Professional Documents

Culture Documents

Polymer Cages: Polyamide 66

Uploaded by

ps1amsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polymer Cages: Polyamide 66

Uploaded by

ps1amsCopyright:

Available Formats

India

P roducts

Bearings, ...

Roller...

P rinciples ...

Bearing ...

M aterials ...

C age ...

P oly mer cages

Polymer cages

Polyamide 66

For the majority of injection moulded cages, polyamide 66 (PA66) is used. This

material, with or without glass reinforcement, is characterized by a favourable

combination of strength and elasticity. The mechanical properties like strength

and elasticity of polymer materials are temperature dependent and subject to

ageing. The most important factors that play a role in the ageing process are

temperature, time and the medium (lubricant) to which the polymer is exposed.

Diagram 1 shows the relationship between these factors for glass fibre

reinforced PA66. It shows that cage life decreases with increasing temperature

and the aggressiveness of the lubricant.

Therefore, whether polyamide cages are suitable for a specific application

depends on the operating conditions and life requirements. The classification of

lubricants into aggressive and mild is reflected by the permissible operating

temperature for cages made of glass fibre reinforced PA66 with various

lubricants

table 1. The permissible operating temperature in

table 1 is

defined as the temperature that provides a cage ageing life of at least 10 000

operating hours.

Some media are even more aggressive than those provided in

table 1. A

typical example is ammonia, used as a refrigerant in compressors. In those

cases, cages made of glass fibre reinforced PA66 should not be used at

operating temperatures above 70 C (160 F).

Polyamide also has a low temperature limit because it loses its elasticity, which

can cause cage failures under extremely cold conditions. As a result, cages

made of glass fibre reinforced PA66 should not be used in applications where

the continuous operating temperature is below 40 C (40 F).

In applications where a high degree of toughness is a critical operational

parameter, such as in railway axleboxes, a super-tough modified PA66 can be

used. For additional information, contact the SKF application engineering

service.

Polyamide 46

Glass fibre reinforced polyamide 46 (PA46) is the standard cage material for

some small and medium-size C ARB toroidal roller bearings. The permissible

operating temperature is 15 C (25 F) higher than for glass fibre reinforced

PA66.

Polyetheretherketone

Glass glass fibre reinforced polyetheretherketone (PEEK) is popular for

demanding applications where there are either high speeds or high

temperatures or a need for chemical resistance. The exceptional properties of

PEEK provide a superior combination of strength and flexibility, high operating

temperature range, high chemical and wear-resistance and good processability.

Due to these outstanding features, PEEK cages are available as standard for

some ball and cylindrical roller bearings, such as hybrid and/or super-precision

bearings. The maximum temperature for high-speed use is limited to 150 C

(300 F) as this is the softening temperature of the polymer. The material does

not show signs of ageing by temperature or oil additives up to 200 C (390 F).

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- Polyamide For Flexible Packaging FilmDocument57 pagesPolyamide For Flexible Packaging Filmtabassim100% (1)

- v5 6R2014 v5 6R2018 PDFDocument141 pagesv5 6R2014 v5 6R2018 PDFbad guy0% (1)

- ME307 Solved SecondM T111Document10 pagesME307 Solved SecondM T111Wolf MoonNo ratings yet

- Design of Surfaces and GuidewaysDocument50 pagesDesign of Surfaces and GuidewaysChristian Luares80% (5)

- Case Study ApolloDocument55 pagesCase Study ApolloVaani Sharma100% (2)

- SKF Cage MaterialsDocument2 pagesSKF Cage MaterialsKamolwan WeerachatsakulNo ratings yet

- SKF Special MaterialsDocument2 pagesSKF Special MaterialsKamolwan WeerachatsakulNo ratings yet

- Velan Ball Valve 1 PDFDocument9 pagesVelan Ball Valve 1 PDFMilena Lemus FonsecaNo ratings yet

- Technical Information: Properties of Polyamide PA66Document10 pagesTechnical Information: Properties of Polyamide PA66Ankur PanwarNo ratings yet

- Polymer Ball Bearings From SKFDocument14 pagesPolymer Ball Bearings From SKFMilan MarkovićNo ratings yet

- NylonDocument65 pagesNylonAkash YadavNo ratings yet

- SBF LongdDocument10 pagesSBF LongdcatalineulaNo ratings yet

- Temperature Limits of High Temperature SystemsDocument7 pagesTemperature Limits of High Temperature SystemsCarlosAlbertoRibeiroRuyNo ratings yet

