italian firm [22]. The data collection has been

also referred to the Environmental Management System active in the production site. Data

regarding raw materials and energy sources have been referred, when possible, to Italian

mean values. When not available, data of other European databases have been employed.

2. The choice of the functional unit (FU)

The first phase of the LCA is the goal and scope definition. It includes an important

step: the clear statement of the functional unit (FU). The FU is defined as the reference

unit expressed as quantified performance of the product system [5]. The FU is important

as basis for data collection and for the comparability of different studies referred to the

same product category. The choice of the FU is not always immediate. In our case study

three different alternatives were checked [3]:

1. FU equal to the entire equipment. The results are presented as global quantities

concerning the whole collector. Probably, this is the most intuitive choice but it could

cause misunderstanding. In fact, there are various typologies of collectors, which can

be roughly divided in two main categories: collectors with forced circulating flow and

collectors with natural circulating flow.1 Performing the LCA related to these two

collectors types, the results could be not comparable.

2. Impacts per unit of collector area. This alternative may be misleading. Enlarging the

collector surface S, the specific environmental impacts (as, for example, the CO2/S)

could decrease. So, two collectors with the same total impacts could have different

specific ones. In fact, the collector with the greater surface would be considered as more

ecological not necessarily being. Furthermore, a greater extension does not imply a

proportional growth of the energy harvest, due to the non-linear relationship between

the collector surface and the collected energy.

3. Impact per unit of energy output. This alternative is generally chosen for energy

systems [23,24], because it refers to the environmental impacts of the energy

performances of the plant. However, it is difficult to apply this FU to the LCA of solar

collectors. The output of this system is an extremely variable data, depending on

1

The first one represents the normal flat collector whose thermal fluid is moved by a pump towards a separate

water tank. The second is a compact collector strictly connected to a smaller water tank, and the fluid is naturally

moved by the difference of density caused by the solar heating.

1034

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

the solar energy input. Confusion could arise referring the impacts to the energy output

because the same collector could have a different eco-profile depending on the location.

Our LCA case study refers to the first FU alternative, and the environmental impacts are

related to the whole collector.

2.1. The studied system

The studied FU is one solar thermal collector (dimensions: 2.005!1.165!0.91 m)

with a total net surface of 2.13 m2. The FU is constituted by three main components:

The absorbing collector (including the main framework, the absorbing plate and the

pipes for the thermal fluid flow);

The water tank (including the heat exchanger, the coverage, the electrical resistance

and the inner pipes for the sanitary water flow);

The external support (employed to fasten the system on the houses roof).

The collector belongs to the category of passive solar device. The water tank and the

absorbing surface are strictly connected, constituting a unique unit, and the thermal fluid

circulation occurs with the natural convection. The internal fluid circuit does not need

pumps and it does not cause power energy consumption. This typology of collector is

particularly recommended for small domestic plants with a mediumlow demand of

sanitary warm water.

The water tank and the collector can be directly installed on sloping roofs. The

producing company also furnishes an optional steel support that allows the installation on

flat roofs. This constructive typology being common in Italy, the external support has also

been included into the FU (see Fig. 1).

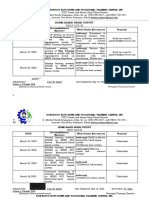

Fig. 1. Solar thermal collector with water tank and support.

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

1035

Impacts related to the three components have been disaggregated to grant the

transparency of the study and to define a dominance analysis referring to the main

components of the plant.

2.2. Technical peculiarities and mass detail

The collector framework is made of painted galvanised steel (0.003 m width). A blackpainted copper plate, welded with pipes for the thermal fluid flow, constitutes the

absorbing surface. An aluminium frame with high-reflectance coefficient to increase the

collectors efficiency protects the plate. The thermal insulation is granted by high-density

polyurethane-PUR foam (0.03 m width).

The collector is covered by high-transparent tempered single glass with low iron-oxides

percentage. The glass (0.004 m width) is shock-proof and it is hermetically fastened to the

framework. To reduce heat losses, vacuum is created inside the collector.

The water tank has 0.16 m3 of capacity and it mainly consists of a galvanised steel

framework. It is protected by the stainless steel coverage, and it is placed on the top of the

collector. The space within the water tank and the external coverage is filled with highdensity PUR foam. There are two circuits for the fluid flows: the heat carrier circuit and the

sanitary water circuit. The thermal fluid is a mixture of water (5080%) and propylene

glycol (2050%) that avoids freezing problems during the cold season. It has been

supposed to use a 50% mixture. The fluid mixture flows along a cylindrical interstice that

works as heat exchanger. The water tank encloses a magnesium anode (to reduce the

corrosion) and an electrical resistance. In the studied FU, this auxiliary resistance is not

computed as a water tanks part but it is considered separately (in the section other

components). So, it is easier to state the incidence of this component on the global ecoprofile.

The section other components also includes the materials for packaging (cardboard

and the low density polyethylene, LDPE) and the external high-density polyethylene

(HDPE) pipes used to connect the collector to the water tank.

Galvanised steel bars, together assembled and fastened to the collector by means of

bolts and screws, constitute the support. Table 1 shows the details of employed materials

and masses.

3. Analysis of life cycle phases

The following sections describe the studys assumptions and the related energy and

environmental impacts occurring during the collectors life cycle. The following phases

have been investigated: production and delivery of energy and raw materials, production

process, installation, maintenance, disposal and transports occurring during each step.

3.1. Transports

As mentioned above, the FU is mainly composed of metallic and plastic

components.

