Professional Documents

Culture Documents

Jyoti Envirotech Solid Waste Project

Uploaded by

Raja Sekhar ReddyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jyoti Envirotech Solid Waste Project

Uploaded by

Raja Sekhar ReddyCopyright:

Available Formats

UNFCCC/CCNUCC

CDM Executive Board

Page 1

PROJECT DESIGN DOCUMENT FORM

FOR CDM PROJECT ACTIVITIES (F-CDM-PDD)

Version 04.1

PROJECT DESIGN DOCUMENT (PDD)

Title of the project activity

Version number of the PDD

Completion date of the PDD

Project participant(s)

Host Party(ies)

Sectoral scope and selected methodology(ies)

Estimated amount of annual average GHG

emission reductions

Methane emission avoidance through treatment

of municipal solid wastes in Lucknow, Uttar

Pradesh, India

01

15.06.2012

Jyoti Enviro Tech Pvt. Ltd.

India

Sectoral Scope 13: Waste Handling And

Disposal

Approved Methodology: AM0025 Avoided

emissions from organic waste through

alternative waste treatment processes Version:

13/EB 65

Average emission reduction of

82,729tCO2/annum

UNFCCC/CCNUCC

CDM Executive Board

Page 2

SECTION A. Description of project activity

A.1. Purpose and general description of project activity

>>

Description of the project activity

Jyoti Enviro Tech Pvt. Ltd is in the process of installation of a solid waste treatment facility to produce

compost and Refuse Derived Fuel (RDF) by aerobic treatment of municipal solid wastes (MSW) in

Lucknow. The objective of the project activity is to avoid methane emissions from anaerobic

decomposition of MSW through aerobic treatment of the wastes in the solid waste treatment facility. The

installed facility would have a capacity to treat 1300 TPD of municipal solid wastes.

Pre-Project Scenario:

At present, the management of municipal solid waste in Lucknow is not sound structured and the reason

behind it is lack of awareness among the citizens as well as inactions of the civic bodies responsible for

handling and management of the MSW. The waste processing and disposal mechanisms in Lucknow are

majorly unscientific and involve mainly open dumping at identified sites without any preprocessing.

There are no measures for landfill gas capture and or destruction. The open disposal leads to uncontrolled

anaerobic decomposition of wastes causing a number of environmental and health hazards, in addition to

unabated release of methane into the atmosphere, which is one of the prominent greenhouse gases. Also,

the leachate generated in the landfill seeps into the soil and pollutes the ground and surface water.

This scenario identified above in the pre-project scenario is the baseline scenario for the project activity.

Project Scenario:

The project activity involves installation of a waste handling and processing plant for treatment of waste

under aerobic conditions to produce composts and refuse derived fuel (RDF). Both these products are

saleable in the market. The project activity through scientific processing of wastes under aerobic

conditions will result in avoidance of methane generation which would have taken place due to anaerobic

decomposition of the wastes in landfill, the existing scenario of waste disposal in the city of Lucknow.

Thus the project activity results in the emission reductions to the tune of 82,729 tCO2/annum on an

average over 10 years of its crediting period.

Contribution of the project activity towards sustainable development

Government of India has stipulated following indicators 1 for sustainable development in the interim

approval guidelines for CDM projects. The sustainability aspect of the project activity has been dealt

under the following four pillars of sustainable development.

Social Well-being:

The project activity will improve the local sanitary conditions of the inhabitants of the city by facilitating

an eco-friendly disposal of MSW. The project activity by avoiding the decay of MSW in unscientific and

ordinary landfills helps in improving the health, moral and sanitary conditions of the local people. Jyoti

1

http://www.cdmindia.in/approval_process.php

UNFCCC/CCNUCC

CDM Executive Board

Page 3

Enviro Tech Pvt. Ltd has also committed to dedicate 2% of the revenue derived from CER, towards

development of local community. The monitorable plan for the same has been detailed in Appendix A in

the later section of this PDD.

Economic Well-Being:

The project provides employment to the community directly at the MSW processing facility and

indirectly through waste collection, transportation of compost and RDF to the end user. Thus, the project

provides fresh job opportunities to the local people and helps in upliftment of the economic stature of the

society.

Environmental Well-being:

Composting of Municipal Solid Waste (MSW) is an attractive option for resource recovery and

environmental improvement. In contrast to the anaerobic decay of biodegradable waste that occurs in the

landfill sites, which results in methane generation among other landfill gases, the MSW processing

project will contribute in mitigation of greenhouse gas (GHG) emissions through aerobic decomposition

and mechanical treatment of the municipal solid waste. Due to the proposed project activity, dumping of

given waste is prevented resulting in reduction in land requirement for waste disposal, leading to

improved environmental conditions and a replicable model.

Technological Well-being:

Successful implementation of this project would lead to further diffusion of MSW processing technology

for treatment of waste generated in India.

A.2. Location of project activity

A.2.1. Host Party(ies)

>>

India

A.2.2. Region/State/Province etc.

>>

Uttar Pradesh

A.2.3. City/Town/Community etc.

>>

Lucknow

UNFCCC/CCNUCC

CDM Executive Board

Page 4

A.2.4. Physical/Geographical location

>>

The proposed project activity will be implemented in Shiveri village in the district of Lucknow in the

state of Uttar Pradesh. Lucknow is the capital of one of the largest states of India, Uttar Pradesh. It is

located at latitudes 26 51' 40.2N and longitudes 80 49'52E. Lucknow is accessible from every part of

India through air, rail and road. It is directly connected with New Delhi, Patna, Kolkata, Mumbai,

Varanasi and other major cities by Amausi airport.

UNFCCC/CCNUCC

CDM Executive Board

Page 5

A.3. Technologies and/or measures

>>

Jyoti Enviro Tech Pvt. Ltd. follows a scientific waste management approach which includes aerobic

treatment of bio-degradable solid waste to produce compost and refuse derived fuel. The waste reaching

the processing plant will be received in two separate parts, biodegradable and non-biodegradable. The

biodegradable part of the wastes would be processed to produce compost and RDF while the inert

materials in non-biodegradable wastes will be delivered to the sanitary landfill. The collection of waste is

estimated to be 1300 TPD. The scope of project activity includes:

Aerobic processing and mechanical treatment of the waste: The collection vehicles that bring in the

waste from the transfer station to the MSW processing site, will be weighed in a weighbridge at the

entrance of the facility every time the vehicles come in and go out and the respective weights will be

recorded. This will be done to have a record of the incoming MSW quantities by weight. Thereafter

the vehicles carrying wastes will be directed to the specified points for unloading. The inert waste

will be unloaded at the identified site for sanitary landfill and the recyclable materials will be

segregated for sale to scrap dealers. The rest of the waste i.e. the biodegradable wastes will be

unloaded at pits which mark the start point of the waste processing line. A seepage line is present at

the bottom of each pit which connects with the similar lines from other pits. This is meant for

collecting the leachate that is generated from the waste deposition at the pits.

Each pit has a hopper adjacent to it. The wastes collected from the pit by the EOT crane is fed into

the hopper through a conveyer belt. The hopper leads the waste into a pre-sorting section and

thereafter through a conveyer belt into a rotary screen trommel where the waste is screened. The

wastes below 100mm as screened in the trommel are led to the composting area whereas those

screened above 100 mm are led by another conveyer belt to the area for production of RDF.

a) Production of compost:

The trommel is a rotary screen that separates the waste on the basis of size. The biodegradable

wastes fed into the trommel is further screened to segregate wastes below and above 100 mm size.

The wastes below 100mm are undergone composting.

