Professional Documents

Culture Documents

(1966, May 3) US3248803 Rotary Drum Heat Exchanger

Uploaded by

aegosmithOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(1966, May 3) US3248803 Rotary Drum Heat Exchanger

Uploaded by

aegosmithCopyright:

Available Formats

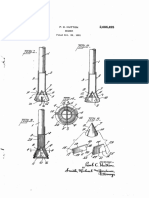

May 3, 1966

G. KRIKORIAN

3,248,803

ROTARY DRUM HEAT EXCHANGER

Filed April 5, 1963

3 Sheets-Sheet 1

May 3, 1966

e. KRIKORIAN

3,248,803

ROTARY DRUM HEAT EXCHANGER

Filed April 5, 1963

3 Sheets-Sheet 5

/02

90

/031

P76.6 4

United States Patent 0 MICC

1

3,248,803

Patented May 3, 1966

2

to maintain said shell in a ?xed position coaxially with

3,248,803

ROTARY DRUM HEAT EXCHANGER

said hub.

In order to provide for expansion and contraction of

Garo Krikorian, Worcester, Mass., assignor to Rice Bar

ton Corporation, Worcester, Mass., a corporation of

Massachusetts

Filed Apr. 5, 1963, Ser. No. 270,919

4 Claims. (Cl. 34-110)

the shell relatively to the rotary hub longitudinally, only

adequately supported and held in a coaxially aligned posi

dryer shown in FIG. 1;

one of the disc headers is rigidly secured to the rotary

hub. Any other said disc header is connected to the rotary

hub by means of a series of axial expansion joints con

nected between the said disc header and said rotary hub,

each said axial expansion joint comprising a sleeve and

The present invention relates to improvements in rotary

drum heat exchangers.

10 pin connection interconnected between said disc header

and said rotary hub permitting relative movement of the

The invention is shown in two alternative forms, in

disc header and said rotary hub only along a line parallel

one form as embodied in a drum-type dryer having a

to said hub axis.

heated outer shell, and in an alternative form as embodied

In the alternative embodiment of the invention shown,

in a cooling roll having a cool outer shell.

In a preferred form of the invention, a rotary drum 15 the outer shell of the cooling drum is supported coaxially

with relation to the end supporting discs by means of

dryer is disclosed having a drum of large diameter which

radial pins which are secured at their outer ends directly

comprises a shell, 21 supporting rotary hub rotating on a

into the outer shell and are ?tted into sleeve sockets

fixed axis, and supporting disc or spoke elements which

formed in the peripheral surface of the end discs.

project outwardly from the hub and provide support for

With the above and other objects in view as may here

the drum. The drum is ?tted with a heating system which

inafter appear, the several features of the invention con

may comprise a network of pipes through which a heat

sist in the devices, combinations and arrangement of parts

ing medium, preferably steam, is circulated about an area

hereinafter described and claimed which together with

adjacent the shell surface to maintain a desired tempera

the advantages to be obtained thereby will be readily

ture of the external surface of the shell. Dryers of the

type referred to are built to operate at high speeds and 25 understood by one skilled in the art from the following

description taken in connection with the accompanying

with a drying surface heated to increasingly high tem

drawings in which:

peratures with the result that di?iculty has been experi

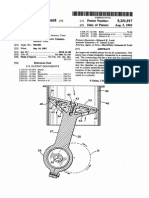

FIG. 1 is .a view in end elevation of a rotary drum

enced in providing a strong drum structure which will

dryer, but with the adjacent disc header removed, illus

provide adequately for the expansion and contraction of

the heated shell portion of the drum and will, at the same 30 trating the several features of the invention;

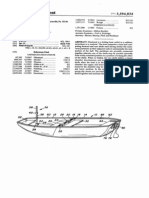

FIG. 2 is a view in side elevation of the rotary drum

time, insure that the rapidly rotating shell is at all times

tion with relation to the hub axis.

In an alternative embodiment of the invention, a cool_

ing roll is disclosed which comprises two solidly formed

end discs, an outer shell which is secured at each end to

said discs to rotate on a ?xed axis, and an inner shell

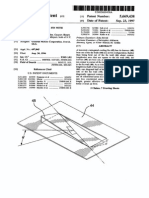

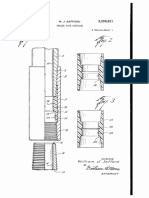

FIG. 3 is a detail view on a large scale and in section

of the lower portion of the drum shown in FIG. 2;

FIG. 4 is a fragmentary view of the drum in end eleva

tion illustrating one of the fastening devices for securing

the drum to the disc header;

FIG. 5 is a detail sectional view taken on a line 55

which cooperates with the outer shell for the circulation

of FIG. 3 illustrating one of the expansion joints; and

of the cooling medium such as water between said shells.

