Professional Documents

Culture Documents

Comparison Between Integer Order and Fractional Order Controllers

Uploaded by

debasishmee5808Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparison Between Integer Order and Fractional Order Controllers

Uploaded by

debasishmee5808Copyright:

Available Formats

17th IEEE Mediterranean Electrotechnical Conference, Beirut, Lebanon, 13-16 April 2014.

Comparison between integer order and fractional

order controllers

Roy ABI ZEID DAOU

Xavier MOREAU

IMS Laboratory, CRONE Group,

University Bordeaux I,

Bordeaux, France

email: xavier.moreau@ims-bordeaux.fr

Biomedical Technologies Department,

Public Health Faculty,

Lebanese German University, Jounieh, Lebanon

email: r.abizeiddaou@lgu.edu.lb

methods were and still are proposed for this purpose in order to

get the optimal values of the integration and differentiation

orders [5].

Most recently, the CRONE controller, also based on the

fractional integration and differentiation, was introduced in

three generations [6].

However, a main difference, other than the way used to

synthesize these controllers, is encountered. The number of

parameters to be defined differs between these controllers. In

fact, the PID needs to define three parameters, the generalized

PID needs 5 parameters and the CRONE controller needs four

parameters.

Nowadays, the use of the fractional controllers is almost

necessary in almost all engineering domains. The reasons

behind this use are diverse; among them we list the most

important:

- The identification of several physical and natural

properties showed that a fractional order differentiation in

implemented when modelling them using transfer function.

Some of the examples are the thermal diffusive interfaces [7],

the muscles activities [8] and much more

- The analogue [9] and digital [10] implementation of the

fractional order controllers is easy;

- Once the user specifications and/or the open loop shape

are defined, the synthesis of the fractional order controller is

not complicated.

As for the fractional calculus, its idea was born in the last

decade of the XVII century after letters exchange between

Leibniz and LHospital [11]. Several definitions of the

fractional integration and differentiation were proposed [12].

The applications in this domain started almost three

centuries later with applications in almost all the engineering

domains [13-15].

Concerning the control systems, the well known PID was

the mostly used controller till 1961 when Manabe introduced

the fractional order concept to such regulators [16]. In 1975,

Oustaloup developed a regulator of order 3/2 in order to control

a laser beam [17] and proposed, some years after, the CRONE

control system [15]. As well, new methods were proposed in

order to search the best values of the generalized PID or the

CRONE controllers [18-19].

To sum up, this paper aims to do a double comparison. It

presents a comparison between fractional order and integer

order controllers, on one hand, and between a priori and a

posteriori controllers on the other hand.

AbstractThis paper presents a comparison between

fractional order controllers and integer order controllers.

The well-known PID is the integer order controller chosen

whereas the generalized PID and the CRONE

(Commande Robuste dOrdre Non Entier which stands

for fractional order robust controller) are the fractional

order controllers studied. Another big difference between

these controllers is that the structure of the PID and the

generalized PID is a priori fixed whereas the structure of

the CRONE is a posteriori deduced from the loop shaping.

Results show that the fractional order controllers are more

robust when small variations appear in the plant and their

behavior is more suitable regarding the user specifications

requirements.

Keywordsfractional order controllers; PID and generalized

PID controllers; CRONE controller; robustness; behavior study;

I.

INTRODUCTION

This paper presents a double comparison between:

1. integer order controllers and fractional order controllers;

2. controllers synthesized using a priori method and

controllers synthesized using a posteriori method.

For the interger order controllers, the PID is used whereas

the generalized PID and the CRONE represent the fractional

order controllers.

As for these controllers, the PID and the generalized PID

controllers are a priori fixed, which means that the

computation of these controllers transfer functions are done

directly according to the user specifications (stability degree,

bandwidth, rejection level of the measured noise, rejection

level of the output disturbance,). Concerning the CRONE

controller, the posterior synthesis method is used. In this case,

the definition of the controller is made with respect to the openloop constraints (robust loop shaping).

Going back to the controllers debut, their synthesis and

their realization has started before almost a century. One of the

earliest forms of a PID controller was developed by Elmer

Sperry in 1911 [1]. However, the first published work

presenting a PID controller was proposed by Russian American

engineer Nicolas Minorsky in 1922 [2].

Many years later, the generalized PID controller, where

the integration and differentiation order can be any positive and

real number less than the unit (e.g., 0 < , < 1 , \ +* ),

was proposed while respecting the tuning rules proposed by

Ziegler and Nichols for integer PIDs [3-4]. Several tuning

978-1-4799-2337-3/14/$31.00 2014 IEEE

292

17th IEEE Mediterranean Electrotechnical Conference, Beirut, Lebanon, 13-16 April 2014.

The stability degree is specified with respect to the phase

margin M. However, it can also be specified using the module

margin MM or the gain margin MG.

(8)

M = + arg ( ju ) ,

In more details, this paper will be composed as follow: in

section 2, the system components and the performance

specifications, in frequency domain, will be show. In section 3,

the PID controller will be presented. Both the integer order and

the fractional order PIDs are shown. Section 4 presents the

CRONE controller whereas section 5 shows an application

example to illustrate the advantages and drawbacks of each

controller. Section 6 ends up with a conclusion and some future

works.

where (s) represent the open-loop transfer function (relation

(7)) and u is the crossover frequency in the open-loop defined

as follow:

( ju ) = 1 .