1036

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

Table 1

Details of employed materials and masses

Absorbing collector

Water tank

Material

Mass (kg)

Material

Mass (kg)

Material

Mass (kg)

Material

Mass (kg)

Galvanised

steel

Glass

33.9

Galvanised

steel

Stainless

steel

Rigid PUR

Thermal

fluid

Copper

Epoxy dust

Steel

Welding rod

Brass

Magnesium

49.6

Galvanised

steel

Stainless

steel

27

Cardboard

LDPE

3.0

0.8

HDPE

Copper

0.87

0.46

10.5

Copper

Stainless steel

8.2

6.1

Rigid PUR

Aluminium

Thermal fluid

Epoxy dust

Welding rod

Brass

Flexible PUR

PVC

Total

4.2

4

0.9

0.3

0.1

0.04

0.01

0.01

68.2

Support

21.0

Other parts

0.5

4.8

5.4

3.8

0.7

0.4

0.2

0.1

0.2

86.2

27.5

5.1

As it is not possible to determine the exact amount of travels for the production of

the solar collector, the tkm is assumed as functional unit for trucks transport.

It represents the energy and environmental impacts referred to the transport of 1000 kg of

products for 1 km route [25]. The impacts are then calculated by means of the masses and

the distances.

It has been assumed that every transport occurs by means of trucks with 28,000 kg

capacity. A different assumption regards the glass transport, purchased from a foreign

company, that is supposed transported by medium and high-capacity trucks. Having not

further information, it has been supposed an averaged condition of half load transport for

double way. Specific impacts related to trucks have been referred to Italian studies

performed by the Italian Agency for the Environment Protection [25,26].

Regarding all the input materials employed during the life cycle steps and considering

the mean distance values, it has been estimated a global transport load of 154 tkm. Details

of estimated air emissions are shown in Table 2.

3.2. The production process

Data regarding the collectors production process have been collected; thanks to a field

analysis. The production process concerns mainly in metals transformation and in

assembling them with other externally worked parts (generally, little plastic or metal

auxiliary parts). The three main components (absorbing collector, water tank and support)

are produced in different periods, then packed and stored in warehouses (Fig. 2).

Successively, external companies sell the collectors, attending to transport and install

them to final users.

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

1037

Table 2

Estimated transports air emissions

Transports air emissions

C6H6 (mg)

C20H12 (mg)

CO2 (kg)

Cd (mg)

NMVOC (g)

CH4 (mg)

CO (g)

NOx (g)

SO2 (g)

Pb (mg)

Particulate (g)

N2O (g)

Zn (g)

5.9

0.03

20

0.3

27.4

890.4

56.4

259.7

16.9

2.1

14.2

2.8

0.9

3.2.1. Production of the absorbing collector

The absorbing collector consists mainly of three parts: the framework, the absorbing

plate (including the pipes for the thermal fluid flow) and the glass.

The framework is obtained using a zinc steel plate. After cutting and bending, it is

glazed with epoxy powders. Both the absorber plate and pipes are copper made. The pipes

are separately worked and then welded to the plate by acetylene welding. Having no

available data about acetylene welding, air emissions have been not computed. However,

little quantities of acetylene are used and consequently air emissions can be neglected.

Absorber and pipes are then black painted to increase their absorbance. The absorbing

plate, the framework and the glass are successively assembled together. Finally, PUR

insulation is blown and the external framework is painted with epoxy powders.

Fig. 3 shows the production process flow-sheet with the succession of employed

materials and numbered sub-processes. Each sub-process has been analysed to state the

energy and mass flows (Fig. 4 shows the details of the process number C.1 representing the

production of the external collectors framework).

3.2.2. Production of the water tank

The water tank mainly consists of three parts: the framework, the interstice and the

external covering. The water tank is made using a galvanised steel sheet cylindrical shaped

(diameter 0.444 m). The side parts are welded to this cylinder. A flange is annexed to one

Fig. 2. Solar collector production flow.

1038

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

Fig. 3. Collector manufacture, process flow-sheet.

side: this flange works as support for the electrical resistance, the magnesium anode and

the coil copper pipe. Successively, another cylindrical steel sheet is externally welded to

the water tank. The thermal fluid flows inside this interstice and exchanges heat with water

tank.

The external covering is separately produced and painted. Finally, the water tank parts

are assembled together and PUR is injected into empty spaces.

Fig. 5 shows the production process flow-sheet with the details of masses and subprocesses.

3.2.3. Production of the support

The support consists of various steel bars. These are cut, drilled and finally fastened

together with bolts. Fig. 6 shows the production process flow-sheet with the details of

masses and sub-processes.

Fig. 4. Details of collectors framework production.

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

1039

Fig. 5. Water tank manufacture, process flow-sheet.

3.3. Air emissions in the factory

Power energy being the only energy source directly employed during the production

process, there are not direct emissions from fossil fuels combustion. The production

(mainly concerning with cutting and drilling processes) causes the production of scraps

and metallic dusts. However, it has not been possible to state the exact quantities of

released dusts. On the basis of data coming from the Environmental Management System,

dusts have been indirectly estimated as percentage (about 1.5%) of the process scraps

mass. Particular emissions are produced during the plasma cutting, the coating and

Fig. 6. Support manufacture, process flow-sheet.

1040

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

Table 3

Main air-emissions due to welding

Collector

Used electrode (kg)

Air emissions

Cr (mg)

Cr (VI) (mg)

Mn (mg)

Ni (mg)

Water tank

0.1

0.2

0.3

0.1

99.1

0.4

0.6

0.2

198.2

0.8

the welding. These processes are described in the following paragraphs. No water

emissions have been detected.

3.3.1. Shielded metal arc welding

Shielded metal arc welding (SMAW) is employed to weld together various collectors

parts with welding rods. The elemental composition of the fumes varies with the electrode

type and with the work-piece composition. Hazardous metals have been recorded in

welding [27].