The waste is collected by the EOT cranes and led to the curing and drying area where the waste is

heaped and biological inoculum are sprayed at regular intervals. In this area, the moisture of the

waste is dried up and maintained at 5-10%. The heaps are turned at scheduled intervals to ensure a

proper aerobic processing of the waste. The heap of waste thus accumulated is further led to the

composting pads. The waste is processed for duration of 20-25 days. In the course of this time,

through monitored processing, the waste is transformed into a brown colored mass resembling

humus. Further, the waste is passed through 3 more stages of trommel for screening the mass of

waste successively into 35mm, 16mm and finally to 4 mm. At this stage, the waste is fed into the

finishing area. Finishing area comprises of sheds where the final product of waste processing,

compost is packed and made ready to be sold in the market.

b) Production of Reduce derived fuel (RDF):

Wastes screened at the trommel above 100mm are directed to a conveyer line carrying them to an

adjacent area where the waste will be processed to produce reduce derived fuel (RDF). The waste is

passed through a vibrating conveyer where a blower segregates any plastic material from the waste.

The rest waste is then passed through the conveyer into the RDF producing machine. The production

of RDF involves processing of the waste by magnetic shredders and subsequent homogenizing of the

UNFCCC/CCNUCC

CDM Executive Board

Page 6

waste in homogenizers. Thereafter, the uniform mass of waste thus prepared is compressed by

hydraulic systems to produce RDF units resembling the shape of soap blocks.

The lifetime of the project equipments is specified as 25 yrs 00 months. Also, it is to be noted that

the project does not involve any technology transfer from Annex 1 countries. The training required

for the persons for operation and maintenance of the equipments would be provided through capacity

building sessions by the technology provider and would be frequently organized by the project

proponent.

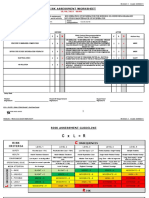

Brief description of type of monitoring equipments: For monitoring the various parameters of the project,

the following equipments would be used.

Sl No

1

2

3

4

5

Parameter

Quantity of compost produced in year y

Quantity of RDF produced in year y

Amount of electricity consumed from the grid as a result of the

project activity

Quantity of waste composted in year y

Raw waste quantity

Description of equipment type

Weight scale

Weight scale

Energy meter

Belt scales

Weigh bridge

Further details on the same have been furnished in Section B.7.1. under section Data and parameters to

be monitored

The various monitoring points in the project boundary have been schematically represented in the

diagram below:

UNFCCC/CCNUCC

CDM Executive Board

Page 7

A.4. Parties and project participants

Party involved

(host) indicates a host Party

India(host)

Private and/or public

entity(ies) project participants

(as applicable)

Indicate if the Party involved

wishes to be considered as

project participant (Yes/No)

Jyoti Enviro Tech Pvt. Ltd. No

(Private entity)

A.5. Public funding of project activity

>>

The project has not received any Official Development Assistance (ODA) from Annex I countries.

SECTION B. Application of selected approved baseline and monitoring methodology

B.1. Reference of methodology

>>

Title of the approved baseline and monitoring methodology: Avoided emissions from organic waste

through alternative waste treatment processes. Version 13, EB 65

Sectoral Scope: 01 and 13

Reference:

Tool for the demonstration and assessment of additionality, Version 06.0.0, EB 65

Methodological tool for Emissions from solid waste disposal sites, Version 06.0.1, EB 66

Tool to calculate the emission factor for an electricity system, Version 02.2.1, EB 63

Methodological tool for Project and leakage emissions from composting Version 01.0.0, EB 65

B.2. Applicability of methodology

>>

The project meets all the applicability criteria as set out in the methodology. The applicability conditions

of the methodology AM0025, Version 13 for the project activity have been justified as below:

Sr.

No

1.

Applicability Conditions as per AM0025

Version 13

The project activity involves one or a

combination of the following waste treatment

options for the fresh waste that in a given year

would have otherwise been disposed of in a

landfill

Justification

The project activity involves a combination of the

waste treatment options a) A composting process

in aerobic conditions d) Mechanical treatment

process to produce refuse-derived fuel

(RDF)/stabilized biomass (SB). The project

activity does not involve the use of RDF. Also,

(a) A composting process in aerobic the project activity does not involve any thermal

conditions;

operation. In the absence of the project the fresh

(b) Gasification to produce syngas and its use; waste would have been disposed off in a landfill.

(c) Anaerobic digestion with biogas collection

and flaring and/or its use. The anaerobic This justifies the applicability criteria.

digester processes only the waste for which

emission reductions are claimed in this

methodology. If the biogas is processed and

upgraded to the quality of natural gas and it is

distributed as energy via natural gas

UNFCCC/CCNUCC

CDM Executive Board

2.

3.

4.

distribution grid, project activities may use

approved

methodology

AM0053

in

conjunction with this methodology. In such

cases the baseline scenario identification

procedure and additionality assessment shall

be undertaken for the combination of the two

components of the project activity i.e.

biomethane

emission

avoidance

and

displacement of natural gas;

(d) Mechanical/thermal treatment process to

produce refuse-derived fuel (RDF)/stabilized

biomass (SB) and its use. The thermal

treatment process (dehydration) occurs under

controlled conditions (up to 300 degrees

Celsius). In case of thermal treatment process,

the process shall generate a stabilized

biomass that would be used as fuel or raw

material in other industrial process. The

physical and chemical properties of the

produced RDF/SB shall be homogenous

and constant over time;

(e) Incineration of fresh waste for energy

generation, electricity and/or heat. The

thermal energy generated is either consumed

on-site and/or exported to a nearby facility.

Electricity generated is either consumed onsite, exported to the grid or exported to a

nearby facility. The incinerator is rotating

fluidized bed or circulating fluidized bed or

hearth or grate type

In case of anaerobic digestion, gasification or

RDF processing of waste, the residual waste

from these processes is aerobically composted

and/or delivered to a landfill.

Page 8

In RDF processing of waste, the residual

biodegradable waste is aerobically composted and

the remainder i.e. the inert portion is delivered to

the pre-identified sanitary landfill.

This justifies the applicability criteria.

In case of composting, the produced compost The compost produced in the project activity will

is either used as soil conditioner or disposed be sold in the market that will be used as a soil

of in landfills

conditioner.

In case of RDF/stabilized biomass processing,

the produced RDF/stabilized biomass should

not be stored in a manner that may result in

anaerobic conditions before its use

This justifies the applicability criteria.

In the project activity the produced RDF will be

sold in the market and will not be stored in a

manner that may result in anaerobic conditions

before its use.

UNFCCC/CCNUCC

CDM Executive Board

5.

6.

7.

8.

9.

If RDF/SB is disposed of in a landfill, project

proponent shall provide degradability analysis

on an annual basis to demonstrate that the

methane generation, in the life-cycle of the

SB is below 1% of related emissions. It has to

be demonstrated regularly that the

characteristics of the produced RDF/SB

should not allow for re-absorption of moisture

of more than 3%. Otherwise, monitoring the

fate of the produced RDF/SB is necessary to

ensure that it is not subject to anaerobic

conditions in its lifecycle;

In the case of incineration of the waste, the

waste should not be stored longer than 10

days. The waste should not be stored in

conditions that would lead to anaerobic

decomposition and, hence generation of CH4;

The proportions and characteristics of

different types of organic waste processed in

the project activity can be determined, in

order to apply a multiphase landfill gas

generation model to estimate the quantity of

landfill gas that would have been generated in

the absence of the project activity;

Page 9

This justifies the applicability criteria.

In the project activity the produced RDF will be

sold in the market and will not be disposed in the

landfill.

Hence this condition is not applicable.

The project activity does not involve the

incineration of waste.

Hence this condition is not applicable.