40

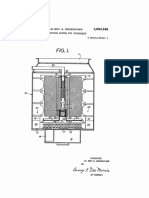

FIG. 6 is a view partly in section of a modi?ed form

In a structure of this type also, the di?erence in the

of the invention as shown in a cooling roll.

amount of expansion and contraction experienced in the

Referring to the drawings, the invention is herein dis

end discs and in the relatively colder outer shell has pre

closed in a preferred form in a rotary drum dryer of the

sented problems.

general type having a rotary drum 10 of substantial diame

It is an object of the invention to provide a novel and

improved drum structure including a series of expansion 45 ter consisting of a sleeve hub 12 supported in sleeve

bearings, not shown, and a shell 18 which is supported

joints in said structure so constructed and arranged that

with relation to the hub by means of two perforated disc

they will permit the shell, heated or cooled as the case

headers 20, 22. The shell has formed therein adjacent the

may be, to expand and to contract freely with relation to

outside peripheral surface a series of parallel longitu

the relatively constant temperature hub and radial sup

porting parts of the drum and which will, at the same 50 dinally extending conduits 24. At the ends of the shell

there are provided manifolds 26, 28 in the form of steel

time, maintain the shell securely in an exactly centered

and longitudinally determined position with relation to

pipes which are bent into a circular form having the same

the hub axis.

diameter as the shell, and abut the two ends of the shell.

A preferred embodiment of the invention comprises a

The manifolds extend entirely around the drum. Each

rotary drum heat exchanger having a shell with an ex 55 conduit 24 is tapped at its two ends into the respective

ternal heat exchanging surface, a rotary hub, and a plural

manifolds.

'

ity of disc headers mounted on the hub for supporting

Steam is passed through the manifolds 26, 28 and

the shell, said heat exchanger being provided with a series

conduits 24 by means of a steam supply system which

of expansion joints connected between each said disc

comprises a steam inlet junction 30 and a large diam

header and said shell around the periphery of said disc

eter pipe 32 ?tted within the sleeve hub 12 through which

header, each said expansion joint comprising .a pin and

steam is introduced into the drum and a condensate out

sleeve connection interconnected between said disc header

let junction 34 and a small diameter condensate outlet

and shell permitting relative movement of the intercon

pipe 36 ?tted within the inlet pipe 32 through which con

nected portions of said disc header and shell only along a

densate is withdrawn from the drum. The steam inlet

line radially of said drum axis. The arrangement is such 65 pipe 32 and condensate outlet pipe 36 are connected with

that the portion of the shell at the location of each said

the manifolds 26, 28 through connecting pipes which

expansion joint is freely adjustable only in a radial direc

tion with relation to said hub, while at the same time that

form no part of the present invention and are therefore

not here further referred to.

portion of the shell is ?xedly secured tangentially with 70 In accordance with the invention, the supporting struc

relation to said disc header. The tangential support pro

ture for the drum shell 18 including the disc headers 20,

vided at each of a plurality of such locations combines

22 is constructed and arranged to provide a drum struc

8,248,803

3

ture of maximum strength and rigidity while at the same

time permitting to the shell 18 complete freedom to ex

pand and contract in accordance with the varying thermal

conditions. The disc headers 20, 22 which, in the em

bodiment shown are constructed of heavy material, are

divided into outwardly disposed rims or ring members

46, 48 which are rigidly secured by an axially extending

bolt 50 to inwardly extending ?anges 52, 54 formed at the

4

18, but, on the other hand, is very rigidly supported

against lateral or turning movement with relation to the

sleeve hub 12.

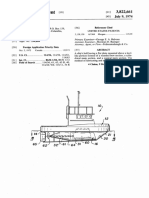

FIG. 6 of the drawings illustrates another embodiment

of the invention in a cooling roll, which comprises a drum

80 having a peripheral surface in the form of a shell 82

which is continuously cooled by the circulation of a cool

ing medium in contact with the inner periphery of said

shell. The drum 80 comprises generally two headers 84,

respective ends of the shell 18, and inner core disc mem

bers 56, 58 which are mounted respectively on the hub 10 86 on which the shell 82 is mounted. The header 84 is

formed on the end of a pivot shaft 88 which carries one

discs 60, 62 which are ?xedly mounted on the sleeve hub

12 of the drum assembly. In the embodiment shown,

the core disc members 56, 58 are positioned in the same

end of the cooling roll assembly, the header 86 being

similarly formed on the end of a hollow shaft 90 which

provides pivotal support for the other end of the cooling

posed rims 46, 48 and are spaced therefrom a su?icient 15 roll assembly. The cooling roll assembly is also provided

transverse planes respectively with the outwardly dis

amount to allow for any relative expansion or contraction

thereof.