Following the US welding classification, it has been assumed to use the welding rod

class E6010. The specific air pollutants, produced consuming 1 kg of rod E6010, mainly

include: Mn (9.91!10K1 g/kg); Ni (0.04!10K1 g/kg); total Cr (0.04!10K1 g/kg) [27].

Table 3 shows welding emissions related to the water tank and the collector production.

3.3.2. Plasma cutting

Regarding dry plasma cutting of 0.008 m plate we estimate, for stainless steel, the

global release of 3040!10K3 kg of fumes per cutting minute and, concerning mild steel,

the release of 2026!10K3 kg of fumes per cutting minute [28]. Table 4 shows the main

components of fumes in dry plasma cutting [28].

Dry plasma cutting is used in the water tank production to cut and drill some stainless

and mild steel plates. As the amount of emission increases increasing the plate thickness

[28], a linear variation of fumes with thickness has been supposed. The used plates have a

thickness of 0.003 m. Concerning the composition of fumes, average values of Table 4

have been chosen. Calculated emissions are summarised in Table 5.

3.3.3. Surface coating

The production process includes the application of epoxy powders. The coating is

applied by melting the powder on the surfaces. The employed epoxy powders had

Table 4

Composition emission in plasma cutting [18]

Main components of fumes in dry plasma cutting

Mild steel (0.008 m)

Stainless steel (0.008 m)

Fe (%)

Mn (%)

Cr (%)

Ni (%)

Cu (%)

Mo (%)

6773

3844

210

410

1220

48

01.4

26

01

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

1041

Table 5

Plasma cuttingglobal air emissions

Mild steel

Cutting time (min)

Stainless steel

16.5

4.5

Pollutant

Mild steel

Stainless steel

Total (g)

NOx (g)

Fe (g)

Mn (g)

Ni (g)

Cr (g)

Cu (g)

Mo (g)

42.6

99.6

8.5

26.6

24.2

4.1

3.5

9.5

2.4

0.6

69.2

123.8

12.7

3.5

9.5

3.4

0.6

1.0

a content of about 7 g of volatile organic compounds per kilogram. Emissions from surface

coating for an uncontrolled facility could be estimated by assuming that all the VOC are

emitted [29]. The coating air emissions are summarised in Table 6.

3.4. Installation

The installation consists of the following steps:

Transport of the FU from the factory to storehouses for the sale by retail;

Transport from storehouse to the user place;

Installation of FUs parts.

Transports from factory to storehouses employ various trucks. Also the destinations are

variable (depending on the selling companies places). For these reasons, the following

average conditions have been assumed:

Functional unit: 1 tkm of 28,000 kg capacity truck;

Covered distance (double way): 100 km.

The FU is transported from storehouse to the user place by van of 3500 kg capacity.

Generally, the company makes one travel for each collector. The average covered distance

(double way) is 30 km. The installation consists of:

To fasten the support on the roof;

To fasten the water tank and the collector to the support.

Table 6

Air emissions of epoxy dust coating

Used epoxy dust (kg)

COV content (g/kg)

Air emissions

Estimated COV emission (g)

Collector

Water tank

0.350

7

0.730

7

2.45

5.11

1042

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

Table 7

Installation transports air emissions

Transports air emissions

C6H6 (mg)

Benzopirene (mg)

CO2 (kg)

Cd (mg)

NMVOC (g)

CH4 (mg)

CO (g)

NOx (g)

SO2 (g)

Pb (mg)

Particulate (g)

N2O (g)

Zn (g)

0.72

0.004

10.17

0.06

12.79

318

46.24

61.23

4.44

0.25

12.43

0.87

0.11

Specific impacts related to transports refer to Italian studies [25,26]. Table 7

shows the calculated transports air emissions. Regarding the drilling operations during

the fastening, it has been measured the consumption of 0.5 MJ of low voltage

electricity.

3.5. Maintenance

As suggested by the selling company we have supposed that the FU would have an

average useful life of 15 years. In absence of rare external damages (as the glass break), the

FU does not necessitate frequent maintenance. The ordinary cycles consist of one

operation every 45 years (in all 23 operations during the FUs useful life). Regarding the

maintenance phase, main assumptions are:

Two maintenance operations (after 5 and 10 years from the purchasing);

Travels of maintenance technicians (overall distance 80 km by diesel car);

Each operation includes the substitution of the following components:

PVC gaskets;

Sealing;

Magnesium anode;

Electrical resistance;

Thermal fluid (50% water; 50% propyleneglycol)

Air emissions produced during the transports are summarised in Table 8.

3.6. Disposal

The FUs manufacture causes the production of scraps and wastes (the amount is

4.4 kg, excluding the packagings that wrap raw materials). The company periodically

deliver the wastes to a company that takes care about disposal.

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

1043

Table 8

Maintenance phases transports air emissions

Global distance

80 (km)

NH3 (mg)

Cd (mg)

CO (g)

CO2 (kg)

Cr (mg)

Particulate (g)

SO2 (g)

Zn (g)

CH4 (mg)

N2O (g)

Ni (mg)

COV (g)

NOx (g)

Cu (g)

Se (mg)

80.0

0.03

28.0

9.2

0.14

3.20

2.88

0.003

480.0

0.80

0.20

4.40

22.0

0.005

0.03

Regarding the FUs disposal, no data are available. In fact, the company started the

production of solar collectors few years ago and, consequently, the sold collectors have not

yet reached their end-life. Furthermore the producing company have not started any

project regarding the collectors recycling (for example, the users could return the

collectors to the factory and the collectors could be successively disassembled in their

components). In particular the metallic components (representing more than 80% of the

total mass) could be potentially recycled.