(9)

The stability degree specification can be presented as the

following constraint:

M M min ,

(10)

II. SYSTEM COMPONENTS AND USER SPECIFICATIONS

In this section, the representation of the system containing

the plant and the controller will be introduced as well as the

performance specifications that the user would specify in

order to get the best performance from the designed controller.

where M min represents the minimal acceptable value of the

phase margin.

The above leads to the following relation,

A. System components

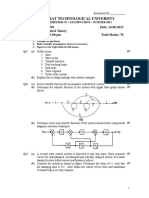

Figure 1 presents the block diagram of the feedback

control system.

Input disturbance

Du (s)

Yref(s)

Reference

signal

Error signal

U(s)

(s)

+

C(s)

+

Controller

arg ( ju ) + Mmin ,

that can be reduced and becomes:

arg C ( ju ) + Mmin arg G ( ju ) .

Sensor noise

Bm(s)

G(s)

Measured

output

where u min represents the minimal acceptable value of u.

Fig. 1 Block diagram of the feedback control system

Referring to equation (9) and knowing that:

( j ) = C ( j ) G ( j ) ,

From this block diagram, the closed-loop relations are

established:

- for the measured output:

- for the error signal:

C ( ju ) G ( ju min )

(s ) = S (s ) Bm (s ) G (s )S (s ) Du (s ) + S (s ) Yref (s ) , (2)

U (s ) = R (s ) Bm (s ) T (s ) Du (s ) + R (s ) Yref (s ) , (3)

where

1 + (s)

- the complementary sensitivity function is:

( s)

T (s) =

= 1 S ( s) ,

1 + ( s)

- the plant input sensitivity function is:

R ( s) = C (s) S ( s)

- the open-loop transfer function is:

(s) = C (s)G (s) .

(15)

.

Concerning the rejection level of the measured noise, it is

calculated using a specification applied to the complementary

sensitivity function module as follow:

- for the control signal:

- the sensitivity function is: S ( s ) =

(14)

a controller gain constraint at the frequency u can be deduced

from relation (13) as follow:

Y (s ) = S (s ) Bm (s ) + G (s )S (s ) Du (s ) + T (s ) Yref (s ) ,(1)

(12)

The bandwidth specification is also computed at the

crossover frequency u. The main goal of this constraint is to

fix the closed-loop dynamics speed. Hence, the frequency

range that is concerned by this condition is

u u min ,

(13)

Y(s) = Ur(s)

Plant model

(11)

T , T ( j ) = ( j ) 1 + ( j ) AT (16)

where AT shows the desired rejected noise level for the given

frequency T:

T ( jT ) = AT .

(17)

(4)

(5)

(6)

If the value of T is chosen to be much bigger than u,

relation (17) can be rewritten as:

T , T ( j ) ( j ) AT .

(18)

(7)

Hence, a new controller gain constraint around the

frequency T is deduced from relation (18) as follow:

T ,

B. Performance specifications

The performance specifications concern different aspects in

frequency domain, from among we list the following:

the stability degree;

the bandwidth;

the rejection level of the measured noise;

the rejection level of the output perturbation;

the plant input sensitivity.

C ( j ) AT G ( j )

(19)

The rejection level of the output disturbance is used for

low frequencies (S < u) and is computed using a

specification of the sensitivity module function as follow:

S ,

S ( j ) = 1 + ( j )

(20)

BS ,

where BS represents the desired rejected output disturbance

level for the frequency S:

293

17th IEEE Mediterranean Electrotechnical Conference, Beirut, Lebanon, 13-16 April 2014.

S ( jS ) = BS .

(21)

When choosing S << u, relation (20) can be written as

1/ 2

1/ 2

1 + (b / ) 2

u

1 + a ( / u ) 2

CPID ( j ) =C0

(b / u )

1 + a 1 ( / ) 2

.

arg CPID ( j )= (arctan(b / u ) / 2 )

+ arctan a / u arctan / a u

(32)

At the open-loop crossover frequency u, relation (32) can

be rewritten as follow:

2

Cu = C PID ( ju ) = C0 1 + b

a

.

(33)

u = arg C PID ( ju ) = (arctan (b ) / 2 )

+ arctan a arctan 1 / a

If b >> 1 (minimization of the noise effect caused by the

integration due to the phase delay of u), system (33) becomes:

Cu = CPID ( ju ) = C0 a

, (34)

= arg C ( j ) = (arctan (b ) / 2 ) +

u

PID

u

m

follow:

(22)

C ( j ) (BS G ( jS ) ) .

The plant input sensitivity is computed using a

specification of the form:

1

S ,

R( j ) = C ( j ) (1 + ( j ))1 DR , (23)

R ,

where DR represents the maximal value at the frequency R:

R( jR ) = DR .

(24)

If the frequency R is much bigger than u, the relation

(23) can be rewritten as:

>> R , C ( j ) DR .

(25)

The constraints (19) and (25) represent almost the same

aspect which is the controller gain at high frequencies. Hence,

they can be reduced to one constraint by choosing the lowest

value of these two relations. Thus,

>> u , C ( j ) Min AT G ( jT )

, DR . (26)

1 +

s

/

i i

(28)

and CD ( s ) =

1 +

/ 1 +

b

h ,

(29)

C PI D (s ) =

C PID (s ) =

1+ a

1 + s /

s / u

a

( )

)))

))

(35)

1 + b s /

u

C0

b

s

/

1 + a s / u

1 +

s / a

,(36)

where and are the integration and the differentiation real

order and vary strictly between 0 and 1.