- Klinger Product Catalogue 40 Pages April 2014 Final Doc Trusted - Worldwide PDFDocument40 pagesKlinger Product Catalogue 40 Pages April 2014 Final Doc Trusted - Worldwide PDFStart JaguarNo ratings yet

- Capron (Honeywell)Document32 pagesCapron (Honeywell)Bart Kemper, P.E.No ratings yet

- Polymers Ref DEC 24Document40 pagesPolymers Ref DEC 24Gowtham Kae KaeNo ratings yet

- PEEK-OPTIMA Processing Guide SecuredDocument0 pagesPEEK-OPTIMA Processing Guide SecuredAngel LagrañaNo ratings yet

- AltuglasDocument4 pagesAltuglasBhanuNo ratings yet

- Polyamide Thermoplastics For Automotive Engine ApplicationsDocument10 pagesPolyamide Thermoplastics For Automotive Engine ApplicationsMatSciGuy100% (1)

- Garlock Metallic CatalogueDocument48 pagesGarlock Metallic Catalogueclaudio perez prietoNo ratings yet

- TOPAS Brochure E 2014 06 PDFDocument20 pagesTOPAS Brochure E 2014 06 PDFanon_936760200No ratings yet

- Ix Metal SubDocument4 pagesIx Metal SubRenan Lucena da CruzNo ratings yet

- MMABR1016Document24 pagesMMABR1016Uday GokhaleNo ratings yet

- Scope and Delimitation of The StudyDocument2 pagesScope and Delimitation of The StudyDan Marionne TabiosNo ratings yet

- Leading High Heat-Resistant PolymersDocument12 pagesLeading High Heat-Resistant PolymerstilakmirleNo ratings yet

- GPT 1-3 PGE Tech SpecificationsDocument4 pagesGPT 1-3 PGE Tech SpecificationsEhtisham AndrAbiNo ratings yet

- Valve and Pumps GUIDELINESDocument32 pagesValve and Pumps GUIDELINESPrakash KarthikeyanNo ratings yet

- Garlock: Compression Packing Technical ManualDocument28 pagesGarlock: Compression Packing Technical ManualjbertralNo ratings yet

- Spe-170480-Ms PDFDocument12 pagesSpe-170480-Ms PDFSasha AlmeidaNo ratings yet

- Plastic Pipes Engineering HandbookDocument88 pagesPlastic Pipes Engineering HandbookFaizan100% (1)

- Wellhead and Christmas TreeDocument4 pagesWellhead and Christmas Treedinesh_hsenidNo ratings yet

- APPPLICATION of Speciality Polymers From Gharda PolymersDocument70 pagesAPPPLICATION of Speciality Polymers From Gharda PolymersBubai111No ratings yet

- Garlock Metallic Gasket Technical ManualDocument48 pagesGarlock Metallic Gasket Technical ManualMarcio NegraoNo ratings yet

- Cryogenic Service Ball ValveDocument2 pagesCryogenic Service Ball ValvesaminasritnNo ratings yet

- Garlock Metallic Gasket CatalogDocument46 pagesGarlock Metallic Gasket CatalogPeterSPNo ratings yet

- Polyisocyanurate vs. Cellular Glass in Low Temperature Mechanical InsulationDocument7 pagesPolyisocyanurate vs. Cellular Glass in Low Temperature Mechanical InsulationmacNo ratings yet

- Compression Packing CatalogDocument34 pagesCompression Packing CatalogRevanNo ratings yet

- 10 2goetzDocument57 pages10 2goetzDonny SinagaNo ratings yet

- EMS Long Fibre Reinforced PolyamidesDocument44 pagesEMS Long Fibre Reinforced PolyamidesnimonhNo ratings yet

- Zytel HTN Whitepaper R8!06!2008Document9 pagesZytel HTN Whitepaper R8!06!2008Leonel DottaNo ratings yet

- Refractory Molds For Glass Sintering: Technology BriefDocument2 pagesRefractory Molds For Glass Sintering: Technology Briefمحمد هاني ابوالنورNo ratings yet

- Compression Packing Selection Guide: Sealing Products For IndustryDocument13 pagesCompression Packing Selection Guide: Sealing Products For IndustryAdverNo ratings yet

- GMG 1 1 Metallic Gaskets CatalogDocument48 pagesGMG 1 1 Metallic Gaskets CatalogTecnico GiganteNo ratings yet

- Garlock MetalGasket CatalogDocument48 pagesGarlock MetalGasket CatalogG100% (1)

- APCYDocument61 pagesAPCYsumitsharma2010No ratings yet

- Sealing For Extreme Cold - Best Practices For Statics SealsDocument3 pagesSealing For Extreme Cold - Best Practices For Statics Sealssujith_das_2No ratings yet