Having no further information, the recycling of materials has been neglected. It is only

supposed that solar collectors would be collected and disposed to the nearest landfill by

truck (50 km double way). Suppose the transports occur by 28,000 kg truck, the release of

1.4 kgCO2 and few quantities of other pollutants has been estimated. Impacts related to the

landifill management have not been considered.

4. Energy analysis

The energy analysis concerns with the energy flows occurring during the life cycle of

the product. The energy consumption could be split into direct energy and embodied

energy. Direct is the energy directly used during a life cycle step (for example, it

includes the electricity or heat energy employed during the production, the fuel for

transports, etc.). Embodied is the energy consumed by all the processes associated with

the production of the materials employed as FUs inputs.

Besides, it is necessary to state how much of the energy consumption is related to the

feedstock rate. This is defined as heat of combustion of raw material inputs, which are

not used as an energy source, to a product system [6]. The feedstock quantifies the

potential of materials (as wood or plastics) to deliver energy when they are burned with

heat recovery after their useful life. The overall energy consumption can be obtained

1044

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

Table 9

Direct energy consumption

Direct energy consumption

Electricity MV

Absorbing collector

Water tank

Support

Total

Electricity LV

Installation

Total

Diesel (for transports)

Materials (process input)

Installation

Maintenance

Disposal

Total

End-energy

Primary energy

66.6 MJ

113.0 MJ

9.6 MJ

191.0 MJPrim

324.0 MJPrim

27.6 MJPrim

542.6 MJPrim

0.56 MJ

1.8 MJPrim

1.8 MJPrim

6.62 kg

3.30 kg

2.96 kg

0.45 kg

346.5 MJPrim

172.7 MJPrim

155.1 MJPrim

23.6 MJPrim

697.9 MJPrim

multiplying the used energy quantities by the calorific value. Following the suggestions of

the Italian Environment Protection Agency (ANPA), all the energy calculations refer to

the gross calorific value for fuels [30]. The following paragraphs show in detail the energy

consumption during all the life cycle phases.

4.1. Direct energy consumption

The FUs LCA has involved two direct energy consumptions: the electricity used for

the production (medium voltage) and installation (low voltage) and the diesel oil used for

transports (during every life cycle phase).

However, the energy quantities described in the previous paragraphs are end-energy

quantities, meaning the energy quantities consumed by final users. All these quantities

have to be valued as primary, defined as the energy embodied in natural resources (e.g.

coal, crude oil, sunlight, uranium) that has not undergone any anthropogenic conversion or

transformation [31]. The secondary sources can be transformed into primary quantities by

means of specific conversion factors. They represent the effective MJs of energy that are

necessary to deliver one MJ of energy to users, including all the energy losses occurring

during the energy source life cycle.2 Table 9 summarises direct energy consumption in

terms of end-energy and primary-energy.

2

The production of electricity refers to the Italian energy mix during the period 19901994 [26]. Data include

all the energy losses occurring in the following phases: extraction, treatment and transport of fuels, production and

distribution of electricity, construction and disposal of structures. It has been assumed the following conversion

factors: low voltage electricity (3.21 MJPrim/MJEnd) and medium voltage electricity (2.87 MJPrim/MJEnd).

Regarding diesel oil for transport, it has been assumed a conversion factor of 1.16 MJPrim/MJEnd. It includes all

the energy losses occurring for extraction, refining and transport of diesel up to the filling station [32].

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

1045

Table 10

Embodied energy consumption

Embodied energy of materials

Fuel (MJprim)

Collector

Water tank

Support

Other

(HDPE pipes-resistance)

Other (packaging)

Maintenance

Total (MJprim)

Feedstock (MJprim)

Total (MJprim)

3297.1

3641.0

1066.4

64.9

215.3

485.9

41.7

3512.5

4126.9

1066.4

106.7

147.0

544.1

8760.6

141.9

627.2

1512.1

289.0

1171.3

10,272.7

4.2. Embodied energy consumption

Analogous to the direct energy consumptions, also the embodied energy consumptions

have to be computed as primary. Table 10 summarises the primary energy demand for all

the employed raw materials. Data regarding the embodied energy of materials refers to

the Italian official environmental database [26]. Missing data are taken from other sources

[32,33]. General assumptions are:

Missing information about Italian stainless steel, it has been referred to average steel

data;

The producing company employs glass with low iron oxides. Missing information

about this glass, it has been referred to common float glass for windows;

The company uses epoxy powders as coating. Missing information about these

powders, data have been referred to epoxy resin. However, epoxy powders are about

0.6% of the overall empty mass and they could be neglected, following 1% cut-off

criteria [5].

No information is available about the eco-profile of welding rods. However, the rod

mass is very low (less than 0.2% of the overall mass) and it has been neglected in the

calculations.

4.3. Global energy consumption

The global energy consumption is obtained by adding embodied and direct

contributions (Figs. 7 and 8). Table 11 shows the energy consumption (split in the

energy carriers). It is possible to point out that:

The global energy consumption is 11.5 GJPrim. The direct energy consumption is only

11%, while the indirect is 89%.

The energy consumption for the production (542.6 MJPrim of electricity) is less than 5%

of the global consumption. This value shows the low incidence of the factory process on

the global energy balance.

1046

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

Fig. 7. Global energy consumption (feedstock and fuel energy demands).

The energy consumption (direct and indirect) related to the water tank manufacture is

about 4.4 GJPrim (38.6% of the global). The production of the collector has a similar

energy demand (3.7 GJPrim and 32% of the global) while the support involves a lower

consumption (about 1.1 GJprim).

Installation and disposal have a low incidence. The computed impacts are mainly

related to transports. About the installation, it is possible to observe that the support is

used for flat-roof installation (and it is the most common case in our region). If the

support is considered as belonging to the installation, its contribution will be about

11.5% of the global consumption.