The proportions and characteristics of different

types of organic waste processed in the project

activity will be determined as per the process

described in section B.7.2 of PDD, in order to

apply a multiphase landfill gas generation model

to estimate the quantity of landfill gas that would

have been generated in the absence of the project

activity.

This justifies the applicability criteria.

The project activity may include electricity The project activity does not include electricity

generation and/or thermal energy generation generation and/or thermal energy generation.

from the biogas,

syngas

captured,

RDF/stabilized

biomass

produced, Hence this condition is not applicable.

combustion heat generated in the incineration

process, respectively, from the anaerobic

digester, the gasifier, RDF/stabilized biomass

combustor, and waste incinerator. The

electricity can be exported to the grid and/or

used internally at the project site. In the case

of RDF/SB produced, the emission reductions

can be claimed only for the cases where the

RDF/SB used for electricity and/or thermal

energy generation can be monitored;

Waste handling in the baseline scenario The MSW 2000 rules stipulated by GoI mandated

UNFCCC/CCNUCC

CDM Executive Board

shows a continuation of current practice of

disposing the waste in a landfill despite

environmental regulation that mandates the

treatment of the waste, if any, using any of

the project activity treatment options

mentioned above

Page 10

the municipal bodies to treat the municipal waste

in a scientific manner 2 . However, despite the

rules, the common practice of handling the waste

in the country is continuation of current practice

of dumping the wastes in a disposal site 3 . In

addition, no single municipality or local body has

complied with the guidelines stipulated by MSW

Rules, 2000 in the country4.

Further, the present scenario of solid waste

management

in

Lucknow

is

highly

unsynchronized and inadequate and entails

dumping of waste in open areas5.

This justifies the applicability criteria.

10.

11.

12.

13.

2

The compliance rate of the environmental

regulations during (part of) the crediting

period is below 50%; if monitored

compliance with the MSW rules exceeds

50%, the project activity shall receive no

further credit, since the assumption that the

policy is not enforced is no longer tenable

Local regulations do not constrain the

establishment

of

RDF

production

plants/thermal treatment plants nor the use of

RDF/stabilized biomass as fuel or raw

material

In case of RDF/stabilized biomass

production, project proponent shall provide

evidences that no GHG emissions occur,

other than biogenic CO2, due to chemical

reactions during the thermal treatment process

(such as Chimney Gas Analysis report);

The project activity does not involve thermal

The compliance rate of Indian MSW Rules, 2000

is below 50%. No single municipality or local

body in India has complied with the guidelines

stipulated in the MSW Rules 20006. However a

conservative value of 4.5% is taken for ex-ante

estimations of emission reductions7.

This justifies the applicability criteria.

There is no such regulations that constrain the

establishment of RDF production nor any

regulation for the use of RDF/stabilized biomass

as fuel or raw material

This justifies the applicability criteria.

The project activity does not involve any thermal

treatment in case of RDF production. The process

involved is purely mechanical treatment.

Hence this condition is not applicable.

There is no waste incineration in the proposed

http://envfor.nic.in/legis/hsm/mswmhr.html

http://www.nswai.com/images/newsletters/jun2010.pdf

4

Sunil Kumar ,Bhattacharyya J.K. , Vaidya A.N., Tapan Chakrabarti , Sukumar Devotta , Akolkar A.B.,

Assessment of the status of municipal solid waste management in metro cities, state capitals, class I cities, and class

II towns in India: An insight, pg 3, Waste Management journal homepage: www.elsevier.com/locate/wasman

5

http://lmc.up.nic.in/nnfinal.pdf Page 26 Paragraph 3.4 describes the present scenario of solid waste management in

Lucknow.

6

Sustainable Waste Management Issues in India by Shikha Saxena, R K Srivastava, and A B Samaddar, Page no 8.

http://static.globaltrade.net/files/pdf/20100318081000.pdf

7

Sustainable Waste Management Issues in India by Shikha Saxena, R K Srivastava, and A B Samaddar, Page no 9.

http://static.globaltrade.net/files/pdf/20100318081000.pdf

3

UNFCCC/CCNUCC

CDM Executive Board

14.

15.

Page 11

treatment process of neither industrial nor project activity.

hospital waste;

Hence, this condition is not applicable.

In case of waste incineration, if auxiliary There is no waste incineration in the proposed

fossil fuel is added into the incinerator, the project activity.

fraction of energy generated by auxiliary

fossil fuel is no more than 50% of the total Hence, this condition is not applicable.

energy generated in the incinerator.

This methodology is not applicable to project Project activity does not involve capture and

activities that involve capture and flaring of flaring of methane from existing waste in the

methane from existing waste in the landfill. landfill.

This should be treated as a separate project

activity due to the difference in waste Hence, this condition is not applicable.

characteristics of existing and fresh waste,

which may have an implication on the

baseline scenario determination.

Thus as per the methodology AM0025, the project activity involves the treatment of fresh waste (i.e

municipal solid waste), originally intended for dumping through a combination of the processes a)

composting b) RDF processing without incineration. The project activity avoids methane emissions by

diverting organic waste from being dumped, where methane emissions are caused by anaerobic

decomposition. By treating the fresh waste through alternative treatment options these methane emissions

are avoided. Therefore, the project meets the applicability conditions of AM0025.

B.3. Project boundary

As per AM0025, the spatial extent of the project boundary is the site of the project activity where the

waste is treated. This includes the facilities for processing the waste, on-site electricity consumption,

onsite fuel use and the sanitary landfill site. The project boundary does not include facilities for waste

collection, sorting and transport to the project site.

The summary of gases and sources included in the project boundary, and justification/ explanation where

gases and sources are not included is listed below:

UNFCCC/CCNUCC

CDM Executive Board

Source

Page 12

GHGs

Baseline scenario

CO2

Justification/Explanation

Excluded

CO2 emissions from the decomposition of organic

waste are not accounted.

Emissions

from

decomposition CH4

of waste at the

landfill site

N2O

Included

The major source of emissions in the baseline since

the fresh waste is being disposed off in the landfill.

Hence included.

Excluded

N2O emissions are small compared to CH4 emissions

from landfills. Exclusion of this gas is conservative

CO2

Excluded

Electricity is not being consumed in the baseline.

Hence excluded.

CH4

Excluded

Excluded for simplification. This is conservative

N2O

Excluded

Excluded for simplification. This is conservative

CO2

Excluded

There is no thermal energy generation in the project

activity. Hence excluded.

CH4

Excluded

There is no thermal energy generation in the project

activity.

N2O

Excluded

There is no thermal energy generation in the project

activity.

CO2

Included

The project activity involves on-site fossil fuel

consumption. Hence included.

CH4

Excluded

Excluded for simplification. This emission source is

assumed to be very small.

N2O

Excluded

Excluded for simplification. This emission source is

assumed to be very small.

CO2

Included

The project activity involves consumption of

electricity from the grid. Hence included.

CH4

Excluded

The project activity does not involve on-site

electricity generation. Hence excluded.

N2O

Excluded

The project activity does not involve on-site

electricity generation. Hence excluded.

CO2

Excluded

The project activity does not involve thermal energy

generation. Hence excluded.

CH4

Excluded

The project activity does not involve thermal energy

generation. Hence excluded.

N2O

Excluded

The project activity does not involve thermal energy

generation. Hence excluded.

Emissions

from

electricity

consumption

Emissions

from thermal

energy

generation

On-site fossil

fuel

consumption

due to the

project

activity other

than for

electricity

generation

Project scenario

Included?

Emissions

from on-site

electricity use

Emissions

from thermal

energy

generation

UNFCCC/CCNUCC

CDM Executive Board

Source

Page 13

GHGs

Project scenario

N2O

Direct

emissions from

CO2

the waste

treatment

processes.