In order to provide a rigid axially centered

support for the shell 18 on the core discs 56, 58, there are

with an inner drum 92 having the end portions thereof

narrowly spaced from the headers 84, 86 and the outer

periphery thereof narrowly spaced from the inner periph

ery of the shell 82 so that a space is provided between

of each disc header twelve identical expansion joints, gen 20 the inner drum 92 and shell 82 for the circulation of cool

ing water. The inner drum 92 is secured at its left-hand

erally designated at 66 comprising sleeve and pin connec

end to a bearing block 94 rigidly fastened into a bore

tions interconnecting said rims 46, 48 and said core disc

in the header 84 by screws 96. At its right-hand end

members 56, 58, each said sleeve and pin connection per

the inner drum 92 is formed with a tubular extension 98

mitting relative movement of the interconnected portions

of said rim and core disc members only along a line radial 25 having a sliding ?t with a sleeve bearing 100 provided in

the header 86.

ly of said drum axis. Said expansion joints have the effect

Coolant is introduced into the cooling roll through an

of securing the rim 46 or 48 to the associated inner core

provided at evenly spaced intervals around the periphery

disc member 56 or 58 in such a manner that the engaged

portion of the rim is permitted to move freely in a radial

inlet pipe 102 which extends through the hollow shaft 90

along the rotational axis of the cooling roll being sup

ported at its left-hand end as shown in FIG. 6 in the

bearing block 94 for the end of the inner drum 92. The

coolant enters the coolant space provided interiorly of

the shell 82 at the left-hand end of the drum assembly,

identical in their construction and mode of operation, only

?ows to the right-hand end of the drum assembly and is

one such joint will be speci?cally described in connection

with FIGS. 35, inclusive. As shown in these ?gures, the 35 drawn off through a passageway formed between the out

side diameter of the pipe 102 and inside diameter of the

expansion joint 66 comprises a metal block 68 formed

hollow shaft 90.

with a pin receiving bore and bolted to the core disc

In accordance with the invention the shell 82 is ?tted

member 56 adjacent the peripheral edge thereof. A

over the peripheral faces of the two headers 84, 86 loose

similarly formed block 70 is bolted to the rim 46 radially

outwardly from the block 68 and is similarly formed with 40 ly to permit expansion and contraction of the rim with re

in and out direction, but is positively secured against

transverse movement with relation to the core disc in

any direction. Inasmuch as these expansion joints are

spect to the two headers, being connected thereto only

a radial pin receiving bore providing a pin receiving

by means of radial pins 104 which are arranged in two

sleeve element in alignment with the bore formed in the

rows in staggered relation at spaced intervals about the

block 68. A guiding pin 72 extends through both of

periphery of the shell adjacent each end thereof. Each

said bores and is press ?tted and pinned into the bore of

the block 68 being, however, slidably ?tted within the 45 pin 104 is press ?tted through the shell and extends radial

ly inwardly into and has a sliding ?t with a socket 106

sleeve element provided by the block 70 and bore there

which is held by a press ?t in a radial bore in the periph

through. With this arrangement, it will readily be ap

ery of the respective header. In the construction shown,

preciated that the portion of the shell, controlled by each

there are twelve pairs of pins 104 mounted at equally

expansion joint including the guiding pin 72, is free to

move radially inwardly and outwardly as the shell con 50 spaced intervals about the periphery of the shell 82.

The pins are further arranged in opposed relation at

tracts or expands, being, however, rigidly secured against

opposite sides of the shell on diameters angularly arranged

any lateral movement by engagement with the respective

with relation to one another and passing through the axis

guiding pin 72.

