Professional Documents

Culture Documents

Journal Article Examines Chemical Decontamination of Tritium-Sorbing Stainless Steel

Uploaded by

Anonymous 1hOgJqwZuzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Journal Article Examines Chemical Decontamination of Tritium-Sorbing Stainless Steel

Uploaded by

Anonymous 1hOgJqwZuzCopyright:

Available Formats

Journal of Nuclear Materials

North-Holland,

Amsterdam

CHEMICAL

STAINLESS

DECONTAMINATION

STEEL

T. HIRABAYASHI,

Department

Received

179

136 (198.5) 179-185

M. SAEKI

and

OF THE TRITIUM-SORBING

SURFACE

OF TYPE 316

E. TACHIKAWA

of Chemrst~~. Japan Atomic Energy Research Institute, Tokai, Iharaki 319 -11.Japan

15 April 1985: accepted

29 July 1985

The chemical decontamination

of Type 316 stainless steel surfaces exposed to gaseous tritium has been examined by using a

technique of combined thermal desorption and chemical treatment with corrosive solutions. With the finding that the tritium

sorbed at the various sites on the stainless steel surface can selectively be eliminated by treatment with a particular corrosive

solution, the distributions

of sites and their properties

have been elucidated.

On the basis of the results, it has been

demonstrated

that a two-step chemical treatment, i.e., the dipping in dilute HCl for the whole surface corrosion and then in a

CuSO,-H*SO,

solution for intergranular

corrosion, leads to an almost complete removal of tritium sorbed on the stainless

steel surface with minimized dissolution of the bulk. It is also shown that the non-oxidizing

acids like HCl accelerate the sorbed

tritium to release in the form of HT, while the oxidizing acids like HNO, allow it in the form of HTO.

1. Introduction

Any handling of a large quantity of gaseous tritium

of high specific activity will produce various kinds of

tritium-contaminated

wastes such as tools, measuring

instruments

and apparatus,

which gradually but continuously release tritium from their surfaces. This makes

it necessary to establish a practical means for removing

tritium from the surface, and the necessity has raised

interest in the study of the interaction between gaseous

tritium and material surfaces.

In a series of experiments [l-3], the sorption-desorption phenomenon

of tritium on stainless steel was

studied and the gaseous tritium was found to be readily

sorbed on the surface of type 316 stainless steel, i.e.,

tritium contamination.

It has also become clear that

there are at least four distinct sorbed states of tritium

on the stainless steel surface [2].

In the present study, an attempt has been made to

find out an effective chemical method for removing the

tritium sorbed at various sites on the surface of type 316

stainless steel. For this purpose,

the tritium-sorbing

surface of stainless steel was chemically

treated by

dipping into various corrosive solutions which are known

to cause intergranular corrosion, pitting or whole surface

corrosion and are often used as corrosion-resistance

test

solutions.

During the treatment

measurements

were

made on both the amounts of tritium released and the

0022-3115/85/$03.30

(North-Holland

0 Elsevier Science Publishers

Physics Publishing Division)

metallic elements dissolved. Furthermore,

the thermal

desorption

spectra of tritium from the stainless steel

were measured before and after the chemical treatment.

Each solution was evaluated on the basis of the results

on removal of tritium. A two-step process - chemical

treatment in the solution for whole surface corrosion,

followed by the solution for intergranular

corrosion has been concluded

to be effective for the chemical

decontamination

of a stainless steel surface exposed to

gaseous tritium. With the present experimental

approach, furthermore,

the distributions

and the properties of sites sorbing tritium have also been elucidated.

2. Experimental

2.1. Muterials and preparation

of tritium-sorbing

specimen

A specimen (30 X 10 X 1.25 mm3) was cut from a

cold-rolled

sheet of austenitic type 316 stainless steel

and its chemical composition

was 0.06% C, 0.56% Si,

1.63% Mn, 0.024% P, 0.007% S, 13.10% Ni, 16.60% Cr,

0.0009% B, 0.026% N and 2.24% MO with the balance of

Fe. Tritium, purchased from New England Nuclear, was

diluted by purified protium to a concentration

of 59.06

TBq mol. - (T : H = 1 : 35.2) and the diluted tritium gas

(HT gas) was stored as hydride in a trap of metallic

uranium powder.

B.V.

ix0

T. ~irabay~s~i et at. / The tntium -sorbing surface qf Qpe 316 stain/es steel

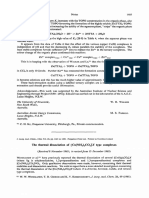

Table 1

List of solutions

used for chemical

treatment

Solution

of the

tritium-sorbing

specimens

Composition

Type of

corrosion

Dilute H,SO,

Dilute HCI

C&O,-H,SO.,

CuSO,-H,SO,-Cu

5% H,SO,

5% HCl

5.5% CuSO, + 15.7% H2S0,

5.5% cuso,

+ 15.7% H,SO,

10% H&,0,

6% FeCI, +O.lS% HCI

65% HNO,

H J,O,

FeCl,-HCl

Cont. HNO,

H 2C20,

causes intergranular

corrosion

of stainless

+cu

expected

Whole surface

Whole surface

intergranular

Intergranular

(Intergranular)

Pitting

Intergranular

steel. when used as electrolytic solution.

The tritium-sorbing

specimen used in this experiment was prepared

in a similar manner to that described earlier (I]; the stainless steel specimen,

the

surface of which was mechanicaily

ground and finally

polished with a suspension of alumina (0.05 pm in grain

diameter), was baked out in a vacuum ( < 10 mPa) for 2

h at 573 K, and then exposed to HT gas of 13.3 kPa for

7 days at 298 K, followed by evacuation for 20 min at

room temperature.

The tritium still remaining on the

surface of the specimen after the procedures described

above is defined as sorbed tritium in this paper. The

total amount of sorbed tritium was (67 f 24) kBq cmmm2.

In table 1 are listed the compositions of the solutions

used for the chemical treatment of the tritium-sorbing

specimens, together with the type of corrosion expected.