CH4

CO2

Emissions

from

waste

CH4

water

treatment

N2O

Included?

Justification/Explanation

Included

May be an important emission source. N2O can be

emitted from composting activities. Hence included.

Included

CO2 emissions from decomposition of organic

waste are not accounted.8

Included

Composting process may not be complete and result

in anaerobic decay resulting in CH4 emissions.

Excluded

There is no waste water treatment involved in the

project activity.

Excluded

There is no waste water treatment involved in the

project activity.

Excluded

There is no waste water treatment involved in the

project activity.

A graphical representation of the project boundary is shown below:

MSW Collection in Lucknow

Consumption of

Electricity

MSW Processing Site

Electricity from

Grid

Bio degradable waste

processing

Compost

RDF

Open market

Segregated Inert

Electricity from

Diesel

Recyclables

Sanitary landfill

PROJECT BOUNDARY

CO2 emissions from the combustion or decomposition of biomass (see definition by the EB in Annex 8 of the EB.s

20th meeting report) are not accounted as GHG emissions. Where the combustion or decomposition of biomass

under a CDM project activity results in a decrease of carbon pools, such stock changes should be considered in the

calculation of emission reductions. This is not the case for waste treatment projects.

UNFCCC/CCNUCC

CDM Executive Board

Page 14

The various monitoring points in the project activity as included within the project boundary have been

schematically represented in the diagram as given below:

B.4. Establishment and description of baseline scenario

>>

The approved methodology AM0025 version 12, recommends the use of the latest version of the tool for

demonstration and assessment of additionality (version 06.0.0) to determine the most plausible baseline

scenarios for the project.

The various steps to establish the additionality of the project as per the methodological tool is

demonstrated pictorially, as given below:

UNFCCC/CCNUCC

CDM Executive Board

Page 15

According to the approved methodology AM0025, the baseline scenario of the activity is defined as

disposal of the waste in open dump yards without taking any measures to capture the landfill gas or avoid

methane emission due to the anaerobic decomposition of waste. The procedure to define the baseline

scenario as per AM0025 is as follows:

Step 1: Identification of alternative scenarios.

The most realistic and credible alternatives available to the project activity have been identified using the

following sub steps

UNFCCC/CCNUCC

CDM Executive Board

Page 16

Sub-step 1a: Defining alternatives to project activity

The approved methodology has provided the following alternatives for the disposal/treatment of the fresh

waste in the absence of the project activity, i.e. the scenario relevant for estimating baseline methane

emissions, to be analysed should include, inter alia:

M1: The project activity (i.e. composting, gasification, anaerobic digestion, RDF processing/thermal

treatment without incineration of organic waste or incineration of waste) not implemented as a CDM

project;

M2: Disposal of the waste at a landfill where landfill gas captured is flared;

M3: Disposal of the waste on a landfill without the capture of landfill gas.

Assessment of the alternatives for waste treatment:

Alternative

M1

Description

The project activity (i.e. composting,

gasification, anaerobic digestion, RDF

processing/thermal treatment without

incineration of organic waste or

incineration of waste) not implemented

as a CDM project;

Justification

This alternative seems to be a realistic and

plausible alternative.

The project activity not implemented as a

CDM project is however not a feasible

alternative as the project involves high

investment cost in order to set up the

processing plant whereas the return from the

project activity is exceptionally low (As

discussed in detail in Section B.5).

However, M1 is still a plausible option and is

subjected to further consideration as a

baseline scenario.

M2

M3

Disposal of the waste at a landfill The cost of construction, operation and

where landfill gas captured is flared;

maintenance of an engineered landfill is high

as compared to the zero/minimal expenditure

in the dumping of waste. Hence the scope of

landfill gas recovery is minimized in India.

Hence this scenario M2 is not feasible and is

thus eliminated from further consideration as

baseline scenario.

Disposal of the waste on a landfill Disposal of the waste on a landfill without the

without the capture of landfill gas.

capture of landfill gas is the most common

practice in India as demonstrated in Section

B.5. The same has been found to be prevalent

in Lucknow in the absence of the project

activity9. Hence this is a common practice that

faces no barriers because of low expenditure,

low O & M cost, non-requirement of skilled

labor etc. Thus this is the most widely

practiced method for MSW disposal

throughout the country.

http://lmc.up.nic.in/nnfinal.pdf page 26 paragraph 3.4

UNFCCC/CCNUCC

CDM Executive Board

Page 17

This alternative M3 is considered as the most

likely baseline scenario for the project

activity.

The methodology further states that If energy is exported to a grid and/or to a nearby industry, or used

on-site realistic and credible alternatives should also be separately determined for:

Power generation in the absence of the project activity;

Heat generation in the absence of the project activity.

Under the scope of the project activity, neither heat nor power generation takes place. Hence the clause as

mentioned above is not applicable to the project activity.

Thus alternatives M1 and M3 are further subjected for baseline consideration. Alternative M2 is not

considered as a plausible and realistic baseline scenario for the project activity.

Sub-step 1b: Consistency with mandatory laws and regulations

The MSW (Management and Handling) Rules, 2000 notified by Ministry of Environment and Forests,

Government of India makes it mandatory for proper and scientific management of solid waste. Under this

rule, land filling of the waste is not allowed but based on the studies10 and surveys carried out it was

observed that the most common practice in India to dispose the solid waste is open dumping and land

filling without any treatment and processing. It is observed that these rules are not implemented/enforced

systematically thus leading to the most widespread practice of dumping waste in the country.

Conclusion: Thus the alternatives M1 and M3, has been considered further.

Outcome of Sub-step 1b:

The two identified realistic and credible alternative scenario(s) to the project activity that are in

compliance with mandatory legislation and regulations taking into account the enforcement in the country

and EB decisions on national and/or sectoral policies and regulations are as follows:

Alternative M1: The project activity carried out without the CDM; and

Alternative M3: Disposal of the waste on a landfill without the capture of landfill gas. (Continuation of

the current practice of disposal in landfill).

Step 2: Identify the fuel for the baseline choice of energy source taking into account the national

and/or sectoral policies as applicable.

Since there is no power generation or heat utilization in the project activity, thus baseline does not involve

use of fuel for energy.

Outcome of Sub-step 2:

Alternatives M1 and M3 have been subjected for further consideration.

Step 3: Step 2 and/or Step 3 of the latest approved version of the Tool for demonstration and

assessment of additionality shall be used to assess which of these alternatives should be excluded

from further consideration (e.g. alternatives facing prohibitive barriers or those clearly

economically unattractive).

The above analysis in Step 1 and Step 2 leaves with two alternatives M1 and M3.

10

Present Scenario of Municipal Solid Waste (MSW) Dumping Grounds in India, by Amiya Kumar Sahu, National

Solid Waste Association of India, Mumbai

UNFCCC/CCNUCC

CDM Executive Board

Page 18

The further analysis has been discussed in detail in Section B.5 below.

Step 4: Where more than one credible and plausible alternative remains, project participants shall,

as a conservative assumption, use the alternative baseline scenario that results in the lowest

baseline emissions as the most likely baseline scenario. The least emission alternative will be

identified for each component of the baseline scenario. In assessing these scenarios, any regulatory

or contractual requirements should be taken into consideration.

As demonstrated in Section B.5, only one alternative remains after applying the Tool for demonstration

and assessment of additionality to assess exclusion of the alternatives from further consideration. Hence

this step is not applicable as there is only one alternative available to the project activity.

As demonstrated in section B.5., it is evident that after investment analysis, only one alternative i.e. M3

remains as the most plausible option and hence, this has been considered as the baseline to the project

activity.