- Ball ValeDocument36 pagesBall Valelouiswang1964No ratings yet

- Garlock Compression Packing Catalog CMP4 41 PDFDocument34 pagesGarlock Compression Packing Catalog CMP4 41 PDFMartin Andrew TugadeNo ratings yet

- Bulletin 11B Shelf Life of SABO FOAMSDocument2 pagesBulletin 11B Shelf Life of SABO FOAMSAhmad TalaatNo ratings yet

- Aircol 266 - 299Document2 pagesAircol 266 - 299Vladislav TrempoletsNo ratings yet

- Case Study On FlowserveDocument7 pagesCase Study On FlowserveekinkuranNo ratings yet

- Amerlock 400GFA High Solids Glassflake Epoxy CoatingDocument4 pagesAmerlock 400GFA High Solids Glassflake Epoxy CoatingSherif AbdelhameedNo ratings yet

- Garlock Metallic Gasket Technical ManualDocument48 pagesGarlock Metallic Gasket Technical ManualALONSO GOMEZNo ratings yet

- (ARENBR0016 (EA4) - Argus PDS Brochure LR5Document8 pages(ARENBR0016 (EA4) - Argus PDS Brochure LR5Juancho GuzmanNo ratings yet

- Aluminium and Aluminium Alloys - Heat Treatment of Aluminium and Aluminium AlloysDocument3 pagesAluminium and Aluminium Alloys - Heat Treatment of Aluminium and Aluminium Alloysdshine2010No ratings yet

- Resin Guidelines 111102132909 Phpapp01Document33 pagesResin Guidelines 111102132909 Phpapp01Agoenk KertawijayaNo ratings yet

- Intense Heat. Extreme Cold. Aggressive Chemicals. InnovativeDocument2 pagesIntense Heat. Extreme Cold. Aggressive Chemicals. InnovativeCristian Jhair PerezNo ratings yet

- Zytel-All in One Extrusion ProcessesDocument10 pagesZytel-All in One Extrusion ProcessesYiğit IlgazNo ratings yet

- Gasket RefDocument21 pagesGasket Refjun_bucayuNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsFrom EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Court Order - Search by Case NumberDocument1 pageCourt Order - Search by Case Numberps1amsNo ratings yet

- Subscribing To The HinduDocument1 pageSubscribing To The Hindups1amsNo ratings yet

- Health Ministry LetterDocument21 pagesHealth Ministry LetterNDTV75% (4)

- Single and Two Stage CompressorsDocument4 pagesSingle and Two Stage CompressorsELGi IndiaNo ratings yet

- 9892002415/9029480701 - Joshi Courier/ RequirementsDocument1 page9892002415/9029480701 - Joshi Courier/ Requirementsps1amsNo ratings yet

- Automobiles Report May 2018Document31 pagesAutomobiles Report May 2018Kanav GuptaNo ratings yet

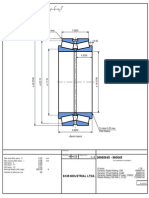

- Sr. No. Bearing Name Companey Bearing No. QtyDocument1 pageSr. No. Bearing Name Companey Bearing No. Qtyps1amsNo ratings yet

- H 317eDocument1 pageH 317eps1amsNo ratings yet

- Automobiles Report Apr 2018Document31 pagesAutomobiles Report Apr 2018ps1amsNo ratings yet

- Pneumatic ToolsDocument5 pagesPneumatic Toolsps1amsNo ratings yet

- Format WritDocument5 pagesFormat Writnayanj04No ratings yet

- Read Me!Document1 pageRead Me!ps1amsNo ratings yet

- Informacion Del ArchivoDocument2 pagesInformacion Del ArchivoAnonymous sZitBEINo ratings yet

- SKM Industrial LtdaDocument1 pageSKM Industrial LtdaGarcia MarcosNo ratings yet

- Fabric ArchitectureDocument1 pageFabric ArchitectureEduardo GrandeNo ratings yet

- Ebike 1Document1 pageEbike 1ps1amsNo ratings yet

- Ser Repair TwowheelerDocument4 pagesSer Repair Twowheelerps1amsNo ratings yet

- New SKF Rolling Bearings Catalogue AvailableDocument1 pageNew SKF Rolling Bearings Catalogue AvailableIdabagus Putu Putra MahartanaNo ratings yet

- AC Purchase and Installation Living RoomDocument4 pagesAC Purchase and Installation Living Roomps1amsNo ratings yet

- Schedule of GST Rates For ServicesDocument19 pagesSchedule of GST Rates For ServicesMoneycontrol News97% (75)