These solutions are generally known as test solutions for

corrosion resistance of stainless steel; dilute H2S0, is

used for whole surface corrosion, dilute HCl for surface

etching, CuSO,-H,SO,(

-Cu)

and cont. HNO,

for

intergranular

corrosion

and FeCl,-HCl

for pitting.

H ,C,O, is used as a screening solution.

2.2. Release of sorbed tritium

The sorbed tritium was forced to release by two

methods: (1) dipping into solution, (2) thermal desorption. The process of the release experiment

was given

below.

The sorbed tritium was partially released, when the

specimen was dipped in 60 ml of various solutions listed

in table 1 for 2 or 24 h at 333 K. The release rates of

tritium in the forms of HT and HTO were measured by

means of a gas proportional

counter and a liquid scintillation counter, respectively,

in a similar manner as

previously reported [I]. The metallic elements dissolved

into the solutions were quantita~vely

analyzed by the

use of an Inductively Coupled Plasma Quantrorecorder

(Shimadzu ICPV-1000).

The tritium still remaining in the specimen after the

treatment with solutions was thermally released by using

the same apparatus as described in the previous paper

121; the specimen was heated in an He flow (30 ml

tin-)

under a constant heating rate (5.0 K min-) in

the temperature

range of - 300-1173 K and the thermal desorption rates of tritium in the forms of HT and

HTO were measured as a function of heating temperature to provide the thermal desorption

spectra of tritium.

3. Results

Three specimens sorbing tritium were first prepared

and the effect of whole surface corrosion on the removal

of sorbed tritium was examined;

the first one, was

dipped in dilute H,SO, for 2 h at 333 K and the second

one for 24 h, and then all the specimens including the

third one, which was not dipped, were individually

heated under the conditions

described above, for obtaining thermal desorption

spectra of tritium in the

forms of HT and HTO, Fig. l(A) represents the relationship between the release rate of tritium and the

dipping time of a specimen in diiute H,SO,,

and fig.

l(B) shows the thermal desorption

spectra of HT and

HTO desorbing from the specimens; the spectra (a), (b)

and (c) in figure (B) were obtained from the specimen

before and after dipping for 2 h and 24 h. respectively.

The spectra (a) were employed as a reference for comparison of spectral change, which were well reproducible and compatible

with those reported elsewhere [2].

The four distinct peaks which appeared at about 430,

540, 750 and 970 K in the spectra are designated here as

peaks HT-I, HTO, HT-lf

and HT-ijI,

respectively.

The relative amount of tritium desorbing thermally from

the specimen was (10 f 0.8)% as HT and (89 rt 0.8)% as

HTO, and the former can be further fractionated

into

T. Hirabayashi et al. / The tritium-sorbing surface of Type 316 stainless steel

8

Dipping

12

time

16

20

24

( h )

Fig. 1. The effect of whole surface corrosion on the removal of

sorbed tritium; figure (A): the release rates of tritium (0. HT;

shaded parts, HTO) from the specimen by dipping in dilute

H,SO,;

figure (B): the thermal desorption

spectra of tritium

desorbing from the specimens before [spectra (a), ----- HT; -. HTO] and after dipping in dilute H,SO, for 2h [spectra (b), 0

HT; 0 HTO] and 24 h [spectra (c); A HT; A HTO].

(4.7 f 0.2)%, (1.7 k 0.2)% and (3.7 f 0.5)% for the respective peaks HT-I, HT-II and HT-III.

Assuming a

uniform dissolution of the specimen from the surface in

dilute H,SO,,

the mean depths dissolved were estimated from the weight loss of the specimens to be 0.18

pm cm -2 for 2 h of dipping and 0.74 urn cme2 for 24

h. This means that the rate of dissolution

becomes

slower with elapse of dipping time due to the lowering

of the corrosive activity of the solution used. It is seen

in figs. l(A) and (B) that the dipping into dilute H,SO,

resulted in a release of sorbed tritium and, consequently, in a decrease in intensity of every peak, particularly the peak HT-I, in thermal desorption spectra. The

respective

amounts of tritium in the forms HT and

HTO released by dipping for 2 h in dilute H,SO, were

found to be 21 and 41% by direct measurement,

while

181

they were evaluated to be 9 and 53% from the reduction

in intensity of thermal desorption spectra.

The release behaviors of tritium in other types of

solutions were also examined. Table 2 summarizes the

results, including the data for dilute H,SO,. The dipping into dilute HCl led to a marked weight loss of the

specimen due to surface etching, through which the

sorbed tritium was effectively removed. The dipping

into FeCl,-HCl

caused an extreme weight loss of the

sample due to pitting, but it could remove no more than

50% of the sorbed

tritium.

In the case of the

CuSO,-H,SO,(-Cu)

solution, the sorbed tritium was

appreciably removed without significant weight loss. In

the table it is also noticed that the observed amounts of

HT and HTO always differ from those evaluated from

the reduction in peak intensities in the thermal desorption spectra, indicating the chemical form of released

tritium being determined

not only by the sorbed state

but also by the oxidizing property of acid used. The

dipping in dilute HCl had a tendency to make the

sorbed tritium release as HT in preference to HTO, and

hence the amount of HT observed was much more than

that evaluated from the spectral change. The dipping in

cont. HNO,, on the contrary, made the sorbed tritium

release as HTO. so that the amount of HT became

negligibly small.

In order to infer the metallic elements responsible

for the sorption of tritium, the metals dissolved by

dipping in various solutions were quantitatively analyzed

by inductively coupled plasma atomic emission spectroscopy. The results obtained are represented

in fig. 2

as proportions

of the dissolved amounts of five elements, of which the type 316 stainless steel was mainly

made up. Data with cont. HNO, were excluded from

the figure, since the amounts of metals dissolved were

too small to be exactly determined. The composition

of

the bulk of the specimen used in this experiment

is

shown in the figure for comparison. As shown in fig. 2,

the proportion of metals dissolved in the dilute H,SO,,

dilute HCl, H,C,O,

or FeCl,-HCl

solution appears to

be roughly the same as that of the bulk component of

the specimen,

while

the dissolution

in CuSO,

-H2S04(-Cu)

is characterized

by a marked increase in

the relative amount of molybdenum

accompanying

a

decrease of chromium.