B.5. Demonstration of additionality

>>

As per the approved methodology, Jyoti Enviro Tech Pvt. Ltd. has identified the above mentioned

realistic and credible alternative(s) (M1 and M3) that were available to them and that would provide

output and services comparable to the project activity (refer section B.4). These alternatives are in

compliance with all applicable legal and regulatory requirements.

The Tool for the demonstration and assessment of additionality stipulates that either Step 2 (Investment

Analysis) or Step 3 (Barrier Analysis), or both can be selected to demonstrate additionality.

As the Project faces financial barriers for its implementation in the absence of CDM, it is appropriate to

choose Step 2 to demonstrate its additionality.

Step 2. Investment analysis

The alternative considered for further analysis is alternative M3 being the most commonly followed

practice.

Sub-step 2a: Determine appropriate analysis method

Since the project generates incomes other than CDM related income, for the purpose of investment

analysis, Option III (Benchmark Analysis) is chosen as it is deemed as the most appropriate analysis

method where the returns on the investment in the project activity is compared to benchmark returns.

Sub-step 2b: Option III. Apply benchmark analysis

The indicator used for carrying out the investment analysis is IRR that will determine the feasibility of the

project activity. This is compared with the Prime Lending Rate available at the time of investment

decision. For this purpose the PLR of Reserve Bank of India has been considered which is found to be

12.00% as per Benchmark PLR of RBI during Aug-2009.11

Sub-step 2c: Calculation and comparison of financial indicators

The IRR for the proposed project activity without CDM revenue is computed for a period of 20 years

lifetime.

A detailed investment analysis has been carried out and presented in the supported excel sheets. The data

and analysis is presented here. The techno-economical parameters used for IRR calculation of the project

activity is provided in the table below:

11

http://www.rbi.org.in/scripts/WSSView.aspx?Id=14988

UNFCCC/CCNUCC

CDM Executive Board

Parameters

Page 19

Unit

Value

MTs/ day

1300

25 yrs 0

months

As per DPR

As per specification

provided by tech supplier

Rs. in Lacs

Rs. in Lacs

Rs. in Lacs

Rs. in Lacs

Rs. in Lacs

Rs. in Lacs

3541.056

1781.286

157.81

104.44

120.11

5704.709

As per DPR

As per DPR

As per DPR

As per DPR

As per DPR

As per DPR

Rs. in Lacs

Rs. in Lacs

Rs. in Lacs

893.4

2700

2111

As per DPR

As per DPR

As per RFP

Applicable Interest Rate on term loan

Percent

12.50%

As per bank terms

Benchmark Prime Lending Rate (PLR)

Percent

12.00%

http://www.iba.org.in/view

plr.asp?memcatid=1

Percent

18%

Percent

12%

Percent

2%

Percent

70%

Percent

70%

Rs/Ton

Rs/Ton

2000

2000

Percent

5%

Percent

5%

Rs. / TON

Rs. / TON

Rs. / TON

Rs. / TON

Rs. / TON

150

100

250

100

150

Capacity (MSW per day)

Project Lifetime

Years

Source

Cost of the project

Buildings & Civil works

Plant and Machinery

Interest payable during construction

Contingencies

Margin Money for working capital

Total cost

Financing pattern

Promoters Contribution through equity

Promoters contribution through loan

Subsidy under JNNURM

Compost and RDF related costs

Recovery of compost from total MSW

processed

Recovery of RDF from total MSW

processed

Recovery of recyclable materials from

total MSW processed

Percentage of compost produced

envisaged to be sold in the market in the

first year

Percentage of RDF produced envisaged

to be sold in the market in the first year

Sale price of compost

Sale price of RDF

Yearly increment in percentage of

compost and RDF for sale in the market

Yearly escalation in sale price of

compost and RDF

Packaging cost of Compost

Marketing cost of Compost

Transportation cost of Compost

Loading/unloading cost of compost

Packaging cost of RDF

As per DPR

As per quote received

from distributor

CPI(Consumer Price

Index) data

As per quote received

from distributor

UNFCCC/CCNUCC

CDM Executive Board

Marketing cost of RDF

Transportation of RDF

Loading/unloading cost of RDF

Page 20

Rs. / TON

Rs. / TON

Rs. / TON

100

250

100

MSW Processing cost

Power consumption cost

Rs Lacs/annum

Diesel consumption cost

Rs Lacs/annum

Plant maintenance cost including that of % of capital cost for

vehicles

plant machineries

ml/ MT of MSW

Use of senitiler

processing

kg./ MT of MSW

Use of bio-culture

processing

Cost of senitiler use

Rs/litre

Cost of bio-culture use

Rs/kg

Cost of daily consumables (oil, lubricants

Rs Lacs/annum

and cotton waste)

Salary and wages of employees and staff

Rs Lacs/annum

165.39

187.20

2%

As per DPR

50

1.0

150

180

As per quote received

26

373

As per DPR

Escalation rates

Escalation in maintenance cost

Escalation in employee wages

Escalation in fuel cost

Escalation in electricity cost

Other commodities escalation

Percent

Percent

Percent

Percent

Percent

4.00%

7.14%

8.74%

8.74%

5.83%

St. line Depn.

- Buildings

- Plant & Machinery

IT Depreciation - Buildings

- Plant & Machinery

Income Tax MAT

Percent

Percent

Percent

Percent

Percent

3.34%

11.3%

10%

15%

11.33%

Income Tax

Percent

33.99%

CPI(Consumer Price

Index) data

WPI(WholeSale Price

Index) data

Depreciation

As per companys law

1956,

www.fastfacts.co.in/resour

ces/DepCoAct.rtf

Income Tax Acthttp://www.indiainbusines

s.nic.in/investment/taxatio

n.htm

Based on the above assumptions the results of the financial analysis have been provided below:

Location

Lucknow MSW project

Benchmark

12.00%

IRR (Without CDM)

6.86%

As evident the IRR of the project activity is below the benchmark. This clearly indicates that investment

barrier exists in project activity implementation which is mitigated by the revenue derived from the

carbon credits that the project activity would obtain due to Clean Development Mechanism. The

additionality of the project is thus evident.

Sub-step 2d: Sensitivity analysis

UNFCCC/CCNUCC

CDM Executive Board

Page 21

The purpose of sensitivity analysis is to examine whether the conclusion regarding the financial viability

of the proposed project is sound and tenable with those reasonable variations in the assumptions. The

investment analysis provides a valid argument in favor of additionality only if it consistently supports (for

realistic range of assumptions) the conclusion that the project activity is unlikely to be the most

financially attractive or is likely to be financially attractive.

Thus, a sensitivity analysis was also applied to the IRR calculations to measure the impact, positive or

negative, of changes in the indicated parameters. The project proponent has chosen various factors as

critical to the operation of the project in accordance with Guidance on the Assessment of Investment

Analysis (Version- 03.1, paragraph- 17), which states that only variables, including the initial investment

cost, that constitute more than 20% of either total project costs or total project revenues should be

subjected to reasonable variation.

Hence the sensitivity is carried out by varying the parameters to 10% on either side, to ascertain the

impact on the profitability and hence, the IRR of the project. The results of the sensitivity analysis are as

presented below

Sensitivity Parameter

Quantity of waste processed

O&M cost

Organic Manure sales

Cost of bioculture used

+10%

13.25%

-ve value

(1.2% increase

leads to an IRR

of -1.04 %)

Hence it is less

than the

benchmark PLR

13.69%

However 10%

increase in sale

price of organic

manures is a

highly

unrealistic under

the higly

stringent market

scenario for

compost sale.