Fig. 8. Global energy consumption (direct and embodied contributions).

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

1047

Table 11

Main energy and resource consumption

Primary energy consumption

Not renewable sources

Coal (kg)

Natural gas (N m3)

Coke (kg)

Wood (kg)

Lignite (kg)

Oil (kg)

Uranium (kg)

Renewable sources (MJ)

Fuel energy (GJ)

Feedstock energy (GJ)

Total primary energy (GJ)

193.7

42.8

1.5

7.6

39.2

88.8

0.001

673.8

10.0

1.5

11.5

The inclusion of other parts (copper resistance and HDPE-pipes) needs of a further

0.2 GJPrim (0.9% of the global). The packaging has, instead, a greater influence

(0.6 GJPrim and 2.5% of global).

Maintenance involves a significant energy consumption (about 11.5% of the global). This

is caused by the use of spare parts (and, in particular, by the substitution of thermal fluid).

The propyleneglycol is an oil-derived fluid and it involves a primary consumption of

77.4 MJprim/kg. Furthermore, this fluid is largely employed in the collector (about 19 kg

all over the life cycle). Consequently, the global use of this fluid has a great incidence

on the results (about 13% of the global consumption).

Transports cause the consumption of about 700 MJprim (6.1% of the global).

Feedstock consumption is about 13% of the global (and about 15% of the indirect

contribution). This energy could be theoretically recovered when materials are burnt

(with heat recovery) after their end-life. Actually, about 60% of feedstock is related to

the use of propyleneglycol; this fluid is mixed to water in the thermal fluid and,

generally, it is wasted without any treatment.

5. Environmental impacts

The main environmental impacts can be included in the following classes:

Resources consumption;

Air emissions;

Water emissions;

Wastes and solid pollutants.

Environmental impacts have been divided into direct and indirect. Direct impacts are

those directly related to the production process and to transports. Indirect are the impacts

related to the production of process inputs (as raw materials and energy sources). The FUs

manufacture caused the direct emission of some air pollutants and the production of

1048

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

Table 12

Resource consumption

Main resources consumption

Ferrous minerals (kg)

Water (m3)

Iron scraps (kg)

Bauxite (kg)

CaCO3 (kg)

Copper minerals (kg)

NaCl (kg)

Zinc (kg)

Sand (kg)

Copper scraps (kg)

Lime (kg)

Clay (kg)

Nitrogen (kg)

293.5

31.6

47.3

14.9

14.3

8.2

7.7

6.8

6.4

5.4

2.0

1.3

1.2

a small quantity of wastes. Emissions related to the production of diesel fuel have been

neglected: these emissions are very low with respect to those related to the fuel

combustion [26].

5.1. Resources consumption

The life cycle analysis has shown an overall consumption of about 415 kg of resources.

The employed materials are summarised in Table 12. It is possible to observe that they are

mainly constituted by ferrous minerals: it reflects the FUs composition mainly made by

steel parts.

5.2. Air emissions

Table 13 shows the direct and indirect air emissions. In detail, we could observe that

The overall CO2 emission is about 650 kg;

Indirect emissions are generally dominant and they are mainly related to the raw

materials production (with an incidence of about 8090%). The other emissions

(related to the production and transports) have an overall incidence of 1020%.

Direct emissions of some metal pollutants (as Fe, Mn, Mo, Cr) related to the

production process are dominant. These emissions are mainly due to cutting and

welding phases.

5.3. Water emissions

Water emissions are only indirect (in fact, neither the production process nor the

transports have water contact). Table 14 shows the main pollutants. Organic releases

amount to 18 kg of chemical oxygen demand (COD); other emission are mainly little

quantities of metallic ions.

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

1049

Table 13

Direct and indirect air emissions

Indirect

CO2 (kg)

CO (kg)

SO2 (kg)

CH4 (kg)

NOx (kg)

Dust (kg)

NMCOV (kg)

Mn (kg)

Fe (kg)

N2O (g)

HCl (g)

Cr (total) (g)

Ni (g)

Cu (g)

Zn (g)

HF (g)

NH3 (g)

Mo (g)

Pb (g)

PAH (g)

Benzene (mg)

Cd (mg)

Direct

Raw materials

Electricity

Transports

580.4

4.4

3.3

2.1

1.3

0.5

0.2

0.0001

0.0004

20.9

35.0

0.01

0.3

0.01

2.3

2.5

2.5

0.003

0.5

0.2

529.0

125.4

35.8

0.01

0.2

0.05

0.1

0.02

0.05

40.8

0.1

0.03

0.002

0.4

0.03

0.03

5.6!10K7

1.5

1.1

0.004

Total

Production

process

0.1

0.07

0.01

0.3

0.1

1.9

0.0003

0.0004

0.005

1.0

10.7

4.7

3.4

0.2

0.03

0.6

0.012

0.001

87.3

1.3

0.003

7.1

0.1

657.0

4.5

3.6

2.2

1.8

0.6

0.3

0.3

0.1

24.3

36.1

10.7

5.1

3.4

3.3

2.6

2.5

0.6

0.5

0.2

623.4

126.9

5.4. Wastes

Wastes directly produced by company are about 4.4 kg. The overall produced wastes

are summarised in Table 15.