With a view to obtaining information

on the relationship between the type of corrosion and the removal

of tritium sorbed at various sites, the tritium still remaining on the specimen after the chemical treatment

was thermally released to observe any change in the

thermal desorption spectra of HT and HTO before and

after the treatment.

It became apparent that the peak

T. Hiruhuyashi

et al. / The trrtium -sorbing surjace of Type 316 stumless .sieel

SUS 316 bulk

dil. t-MO4

dil.HCl

HzC204

FeCla-HC(

20

Proportion

40

of metals

60

80

dissolved

100

(wt%)

Fig. 2. The proportion

of metallic elements dissolved by dipping in various solutions for 2 h at 333 K.

HT-I in the spectra was easily eliminated by dipping

irrespective of the kind of solution used, whereas the

other peaks were considerably

altered in intensity. depending upon the solution used. Figs. 3 and 4 show two

of the most characteristic

changes of the thermal desorption spectra, which were obtained from the specimen dippped

for 2 and 24 h in dilute HCl and

CL&O,-H,SO,.

As can be seen from fig. 3, the dipping

for 2 h in dilute HCl led to a marked decrease of peak

400

700

Temperature

1000

(K 1

Fig. 3. Thermal desorption

spectra of tritium desorbing from

the specimens before [spectra (a), ---- HT; -.

HTO] and after

dipping in dilute HCI for 2 h [spectra (b), 0 HT; 0 HTO and

24 h [spectrum (c), A HTO].

T Hirabayashi et al. / The tritium -sorbing surface of Type 316 stainless steel

400

700

Temperature

1000

( K1

Fig. 4. Thermal desorption

spectra of tritium desorbing from

the specimens before [spectra (a), ---- HT; - .- HTO] and after

dipping in CuSO,-H,SO,

for 2 h [spectra (b), 0 HT; 0 HTO]

and 24 h [spectra (c), A HT; A HTO].

HT-IZZ

as well as peak HT-Z but to a very small

of peak HT-ZZ that disappeared

eventually

when the dipping was prolonged up to 24 h. The peak

HTO also decreased in intensity with elapse of dipping

time in dilute HCl but still remained faintly after dipping for 24 h. On the other hand, it is clear from fig. 4

that the dipping in CuSO,-H,SO,

resulted in a marked

decrease of peak HT-ZZ but in only a small decrease of

peak HT-ZZZ. The peak HTO decreased more slqwly in

CuSO,-H,SO,

than in dilute HCl.

Furthermore,

an attempt was made to remove the

sorbed tritium by two steps of chemical treatment; after

being dipped for 2 h in dilute HCl, by which the tritium

corresponding

to peaks HT-ZZ and HTO was not yet

completely removed as predicted from fig. 3, the specimen was further dipped for 24 h in CuSO,-H,SO,.

This two-step treatment resulted in an almost complete

removal of tritium (62% as HTO-form

and 34% as

HT-form) with a minimized weight loss (2.45 mg cmm2)

of the sample.

decrease

4. Discussion

The distribution

of tritium

stainless steel has already been

autoradiography

and observed

neous at ambient temperature

ously [2], there are four distinct

dissolved in cold-rolled

examined by the use of

to be definitely heteroge[4,5]. As reported previsorbed states of tritium

183

on the surface of stainless steel. In this work, it has been

found that the tritium sorbed in each state can selectively be eliminated by chemical treatment with a particular corrosive solution. This result will provide information on the distribution

of the sites. Table 3 summarizes the results on the distribution

of the sites sorbing tritium and the type of corrosion effective to remove

sorbed tritium, together with the related information

reported in the preceding papers [2,3]. In the following,

the distributions

and the properties

of sites sorbing

tritium are discussed.

Theoretical studies [6-81 have recently predicted that

the d electron of nickel causes a dissociation

of a

hydrogen molecule with little or no activation barrier.

This is due to the interaction between the antibonding

orbitals of hydrogen

molecules and the lobe-shaped

orbitals of the d electrons of nickel [6]. Another calculation [9] has shown that the interaction energies between

hydrogen and the transition

metal surfaces are dominated by the degree of filling of the d orbitals. Since

type 316 stainless steel consists of transition metals, the

d electron on the surface of stainless steel also seems to

play an important role in the dissociation of tritium into

atomic species. The tritrium dissociated

will subsequently be trapped on the various sites as described

below.

The peak HT-ZZZ in the thermal desorption spectra

diminished

to a significant extent as a result of whole

surface corrosion (figs. 1 and 3), but only to a limited

extent by intergranular

corrosion (fig. 4). This implies

that the sites sorbing tritium for peak HT-ZZZ do not

exist on the top of surface metal but between or under

and that they are distributed

the surface

atoms,

throughout the whole surface layer. It has been recently

revealed [lO,ll] that the hydrogen dissociated by the d

electron as mentioned

above can be trapped at subsurface sites of nickel, where the bonding is predominantly with a free-electron-like

s electron. This type of

bonding, namely subsurface bonding, is different from

either to the hydride bond and the low-temperature

hydrogen

bond [lo]. Such a bonding has also been

reported to exist with other transition metals such as

niobium [12] and is expected to be markedly stronger

than normal chemisorption.

The nickel site of stainless

steel [2,3] seems to be similar to the subsurface site of

pure nickel with regard to the trapping of tritium. The

sorption-desorption

behavior of tritium on the nickel

site of stainless steel can be understood in the following

manner. The tritium first dissociates at d electrons on

the surface and subsequently

interacts with the subsurface site of nickel in the surface layer of stainless

steel, forming a strong subsurface bonding. The bound

184

T. Hirabayashi et al. / The tritium-sorbing surface of Qpe 316 stainless steel

tritium corresponding

to peak HT-III.

thus. is thermally desorbed with a higher activation energy than the

other types of sorbed tritium [2].

From the results shown in figs. 2 and 4, it seems that

the sites sorbing tritium for peak HT-II are distributed

along the intergranule,

where molybdenum

segregates.