(explained in

subsequent

paragraphs on

barrier analysis)

-ve value

1.6% leads to a

decrease of IRR

to 0.91%

Hence it is less

than the

benchmark PLR

Variation and resultant IRR

0%

-10%

-ve value

16.88%

However this is

not a realistic

scenario as the

O&M cost is not

expected to

decrease in future

-ve value

-5% leads to a

decrease of IRR

to -3.02%

Hence it is less

than the

benchmark PLR

6.86%

15.13%

However this is

not a realistic

scenario as the

bioculture cost is

not expected to

decrease in future

as is evident from

the WPI for all

commodities as

published by

UNFCCC/CCNUCC

CDM Executive Board

Page 22

Fuel and electricity cost

-ve value

2.4% leads to a

decrease of IRR

to -0.57%

Hence it is less

than the

benchmark PLR

Project capital cost

5.70%

Hence it is less

than the

benchmark PLR

0.77%

Hence it is less

than the

benchmark PLR

Packaging, marketing and

transportation expense

RBI.

12.79%

However this is

not a realistic

scenario as the

fuel and

electricity cost is

not expected to

decrease in future

as is evident from

the WPI for fuel,

power and

electricity, as

published by

RBI.

8.18%

Hence it is less

than the

benchmark PLR

10.40%

Hence it is less

than the

benchmark PLR

Thus, the sensitivity analysis for the project reveals that even with significant changes in various

parameters, the project IRR does not cross benchmark rates. Therefore, the project activity is clearly

additional and is not a businessasusual scenario.

Step 3: Barrier Analysis

The major barrier applicable to the alternative M1 is A) Technology Barrier B) Other Barrier and C)

Investment Barrier.

Sub-step 3a: Identify barriers that would prevent the implementation of the proposed CDM project

Activity

A) Technological Barrier

The plant would use state of the art technology in the process of waste handling and compost

manufacturing. EOT (Electric Overhead Transport) cranes would transfer the wastes from one

processing station to the other. Automation will be ensured wherever possible. Hydraulic type

press system would be installed for the RDF manufacturing. Thus the plant would employ the

latest technologies in the field of waste handling and management that involves a lot of

technology transfer from international suppliers and exorbitant costs. Also, smooth operation of

the plant would require proper training of the operating personnel on the equipments and hence,

regular capacity building training programs would have to be organized by the project proponent.

Another threat posed by the variation in feedstock quality is the content of highly abrasive and

corrosive materials in it. These cause rapid wear and corrosion of the process equipments. Hence

all MSW plants entail high cost of operation and maintenance due to frequent repairs,

breakdowns and shutdowns.

B) Market barrier:

UNFCCC/CCNUCC

CDM Executive Board

Page 23

Organic waste recycling is still neglected by private initiatives, because of its low value and the

lack of a market for compost. Limited markets for compost sales and low prices for compost are a

major challenge that all systems face12. The persisting skepticism among the farmers about the

quality of composts poses a constant threat on the marketability of the composts. Misconceptions

like soil contamination due to use of composts, are still borne in the minds of many. Thus the

emphasis on quality control of final products is of utmost importance. Also, increased awareness

among the farmers on the benefits derived out of compost usage as value added substitutes to

chemical fertilizers have to be encouraged through campaigns and other promotional activities.

Also, high cost of transportation sometimes makes it difficult to justify the use of composts when

compared to the benefits derived out of it.

C) Investment barrier

The project proponent has demonstrated through investment analysis that without CDM revenue

the project activity is not a financially attractive proposition. At the inception, the project had

received refusal for loans from financial institutions for unimpressive returns envisaged from the

project and the project proponent was suggested to estimate the returns along with additional

revenue as may be associated with the project activity (for e.g. revenue from carbon credits). The

project proponent had re-submitted their application for loan with the consideration of the CDM

revenue and thereafter received the sanction.

All these factors substantiate to prove that additional efforts are required for overcoming the market

barrier for the compost produced in the plant. In this context the additional incentive available to the plant

through Clean Development Mechanism would be utilized for market development of the compost

produced in the plant and also to partially compensate for the losses for not being able to sell compost in

the market

Thus the barriers as illustrated above pose a serious obstacle to the project activity, and thus would lead to

high operational uncertainties if not implemented as a CDM project activity.

Sub-step 3 b. Shows that the identified barriers would not prevent a wide spread implementation of at

least one of the alternatives (except the proposed project activity):

As discussed above, dumping of the solid waste in a landfill without gas capture (M3) is a common

practice in India and none of the barriers discussed above would prevent it from occurring.

The barriers identified i.e. technological barrier and the market barrier does not in any way prevent the

continuation of the baseline scenario. Hence project activity satisfies the additionality criteria as per

clause 3b) of the tool for the demonstration and assessment of additionality, Version 06.0.0.

Step 4: Common practice analysis

According to the methodology AM0025, project proponents should provide evidence of the early stage

of development of the project activity and that it is not common practice in the country. To this end, they

should provide an analysis of waste management practices.

In order to justify the early development of the project activity the chronology for the same has been

presented below as we proceed further.

As per the Tool to for the demonstration and assessment of additionality (Version 06.0.0) similar type

of project is defined as follows:

12

http://www.tn.gov.in/cma/swm_in_india.pdf page 145.

UNFCCC/CCNUCC

CDM Executive Board

Page 24

Sub-step 4b: Discuss any similar Options that are occurring

The above analysis demonstrates the similar activities occurring as the project activity. But it can be seen

that all the treatment facilities are composting facilities and none of the plants have RDF production

facility. Most of these composting facilities have applied for CDM benefits and those that have not are

facing difficulties.

The project activity conforms to the measures of Methane formation avoidance as mentioned in

paragraph 6 of the Tool for the demonstration and assessment of additionality. Hence analysis of the

project activity as per paragraph 47 is illustrated as follows:

Step 1: Calculate applicable output range as +/-50% of the design output or capacity of the proposed

project activity.

The capacity of the project activity is 1300 TPD. Hence considering an output range of +/-50%, the

analysis would entail all projects of capacities between 1950 TPD and 650 TPD. Therefore as per the

table of cities as listed above, the cities considered for present analysis would include the following

Processing of Waste

Disposal of waste

Uncontrolled Sanitary

Earth

dumping

landfill

cover

Waste

Quantity

(TPD)

1669

Composting

Pelletisation

300

Ahmedabad

1302

500

Pune

1175

500

Surat

1000

Kanpur

1100

Jaipur

904

Ludhiana

735

Agra

654

City

Bangalore

CDM

status

Step 2: In the applicable geographical area, identify all plants that deliver the same output or capacity,

within the applicable output range calculated in Step 1, as the proposed project activity and have started

commercial operation before the start date of the project. Note their number Nall. Registered CDM

project activities and projects activities undergoing validation shall not be included in this step.

The applicable geographical area for the project activity would entail the entire host country i.e. India. Of

the selected cities as listed above, the same output i.e. organic composts and RDF is produced by

Bangalore and Pune. However all the projects are under validation. Hence as per the given definitions,

Nall for the present analysis of the project activity is equal to 0 since all the plants with similar output and

within the applicable capacity range have considered CDM benefits associated to the projects

Nall = 0

Step 3: Within plants identified in Step 2, identify those that apply technologies different than the

technology applied in the proposed project activity. Note their number Ndiff.

All the plants as included in Nall use the same technology for compost production and RDF

manufacturing. Hence, under the scope of the present analysis Ndiff = 0

UNFCCC/CCNUCC

CDM Executive Board

Page 25

Step 4: Calculate factor F=1-Ndiff/Nall representing the share of plants using technology similar to the

technology used in the proposed project activity in all plants that deliver the same output or capacity as

the proposed project activity.

Under the scope of the project activity, the factor is calculated as follows

F = 1-Ndiff/Nall = 1 0= 1

Therefore under the scope of the project activity, the factor F cannot be determined.