Table 14

Water emissions

Water pollutants

COD (kg)

Fe (g)

Mg (g)

K (g)

NH3 (g)

Phosphorus (g)

Cr (g)

Pb (g)

Na (g)

Ni (g)

Mn (g)

Cd (mg)

Hg (mg)

18.1

49.8

16.4

7.8

4.8

1.4

1.1

0.5

0.4

0.4

0.3

5.4

4.0

1050

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

Table 15

Wastes production

Wastes production

Normal wastes (kg)

Special wastes (kg)

Ashes (kg)

59.5

5.2

6.8

5.5. Potential environmental impacts

The eco-profile of the collectors can be summarised employing the following potential

environmental indexes:

Global warming potential (GWP);

acidification potential (AP)

ozone depleting potential (ODP);

nutrification potential (NP)

photochemical ozone creation potential (POPC)

These indexes have been calculated employing the characterisation factors regarding

the compilation of the Italian Environmental Product Declaration (EPD) [30]. Results are

summarised in Table 16.

6. Energy and CO2 payback times

The energy payback-time (EPT) can be defined as the time necessary for a solar equipment

to collect the energy (valued as primary) equivalent to that used to produce it [34]

EPT Z

LCAenergy

Euseful K EUse

(1)

where

LCAenergy primary energy consumed during all the life cycle phases (GJ);

Euseful yearly useful saved energy (GJ per year);

Euse energy employed during the use of the renewable system (GJ per year).

Table 16

Potential environmental impacts

Potential environmental impacts

GWP (kgCO2 eq.)

AP (kgSO2 eq.)

ODP (kgCFC-11 eq.)

NP (kg3K

PO4 eq.)

POPC (kgC2H4 eq.)

721

5

Negligible

0.7

0.4

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

1051

In passive collector systems the water circulation occurs naturally and, consequently, the

Euse is null. The energy saving referred to the use of solar collector has been calculated

considering the average temperatures and solar inputs of the city of Palermo (Italy, 388

latitude) [3,9]. The useful primary energy saving Euseful is estimated 6.6 GJ per year [34].

The payback-time related to the studied equipment results lower than 2 years. This value

shows the great energy convenience of such technology.

Knowing the yearly Euseful, we have also calculated the yearly emission saving (EMSi).

It represents the emissions that the auxiliary system would produce to deliver as much

energy as that saved by means of the solar collector. The EMS depends on the typology of

the employed auxiliary heater. The global impacts during the life cycle and the emission

saving are summarised by the emission payback-time (EMPT). It is defined as the

time during which the avoided emissions due to the employment of the solar plant are equal

to those released during the production and use of the renewable plant itself. It is possible to

calculate the EMPT relatively to the pollutant i as [34]

EMPTKi Z

EMi

EMSKi K EMUSEKi

(2)

EMi global emissions of generic pollutant i related to the production, assembly,

transport, maintenance and disposal of the solar plant (kgi);

EMSi yearly emission saving of generic pollutant i (kgi/year);

EMUSEi yearly emission of pollutant i related to the use of the renewable plant (kgi/year).

The EMuse could be caused by the use of the conventional energy that the plant needs to

work (mainly the electricity used by pumps). In passive collectors the EMuse term is null.

The global warming potential (GWP) related to the collector life cycle is 721 kgeq.CO2

(see Table 16). Considering a domestic gas boiler as auxiliary system, it is assumed a

specific global warming factor of 65.7!10K3 kgeq.CO2 per MJ of useful heat [26]. The

yearly CO2-eq. emission saving is estimated to be 407 kgeq.CO2 [34]. Similarly to the energy

payback-time, even the CO2 payback-time resulted lower than 2 years.

The positive judgements revealed by the low values of energy and CO2 payback times

substantially agree with the results of different studies [14,1719].

7. Conclusions

The present report shows the results of an LCA performed upon a solar thermal collector.

Production process, installation, maintenance, transports and disposal are checked.

The collected information could become an important starting point to improve the

ecological performances of the product. It is important to carry out a database of FUs

environmental performances as a powerful tool for the eco-oriented design. On the other

hand, we would like to point out that the life cycle thinking is basic in the design for

environment but the final decision regarding the product cannot be just environmental

oriented. Other aspects like cost, physical lifetime, and energy performances are important

1052

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

factors underpinning customers preferences. To achieve a more realistic evaluation, it is

important to consider a set of core criteria in addition to the main function, keeping in mind

that designers generally do not give top priority to the environmental matters. In this respect,

design for environment means to take environmental issues into account without

compromising the other features of the product and to seek a balance among all the

competing requirements.

Regarding the studied FU, it has been estimated an overall primary energy consumption

of 11.5 GJ. However, the energy directly used during the production process and installation

is only the 5% of the overall consumption; another 6% is consumed for transports during the

various life cycle phases. The remaining percentage is employed for the production of raw

materials, used as process inputs. These results show that the direct energy requirement is

less important than the indirect one (in fact, the production processes consist mainly in

cutting, welding, bending and assembling steps with a low energy demand). Consequently,

including or neglecting some materials, the results will be sensibly modified. For example

excluding the collectors support, the primary demand decreases of 1 GJ (10% of the overall

consumption). Furthermore, maintenance can involve a large primary energy consumption

related to the substitution of spare parts. Two maintenance cycles has been supposed with an

overall primary energy demand of 1.1 GJ.

The production of the solar collector causes mainly direct emissions of metals (Fe, Mn,

Mo, Cr, etc.) related to cutting and welding phases. Regarding the other pollutants, it is

possible to comment in a similar way as done in the energy analysis. In fact, the indirect

emissions (related to production of raw materials) are about the 8090% of the overall

releases, and the results sensibly depend on the materials included in the calculations. Direct

emissions related to transports have an incidence of 1015%. Water soil releases and wastes

are very low.

As previously shown, it is very important to clearly define the studys boundaries and the

involved materials. To grant transparency of results, the study has been presented as much

disaggregated as possible and all the studys assumptions have been described in detail. It is

possible to separate all the contributions and follow all the calculation steps, to modify the

initial hypothesis (e.g. excluding or adding some components) and to re-calculate the LCA

results.