It is generally known that some particular

metallic

elements tend to segregate along the intergranule and to

have a scavenging

action for impurities,

especially

carbon. Among the major constituent metals of stainless

steel, the affinities for carbon decrease as follows:

Mo>Cr>Mn>Fe>Ni.

Molybdenum

having the strongest affinity for carbon

may form a certain molybdenum

carbide in the intergranule, such as Mo,M,,C,

Mo,M,C

or Mo,M,C

(M = Fe, Cr, Ni, Mn) [13-151, due to the configurational restriction

of molybdenum

having the largest

atomic radius of the major constituent metals. It is also

known that the intergranule, unstable due to the formation of such a carbide, is easily attacked by the moderate oxidizing power of Cu2+ contained in the solution

of CuSO,-H,SO,,

but the other stable surface is passivated [16]. Thus, when the tritium is sorbed along the

intergranule in an interaction with such a molybdenum

carbide, an intergranular

corrosion leads to the destruction of the sites sorbing tritium, resulting in an effective

removal of tritium for peak HT-II as seen in fig. 4.

The peak HTO in the spectra was not completely

eliminated

by either the intergranular

or the whole

surface corrosion, but efficiently by applying both corrosion processes. This experimental

fact suggests that

the sites sorbing tritium for peak HTO are distributed

not only on the surface but also along the intergranule.

As commonly accepted [17,18], O*- and OH- ions will

exist in metal oxides on the surface and along the

intergranule. Thus the tritium dissociated and sorbed on

this type of site will form an OT- ion by combining

with an O*- ion or by an isotopic exchange reaction

with protium existing as an OH- ion. This tritium will

thermally desorb in the form of HTO by the mechanism

as previously postulated [2].

The tritium for peak HT.1 was very easily eliminated

by dipping the specimen for a short time in any solution. Further, the previous experiments [2] revealed that

no dissociation

of H-T bonding was involved in the

sorption of tritium for peak HT-I. These suggest that

the tritium for peak HT-I is weakly adsorbed on the

topmost surface in the form of molecular species such as

the HT+ ion. In other words, the molecular tritium

cannot penetrate into the bulk unless dissociated, though

the size of the HT+ ion on the surface can be estimated

T. Hirabayashi et al. / The tritium -sorbing surface of Type 316 stainless steel

to be smaller than that of the T- ion [19]. This is

consistent with the results pointed out by Ransom and

Ficalora [20] that the hydrogen is chemisorbed

on iron

ion. Such a molecular species is possibly

as a Hl

trapped on the strongly chemisorbed species such as the

OT- ion, or the OH- or 0 *- ions existing intrinsically

on the surface layer, and consequently,

distributes

all

over the surface of stainless steel.

On the basis of a detailed knowledge of the properties and the distributions

of sorption sites, it has been

experimentally

demonstrated

that the complete decontamination of a stainless steel surface exposed to gaseous tritium requires two steps of chemical treatments

for the whole surface and intergranular

corrosion. The

apparent effectiveness of this two-step process has been

evidenced

The

dominated

at the end

chemical

by

the

of section

form

oxidizing

of

3.

the

property

tritium

of the

released

acid

185

intergranule;

those for peak HT-Z (430 K) all over

the top of surface.

(2) Two-step chemical treatment with the solutions for

whole surface and intergranular

corrosion leads to

an almost complete removal of tritium sorbed on

the surface with a minimized dissolution.

(3) The non-oxidizing

acids like HCl assist the sorbed

tritium to release in the form of HT, while the

oxidizing acids like HNO, allow it in the form of

HTO.

Acknowledgments

The authors wish to thank Mr C. Sagawa for analyses

by inductively coupled plasma atomic emission spectroscopy.

is

solu-

used (table 2), though that in thermal desorption is

determined primarily by the sorbed state. Non-oxidizing

acids like HCl assist the sorbed tritium to release in the

form of HT. This may be because the tritium combines

with nascent hydrogen, generated in the dissolution of

stainless steel, forming HT, even though the tritium was

mostly sorbed on an oxygen-containing

site and mostly

released as HTO in themral desorption.

On the other

hand, the oxidizing acids like HNO, seem not only to

stabilize the formed OT- ion but also to oxidize the

tritium in the forms of atomic and molecular species,

and hence almost all of the sorbed tritium is removed in

the form of HTO. As reported previously [3], the relative proportion

of HT and HTO in thermal desorption

agrees with that released in the etching treatment by the

acid solution, having a composition

of 2.4% HNO,,

3.2% HCl and 94.4% H,O corresponding

to a 1%:10

dilution of aqua regia. This may be because of the

balanced action of HNO, and HCl at this concentration. Thus the chemical forms of tritium released could

be controlled to a certain extent by selecting a suitable

acid among various oxidizing and non-oxidizing

acids.

tion

5. Conclusions

The following conclusions have been obtained from

the results:

(1) The sites sorbing tritium, which give the peak HTZZZ (970 K) in the thermal desorption

spectra, are

distributed throughout the whole surface layer; those

for peak HT-ZZ (750 K) along the intergranule,

where molybdenum

segregates; those for peak HTO

(540 K) not only on the surface but also along the

References

and M. Saeki, .I. Nucl. Mater. 120 (1984)

PI T. Hirabayashi

309.

M. Seaki and E. Tachikawa,

J. Nucl.

PI T. Hirabayashi,

Mater. 126 (1984) 38.

M. Seaki and E. Tachikawa,

J. Nucl.

131 T. Hirabayashi,

Mater. 127 (1985) 187.

[41 G.W. Powell, J.D. Braun, K.F. Chaney and G.L. Downs,

Corrosion-Nate

26 (1970) 223.

T.S. Elleman and K. Verghese, J. Nucl.

151 P.M. Abraham,

Mater. 73 (1978) 77.

161 C. Satoko and M. Tsukada, Surface Sci. 134 (1983) 1.

[71 C.F. Melius, J.W. Moskowitz, A.P. Mortola, M.B. Bailhe

and M.A. Ratner, Surface Sci. 59 (1976) 279.