The proposed project activity is a .common practice. within a sector in the applicable geographical area

if both the following conditions are fulfilled:

(a) the factor F is greater than 0.2, and

(b) Nall-Ndiff is greater than 3.

Since as per the above analysis, F = 1 which is greater than 0.2

Nall - Ndiff = 0 which is less than 3

As per the methodology, the proposed project activity is a common practice within a sector in the

applicable geographical area if both the following conditions are fulfilled.

Thus, since one of the criterions as imposed by the tool, is not satisfied by the project activity, hence it is

prudent to conclude that the project activity is not a common practice and hence additional. , the analysis

shows that the project activity is additional.

Also as per the India Infrastructure Report 2006, the few aerobic compost plants that have been set up are

typically functioning much below installed capacity, and most are facing a problem of marketing the

compost due to an ineffective marketing mechanism.

Thus it can be concluded that extremely few similar activities can be observed in India, and when they are

observed, they face considerable barriers and have not had much success from an economic perspective.

The experience provided by these composting attempts only serves to reinforce the fact that implementing

composting activities is financially unviable. Therefore, as demonstrated by the investment and barrier

analyses in Steps 2 and 3, it is clear that the project is not financially viable without the revenue from

CDM, and there are significant barriers to its implementation.

In addition, as detailed in Step 4, the proposed project is not common practice either, and in the limited

cases where aerobic composting is taking place, it is proving to be a failure from an economic

perspective. It can therefore be concluded that the proposed project is additional, and would not occur

without CDM, due to the financial and technological barriers in place. Moreover, the CDM registration of

the Project will also serve as a model for other projects and promote the dissemination of sustainable

waste management practices.

Serious consideration of CDM:

As per paragraph 2 of EB 62/ Annex 13 Guidelines to the demonstration and assessment of prior

consideration of the CDM, for project activities with a start date after 2nd August 2008, the project

proponent must inform a Host Party designated national authority (DNA) and the UNFCCC secretariat

in writing of the commencement of the project activity and of their intension to seek CDM status. Such

notification must be made within six months of the project activity start date and shall contain the precise

geographical location and brief description of the proposed project activity using the standardized form

F-CDM Prior consideration.

As mentioned in the section C.1.1, the start date for the project activity is 10/10/2011 i.e. date of placing

the first purchase order for the project activity.

UNFCCC/CCNUCC

CDM Executive Board

Page 26

The project proponent had intimated the Host Party designated national authority (DNA) i.e. Ministry of

environment and Forests (Govt. of India) and the UNFCCC secretariat, about the project activity on

09/10/2011. This intimation was made in the F-CDM-Prior consideration format as prescribed by

UNFCCC . Thus, the intimation to Host party DNA and UNFCCC secretariat was made within six

months from the project start date as this is in accordance to the Guideline to the demonstration and

assessment of prior consideration of the CDM.

As per the Guidelines on the demonstration and assessment of prior consideration of the CDM, version

04, EB 62 Annex 13, serious consideration of CDM has been demonstrated below:

Date

14/09/2009

28/10/2009

11/11/2009

07/09/2010

23/10/2010

Project Related Activity

Financial proposal from

Jyoti Build-Tech Pvt. Ltd.

Revised financial proposal

from Jyoti Build-Tech Pvt.

Ltd.

Letter of award for

development of Integrated

Solid waste management

facilities for Lucknow

Municipal Corporation, UP.

Receipt of certificate of

incorporation

for

M/s

JYOTI

ENVIROTECH

PRIVATE LIMITED.

Concession

agreement

signed between Lucknow

Municipal

Corporation,

Uttar Pradesh Jal Nigam

and Jyoti Enviro Tech Pvt.

Ltd.

07/06/2011

03/10/2011

09/10/2011

23/03/2012

Evidence

Copy of proposal

Copy of proposal

Copy of the letter of

award

Copy of certificate

Copy

of

Agreement

Environmental

Clearance

received for development of

Municipal Solid Waste Landfill

and processing facility at

Village-Shiveri

Jyoti Enviro Tech Pvt. Ltd.

appointed CDM consultants for

the project

No objection certificate from

Airports Authority of India.

Project proponent submitted the

Prior consideration of the CDM

form to host party DNA

(Ministry of Environment and

Forests, Govt. of India) and the

UNFCCC secretariat.

21/09/2011

10/10/2011

CDM Related Activity

Purchase order raised for

Plant Machinery

Stakeholder

Meeting

Copy of

Approval

letter

the

of

Copy of work order

placed on the CDM

consultants.

Copy of no objection

certificate

Copy

of

Prior

consideration of the

CDM

form,

as

submitted to MoEF,

GoI and UNFCCC.

Copy of Purchase

order.

Consultation Copy of the Minutes

of Meeting

UNFCCC/CCNUCC

CDM Executive Board

Page 27

B.6. Emission reductions

B.6.1. Explanation of methodological choices

>>

Approved baseline and monitoring methodology AM0025- Avoided emissions from organic waste

through alternative waste treatment processes, Version 13 has been used to calculate emission reductions

from the project. The estimation of project emission, baseline emission and leakage emission are

described below.

Project emissions:

The proposed project uses MSW processing (RDF and compost production processes) to treat the organic

waste. Therefore, the project emissions in year y are calculated as follows:

PEy = PEelec,y + PEfuel, on-site,y + PEc,y + PEa,y + PEg,y+ PEr,y + PEi,y + PEw,y + PEco-firing,y

Where:

PEy

PEelec,y

PEfuel, on-site,y

PEc,y

PEa,y

PEg,y

PEr,y

PEi,y

PEw,y

PEco-firing,y

(1)

= Is the project emissions during the year y (tCO2e)

= Is the emissions from electricity consumption on-site due to the project activity in year

y (tCO2e)

=Is the emissions on-site due to fuel consumption on-site in year y (tCO2e)

=Is the emissions during the composting process in year y (tCO2e)

=Is the emissions from the anaerobic digestion process in year y (tCO2e)

=Is the emissions from the gasification process in year y (tCO2e)

=Is the emissions from the combustion of RDF/stabilized biomass in year y (tCO2e)

=Is the emissions from waste incineration in year y (tCO2e)

=Is the emissions from wastewater treatment in year y (tCO2e)

=Is the emissions from thermal energy generation/electricity generation from on site

fossil fuel consumption during co-firing in year y (tCO2e)

The project activity involves composting and mechanical treatment to produce compost and RDF. It

involves the electricity consumption onsite and on-site fuel consumption. Hence the equation applicable

to the project activity is as follows:

Hence for the project activity:

PEa,y

=0 as the project does not entail anaerobic digestion.

PEg,y

=0 as the project does not entail gasification.

PEr,y

=0 as the project does not entail combustion of RDF/stabilized.

PEi,y

=0 as the project does not entail waste incineration.

PEw,y

=0 as the project does not entail wastewater treatment.

PEco-firing,y

=0 as the project does not entail thermal energy generation/electricity generation from on

site fossil fuel consumption.

Therefore,

PEy = PEelec,y + PEfuel, on-site,y + PEc,y

(2)

Emissions from electricity use on site (PEelec,y):

The project uses electricity from the NEWNE grid at processing plant at Lucknow. The emissions from

electricity use are therefore calculated as:

PEelec,y = EGPJ,FF,y * CEFelec

(3)

UNFCCC/CCNUCC

CDM Executive Board

Where:

EGPJ,FF,y

CEFelec

Page 28

= Is the amount of electricity generated in an on-site fossil fuel fired power plant or

consumed from the grid as a result of the project activity, measured using an electricity

meter (MWh)

= Is the carbon emissions factor for electricity consumed in the project activity

(tCO2e/MWh)

Under the scope of the project activity, electricity use on site would include the electricity consumption

due to the plant equipments and machineries on site that are used to produce the composts the RDF.