The module and the phase of the generalized PID

controller are as follow:

/2

/2

1 + (b / ) 2

u

1 + a ( / u ) 2

CPI D ( j ) =C0

1 + a 1 ( / ) 2

(b / u )

arg CPI D ( j )= (arctan (b / u ) / 2 )

+ arctan a / u arctan / a u

(37)

At the open-loop crossover frequency u, relation (37)

can be rewritten as follow:

2 /2

Cu* = C ( ju ) = C0 1 + b

a / 2

PI D

.

(38)

* = arg C ( j ) = (arctan(b ) / 2 )

u

u

PI D

+ arctan a arctan 1 / a

where m represents the frequency for which the controller

phase is maximal (e.g., m = Max[argC(j)] = argC(jm)).

Inserting u in equation (27) leads to the following PID

transfer function:

( (

B. Generalized PID

The computation of the generalized PID (or PID) is made

based on the values found when calculating the PID controller.

In fact, the generalized PID requires 5 parameters. Its form is

as follows:

where i, b et h are the transitional frequencies and C0 is a

constant.

In order to calculate these parameters, the user constraints

must be used. In the following, the method to calculate the

optimal values of the PID parameters is shown.

Lets start by introducing some new constants as follow:

a = h / b , b = u / i and m = b h , (30)

1 + b s /

u

C0

b

s

/

where m = arcsin((a 1) / (a + 1)) .

III. PID CONTROLLER

A. Integer order PID

First, the well known PID controller is described. It is the

eldest controller. It consists on a gain, an integration of order 1

and a derivation of order 1. Two different arrangement of the

PID controller exist: the parallel arrangement and the cascade

arrangement.

The cascade arrangement will be treated in this paper. Its

transfer function can be presented as follow:

CPID (s ) = C0 C I (s ) CD (s ) ,

(27)

with CI ( s ) =

( (

. (31)

Hence, the PID module and phase are given by:

294

( )

))

)))

17th IEEE Mediterranean Electrotechnical Conference, Beirut, Lebanon, 13-16 April 2014.

values of the vector once all five relations ((42) to (47)) are

valid. So, different simulations may lead to different values of

the five parameters as the simulation stops once these five

equations are satisfied. The initial vector and the lower and

upper bound vectors have a big impact on the output values.

Note that, in order to emphasize the fractional behaviour of the

generalized PID controller, the value of the integrator and

differentiator orders, and , should vary between 0.2 and 0.8.

If b >> 1 (minimization of the noise effect caused by the

integration due to the phase delay of u), system (38) becomes:

Cu* = C ( ju ) = C0 a / 2

PI D

, (39)

*

u = arg CPI D ( ju ) = (arctan(b) / 2) + m

where m = arcsin ((a 1) / (a + 1)) .

(40)

After recalculating the controller module and phase at

central frequency u, we obtain for low frequencies ( << u)

C ( j ) C0 (u / (b ))

PI D

,

(41)

arg

CPI D ( j ) / 2

and for high frequencies ( >> u)

C ( j ) C0 a

PI D

.

(42)

arg

CPI D ( j ) 0

Considering the system (31), the constraints listed above

can be rewritten to suit best the generalized PID controller as

follow:

(arctan(b) / 2) + m + M min arg G ( ju ) ,(43)

C0 1 + b2

/2

b a /2 G ( ju min )

1

IV. CRONE CONTROLLER

After presenting both PID controllers, this paragraph

presents the CRONE controller.

The CRONE controller is designed using the open-loop

constraints (robust loop shaping), which means it is based on

the a posterior synthesis method.

Three generations of the CRONE controller have been

developed [20].

In the first generation, the constant phase n/2

characterizes this controller around frequency u. When

the frequency u varies, the constant phase controller

doesnt contribute to the phase margin variations;

In the second generation, a phase change is observed in the

plant when varying the frequency u;

In the third generation, the plants phase and margin

change when varying the frequency u.

The first step consists on defining the necessary

specifications for the synthesis of the nominal plant transfer

function. All calculations are made in the frequency domain.

The second step consists on reassigning the frequency

closed-loop specifications into open-loop frequency

specifications for the nominal plant. These new conditions take

into account the plant behaviour at:

low frequencies in order to have good accuracy in the

steady state;

middle frequencies, especially around the frequency u, to

get the stability degree robustness;

high frequencies to have good input plant sensitivity.

(44)

T ,

C0 a AT G( jT )

S ,

C0 (u / (b )) (BS G ( jS ) )

(45)

1

,(46)

(47)

and >> R , C0 a DR .

In order to determine the optimal values of the parameters

vector = [C0, b, a, , ], two phases are required.

- The first one depends on the initial values of the vector

depending on some values found when computing

the PID controller;

- The second phase involves the search for the optimal

values of this vector.

In order to accomplish the first phase, the five following

steps must be achieved.

1 We consider = 1, = 1, b = 10, u = u min and

Once the behaviour of the system in the open-loop is

defined, a decision should be made concerning the CRONE

generation that will be used. This decision depends on the plant

uncertainties. In this paper, only the first or the second

generations will be applied as the third one presents complex

differentiation and integration orders, and the use of special

programs or toolboxes as the one designed by the CRONE

group [21].