181 H. Deuss and A. van der Avoid, Phys. Rev. B8 (1973)

2441.

S. Holloway and J.K. Nerskov,

Surface

[91 P.,Nordlander,

Sci. 136 (1984) 59.

F. Greuter and E.W. Plummer, Phys. Rev.

WI W. Eberhardt,

Lett. 46 (1981) 1085.

1111 M. Lagos, Surface Sci. 122 (1982) L601.

WY M. Lagos and I.K. Schuller, Surface Sci. 138 (1984) L161.

Bull. Japan Inst. Metals 1

[I31 Y. Imai and T. Masumoto,

(1962) 411 and 466 (in japanese).

A. Baumel

and E. Schmidtmann,

Arch.

[I41 H. Thier,

Eisenhuttenw.

40 (1969) 333.

Metall. Trans. 11A (1980)

[I51 A. Inoue and T. Masumoto,

739.

Designation

A-393-55,

Conducting

Acidified

[161 ASTM

CuSO, Test for Intergranular

Attack in Austenitic Stainless Steel (1955); Fed. Test Method, Std. No. 151, Metals

Test Method (1956).

P71 R.O. Adams, J. Vat. Sci. Technol. Al (1983) 12.

[181 J.E. Castle and C.R. Clayton, Corrosion Sci. 17 (1977) 7.

[I91 R.W. Pasco and P.J. Ficalora, Surface Sci. 134 (1983) 476.

PO1 C.M. Ranson and P.J. Ficalora, Met. Trans. 11A (1980)

801.

You might also like

- 10.1016@S0043 13549600240 0Document3 pages10.1016@S0043 13549600240 0Babak KamyarNo ratings yet

- Thermodynamics of Titanium and Oxygen Dissolved in Liquid Iron Equilibrated With Titanium OxidesDocument10 pagesThermodynamics of Titanium and Oxygen Dissolved in Liquid Iron Equilibrated With Titanium Oxidesarchivossubidos_No ratings yet

- Synthesis and Antibacterial Activity of Cephalexin Metal ComplexesDocument8 pagesSynthesis and Antibacterial Activity of Cephalexin Metal ComplexesDewi Sri SulastriNo ratings yet

- Extraction of Titanium Dioxide from Ilmenite and Titaniferous Slag Using Fused Salt SolventsDocument6 pagesExtraction of Titanium Dioxide from Ilmenite and Titaniferous Slag Using Fused Salt SolventssecateNo ratings yet

- Corosion PDFDocument12 pagesCorosion PDFeid elsayedNo ratings yet

- Catalysis by Microporous MaterialsDocument8 pagesCatalysis by Microporous MaterialsaocpgsNo ratings yet

- 37 326 PDFDocument6 pages37 326 PDFEidelsayedNo ratings yet

- Hydrometallurgy: Yuji Sasaki, Tomoya Suzuki, Keisuke Morita, Kazuharu YoshizukaDocument3 pagesHydrometallurgy: Yuji Sasaki, Tomoya Suzuki, Keisuke Morita, Kazuharu YoshizukaBety R. CamposNo ratings yet

- Synthesis of 1,4-Benzenedicarbonyl Thiourea Resins and Their Adsorption Properties For Ag (I)Document6 pagesSynthesis of 1,4-Benzenedicarbonyl Thiourea Resins and Their Adsorption Properties For Ag (I)Viviana TorresNo ratings yet

- Solubility of Stibnite Ore in HCL Solutions: Sabri Colak, and Sinan YapiciDocument8 pagesSolubility of Stibnite Ore in HCL Solutions: Sabri Colak, and Sinan YapiciAbdullah UYSALNo ratings yet

- Dehydration of Crystalline MnSO4 4H2ODocument10 pagesDehydration of Crystalline MnSO4 4H2OrichardNo ratings yet

- Tris Oxalato 3Document7 pagesTris Oxalato 3nathaloaNo ratings yet

- Chowdhury 1993Document12 pagesChowdhury 1993korope8705No ratings yet

- Chemical Degradation of Trimethyl Phosphate As Surrogate For OrganophosporusDocument11 pagesChemical Degradation of Trimethyl Phosphate As Surrogate For OrganophosporusNura LailatussoimahNo ratings yet

- Choi 2019Document11 pagesChoi 2019mylover huNo ratings yet

- Thermochimica Acta, 55 (1982) 327-332: Thermogravimetric and spectroscopic studies on trans-Co(en)2Cl2Cl and cis-Co(en)2(NCS)ClClO4 in molten KSCN and ZnCl2-KCl eutecticDocument6 pagesThermochimica Acta, 55 (1982) 327-332: Thermogravimetric and spectroscopic studies on trans-Co(en)2Cl2Cl and cis-Co(en)2(NCS)ClClO4 in molten KSCN and ZnCl2-KCl eutecticlaura preciadoNo ratings yet

- Investigation of Corrosion Inhibition of Quaternary Ammonium Salt On N80 Steel in 5M HCL SolutionDocument5 pagesInvestigation of Corrosion Inhibition of Quaternary Ammonium Salt On N80 Steel in 5M HCL SolutionNoheilly VásquezNo ratings yet

- Kinetics of Acetone Hydrogenation Over Pt/A1203 CatalystsDocument7 pagesKinetics of Acetone Hydrogenation Over Pt/A1203 CatalystsNaufal AdityasNo ratings yet

- The Corrosion Behaviour of Aisi 304 Stainless Steel in Methanol H2SO4 MixturesDocument11 pagesThe Corrosion Behaviour of Aisi 304 Stainless Steel in Methanol H2SO4 MixturesnicusebpNo ratings yet

- Characterization of Sewage Sludge Ashes To Be Used As A Ceramic Raw MaterialDocument6 pagesCharacterization of Sewage Sludge Ashes To Be Used As A Ceramic Raw MaterialDrShrikant JahagirdarNo ratings yet

- Stork 1963Document16 pagesStork 1963Daniel JiménezNo ratings yet

- Corrosion Science: M.J. Muñoz-Portero, J. García-Antón, J.L. Guiñón, R. Leiva-GarcíaDocument11 pagesCorrosion Science: M.J. Muñoz-Portero, J. García-Antón, J.L. Guiñón, R. Leiva-GarcíaFadli IkhsanNo ratings yet