of the headers. It will be evident that each opposed

In the illustrated construction, provision is made also

for expansion and contraction of the shell in an axial 55 pair of pins will provide a ?xed support for the shell,

including the rotational axis thereof, against movement

direction. Further in accordance with the invention, ex

in a direction transversely of the said diameter on which

pansion joints are provided between the sleeve hub 12 of

said pins are located while permitting expansion and con

the drum and one of the core header discs on which the

traction of the shell longitudinally of said diameter, so

shell 18 is carried. As best shown in FIGS. 1 and 2 of

the drawings, the header core disc 56 is rigidly secured 60 that the rotational axis of the shell is rigidly held at the

point of intersection of all of said diameters in a position

to the hub disc 68 by bolts 76. The header core disc 58,

concentric with the hub axis. The arrangement is such

on the other hand, is supported with relation to the hub

that the shell 82 is at all times supported securely in an

disc 62 by means of expansion pins 78 which are ?tted

exactly centered position with relation to the rotational

into aligned axially extending bores in the disc member

58 slidable on the hub disc 62. The pins 78 will prefer 65 axis of the pivot shaft 88 and shaft 90 while at the same

time it is permitted to expand and to contract freely in

ably have a press ?t with the pin receiving bore in the

a radial direction independently of the headers 84, 86.

hub disc 62 and a sliding ?t with the bore in the header

In order to prevent leakage of the cooling medium through

core disc 58 thus providing an axially expandable pin and

the relatively loose connections provided between the shell

sleeve bearing connection between said hub disc 62 and

said slidable header core disc 58. A substantial number 70 82 and the headers 84, 86, the header 86 is provided ad

jacent its outer edge with a ring 108 which overlies the

of these pins is provided at spaced intervals around the

end of the shell 82. The header 84 is similarly provided

circumference of the hub disc in order to provide a strong

support for the header core disc 58. The arrangement

with a ring 110 which overlies the opposite end of the

is such that the header core disc 58 is free to move axial

shell 82. O-rings 112, 114 mounted in the inner faces of

ly as dictated by the expansion or contraction of the shell 75 the rings 108, 110, respectively, prevent the escape of

3,248,803

coolant past the ends of the outer shell 82. The shell

82 and headers 84, 86 of the cooling roll illustrated in

receiving hole in the shell 82 is now lined up with the

associated socket 106, and a pin 104 is driven into posi

tion through the shell 82. Finally the rings 110, 108 are

assembled and screwed to the outer faces of the headers

shell, a guide block having a bore extending along the

same radial line secured to said disc header, a guide pin

extending through both of said bores, and means secur

ing said guide pin within one of said bores in position for

sliding engagement with the other said bore.

3. A rotary drum according to claim 1 in which a plu

rality of pin and sleeve bearing expansion joints are pro

vided between each said disc header and said shell even

ly spaced from one another about the periphery of said

rotary drum and are paired in opposed relation at oppo

site ends of a plurality of pairs of perpendicularly cross

84, 86 in the positions shown.

ing diameters.

With the construction shown, the outer shell 82 is

permitted to expand and to contract radially with rela

tion to the relatively thick-walled headers 84, 86 by means

4. A rotary drum according to claim 1 including a said

disc header shiftable axially on said hub in accordance

FIG. 6 may be assembled as follows:

The sockets 106 are press ?tted into bores in the pe

ripheries of the two headers 84, 86 and the shell 82,

similarly drilled to receive the pins 104, is then slid

into position axially over the headers 84, 86. Each pin

with the axial contraction and expansion of said shell,

said axially shiftable header comprising a shell support

ing disc member having radial pin and sleeve bearing

of the pin and socket connections above described, while

at the same time the shell is at all times held ?rmly in

its centered position with relation to the rotational axis of

expansion joints with said shell, a hub disc member ?xed

the cooling roll. Expansion and contraction of the out

to said hub in radially overlapping relation to said shell

er shell 82 axially with relation to the inner drum 92 is 20 supporting disc member, and a plurality of axially extend

permitted by the sliding ?t provided between the bearing

ing pin and sleeve bearing connections between the over

100 formed within the right-hand header 84 and the tu

lapping portions of said hub disc member and said shell

bular extension 98 of the drum 92.

supporting disc member spaced about the axis of said

The invention having been described what is claimed is:

hub on which the said shell supporting disc member is

1. A rotary drum for use in a rotary drum heat ex 25 keyed to turn with and is freely shiftable axially with rela

changer which comprises a shell having an external heat

tion to said hub disc member and hub.

exchanging surface, a rotary hub, a plurality of disc head

ers mounted on the hub and spaced from one another

References Cited by the Examiner

along the length of the shell for supporting said shell, a

UNITED STATES PATENTS

series of expansion joints on which the shell is supported

30

from said disc headers comprising opposed pairs of pin

1,692,537

11/1928 Baumann.

and sleeve bearing connections at opposite sides of each

disc header along diameters intersecting the hub axis at

a substantial angle to one another, the pins extending

radially of the drum axis for movement relatively to said 35

1,692,538

11/1928

sleeve bearings only along said diameter, each opposed

pair of pin and sleeve bearing connections on a said

diameter providing a ?xed support for said shell including

the rotational axis thereof against movement in a direc

tion transversely of said diameter, while permitting ex 40

pansion and contraction of the shell longitudinally of

said diameter, whereby the rotational axis of the shell is

1,873,743

2,563,692

Baumann __________ __ 253--69

8/ 1932 Doran.