Hence, the open-loop behaviour due to the plant gain

uncertainties (e.g., taking into consideration the second

CRONE generation) leads to the following transfer function:

M = M min ;

2

We

0 = C I ( j u ) G ( j u )

calculate

and

0 = arg C I ( ju ) + arg G ( ju ) ;

3 We deduce m = M 0 ;

4 We calculate the value of a with respect to the relation

a = (1 + sin m ) / (1 sin m ) ;

5 Knowing that ( ju ) = 1 , we deduce the value of C0 as

follow:

C0 = a

/2

1+ s / b b 1+ s / h

nh

( s ) = 0

,(48)

(1 + s / h )

s / b 1+ s / b

where b and h represent the low and high transitional

frequencies, n is the fractional order varying between 1 and 2,

nb and nh are the asymptotic order behaviours for low and high

frequencies and 0 is a constant that assures a unit gain at the

frequency u. This constant is calculated as follow:

The second phase consists on determining the optimal

values of the vector . For this purpose, the optimization

toolbox of Matlab and its function fmincon is used or the

genetic algorithms can be also used.

In this paper, the optimisation function will be used. This

function requires a large number of inputs and returns the five

295

17th IEEE Mediterranean Electrotechnical Conference, Beirut, Lebanon, 13-16 April 2014.

0 = (u / b ) 1 + (u / b )

( n nb ) /2

( nh n) /2

(1 + ( / ) )

2

(49)

Knowing that ( s ) = Ccrone ( s ) G ( s ) ,

(50)

the CRONE transfer function Ccrone(s) is deduced for the

nominal plant value, which is to say:

(51)

Ccrone ( s ) = ( s ) / G ( s ) .

V. APPLICATION EXAMPLE

After presenting the three controllers, an application will be

shown in this part. The plant is a hydro electromechanical

system constituted of a double direction pump, a perturbation

pump, a water level sensor and two tanks as shown in figure 2.

G (s) =

2.24 104

.

(53)

s

s

1

+

3.6 103

As for the user specifications, they can be resumed by the

following:

- the stability degree: M min = 45 ;

(54)

- the bandwidth : u min = 0.0108 rad / s ;

- the rejection level of the measured noise:

T = 0.108 rad / s, T ( j ) 0.1 ;

(55)

- the rejection level of the output perturbation:

S = 0.00108 rad / s, S ( j ) 0.1 ;

(56)

- the plant input sensitivity:

R = 10.8 rad / s, R ( j ) 100 .

(57)

Depending on the user specifications and the methods used

to calculate the controllers defined previously, the transfer

functions of the PID, the generalized PID and the CRONE

controller of second generation are as follow:

1 + s / 1.1 103 1 + s / 6 103

, (58)

CPID (s ) = 83.62

s / 1.1 10 3 1 + s / 19.6 10 3

1 + s / 8.3 10 4

C PI D (s ) = 46

s / 8.3 10 4

1 + s / 7.95 10 3

1 + s / 1.47 10 2

Figure 2 hydro-electro mechanical system

The identification of this system shows that it can be

presented by the following transfer function form:

k

,

(52)

G ( s) =

( s (1 + s / 0 ) )

(59)

0.5435

1 + s / 6.98 10 4

.

(60)

1 + s / 0.5014

1

1 + s / 0.5014

In the following, some frequency and time domain output

show the behaviour and the robustness of the three controllers

when varying the values of the plants variables.

As we are limited in space, figure 3 shows the step

responses for the system when taking into consideration the

first and the third operational points. As for the frequency

response, almost the same is observed. So, the first overshoot is

maintained for the CRONE controller when varying the water

level sensor, which is not the case for the other controllers.

Table 1 Values of k and 0 for each operational point

k (V/V)

8.30 10-4

5.90 10-4

2.24 10-4

3.7

0.5

1 + s / 3.6 103

Ccrone (s ) = 32.62

s / 3.6 103

where k represents the constant of the water level sensor and

0 the response time of the system. A complete modelling of

the system can be found in [22].

As the plants transfer function is nonlinear, three different

water levels were chosen and a linear study around these

points was made. For each level, the values of k and 0 were

maintained. One of these three levels was identified to be the

nominal level and the two others were used to study the

robustness of the controllers. Table 1 summarizes these

values.

Water Level (cm)

2

4

6

Max/Min

0.2

0 (rad/s)

4.0 10-3

3.8 10-3

3.6 10-3

1.11

VI. CONCLUSION

A comparison between three controllers was proposed in

this work. Two of the controllers are of fractional order (the

generalized PID and the CRONE) whereas the third one has

an integer order integration and derivation (the PID).

The third operational point, which refers to the 6cm water

level, was chosen to be the nominal transfer function. Hence,

this transfer function can be written as follow:

296

17th IEEE Mediterranean Electrotechnical Conference, Beirut, Lebanon, 13-16 April 2014.

Also, two controllers are synthesized using the a priori

method (the PID and generalized PID) whereas the CRONE

is calculated using a posteriori synthesis method.

The methods used to calculate the three controllers were

shown and these controllers were implemented to control a

hydro electromechanical system.

The obtained results showed that the CRONE controller is

robust to plant small variations, which is not the case for the

two other controllers.

As a future work, we will apply this comparative study to

other systems such as diffusive thermal systems.