Emissions from fuel use on-site (PEfuel,on-site,y):

Project participants shall account for CO2 emissions from any on-site fuel combustion (other than

electricity generation, e.g. vehicles used on-site, heat generation, for starting the gasifier, auxiliary

fossil fuels need to be added into incinerator, heat generation for mechanical/thermal treatment process,

etc.). Emissions are calculated from the quantity of fuel used and the specific CO2-emission factor of

the fuel, as follows:

PEfuel,on-site,y = Fcons,y * NCVfuel * EFfuel

Where:

PEfuel, on-site,y

Fcons,y

NCVfuel

EFfuel

(4)

= Is the CO2 emissions due to on-site fuel combustion in year y (tCO2)

= Is the fuel consumption on site in year y (l or kg)

= Is the net caloric value of the fuel (MJ/l or MJ/kg)

= Is the CO2 emissions factor of the fuel (tCO2/MJ)

As per methodology project participants may use IPCC default values for the net calorific values and CO2

emission factors.

Under the scope of the project activity, fuel use on-site would include consumption of diesel fuel by the

vehicles (e.g. excavators, earth movers etc) as may be engaged for the project activity on-site. Further, the

project may also include Diesel Generator(s) placed on site to provide necessary power back-up in

incidents of exigency. Thus the diesel fuel consumed by the DG set would also be monitored and be

counted in fuel use quantity on-site.

Hence, for the project activity: NCVfuel = NCVy,diesel

And EFfuel = EF,diesel

Emissions from composting (PEc,y):

As per the methodological tool for Project and leakage emissions from composting Version 01.0.0, EB

65 Annex 09, emission from composting

PEc,y = PEEC,y + PEFC,y + PECH4,y + PEN2O,y + PERO,y

(5)

Where:

PEEC,y

= Project emissions from electricity consumption associated with composting in year y

(tCO2/yr)

This has already been accounted for under the variable PEelec,y as explained previously

and hence may not be further included to avoid double counting.

UNFCCC/CCNUCC

CDM Executive Board

Page 29

PEFC,y

= Project emissions from fossil fuel consumption associated with composting in year y

(tCO2/yr)

This has already been accounted for under the variable PEfuel,on-site,y as explained

previously and hence may not be further included to avoid double counting.

PECH4,y

= Project emissions of methane from the composting process in year y (tCO2e/yr)

PEN2O,y

= Project emissions of nitrous oxide from the composting process in year y (tCO2e/yr)

PERO,y

=Project emissions of methane from run-off wastewater associated with co-composting

in year y (tCO2e/yr).

The leachate generated in the project activity will be gainfully utilized in maintaining

the moist environment of the bio degradable waste. Hence the project activity would not

entail any project emission from run-off wastewater.

PERO,y= 0

Therefore

PEc,y = PECH4,y + PEN2O,y

(6)

Determination of project emissions of methane (PECH4,y )

Project emissions of methane from composting (PECH4,y) are determined as follows:

PECH4,y = Qy * EFCH4,y * GWPCH4

(7)

Where:

Qy

= Quantity of waste composted in year y (t / yr)

EFCH4,y

= Emission factor of methane per tonne of waste composted valid for year y (tCH4/ t)

For the value of EFCH4,y, a default value as provided in section IV of the tool will be considered.

i.e. EFCH4,y = EFCH4,default.

GWPCH4 = Global Warming Potential of CH4 (tCO2e / tCH4 )

Determination of project emissions of nitrous oxide (PEN2O,y )

The N2O emissions from composting are calculated as follows:

PEN2O,y

= Qy * EFN2O,y * GWPN2O

(8)

Where:

Qy

= Quantity of waste composted in year y (t / yr)

EFN20,y

= Emission factor of methane per tonne of waste composted valid for year y (tN2O/ t)

For the value of EFN2O,y, a default value as provided in section IV of the tool will be considered.

i.e. EFN20,y = EFN20,default.

GWPN20 = Global Warming Potential of N20 (tCO2e / tN2O )

Baseline emissions:

To calculate the baseline emissions project participants shall use the following equation:

BEy = (MBy - MDreg,y) + BEEN,y

(9)

UNFCCC/CCNUCC

CDM Executive Board

Where:

BEy

MBy

MDreg,y

BEEN,y

Page 30

= Is the baseline emissions in year y (tCO2e)

= Is the methane produced in the landfill in the absence of the project activity in year y

(tCO2e)

= Is methane that would be destroyed in the absence of the project activity in year y

(tCO2e)

= Baseline emissions from generation of energy displaced by the project activity in year

y (tCO2e). Since the project activity does not entail generation of energy, hence BEEN,y=

0.

Methane that would be destroyed in the absence of the project activity (MDreg.y)

The methodology states that In cases where regulatory or contractual requirements do not specify

MDreg,y, an Adjustment Factor (AF) shall be used and justified, taking into account the project context.

In doing so, the project participant should take into account that some of the methane generated by the

landfill may be captured and destroyed to comply with other relevant regulations or contractual

requirements, or to address safety and odour concerns.

MDreg,y = MBy * AF

Where:

AF = Is Adjustment Factor for MBy (%)

The parameter AF shall be estimated as follows: In cases where a specific system for collection and

destruction of methane is mandated by regulatory or contractual requirements, the ratio between the

destruction efficiency of that system and the destruction efficiency of the system used in the project

activity shall be used

In the host country India, there is no regulation for capture and destruction of methane generated by the

landfill. Hence, the adjustment factor the project activity is 0 as per the present scenario.

i.e. AF = 0

Therefore, MDreg,y = 0

However, in due course of time, the value of AF may undergo changes as per the governmental

regulations imposed in the host country (India) with respect to MSW management.

Rate of compliance

In cases where there are regulations that mandate the use of one of the project activity treatment options

and which is not being enforced, the baseline scenario is identified as a gradual improvement of waste

management practices to the acceptable technical options expected over a period of time to comply with

the MSW Management Rules. The adjusted baseline emissions (BEy,a) are calculated as follows:

BEy,a = BEy * ( 1 RATECompliancey)

Where:

BEy

RATECompliancey

(10)

= Is the CO2-equivalent emissions as determined from equation 14

= Is the state-level compliance rate of the MSW Management Rules in that year

y. The compliance rate shall be lower than 50%; if it exceeds 50% the project

activity shall receive no further credit.

UNFCCC/CCNUCC

CDM Executive Board

Page 31

The compliance ratio RATECompliancey shall be monitored ex post based on the official reports for instance

annual reports provided by municipal bodies.

For details on the consideration the value of RATECompliancey, for the purpose of ex ante calculation, refer

to annexure 1.

Methane generation from the landfill in the absence of the project activity (MBy)

The amount of methane that is generated each year (MBy) is calculated as per the latest version of the

approved methodological tool Emissions from solid waste disposal sites (Version 06.0.1, EB 66 Annex

46). Considering the following additional equation:

MBy

= BECH4,SWDS,y

Where:

BECH4,SWDS,y

= Is the methane generation from the landfill in the absence of the project activity at

year y that is methane emissions avoided during the year y from preventing waste

disposal at the solid waste disposal site during the period from the start of the project

activity to the end of the year y (tCO2e) as calculated using Application B in the

methodological tool Emissions from solid waste disposal sites. The tool estimates

methane generation adjusted for, using adjustment factor (fy), any landfill gas in the

baseline that would have been captured and destroyed to comply with relevant

regulations or contractual requirements, or to address safety and odor concerns. As this is

already accounted for in this methodology, fy in the tool shall be assigned a value 0

The amount of methane that is generated each year (BECH4,SWDS,y, tCO2e) is calculated for each year with