8/1951

Ostertag _________ __ 34-124 X

2,622,843

12/ 1952 Williams.

2,628,433

2,817,908

3,060,592

2/ 1953

12/ 1957

10/1962

Ostertag __________ __ 34-124

Hornbostel ________ __ 341 10

Ostertag ___________ __ 34124

3,169,050

2/1965

Kroon ____________ __ 34124

FOREIGN PATENTS

531,605

8/1931 Germany.

rigidly held at the intersection of said diameters concen

tric with the hub axis.

WILLIAM F. ODEA, Primary Examiner.

2. A rotary drum according to claim 1 in which each 45

said expansion joint comprises a guide block having a

bore extending radially of the shell axis secured to said

NORMAN YUDKOFF, Examiner.

J. SOFER, Assistant Examiner.

You might also like

- Umted States Patent (19) (11) Patent Number: 5,642,778: Gentry (45) Date of Patent: Jul. 1, 1997Document15 pagesUmted States Patent (19) (11) Patent Number: 5,642,778: Gentry (45) Date of Patent: Jul. 1, 1997aegosmithNo ratings yet

- US3200917Document5 pagesUS3200917张淼No ratings yet

- Intersecting Spherical Pressure TankDocument25 pagesIntersecting Spherical Pressure TankLuci Oktaria SitorusNo ratings yet

- (1956), June 14) US2970812 Drum Type Heat ExchangerDocument4 pages(1956), June 14) US2970812 Drum Type Heat ExchangeraegosmithNo ratings yet

- United States Patent (191: McguganDocument6 pagesUnited States Patent (191: McguganJamesStenhouseNo ratings yet

- Chlorine CylinderDocument9 pagesChlorine Cylinderjoseph_mscNo ratings yet

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Document7 pagesSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNo ratings yet

- O/65ézá / /zzáez: Ozzezz67Document4 pagesO/65ézá / /zzáez: Ozzezz67TECUMCE GOMEZ PEREZNo ratings yet

- US4143639 Friction Heat Space Heater, Eugene FrenetteDocument6 pagesUS4143639 Friction Heat Space Heater, Eugene FrenetteBastien Gall de SilléNo ratings yet

- CN205423574 (U) EnglishDocument2 pagesCN205423574 (U) EnglishGabriel PhilippiNo ratings yet

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- Siled Sept. 8, 1966: T, N. NccomeDocument5 pagesSiled Sept. 8, 1966: T, N. NccomeliNo ratings yet

- United States PatentDocument7 pagesUnited States PatentDouglas TondelloNo ratings yet

- April 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965Document4 pagesApril 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965fgrt490No ratings yet

- (1947, June 21) US2547086 Heating DrumDocument3 pages(1947, June 21) US2547086 Heating DrumaegosmithNo ratings yet

- US5231917 - Wobble PistonDocument5 pagesUS5231917 - Wobble PistondevheadbotNo ratings yet

- Us2960824 PDFDocument5 pagesUs2960824 PDFgrigNo ratings yet

- Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1Document5 pagesJan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1luiscremaschiNo ratings yet

- US2427676Document4 pagesUS2427676udrogono2No ratings yet

- Foldable Boat FlierDocument5 pagesFoldable Boat FlierRakeshNo ratings yet

- United States Patent: SchwartzmanDocument4 pagesUnited States Patent: SchwartzmanJames LindonNo ratings yet

- No. 686,313. Patented Nov. 12, 1901. A. S. MANN..: Feed Water HeaterDocument5 pagesNo. 686,313. Patented Nov. 12, 1901. A. S. MANN..: Feed Water HeaterpavandattaNo ratings yet

- Title - Wood Chipper ConstructionDocument4 pagesTitle - Wood Chipper Constructionمحمد عبدالدايمNo ratings yet

- Clem Engine Paper PresentationDocument6 pagesClem Engine Paper PresentationDankamialNo ratings yet

- European Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)Document10 pagesEuropean Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)shamsNo ratings yet

- Umted States Patent (191 (11) 4,173,936: Secord Et Al. (45) Nov. 13, 1979Document8 pagesUmted States Patent (191 (11) 4,173,936: Secord Et Al. (45) Nov. 13, 1979venkatrangan2003No ratings yet