Fig. 4 Output responses in tracking mode for a step input of 10 mV

with: (a) the PID controller, (b) the generalized PI D controller and

(c) the CRONE controller

REFERENCES

B. Stuart, A Brief History of Automatic Control, June 1996.

N. Minorsky, Directional stability of automatically steered bodies, J.

Amer. Soc. Naval Eng., vol. 34, issue 2, pp. 280309, 1922

[3] V. Duarte, J. Sa da Costa, Tuning rules for fractional PID controllers,

in Proceedings of the 2nd IFAC Workshop on Fractional Differentiation

and its applications, Porto, Portugal, July 19-21, 2006.

[4] J. G. Ziegler and N. B. Nichols, Optimum settings for automatic

controllers, Transactions of ASME, vol. 64, pp. 759-768, 1942.

[5] I. Podlubny, Fractional-order systems and PID-controllers, IEEE

Transaction on Automatic Control, Vol.44, pp.208-214, 1999.

[6] M. Moze, J. Sabatier, A. Oustaloup, Synthesis of a Third Generation

crone Controller using -Analysis Tools, IEEE Industrial Electronics,

IECON 2006, November 2006, Paris, France

[7] FADI ASCC 2013

[8] A. Sommacal, P. Melchior, J.M. Cabelguen, A. Oustaloup, A.J. Ijspeert,

Fractional Multi-Models of the Gastrocnemius Frog Muscle, Journal of

Vibration and Control. Sage Publishing, Vol. 14, No. 9-10, pp. 14151430, 2008.

[9] R. Abi Zeid Daou, C. Francis and X. Moreau, Fractional order systems

applied to electrical domain part 2: implementation results and

Uncertainties influence, 2nd International Conference on Advances in

Computational Tools for Engineering Applications (ACTEA), Lebanon,

December 2012.

[10] S. Das, Functional Fractional Calculus for System Identification and

Controls, Springer, ISBN: 978-3540727026, 2007.

[11] K.S. Miller and B. Ross, An introduction to the fractional calculus and

fractional differential equations, A Wiley-Interscience Publication,

1993.

[12] K.B. Oldham and J. Spanier, The fractional calculus, Academic Press,

New-York and London, 1974.

[13] O. Cois, Systmes linaires non entiers et identification par modle

non entier : application en thermique , Thse de Doctorat de

lUniversit Bordeaux 1, 2002.

[14] J. Lin, Modlisation et identification de systmes d'ordre non entier ,

Thse de Doctorat, Universit de Poitiers, 2001.

[15] A. Oustaloup, La drivation non entire : thorie, synthse et

applications , Edition Herms, Paris, 1995.

[16] S. Manabe, The non-integer integral and its application to control

systems, ETJ of Japan, Vol. 6, pp.83-87, 1961.

[17] A. Oustaloup, Etude et ralisation d'un systme d'asservissement

d'ordre 3/2 de la frquence d'un laser colorant continu , Thse de

Docteur-Ingnieur, Universit Bordeaux 1, 1975.

[18] S. G.Samko, A. A. Kilbas and O. I. Marichev, Fractional integrals and

derivatives: theory and applications, Gordon and Breach Science

Publishers, 1993.

[19] B. M. Vinagre, I. Podlubny, L. Dorcak and V. Feliu, On fractional PID

controllers: a frequency domain approach, IFAC Workshop on Digital

Control, Past, Present and Future of PID Control, pp. 53-58, Terressa,

Spain, 2000.

[20] J. Sabatier, A. Garcia Iturricha, A. Oustaloup, F. Levron, "Third

generation CRONE control of continuous linear time periodic systems",

Proceedings of IFAC Conference on System Structure and Control,

CSSC'98, Nantes, France, July 8-10, 1998

[21] http://www.imsbordeaux.fr/CRONE/toolbox/pages/accueilSITE.php?guidPage=home_p

age

[22]R. Abi Zeid Daou, X. Moreau, A comparison between integer order and

fractional order controllers applied to a hydro-electromechanical

system, Transaction on Control and Mechanical Systems, V.2, No. 3,

pp. 131-143, 2013

[1]

[2]

(a)

(b)

(c)

297

You might also like

- Regulationofapump Tank SensorsystemusingtwofractionalcontrollersDocument23 pagesRegulationofapump Tank SensorsystemusingtwofractionalcontrollersJosh GonzalesNo ratings yet

- Frequency Response Based Multivariable Control Design For Motion SystemsDocument6 pagesFrequency Response Based Multivariable Control Design For Motion SystemsGapuk MaboekNo ratings yet

- Design and Experimentation of A Self-Tuning PID Control Applied To The 3DOF HelicopterDocument21 pagesDesign and Experimentation of A Self-Tuning PID Control Applied To The 3DOF HelicopterMairaj-ud-din MuftiNo ratings yet

- Two-Degree-of-Freedom PID Controllers TutorialDocument11 pagesTwo-Degree-of-Freedom PID Controllers TutorialPrithvi Natraj0% (1)

- Computers and Mathematics With Applications: Ramiro S. Barbosa, J.A. Tenreiro Machado, Isabel S. JesusDocument8 pagesComputers and Mathematics With Applications: Ramiro S. Barbosa, J.A. Tenreiro Machado, Isabel S. Jesusdebasishmee5808No ratings yet

- Comparative Study of Monotonic and Non-Monotonic Phase LTI Systems Using Improved Analytical PID ControllerDocument7 pagesComparative Study of Monotonic and Non-Monotonic Phase LTI Systems Using Improved Analytical PID ControllerIOSRjournalNo ratings yet

- Robust PID controller toolbox using convex optimizationDocument6 pagesRobust PID controller toolbox using convex optimizationAnonymous WkbmWCa8MNo ratings yet