- Articles: Structural Investigation of The Hydrolysis-Condensation Process of Modified Titanium IsopropoxideDocument5 pagesArticles: Structural Investigation of The Hydrolysis-Condensation Process of Modified Titanium IsopropoxideDeddy Triyono Nugroho AdiNo ratings yet

- Factors Affecting Blowhole Formation in Continuous Casting of Steel BeamsDocument7 pagesFactors Affecting Blowhole Formation in Continuous Casting of Steel BeamsJitendra UmaraliyaNo ratings yet

- Articulo Oscar CuevasDocument4 pagesArticulo Oscar CuevasAndres PedrozaNo ratings yet

- Kimia Organik LanjutanDocument1 pageKimia Organik Lanjutanpanda biruNo ratings yet

- 2009 Central European Journal of Chemistry PDFDocument8 pages2009 Central European Journal of Chemistry PDFnoxscapesNo ratings yet

- Thermal behaviour and kinetic analysis of double ammonium sulphate hexahydratesDocument8 pagesThermal behaviour and kinetic analysis of double ammonium sulphate hexahydratesnathaloaNo ratings yet

- P010 008 Leikola PDFDocument16 pagesP010 008 Leikola PDFАйкен ТабылбаеваNo ratings yet

- Refining of Metals IntroductionDocument33 pagesRefining of Metals IntroductionRakesh Kamath100% (5)

- Tobacco Rob Extract As Green Corrosion Inhibitor For N80 Steel in HCL SolutionDocument31 pagesTobacco Rob Extract As Green Corrosion Inhibitor For N80 Steel in HCL Solutionsri sandra deviNo ratings yet

- 1,2,3-Triazole Derivatives As Corrosion Inhibitors For Mild Steel in Acidic Medium - Experimental and Computational Chemistry StudiesDocument11 pages1,2,3-Triazole Derivatives As Corrosion Inhibitors For Mild Steel in Acidic Medium - Experimental and Computational Chemistry StudiesDaniel GonzagaNo ratings yet

- The Corrosion of Carbon Steel in Lithium Bromide Solution at Moderate TemperaturesDocument11 pagesThe Corrosion of Carbon Steel in Lithium Bromide Solution at Moderate TemperaturesKArenNo ratings yet

- Sulfuric Acid Dew Point Corrosion in Waste Heat Boiler Tube For Coppe PDFDocument8 pagesSulfuric Acid Dew Point Corrosion in Waste Heat Boiler Tube For Coppe PDFFaiz AgungNo ratings yet

- Extraction of Valuable Metals from Slag Using Ammonium SulfateDocument12 pagesExtraction of Valuable Metals from Slag Using Ammonium Sulfatechappy_ladyNo ratings yet

- Jaots 19 1 59 65Document8 pagesJaots 19 1 59 65Sanjeev SahuNo ratings yet

- Wend Land T 1966Document4 pagesWend Land T 1966Rama Rós LahhamNo ratings yet

- NSEC Solved Paper 2015Document26 pagesNSEC Solved Paper 2015ADITYANo ratings yet

- Xiao 2017Document66 pagesXiao 2017Yuliastri DewiNo ratings yet

- Artigo TGDocument14 pagesArtigo TGNullianySilvaNo ratings yet

- Jurnal TiO2Document14 pagesJurnal TiO2Nurul AfiqahNo ratings yet

- Analytical Method To Monitor Industrial Pickling Baths Initially Constituted by HF, HNODocument20 pagesAnalytical Method To Monitor Industrial Pickling Baths Initially Constituted by HF, HNOAddie Restu FirmansyahNo ratings yet

- Flux Skimming PDFDocument6 pagesFlux Skimming PDFpbp2956No ratings yet

- 4 5 PDFDocument11 pages4 5 PDFRomNo ratings yet

- Leaching of A Cu-Co OreDocument7 pagesLeaching of A Cu-Co OreEDWIN LEONARDO ESPINOZA PACHECONo ratings yet

- 1989 Adsorption of Gold-Thiourea Complex On ActivatedDocument5 pages1989 Adsorption of Gold-Thiourea Complex On ActivatedHishamNo ratings yet

- The Thermal Decomposition of Metal: Complexes - XiiDocument7 pagesThe Thermal Decomposition of Metal: Complexes - XiiCrhiiztiian RojjazNo ratings yet

- Boiler Corrosion MagnetiteDocument14 pagesBoiler Corrosion MagnetiteJakeTheSnake69No ratings yet

- Optimization of Ascorbic Acid-Modified Chitosan for Adsorption of Iron(III) and Chromium(III) IonsDocument6 pagesOptimization of Ascorbic Acid-Modified Chitosan for Adsorption of Iron(III) and Chromium(III) IonsArifa RahmaNo ratings yet

- Guin2006 Article One-potSizeAndShapeControlledSDocument5 pagesGuin2006 Article One-potSizeAndShapeControlledSChris CordierNo ratings yet

- Effect of Brookite Phase On The Anatase-Rutile Transition in Titania NanoparticlesDocument6 pagesEffect of Brookite Phase On The Anatase-Rutile Transition in Titania NanoparticlesLucas MarchiniNo ratings yet

- Pretreatment Effect of Gold/iron/zeolite-Y On Carbon Monoxide OxidationDocument11 pagesPretreatment Effect of Gold/iron/zeolite-Y On Carbon Monoxide OxidationhernandeszNo ratings yet

- Ferdian 14060Document7 pagesFerdian 14060Marko JukićNo ratings yet

- Infrared Study of A Novel Acid-Base Site On ZrO2 by Adsorbed Probe Molecules.Document7 pagesInfrared Study of A Novel Acid-Base Site On ZrO2 by Adsorbed Probe Molecules.rafelNo ratings yet