- Fag India CRB & SRB Dt. 01-02-14Document9 pagesFag India CRB & SRB Dt. 01-02-14ps1amsNo ratings yet

- H 317Document1 pageH 317ps1amsNo ratings yet

- Importance of Finish To Start SuccessorsDocument8 pagesImportance of Finish To Start Successorsps1amsNo ratings yet

- MTS 01 MDocument19 pagesMTS 01 MrohunwarriorNo ratings yet

- Polymer Cages: Fig. 5 Fig. 6 Fig. 7 Fig. 8 Fig. 9Document1 pagePolymer Cages: Fig. 5 Fig. 6 Fig. 7 Fig. 8 Fig. 9ps1amsNo ratings yet

- MS Project Test QuestionDocument3 pagesMS Project Test Questionps1amsNo ratings yet

- 4 - Crystal Structure PDFDocument66 pages4 - Crystal Structure PDFManoj SelvamNo ratings yet

- Project Lifespan EstimatesDocument9 pagesProject Lifespan EstimatesSama88823No ratings yet

- Slip FormationDocument28 pagesSlip Formationpawan_aggarwal_22100% (2)

- Dipl Massl SDocument104 pagesDipl Massl SAl Rajiun Nazmus SakibNo ratings yet

- DSR Vol. 2Document230 pagesDSR Vol. 2Charan ElectricalsNo ratings yet

- Refrigeration and Air Conditioning Using Alcohol As A RefrigerantDocument3 pagesRefrigeration and Air Conditioning Using Alcohol As A RefrigerantMalliebooNo ratings yet

- 201906beaconenglish-Corrosion Under InsulationDocument1 page201906beaconenglish-Corrosion Under InsulationguhadebasisNo ratings yet

- 07a70101 Geotechnical Engineering-IiDocument7 pages07a70101 Geotechnical Engineering-IiSamiullah MohammedNo ratings yet

- Dhajji HouseDocument5 pagesDhajji HouseTejesh NanawareNo ratings yet

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- Wa0082 PDFDocument34 pagesWa0082 PDFmiteshNo ratings yet

- PVC ValveDocument28 pagesPVC ValveVincent Ferrer NironNo ratings yet

- PEGS-0710-COR-036 - External Protection of Piping and Equipment by Thermal Spray CoatingDocument23 pagesPEGS-0710-COR-036 - External Protection of Piping and Equipment by Thermal Spray CoatingĐiệnBiênNhâmNo ratings yet

- Submission: Document No Received Date Review Date NotesDocument1 pageSubmission: Document No Received Date Review Date NotesMahmoud AbbassNo ratings yet

- Copeland Scroll Digital Zfd13kveDocument31 pagesCopeland Scroll Digital Zfd13kveMaximiliano VegaNo ratings yet

- Material Specification SA - HSP Lampung - Lobby - 2nd FloorDocument2 pagesMaterial Specification SA - HSP Lampung - Lobby - 2nd FloorAnjani DwitaNo ratings yet

- BS en 13391 2004Document24 pagesBS en 13391 2004Ronaldo AlmeidaNo ratings yet

- APT Catalogo 2018Document48 pagesAPT Catalogo 2018Vesna NikolicNo ratings yet

- Natural Science ReviewerDocument10 pagesNatural Science ReviewerLiam SkrooNo ratings yet

- Elastic Properties of Materials Elastic Properties of MaterialsDocument32 pagesElastic Properties of Materials Elastic Properties of MaterialsCHRISTOPHER TEBIT SEMBINo ratings yet

- Design and Analysis of Truss: The STAAD Pro Graphical User Interface: It Is Used To Generate The Model, WhichDocument6 pagesDesign and Analysis of Truss: The STAAD Pro Graphical User Interface: It Is Used To Generate The Model, WhichMahmoud IbrahimNo ratings yet

- Typical DetailsDocument13 pagesTypical Detailsohomele4424No ratings yet

- Equipment Damage Curves ConductorsDocument5 pagesEquipment Damage Curves ConductorsrobertoseniorNo ratings yet

- Piping Stress Analysis TrainingDocument3 pagesPiping Stress Analysis TrainingGodwin100% (1)

- ITP - Public Address InstallationDocument9 pagesITP - Public Address InstallationGultom Juliana LiliesNo ratings yet

- Types of Welding ElectrodesDocument34 pagesTypes of Welding ElectrodesAileen May Caminero SumampaoNo ratings yet

- Elements - turbine-Turbo-TOC KaydonDocument3 pagesElements - turbine-Turbo-TOC KaydonnguyenanhtuanbNo ratings yet