- Internal Model Control. 4. P I D Controller Design-Rivera 86Document14 pagesInternal Model Control. 4. P I D Controller Design-Rivera 86jricardo01976No ratings yet

- Optimal FOPI-FOPD Controller Design For Rotary Inverted Pendulum System Using Grey Wolves' Optimization TechniqueDocument10 pagesOptimal FOPI-FOPD Controller Design For Rotary Inverted Pendulum System Using Grey Wolves' Optimization TechniqueTELKOMNIKANo ratings yet

- Control Systems NotesDocument133 pagesControl Systems Noteseee limatNo ratings yet

- PID Control TheoryDocument17 pagesPID Control TheoryManuel Santos MNo ratings yet

- Detecting Actuator Faults in a Boeing 747Document7 pagesDetecting Actuator Faults in a Boeing 747jfnegretiNo ratings yet

- Robust Iterative PID Controller Based On Linear Matrix Inequality For A Sample Power SystemDocument9 pagesRobust Iterative PID Controller Based On Linear Matrix Inequality For A Sample Power Systemsjo05No ratings yet

- AUTOMATIC - CONTROL - SYSTEM - UNIT - 1 - For MergeDocument45 pagesAUTOMATIC - CONTROL - SYSTEM - UNIT - 1 - For MergemanishaNo ratings yet

- Reconfigurable Fault-Tolerant Control Using GIMC StructureDocument7 pagesReconfigurable Fault-Tolerant Control Using GIMC StructureMinu PriyaNo ratings yet

- Robust Fault Tolerant Control With Sensor Faults For A Four Rotor HelicopterDocument14 pagesRobust Fault Tolerant Control With Sensor Faults For A Four Rotor Helicopterstalker2222No ratings yet

- Robust Adaptive Controller Design For Excavator Arm: Nga Thi-Thuy VuDocument6 pagesRobust Adaptive Controller Design For Excavator Arm: Nga Thi-Thuy VuAsif SaleemNo ratings yet

- Fuzzy: Design and Analysis of A Fuzzy Proportional-Integral-Derivative ControllerDocument18 pagesFuzzy: Design and Analysis of A Fuzzy Proportional-Integral-Derivative ControllerDaniel ThomasNo ratings yet

- Control Systems NotesDocument152 pagesControl Systems Notesdarlachantisaideepthi450No ratings yet

- Research Article: The Best Achievable Tracking Performances For SIMO Feedback Control SystemsDocument13 pagesResearch Article: The Best Achievable Tracking Performances For SIMO Feedback Control SystemsAnonymous HdETOphR5No ratings yet

- Implementation of Inverted Pendulum Control, Plunks On Miscellaneous TacticsDocument6 pagesImplementation of Inverted Pendulum Control, Plunks On Miscellaneous TacticsirqoviNo ratings yet

- Backstepping Control of Wind TunnelDocument10 pagesBackstepping Control of Wind TunnellamuelNo ratings yet

- InTech-Pid Control TheoryDocument17 pagesInTech-Pid Control TheoryAbner BezerraNo ratings yet

- 39 PDFDocument12 pages39 PDFVignesh RamakrishnanNo ratings yet

- PID Control System Analysis and DesignDocument48 pagesPID Control System Analysis and DesignAsghar AliNo ratings yet

- Evaluation of Effect of Parameters of Fractional Order Pid Controller For A Class of Linear SystemsDocument17 pagesEvaluation of Effect of Parameters of Fractional Order Pid Controller For A Class of Linear SystemsIAEME PublicationNo ratings yet

- Fuzzy Remote Control of A DC DriveDocument18 pagesFuzzy Remote Control of A DC Drivejames1823No ratings yet

- L1AdaptCntrl CSM Oct2011Document52 pagesL1AdaptCntrl CSM Oct2011alexanderkaleNo ratings yet

- A Digital-Based Optimal AVR Design of Synchronous Generator Exciter Using LQR TechniqueDocument13 pagesA Digital-Based Optimal AVR Design of Synchronous Generator Exciter Using LQR Technique3KaiserENo ratings yet

- IFAC Berlin 2020Document6 pagesIFAC Berlin 2020JLuis LuNaNo ratings yet

- Control Systems Lecture NotesDocument132 pagesControl Systems Lecture Notessumit soniNo ratings yet

- MPC Tuning For Systems With Right Half Plane ZerosDocument6 pagesMPC Tuning For Systems With Right Half Plane ZerosAhmed Chahine ZorganeNo ratings yet

- UPFC Control Based On New IP Type Controller: Mojtaba Shirvani, Babak Keyvani, Mostafa Abdollahi and Ahmad MemaripourDocument8 pagesUPFC Control Based On New IP Type Controller: Mojtaba Shirvani, Babak Keyvani, Mostafa Abdollahi and Ahmad MemaripourMmillion AlemayehuNo ratings yet

- GRT Institute of Engineering and Technology,: P.I.D.T.Bala Durai Kannan, Ap / Eee, GRT IetDocument12 pagesGRT Institute of Engineering and Technology,: P.I.D.T.Bala Durai Kannan, Ap / Eee, GRT IetDharani KumarNo ratings yet

- CS Two MarksDocument7 pagesCS Two MarkssivaeinfoNo ratings yet

- Lecture2 3Document25 pagesLecture2 3vrushalibhattNo ratings yet

- PWM DC-AC Converter Regulation Using A Multi-LoopDocument8 pagesPWM DC-AC Converter Regulation Using A Multi-LoopErsin CanakNo ratings yet