- 8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336Document9 pages8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336tyrer567899No ratings yet

- Nov. 9, 1965 G. C. Molotzak 3,216,390Document5 pagesNov. 9, 1965 G. C. Molotzak 3,216,390احمد عبدالكريمNo ratings yet

- Filed July 30, 1923: Pedal of Erator For Flush ValvesDocument3 pagesFiled July 30, 1923: Pedal of Erator For Flush ValvesmarlondijiNo ratings yet

- United States Patent (191: Beales Et Al. (45) Date of Patent: Sep. 23, 1997Document13 pagesUnited States Patent (191: Beales Et Al. (45) Date of Patent: Sep. 23, 1997Amit PatelNo ratings yet

- 1,018,037 ... Patented Feb. 20, 1912.: .??? Coax/K Wyùkkevaoma ????Document3 pages1,018,037 ... Patented Feb. 20, 1912.: .??? Coax/K Wyùkkevaoma ????fernando Ancaya AncayaNo ratings yet

- Us5361479 PDFDocument5 pagesUs5361479 PDFmohammadreza91No ratings yet

- Original: FiledDocument4 pagesOriginal: FiledwcaskeyNo ratings yet

- Tài liệu5Document12 pagesTài liệu5Hoàng ĐứcNo ratings yet

- United States Patent (191: Lown (45) Nov. 11, 1980Document4 pagesUnited States Patent (191: Lown (45) Nov. 11, 1980HamedJamshidiNo ratings yet

- (1975, Sept. 9) US3903963 Heat ExchangerDocument4 pages(1975, Sept. 9) US3903963 Heat ExchangeraegosmithNo ratings yet

- Us3771455 PDFDocument3 pagesUs3771455 PDFdgfsduuwioNo ratings yet

- Rat Hole DiggerDocument4 pagesRat Hole DiggerDarshan MakwanaNo ratings yet

- United States Patent (191: (73) AssigneeDocument6 pagesUnited States Patent (191: (73) AssigneeRodrigoPomaNo ratings yet

- Us4070957 PDFDocument8 pagesUs4070957 PDFpertmasterNo ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- US3094165 Wheeler Manfac-PatentDocument7 pagesUS3094165 Wheeler Manfac-Patentsoubhadra nagNo ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- In The DrawingsDocument8 pagesIn The DrawingsLalit KumarNo ratings yet

- United States Patent (19) : Patent Number: (45) Date of PatentDocument10 pagesUnited States Patent (19) : Patent Number: (45) Date of PatentMichael JordanNo ratings yet

- Iii Iihiii: United States Patent (19) 11 Patent Number: 5,732,772Document10 pagesIii Iihiii: United States Patent (19) 11 Patent Number: 5,732,772abodolkuhaaNo ratings yet

- United States Patent (191: RandallDocument6 pagesUnited States Patent (191: RandallluiscremaschiNo ratings yet

- TEPZZ - 4 885B - T: European Patent SpecificationDocument10 pagesTEPZZ - 4 885B - T: European Patent SpecificationshamsNo ratings yet

- Byyeqwla: 2 I / I I VDocument5 pagesByyeqwla: 2 I / I I VaegosmithNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- Jan. 4, L 1966 T. W. Spack 3,227,148Document6 pagesJan. 4, L 1966 T. W. Spack 3,227,148MainAvelNo ratings yet

- Patented May 4:, 1915.: (Nven ForDocument4 pagesPatented May 4:, 1915.: (Nven Forbelchior alvaroNo ratings yet

- United States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994Document6 pagesUnited States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994mohammadreza91No ratings yet

- United States Patent: SimpsonDocument5 pagesUnited States Patent: Simpsonاحمد عبدالكريمNo ratings yet

- Gaugler, R. S. (1944) - U.S.A. Patent No. 2350348.Document5 pagesGaugler, R. S. (1944) - U.S.A. Patent No. 2350348.pathiNo ratings yet

- Dau TomDocument6 pagesDau TomPham LoiNo ratings yet

- Us3266821 PDFDocument5 pagesUs3266821 PDFDiogo CorreaNo ratings yet

- Us 6557638Document21 pagesUs 6557638daniel_iosif_glNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Y Try RRRRRRR RRRRRRRR RRRRRRRRDocument1 pageY Try RRRRRRR RRRRRRRR RRRRRRRRaegosmithNo ratings yet