The last part of the study focused on the calculation of energy and CO2 payback times.

According to the results of other authors, these indicators resulted very low (less than 2

years) showing the great environmental convenience of this technology.

References

[1] Commission of the European Communities. Sixth environment action programme of the European

community. Environment 2010: our future, our choice. Communication from the Commission to the Council,

COM 2001, 31 Final.

[2] Commission of the European Communities. Green paper on integrated product policy, COM 2001, 68 Final.

[3] Ardente F, Beccali G, Cellura M, Lo Brano V. The environmental product declaration EPD with a particular

application to a solar thermal collector. Proceedings of conference ECOSUD 2003, Siena; 46, 2003.

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

1053

[4] Commission of the European Communities. Communication from the Commission to the Council and the

European ParliamentIntegrated product policy building on environmental life-cycle thinking, COM 2003,

302 Final.

[5] ISO14040. Environmental managementLife cycle assessmentPrinciples and framework; 1998.

[6] ISO14041. Environmental managementLife cycle assessmentGoal and scope definition and inventory

analysis; 1999.

[7] ISO 14042. Environmental managementLife cycle assessmentLife cycle impact assessment; 2000.

[8] Goralczyk M. Life cycle assessment in the renewable energy sector. Appl Energy 2003;75:20511.

[9] Duffie JA, Beckman WA. Lenergia solare nelle applicazioni termiche (Italian language), Liguori ed.; 1978.

[10] Diakoulaki D, Zervos A, Sarafidis J, Mirasgedis S. Cost benefit analysis for solar water heating systems.

Energy Convers Manage 2001;42:172739.

[11] Souliotis M, Tripanagnostopoulos Y. Experimental study of CPC type ICS solar systems. Solar Energy 2004;

76:389408.

[12] Tripanagnostopoulos YGT, Souliotis MK, Battisti R, Corrado A. Application aspects of hybrid PV/T solar

systems. ISES solar world congress 2003, Goteborg, Sweden; June 1419, 2003.

[13] Kalogirou SA. Solar thermal collector and applications. Progr Energy Combust Sci 2004;30:23195.

[14] Wagner HJ. Ermittlung des primaerenergieaufwanfes und Abschaetzung der emissionen zur Herstellung und

zum Betrieb von ausgewaehlten absorberanlangen zur Schimmbadwasserwaermung und von Solarkollectoranlangen zur Brauchwassererwaermung (German language),VDI Berichte, Reihe 6, no. 325; 1995.

[15] Veenstra A, Oversloot HP, Spoorenberg HHR. The environmental performance of solar energy systems and

related energy saving installations. Dissemination workshop of the International Energy Agency (IEA)Task

27Performance of Solar Facade, Copenhagen; April 2002.

[16] Andresen I, Thyholt M, Geissler S, Rappl B. Sustainable use of aluminium in buildings. Report no. 1:

overview of research studies. SINTEF civil and environmental engineering architecture and building

technology, Norway. Report no. STF22 A01525. p. 2548.

[17] Tsilingiridis G, Martinopoulos G, Kyriakis N. Life cycle environmental impact of a thermosyphonic domestic

solar hot water system in comparison with electrical and gas water heating. Renewable Energy 2004;29:

127788.

[18] Mirasgedis S, Diakoulaki D, Assimacopoulos D. Solar energy and the abatement of atmospheric emissions.

Renewable Energy 1996;7(4):32938.

[19] Crawford RH, Treloar GJ. Net energy analysis of solar and conventional domestic hot water systems in

Melbourne, Australia. Solar Energy 2004;76:15963.

[20] Ardente F, Beccali G, Cellura M. Eco-sustainable energy and environmental strategies in design for recycling:

the software ENDLESS. Ecolog Modell 2003;163:10118.

[21] Ardente F, Beccali M, Cellura M. FALCADE: a fuzzy software for the energy and environmental balances of

products. Ecolog Modell 2003;176(34):35979.

[22] Ardente F, Beccali G, Cellura M, Lo Brano V. Life cycle analysis of solar thermal collector (first part: life

cycle inventory). First report of the International Energy Agency (IEA)Task 27Performance of solar

facade, Subtask CProject C1 environmental performance; March 2003.

[23] The Swedish Environmental Management Council. Product-specific requirements (PSR)Electricity and

district heating generation; 2001.

[24] The Swedish Environmental Management Council. Product-specific requirements (PSR)Electrical

manipulating industrial robot; 2002.

[25] ANPAItalian National Agency for Environment Protection. Banca dati italiana a supporto della valutazione

del ciclo di vitaManuale settore trasporti (Italian language); 2000.

[26] ANPAItalian National Agency for Environment Protection. Banca dati italiana a supporto della valutazione

del ciclo di vita. Italian environmental database version 2.0; 2000.

[27] US Environmental Protection Agency (EPA). Compilation of air pollutant emission factors, 5th ed., vol. I:

stationary point and area sources. Chapter 12: Metallurgical industry; section 12.19: electric arc welding;

January 1995.

[28] von Bromsen B, Lilieberg L, Frojd N. Emission of fume, nitrogen oxides and noise in plasma cutting of

stainless and mild steel, the Swedish Institute of Production Engineering Research, doc IE-174-93 edition;

March 1994.

1054

F. Ardente et al. / Renewable Energy 30 (2005) 10311054

[29] US Environmental Protection Agency (EPA). Compilation of air pollutant emission factors, 5th ed., vol. I:

stationary point and area sources. Chapter 4: Evaporation loss sources; section 4.2.2.1: general industrial

surface coating; January 1995.