- Tutorial Xinda-Hu ImpDocument8 pagesTutorial Xinda-Hu ImpMuhammad SiddiqueNo ratings yet

- Control Systems Typed NotesDocument129 pagesControl Systems Typed Notesta003744No ratings yet

- Performance Analysis and Comparative Study of LMI-Based Iterative PID Load-Frequency ControllersDocument13 pagesPerformance Analysis and Comparative Study of LMI-Based Iterative PID Load-Frequency Controllerssmprabu24317No ratings yet

- J.B. Institute Control Systems Lecture NotesDocument135 pagesJ.B. Institute Control Systems Lecture Notessugunasri UNo ratings yet

- Linear Control System DeceDocument7 pagesLinear Control System Decepardeep4372No ratings yet

- Controller DesignDocument253 pagesController DesignymvbnNo ratings yet

- Note On Fractional-Order Proportional - Integral - Differential Controller DesignDocument12 pagesNote On Fractional-Order Proportional - Integral - Differential Controller DesignSyamasree RahaNo ratings yet

- Magnitude Symetric Optimum CriterionDocument9 pagesMagnitude Symetric Optimum CriterionasuhuaneNo ratings yet

- PID SIMULATOR GUIDEDocument18 pagesPID SIMULATOR GUIDEAAYUSH KUMARNo ratings yet

- On Sensorless Induction Motor Drives: Sliding Mode Observer and Output Feedback ControllerDocument8 pagesOn Sensorless Induction Motor Drives: Sliding Mode Observer and Output Feedback ControllerRaja ReddyNo ratings yet

- TRMS Paper PDFDocument6 pagesTRMS Paper PDFAchmadNo ratings yet

- A Generalized Predictive Force Controller For Electropneumatic CylindersDocument6 pagesA Generalized Predictive Force Controller For Electropneumatic CylindersEngr Nayyer Nayyab MalikNo ratings yet

- Optimal Approximation of Analog PID Controllers of Complex Fractional-OrderDocument28 pagesOptimal Approximation of Analog PID Controllers of Complex Fractional-OrderGabriel CelestinoNo ratings yet

- Control System Unit 1 (5 TH Sem.)Document61 pagesControl System Unit 1 (5 TH Sem.)kishan guptaNo ratings yet

- FUZZY BASED CONTROLLER FOR HEAVY DUTY GAS TURBINEDocument5 pagesFUZZY BASED CONTROLLER FOR HEAVY DUTY GAS TURBINERichard CleeNo ratings yet

- Sun 2013Document6 pagesSun 2013t123medNo ratings yet

- Lastest Advancements in Process Control in RefineryDocument15 pagesLastest Advancements in Process Control in Refinerydiazf2004No ratings yet

- Closedloop PID Control of Universal MotorDocument9 pagesClosedloop PID Control of Universal MotorabhywaNo ratings yet

- On Sliding Mode Control For Nonlinear Electrical SDocument7 pagesOn Sliding Mode Control For Nonlinear Electrical SDany M.TNo ratings yet

- Control Systems PDFDocument133 pagesControl Systems PDFShaboddinNo ratings yet

- Nonlinear Control Feedback Linearization Sliding Mode ControlFrom EverandNonlinear Control Feedback Linearization Sliding Mode ControlNo ratings yet

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsFrom EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNo ratings yet

- Bhimbra-Generalized Theory Electrical MachinesDocument10 pagesBhimbra-Generalized Theory Electrical Machinesdebasishmee5808No ratings yet

- nRF24L01P Product Specification 1 0Document78 pagesnRF24L01P Product Specification 1 0CaelumBlimpNo ratings yet

- 10 1109@91 481843Document12 pages10 1109@91 481843debasishmee5808No ratings yet

- Control SystemDocument22 pagesControl SystemKamran RazaNo ratings yet

- RID 1 ModrobDocument4 pagesRID 1 ModrobbalakaleesNo ratings yet

- Sophus 3Document1 pageSophus 3debasishmee5808No ratings yet

- TrademarksDocument1 pageTrademarksDhyan SwaroopNo ratings yet

- RID 1 ModrobDocument6 pagesRID 1 Modrobdebasishmee5808No ratings yet

- Extramural Funding2012-13Document2 pagesExtramural Funding2012-13debasishmee5808No ratings yet

- Adjunct 2Document5 pagesAdjunct 2debasishmee5808No ratings yet

- Electromagnetic Field TheoryDocument3 pagesElectromagnetic Field Theorydebasishmee5808No ratings yet

- Adaptive Control of Linearizable Systems: Fully-StateDocument9 pagesAdaptive Control of Linearizable Systems: Fully-Statedebasishmee5808No ratings yet

- AssignmentsDocument11 pagesAssignmentsdebasishmee5808No ratings yet

- AssignmentsDocument11 pagesAssignmentsdebasishmee5808No ratings yet

- Duplicate Doc Diploma CertiDocument1 pageDuplicate Doc Diploma Certidebasishmee5808No ratings yet

- Book ListDocument6 pagesBook Listdebasishmee58080% (1)

- Control System - I: Weekly Lesson PlanDocument5 pagesControl System - I: Weekly Lesson Plandebasishmee5808No ratings yet

- T Year B.tech Sylla1sbus Revised 18.08.10Document33 pagesT Year B.tech Sylla1sbus Revised 18.08.10Manoj KarmakarNo ratings yet