- Characterization, Synthesis and Catalysis of Hydrotalcite-Related Materials For Highly Efficient Materials TransformationsDocument17 pagesCharacterization, Synthesis and Catalysis of Hydrotalcite-Related Materials For Highly Efficient Materials TransformationsaegosmithNo ratings yet

- Pub101193234 PDFDocument8 pagesPub101193234 PDFaegosmithNo ratings yet

- Seperation Sequances PDFDocument38 pagesSeperation Sequances PDFaegosmithNo ratings yet

- YtryrrrrrrrrrrrrrrrrrrrrrrrDocument1 pageYtryrrrrrrrrrrrrrrrrrrrrrrraegosmithNo ratings yet

- Size Effect of Layered Double Hydroxide Platelets On The Crystallization Behavior of Isotactic PolypropyleneDocument8 pagesSize Effect of Layered Double Hydroxide Platelets On The Crystallization Behavior of Isotactic PolypropyleneaegosmithNo ratings yet

- Adsorption of Phenanthrene On Activated Carbons - Breakthrough Curve ModelingDocument9 pagesAdsorption of Phenanthrene On Activated Carbons - Breakthrough Curve ModelingaegosmithNo ratings yet

- ContributorsDocument3 pagesContributorsBamrung SungnoenNo ratings yet

- Static Liquid Holdup in Packed Beds of Spherical ParticlesDocument4 pagesStatic Liquid Holdup in Packed Beds of Spherical ParticlesaegosmithNo ratings yet

- Prediction of Breakthrough Curves For Adsorption On Activated Carbon Fibers in A Fixed BedDocument5 pagesPrediction of Breakthrough Curves For Adsorption On Activated Carbon Fibers in A Fixed BedaegosmithNo ratings yet

- A Review of Explicit Approximations of Colebrook's Equation: Srbislav GenićDocument5 pagesA Review of Explicit Approximations of Colebrook's Equation: Srbislav GenićLutfi LailaNo ratings yet

- CopyrightDocument1 pageCopyrightaegosmithNo ratings yet

- Chapter 23 Thermophilic Biohydrogen Production PDFDocument12 pagesChapter 23 Thermophilic Biohydrogen Production PDFaegosmithNo ratings yet

- Adsorption of Phenanthrene On Activated Carbons - Breakthrough Curve ModelingDocument9 pagesAdsorption of Phenanthrene On Activated Carbons - Breakthrough Curve ModelingaegosmithNo ratings yet

- Appendix 1 Abbreviations UsedDocument2 pagesAppendix 1 Abbreviations UsedaegosmithNo ratings yet

- PrefaceDocument1 pagePrefaceaegosmithNo ratings yet

- CopyrightDocument1 pageCopyrightaegosmithNo ratings yet

- Appendix 5 A Selection of Other Useful Contact Points Including Networks and WebsitesDocument4 pagesAppendix 5 A Selection of Other Useful Contact Points Including Networks and WebsitesaegosmithNo ratings yet

- BibliographyDocument7 pagesBibliographyBamrung SungnoenNo ratings yet

- Appendix 2 NomenclatureDocument2 pagesAppendix 2 NomenclatureaegosmithNo ratings yet

- CopyrightDocument1 pageCopyrightaegosmithNo ratings yet

- Experimental Methods and Instrumentation For Chemical EngineersDocument1 pageExperimental Methods and Instrumentation For Chemical EngineersaegosmithNo ratings yet

- Structure of The Book: New Chapter Significantly Modified ChapterDocument1 pageStructure of The Book: New Chapter Significantly Modified ChapterBamrung SungnoenNo ratings yet

- Appendix 3 Equipment SuppliersDocument16 pagesAppendix 3 Equipment SuppliersaegosmithNo ratings yet

- Prediction of Breakthrough Curves For Adsorption On Activated Carbon Fibers in A Fixed BedDocument5 pagesPrediction of Breakthrough Curves For Adsorption On Activated Carbon Fibers in A Fixed BedaegosmithNo ratings yet

- CopyrightDocument1 pageCopyrightaegosmithNo ratings yet

- 2 CopyrightDocument1 page2 CopyrightRisely FerrazNo ratings yet

- Appendix AnswersDocument14 pagesAppendix AnswersaegosmithNo ratings yet

- Appendix AnswersDocument14 pagesAppendix AnswersaegosmithNo ratings yet

- Ess Check ListDocument2 pagesEss Check ListBabu Viswanath MNo ratings yet

- Petitioner Vs Vs Respondent: First DivisionDocument4 pagesPetitioner Vs Vs Respondent: First DivisionAndrei Anne PalomarNo ratings yet