- Ammoniacal Thiosulphate Leaching of Gold Ore: R.K. Rath, N. Hiroyoshi, M. Tsunekawa, T. HirajimaDocument9 pagesAmmoniacal Thiosulphate Leaching of Gold Ore: R.K. Rath, N. Hiroyoshi, M. Tsunekawa, T. HirajimaGustavo CabreraNo ratings yet

- Studymate Solutions To CBSE Board Examination 2013-2014: Chemistry (Theory)Document11 pagesStudymate Solutions To CBSE Board Examination 2013-2014: Chemistry (Theory)Gautam SharmaNo ratings yet

- Gas Hydrates 1: Fundamentals, Characterization and ModelingFrom EverandGas Hydrates 1: Fundamentals, Characterization and ModelingDaniel BrosetaNo ratings yet

- Organometallic Chemistry: Plenary Lectures Presented at the Fourth International Conference on Organometallic ChemistryFrom EverandOrganometallic Chemistry: Plenary Lectures Presented at the Fourth International Conference on Organometallic ChemistryF. G. A. StoneNo ratings yet

- TR 16 15 PDFDocument314 pagesTR 16 15 PDFAnonymous 1hOgJqwZuzNo ratings yet

- Pub1494 Web PDFDocument115 pagesPub1494 Web PDFAnonymous 1hOgJqwZuzNo ratings yet

- Cebama 2016 03 D1.03 WP1 ExpStudies StateOfTheArt PDFDocument237 pagesCebama 2016 03 D1.03 WP1 ExpStudies StateOfTheArt PDFAnonymous 1hOgJqwZuzNo ratings yet

- Pub1483 WebDocument124 pagesPub1483 WebAnonymous 1hOgJqwZuzNo ratings yet

- Evaluation of Facilities Handling Tritium Info-0796 eDocument49 pagesEvaluation of Facilities Handling Tritium Info-0796 eAnonymous 1hOgJqwZuzNo ratings yet

- NP 2656Document294 pagesNP 2656Anonymous 1hOgJqwZuzNo ratings yet

- PPChem 2015 17 06 342-353 NewDocument12 pagesPPChem 2015 17 06 342-353 NewyogaNo ratings yet

- An Overview of Gas Research in Support of The UK Geological Disposal ProgrammeDocument8 pagesAn Overview of Gas Research in Support of The UK Geological Disposal ProgrammeAnonymous 1hOgJqwZuzNo ratings yet

- Darlington Refurbisment - LILW ManagementDocument69 pagesDarlington Refurbisment - LILW ManagementAnonymous 1hOgJqwZuzNo ratings yet

- The NUMO Structured Approach To HLW Disposal in JapanDocument44 pagesThe NUMO Structured Approach To HLW Disposal in JapanAnonymous 1hOgJqwZuzNo ratings yet

- Cdna12526enc 001Document170 pagesCdna12526enc 001Anonymous 1hOgJqwZuzNo ratings yet

- Alavi 2009Document16 pagesAlavi 2009Anonymous 1hOgJqwZuzNo ratings yet

- Pressurized Water Reactor Secondary Water Chemistry Guidelines-Revision 7Document351 pagesPressurized Water Reactor Secondary Water Chemistry Guidelines-Revision 7Anonymous 1hOgJqwZuzNo ratings yet

- PerfectDocument8 pagesPerfectAnonymous 1hOgJqwZuzNo ratings yet

- 15 - Chemistry in CANDU Process SystemsDocument48 pages15 - Chemistry in CANDU Process SystemsAnonymous 1hOgJqwZuzNo ratings yet

- Combined Heavy Water Upgrading and Detritiation For CANDU Applications PDFDocument12 pagesCombined Heavy Water Upgrading and Detritiation For CANDU Applications PDFAnonymous 1hOgJqwZuzNo ratings yet

- Overview of Iaea Project On Safety Aspects of NPP Ageing Jaroslav Pachner Division of Nuclear Installation Safety, IAEADocument10 pagesOverview of Iaea Project On Safety Aspects of NPP Ageing Jaroslav Pachner Division of Nuclear Installation Safety, IAEAAnonymous 1hOgJqwZuzNo ratings yet

- GP Report-Thompson-CANDU6 PDFDocument66 pagesGP Report-Thompson-CANDU6 PDFAnonymous 1hOgJqwZuzNo ratings yet

- REGDOC 2 6 3 Fitness For Service Aging Management EngDocument36 pagesREGDOC 2 6 3 Fitness For Service Aging Management EngAnonymous 1hOgJqwZuzNo ratings yet

- Evaluation of Facilities Handling Tritium Info-0796 eDocument49 pagesEvaluation of Facilities Handling Tritium Info-0796 eAnonymous 1hOgJqwZuzNo ratings yet

- Introduction To Wolsong Tritium Removal Facility (WTRF)Document2 pagesIntroduction To Wolsong Tritium Removal Facility (WTRF)Anonymous 1hOgJqwZuzNo ratings yet

- REGDOC 2 3 3 Periodic Safety Reviews EngDocument23 pagesREGDOC 2 3 3 Periodic Safety Reviews EngAnonymous 1hOgJqwZuzNo ratings yet

- TF PDFDocument4 pagesTF PDFAnonymous 1hOgJqwZuzNo ratings yet

- Epri HXDocument300 pagesEpri HXAnonymous 1hOgJqwZuz100% (1)

- 22068939Document146 pages22068939Anonymous 1hOgJqwZuzNo ratings yet

- C in Radioactive Waste For Decommissioning of The Ignalina Nuclear Power PlantDocument8 pagesC in Radioactive Waste For Decommissioning of The Ignalina Nuclear Power PlantAnonymous 1hOgJqwZuzNo ratings yet

- Responses To Questions Fifth Report Joint Convention Safety of Spent Fuel Management and Safety of Radioactive WasteDocument109 pagesResponses To Questions Fifth Report Joint Convention Safety of Spent Fuel Management and Safety of Radioactive WasteAnonymous 1hOgJqwZuzNo ratings yet

- Fusion Engineering and DesignDocument5 pagesFusion Engineering and DesignAnonymous 1hOgJqwZuzNo ratings yet