- Lec 2Document25 pagesLec 2debasishmee5808No ratings yet

- 2 14 24Document11 pages2 14 24debasishmee5808No ratings yet

- Lec 1Document18 pagesLec 1cavanzasNo ratings yet

- Lec 1Document18 pagesLec 1cavanzasNo ratings yet

- Introduction To Nba 16 NovDocument32 pagesIntroduction To Nba 16 Novdebasishmee5808No ratings yet

- Lec 2Document25 pagesLec 2debasishmee5808No ratings yet

- Syllabus For B.Tech (Electrical Engineering) Up To Fourth YearDocument67 pagesSyllabus For B.Tech (Electrical Engineering) Up To Fourth YearDr. Kaushik MandalNo ratings yet

- Best Practices of Report Writing Based On Study of Reports: Venue: India Habitat Centre, New DelhiDocument24 pagesBest Practices of Report Writing Based On Study of Reports: Venue: India Habitat Centre, New Delhidebasishmee5808No ratings yet

- Graphical AbstractDocument2 pagesGraphical Abstractdebasishmee5808No ratings yet

- Time ManagementDocument19 pagesTime ManagementShyam_Nair_9667No ratings yet

- Chapter TwoDocument85 pagesChapter Twohabte gebreial shrashrNo ratings yet

- Experiment 1Document15 pagesExperiment 1RamaDinakaran100% (1)

- Control Engineering at LSPUDocument35 pagesControl Engineering at LSPUCllyan ReyesNo ratings yet

- Control Engineering: 2 Marks Questions & AnswersDocument16 pagesControl Engineering: 2 Marks Questions & AnswersLakshumaiah MajjariNo ratings yet

- Chapter 8 Manual OgataDocument53 pagesChapter 8 Manual OgataKalim UllahNo ratings yet

- Marlin Ch04Document37 pagesMarlin Ch04Taniadi SuriaNo ratings yet

- Nolinearities - ServoMechanisms and Rgulating System Design - TextDocument696 pagesNolinearities - ServoMechanisms and Rgulating System Design - Textsdpsk100% (1)

- Syde 352Document10 pagesSyde 352alldaylam3No ratings yet

- PTSP Probability and Stochastic ProcesssDocument35 pagesPTSP Probability and Stochastic ProcesssnagasmsNo ratings yet

- Automatic Bus Suspension PID Controller DesignDocument50 pagesAutomatic Bus Suspension PID Controller Designchuhuynh100% (1)

- Gyrostellar EstimationDocument6 pagesGyrostellar EstimationMarcAlomarPayerasNo ratings yet

- Control System Lab 9Document10 pagesControl System Lab 9Niamatullah WazirNo ratings yet

- Moog Technical Bulletin 103Document11 pagesMoog Technical Bulletin 103William PetersNo ratings yet

- 2021 Integrated MIMO Fault Detection and Disturbance Observer-Based ControDocument10 pages2021 Integrated MIMO Fault Detection and Disturbance Observer-Based ControThanh Hai NguyenNo ratings yet

- Sid 40bDocument102 pagesSid 40bmuhammad nazirNo ratings yet

- Digital Image Processing Q&A - Frequency Domain TechniquesDocument19 pagesDigital Image Processing Q&A - Frequency Domain TechniquesSandeep KishoreNo ratings yet

- EL7133 ExercisesDocument92 pagesEL7133 ExercisesSpiros LoutridisNo ratings yet

- Modelling and Load Frequency Control L12Document27 pagesModelling and Load Frequency Control L12Rajat RaiNo ratings yet

- Lab 2, Part B: Robot DC Motor: Speed Measurement Circuit DesignDocument31 pagesLab 2, Part B: Robot DC Motor: Speed Measurement Circuit DesignNunjaNo ratings yet

- Chapter 11 (11-23-04)Document61 pagesChapter 11 (11-23-04)sruthimeena6891No ratings yet

- Pid PostDocument33 pagesPid PostosamahNo ratings yet

- EE-361 Feedback Control Systems Basic MATLAB Commands Experiment # 1Document8 pagesEE-361 Feedback Control Systems Basic MATLAB Commands Experiment # 1Shiza ShakeelNo ratings yet

- Laplace Transform ChapterDocument56 pagesLaplace Transform ChapterzohaibNo ratings yet

- Control Theory Summer 2013 CTDocument2 pagesControl Theory Summer 2013 CTvisupinuNo ratings yet

- Lead Compensator: Design ExampleDocument34 pagesLead Compensator: Design ExampleDharun SanthoshNo ratings yet

- Electrical Machines Modelling and ControlDocument106 pagesElectrical Machines Modelling and ControlMohamed MamdouhNo ratings yet

- Matlab Control System Toolbox User's Guide (PDFDrive)Document1,816 pagesMatlab Control System Toolbox User's Guide (PDFDrive)Fathi HarrathNo ratings yet

- Modelling & Simulation of Mechatronic Systems: (Course Code-Emeg6422)Document28 pagesModelling & Simulation of Mechatronic Systems: (Course Code-Emeg6422)MEWAEL MIZANNo ratings yet

- A General Unified Approach To Modelling Switching-Converter Power StagesDocument31 pagesA General Unified Approach To Modelling Switching-Converter Power StagesFernando BotteronNo ratings yet

- Modeling DC Motor Position ControlDocument4 pagesModeling DC Motor Position ControlKartik DetrojaNo ratings yet