- JIGL-Chapter5 (Administrative Law)Document21 pagesJIGL-Chapter5 (Administrative Law)KHUSHBOO SHARMANo ratings yet

- In This Chapter : Me, ShankarDocument20 pagesIn This Chapter : Me, ShankarPied AvocetNo ratings yet

- NEW GL Archiving of Totals and DocumentsDocument5 pagesNEW GL Archiving of Totals and Documentsantonio xavierNo ratings yet

- Dyson Cylinder DC22 Vacuum User GuideDocument16 pagesDyson Cylinder DC22 Vacuum User Guidejames ryerNo ratings yet

- Candlestick Charting: Quick Reference GuideDocument24 pagesCandlestick Charting: Quick Reference GuideelisaNo ratings yet

- The Tipster1901, From "Wall Street Stories" by Lefevre, EdwinDocument20 pagesThe Tipster1901, From "Wall Street Stories" by Lefevre, EdwinGutenberg.orgNo ratings yet

- ADR PresentationDocument9 pagesADR PresentationAshraf AliNo ratings yet

- Celebration of International Day For Street ChildrenDocument3 pagesCelebration of International Day For Street ChildrenGhanaWeb EditorialNo ratings yet

- Notes On Qawaid FiqhiyaDocument2 pagesNotes On Qawaid FiqhiyatariqsoasNo ratings yet

- ANSYS Meshing Users GuideDocument520 pagesANSYS Meshing Users GuideJayakrishnan P SNo ratings yet

- Obituary of Nelson Mandela - Nelson Mandela - A Leader Above All Others (Guardian Editorial)Document3 pagesObituary of Nelson Mandela - Nelson Mandela - A Leader Above All Others (Guardian Editorial)somebody535100% (1)

- QCP Installation of Ahu FahuDocument7 pagesQCP Installation of Ahu FahuThulani DlaminiNo ratings yet

- Opposition To Motion To DismissDocument24 pagesOpposition To Motion To DismissAnonymous 7nOdcANo ratings yet

- New Income Slab Rates CalculationsDocument6 pagesNew Income Slab Rates Calculationsphani raja kumarNo ratings yet

- Best of Best As of May 15, 2019 330pmDocument34 pagesBest of Best As of May 15, 2019 330pmBpsmu Rmfb XI100% (1)

- 1st Indorsement RYAN SIMBULAN DAYRITDocument8 pages1st Indorsement RYAN SIMBULAN DAYRITAnna Camille TadeoNo ratings yet

- Safety Data Sheet: Ubstance and Ource DentificationDocument6 pagesSafety Data Sheet: Ubstance and Ource DentificationMuhNo ratings yet

- Financial Analysts - Occupational Outlook Handbook - U.S. Bureau of Labor StatisticsDocument6 pagesFinancial Analysts - Occupational Outlook Handbook - U.S. Bureau of Labor StatisticsHannah Denise BatallangNo ratings yet

- Questa Sim Qrun UserDocument50 pagesQuesta Sim Qrun UsertungnguyenNo ratings yet

- Digest NegoDocument9 pagesDigest NegoMichael RentozaNo ratings yet

- Issues in EducationDocument15 pagesIssues in EducationChinie DomingoNo ratings yet

- The Unity of The FaithDocument2 pagesThe Unity of The FaithGrace Church ModestoNo ratings yet

- LCIA Vs UNCITRAL - WEIGHING THE PROS AND CONSDocument1 pageLCIA Vs UNCITRAL - WEIGHING THE PROS AND CONSShahrukh NawazNo ratings yet

- Prelims Case Analysis AnswersDocument2 pagesPrelims Case Analysis AnswersGirl langNo ratings yet

- 9-14-10 Captain Frank G Sabatino-To Receive His FirearmDocument2 pages9-14-10 Captain Frank G Sabatino-To Receive His FirearmEwing Township, NJNo ratings yet

- Davao October 2014 Criminologist Board Exam Room AssignmentsDocument113 pagesDavao October 2014 Criminologist Board Exam Room AssignmentsPRC Board0% (1)

- ASME - Lessens Learned - MT or PT at Weld Joint Preparation and The Outside Peripheral Edge of The Flat Plate After WDocument17 pagesASME - Lessens Learned - MT or PT at Weld Joint Preparation and The Outside Peripheral Edge of The Flat Plate After Wpranav.kunte3312No ratings yet

- Passbolt On AlmaLinux 9Document12 pagesPassbolt On AlmaLinux 9Xuân Lâm HuỳnhNo ratings yet