[30] ANPAItalian National Agency for Environment Protection. Regole per la redazione della Dichiarazione

Ambientale di Prodotto (Italian language); July 2001.

[31] Intergovernmental Panel on Climate Change (IPCC). Third assessment reportAnnex BGlossary of terms;

2000.

ko-Institut (Institut fur angewandte O

kologie). Global emission model for integrated systems (GEMIS),

[32] O

German environmental database.

[33] Boustead Ltd. Boustead Model, environmental database; 2001.

[34] Ardente F, Beccali G, Cellura M, Lo Brano V. Life cycle assessment of a solar thermal collector: sensitivity

analysis, energy and environmental balances. Renewable Energy 2005;30:10930.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Electrical CircuitsDocument53 pagesElectrical Circuitssuganyav6No ratings yet

- Chart Summary Analysis - Brandon LeeDocument18 pagesChart Summary Analysis - Brandon LeeEyeOfLunaNo ratings yet

- Service Station Manual Vespa LX 125 - 150 4t Euro 3Document241 pagesService Station Manual Vespa LX 125 - 150 4t Euro 3Adèle Standard100% (1)

- ATPL Notes - ElectricsDocument23 pagesATPL Notes - ElectricsMoslem Grimaldi100% (3)

- Introduction To MicroWavesDocument5 pagesIntroduction To MicroWavesKrish_666No ratings yet

- Ashrae 90.1-2010Document92 pagesAshrae 90.1-2010asarlakNo ratings yet

- Capability Statement WGIM Integrity Operating WindowsDocument3 pagesCapability Statement WGIM Integrity Operating WindowsRomainKabs100% (2)

- S41/42 + S62 + S86 + S110 Plate Heat ExchangerDocument2 pagesS41/42 + S62 + S86 + S110 Plate Heat ExchangerTrần Khắc ĐộNo ratings yet

- Sulfuric AlkylationDocument18 pagesSulfuric AlkylationRaghunath Venkatramanan100% (1)

- Medical Gas Design Flow Calculations: Maunally Change MA FormulaDocument5 pagesMedical Gas Design Flow Calculations: Maunally Change MA FormulaAdnan Ahmed KidwaiNo ratings yet

- Lint InterceptorDocument1 pageLint InterceptorAdnan Ahmed KidwaiNo ratings yet

- Teddington Layman S GuideDocument7 pagesTeddington Layman S GuideAdnan Ahmed KidwaiNo ratings yet

- Complete Guide For Masters OnlyDocument2 pagesComplete Guide For Masters OnlyAdnan Ahmed KidwaiNo ratings yet

- 1 Home Base Work March 19-MRCH 31Document3 pages1 Home Base Work March 19-MRCH 31Celso AmotoNo ratings yet

- 215 D Schema Hydraulique - cssiSImageServletDocument2 pages215 D Schema Hydraulique - cssiSImageServletSieda SiedaNo ratings yet

- 1.TareaParticipacion 2do - ParcialDocument19 pages1.TareaParticipacion 2do - ParcialLeonardo EstradaNo ratings yet

- Heat QuestionsDocument3 pagesHeat QuestionsJanathNo ratings yet

- 2D& 3D-Kate Susannah - Lindsay Sorin and Michelle Maranto-Option 2 - 22.03.23Document11 pages2D& 3D-Kate Susannah - Lindsay Sorin and Michelle Maranto-Option 2 - 22.03.23Miliausha KarimNo ratings yet

- Sungrow Hybrid SH5K-30 5kW Inverter ManualDocument154 pagesSungrow Hybrid SH5K-30 5kW Inverter Manualraymknd gerard macarineNo ratings yet

- MegaFlex - 480V UL UPS Brochure - 041720Document9 pagesMegaFlex - 480V UL UPS Brochure - 041720GeorgeNo ratings yet

- For Less: Stack MoreDocument12 pagesFor Less: Stack MoreKshitiz MittalNo ratings yet

- Valves and Nozzles Rosco Maximizer IIDocument3 pagesValves and Nozzles Rosco Maximizer IIalfredo torresNo ratings yet

- Topic 2 - Radar SystemsDocument37 pagesTopic 2 - Radar SystemsstavrouhristosNo ratings yet

- CALEFACCION Combitronic - 22297Document20 pagesCALEFACCION Combitronic - 22297AlbertoNo ratings yet

- How To Avoid Wastage of EnergyDocument1 pageHow To Avoid Wastage of EnergyNazrawi IJobsNo ratings yet

- Operation ManualDocument81 pagesOperation ManualHalilintar BiruNo ratings yet

- Motores de Fund.Document26 pagesMotores de Fund.Edwing William Salhuana MendozaNo ratings yet

- York YFM Fan-Coil UnitsDocument16 pagesYork YFM Fan-Coil UnitsInviairNo ratings yet

- Bruce E. Depalma: N-Machine: Extraction of Electrical Energy Directly From Space: The N-MachineDocument7 pagesBruce E. Depalma: N-Machine: Extraction of Electrical Energy Directly From Space: The N-MachinebanzailoicNo ratings yet

- Arc Mercer 2011 Fall NewsletterDocument12 pagesArc Mercer 2011 Fall NewsletterarcmercerNo ratings yet

- 1.diesel Engine AssemblyDocument22 pages1.diesel Engine Assemblypepenapao1217No ratings yet

- Safe Handling of Petroleum ProductsDocument12 pagesSafe Handling of Petroleum ProductsMwkthangkwr BrahmaNo ratings yet

- NACHI Full Catalog Small RevDocument468 pagesNACHI Full Catalog Small RevSombat MahamadNo ratings yet

- OGAS Company ContactDocument4 pagesOGAS Company ContactrnoordinNo ratings yet