- Journal of Nuclear Materials: A 1 A B B B B C C C D D e F F G G A BDocument4 pagesJournal of Nuclear Materials: A 1 A B B B B C C C D D e F F G G A BAnonymous 1hOgJqwZuzNo ratings yet

- Fusion Engineering and Design: Preliminary Results From A Detritiation Facility Dedicated To Soft Housekeeping WasteDocument5 pagesFusion Engineering and Design: Preliminary Results From A Detritiation Facility Dedicated To Soft Housekeeping WasteAnonymous 1hOgJqwZuzNo ratings yet

- Notes Chapter 5 Physical States of Matter Reduced Syllabus 2020Document18 pagesNotes Chapter 5 Physical States of Matter Reduced Syllabus 2020Umme AbdullahNo ratings yet

- Bangalore University MSc Sericulture SyllabusDocument39 pagesBangalore University MSc Sericulture SyllabusAKSHATA PATILNo ratings yet

- HHA - X-MET8000 Optimum + Expert Performance Document (Alloy) - Thin Window - V1-3Document5 pagesHHA - X-MET8000 Optimum + Expert Performance Document (Alloy) - Thin Window - V1-3Paula InesNo ratings yet

- Advances in Air Filtration Technologies - Structure-Based andDocument13 pagesAdvances in Air Filtration Technologies - Structure-Based andamaNo ratings yet

- Methods To Reduce Fat Content and Optimize Ingredient Composition of Mayonnaise and DressingsDocument4 pagesMethods To Reduce Fat Content and Optimize Ingredient Composition of Mayonnaise and DressingsJulio ReyesNo ratings yet

- Food Chemistry: C.M. Ajila, S.G. Bhat, U.J.S. Prasada RaoDocument6 pagesFood Chemistry: C.M. Ajila, S.G. Bhat, U.J.S. Prasada RaoMonica FigueiraNo ratings yet

- BIO303 Biochemistry IIDocument38 pagesBIO303 Biochemistry IIHanifullah JanNo ratings yet

- Atmospheric Testing in Confined SpacesDocument4 pagesAtmospheric Testing in Confined SpacesfrancisNo ratings yet

- An Introduction To Condensers and Auxilary Equipment For Steam Power Plants R1Document34 pagesAn Introduction To Condensers and Auxilary Equipment For Steam Power Plants R1jenixson tamondongNo ratings yet

- Steel Castings, Welding, Qualifications of Procedures and PersonnelDocument15 pagesSteel Castings, Welding, Qualifications of Procedures and PersonnelRafael CossolinoNo ratings yet

- Composites in Pediatric Dentistry: ROLL NO. - 21277010001 Dr. Lopamoodra Das Batch-2018-2021Document20 pagesComposites in Pediatric Dentistry: ROLL NO. - 21277010001 Dr. Lopamoodra Das Batch-2018-2021Khushboorana A Scientist100% (1)

- 2019 Usnco Exam Part III PDFDocument18 pages2019 Usnco Exam Part III PDFFernando RiosNo ratings yet

- Podesta Military Tribunal Day Two - 4 May 2021Document3 pagesPodesta Military Tribunal Day Two - 4 May 2021Ronald Wederfoort100% (5)

- A Study On The Effects of Different BiofertilizerDocument5 pagesA Study On The Effects of Different BiofertilizerOliver TalipNo ratings yet

- Technical Report 1 - Sdb24103 (Sept 2022) Mohd Iqmal HafizDocument15 pagesTechnical Report 1 - Sdb24103 (Sept 2022) Mohd Iqmal HafiziqmalNo ratings yet

- Mineral IdentificationDocument17 pagesMineral IdentificationClay ASNo ratings yet

- Total Synthesis of the Daphniphyllum Alkaloids MeetingDocument15 pagesTotal Synthesis of the Daphniphyllum Alkaloids MeetingSơn Nguyễn KimNo ratings yet

- WASTEWATER STABILIZATION LAGOON PROCESS PowerPoint Presentation, Free Download - ID - 6206424Document2 pagesWASTEWATER STABILIZATION LAGOON PROCESS PowerPoint Presentation, Free Download - ID - 6206424shoyebNo ratings yet

- Balancing Redox Reactions: Examples: MN O I I NDocument4 pagesBalancing Redox Reactions: Examples: MN O I I NSHENIVEL BANTENo ratings yet

- DesmopresinDocument9 pagesDesmopresinNARESH JANDIALNo ratings yet

- Catalyst Characterization PPT NewDocument34 pagesCatalyst Characterization PPT NewTesfaye KassawNo ratings yet

- LK Valves Product Catalogue Rev. 6Document211 pagesLK Valves Product Catalogue Rev. 6MRGEMEGP1No ratings yet

- Properties of Asphaltenes from Alberta Crude OilsDocument6 pagesProperties of Asphaltenes from Alberta Crude OilsshadyghanemNo ratings yet

- Textile Effects Erionyl FF Huntsman CorporationDocument9 pagesTextile Effects Erionyl FF Huntsman CorporationRickgableNo ratings yet

- 2019 تأثير الماء والبذور الممغنطة على المحصول وامتصاص معادن الطماطم الثقيلةDocument10 pages2019 تأثير الماء والبذور الممغنطة على المحصول وامتصاص معادن الطماطم الثقيلةMUHAMMED ALSUVAİDNo ratings yet

- HB EstimationDocument4 pagesHB EstimationSushmitaNo ratings yet

- Appendix 3 - Neutralization Amine MSDSDocument9 pagesAppendix 3 - Neutralization Amine MSDSHERWIN SEPTIYANNo ratings yet

- Unesco - Eolss Sample Chapters: Membrane CharacterizationDocument14 pagesUnesco - Eolss Sample Chapters: Membrane CharacterizationsumitNo ratings yet

- Internship PPT 7th SemDocument22 pagesInternship PPT 7th SemJAY JOSHINo ratings yet

- Sasol Italy S.p.A. Material Safety Data Sheet for Emulgante CO-55Document4 pagesSasol Italy S.p.A. Material Safety Data Sheet for Emulgante CO-55Mohamed HalemNo ratings yet