Professional Documents

Culture Documents

Horizon Afc 744akt

Uploaded by

KBR Graphics CanadaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Horizon Afc 744akt

Uploaded by

KBR Graphics CanadaCopyright:

Available Formats

Computerized Cross Folder AFC-744AKTSC

Mobile Knife Fold Unit MKU-54/54T

Press Stacker PST-40

Press Stacking & Semi-auto Bundling Unit TST-37

Computerized Cross Folder AFC-744AKTSC

The AFC-744AKTSC B1-format folder is the newest in AFC-744AKTSC Automatic Set-up Fold Patterns

Horizon’s expanding line-up of quality-engineered folders

that combines simple operation, quick changeover, high

Open Accordion Zigzag Zigzag

production speed, and superior fold quality. Parallel Fold Short Fold

Gate Fold Fold (4 panel) Fold (5 panel) Fold

Letter Fold

The AFC-744AKTSC is equipped with a large, icon-based touch-screen for user-

friendly operation, automated fold plate and sheet guide adjustments driven by

stepper motors, high-speed belts (230 m/min.), and the highest level of precision 16-page 32-page

Double 8-page 12-page 16-page

engineering for top quality folding. DL Fold Transformation Transformation

Parallel Fold Cross Fold Cross Fold Cross Fold

Fold Fold

The AFC-744AKTSC also offers Horizon’s advanced rotary vacuum feed system,

for fast, smooth feeding of various stock types.

AFC-744AKTSC + RFU-74 Round Pile Feeder Unit

+ MKU-CU(Option) + MKU-54(Option) + TST-37(Option)

The AFC-744AKTSC is also compatible with the Horizon i2i network flow system,

which allows you to remotely monitor work in progress, productivity, set-up

conditions, and other key production information.

What is i2i System? i2i Network Flow System based on the view of CIP3 or CIP4

M I S Net>Work>Flow i2i System

JMF

(Based on CIP4) 4. Scan the Job Ticket

with barcode reader Hydraulic Cutter

on Satellite PC 5. Transfer the job data

APC-61IISB

6. Receive job status and

JDF JDF JDF fine-tune profile

(Based on CIP4) (Based on CIP4) (Based on CIP4) Satellite PC

Computerized Cross Folder

AFC-544AKTSC

7. Receive job status

Prepress Press Postpress of each machine Computerized Cross Folder

AFC-546AKTSC

Computerized Cross Folder

PPF Satellite PC AFC-744AKTSC

Control Server

Single-Clamp Binder

1. Load JDF/PPF and

PPF (Based on CIP3) arrange Job

BQ-270

The Horizon i2i system can be integrated with pre-press and printing workflow Satellite PC

to create a comprehensive automated CIP4 bindery with the prospect of jobs Saddle-stitching System

StitchLiner5500

passing from the eye of the creator to the eye of the beholder in a single i2i

CTP Press 2. Print out the Job Ticket

Net>Work>Flow for ultimate flexibility and efficiency in the on-demand era. Satellite PC High Performance Binding System

CABS5000

3. Put the Job Ticket on the

Thermal Plate Print stack of printed sheets

Satellite PC

Computerized Cross Folder AFC-744AKTSC

An accurate computer-controlled cross-folder for maximum LCD Touch-screen

sheet width 740 mm (29.1"). The AFC-744AKTSC combines a The large and interactive icon-based touch-screen is provided for operator

convenience.

sophisticated but user-friendly set-up and management system To set-up the machine, the operator touches the icon for the desired fold pattern (14

fold patterns are available, including 16-page cross-fold, 8-page cross-fold, and

with state-of-the-art technology and rock-solid construction. direct mail fold) and inputs the paper size. The folder automatically calculates and

then sets each of eight variable sub-stations, including the feed guide, register

SHOWS AUTOMATED SET-UP SECTIONS. guide, 1st to 4th buckles, and two knife stoppers.

A total of 8 sections (1st to 4th buckles, 1st The LCD touch-screen prompts the operator through all remaining settings,

and 2nd knife stopper, feed guide bar, and including how many sheets to insert to adjust the roller gap, for quick and easy

1st to 4th Buckles side lay guide) are set-up automatically. changeover.

Buckle Folding Required micro-adjustments are accomplished in second and can be performed on-

the-fly.

The specially-coated buckle plates create less friction with the paper to Side Lay Guide

The AFC-744AKTSC can memorize up to 100 different job settings including fine-

help maintain fold accuracy.

tunings, suction time, feed intervals, knife delay, etc., for instant total job recall. Side Lay Guide

The 1st buckle plate is equipped with a swing-arm deflector to prevent damage

The Operation Record screen provides complete system status at a glance. In the event of double

or marking of the sheet. And the 2nd to 4th buckles are equipped with an

integrated deflector / stopper combination for operator convenience. Optional devices such as the Gate Fold Plate and Press Stacker can be set-up and feeds, only the register

operated through the main LCD console on the AFC-744AKTSC. alignment table stops to

The buckle section is set-up automatically by inputting the fold pattern and

allow for quick removal of

sheet size via the LCD touch-screen display.

the jammed sheets while

other sheets in the folder

1st & 2nd Knife Stopper are processed completely.

The register alignment

Knife Folding table is coated with a

special anti-static plating.

1st

Knife

Suction Head

2nd

Knife

The feed interval is automatically set according to the knife delay

time for maximum folding efficiency.

The inclination of the knife can be easily adjusted with the knife

tilt adjusting knob.

The knife inching function provides easier alignment of the knife An innovative suction head

position to perforate or score at fold lines on the sheet, and avoids provides smooth feeding

trial-and-error test folding. free from double feeding,

even with recycled paper.

A newly developed single

Sub-Control Panel cylinder suction head

system prevents sheets

Basic operation, start, stop, and other adjustments (belt speed, feed

from fluttering for accurate

intervals, and knife delay time) are performed on the sub-control

sheet separation.

console.

Forward and reverse inching are also useful for adjustment.

Feed Rotor

Below Knife Section

The buckle plates under the knife can be installed either on operation side or drive side of the folder.

AFC-744AKTSC + PFU-74 Palette Feeder Unit

The slitter under the knife fold section employs a removable roller shaft so that the position of

the slitter wheel can be changed easily. Folding Rollers

The slitter also allows for the trimming of the edges of an 8-page folded signature. Trimmings Helical gears driven with flexible

cross couplings for quality fold. Feed Guide Bar

are efficiently removed.

For 32-page cross fold, the perforation shaft and blade can be attached below the 2nd knife Feed Table

fold section. (Option) The high quality

For consistently reliable feeding, the feed table lift is inverter-

polyurethane feed rotor

controlled to maintain proper distance between sheets and the

smoothly delivers sheets to

vacuum feed wheel.

Perforation the register alignment table

The pile height control system employs a capacity sensor for without sheet scratching or

The AFC-744AKTSC can be a straight perforator. It supports perforation, The folding rollers feature a unique combination of steel and reliable sheet feeding regardless of the print condition. buffing.

slit perforation, scoring, slit, and center cut-slit. specially-formulated polyurethane rubber for superior grip and The pile height sensor can also be positioned as needed for The vacuum pick-up point

The perforation shaft is quick and easy to install or detach. 3 sets of cutter sharp, consistent folding on a wide variety of stocks. different sheet sizes. and the front and side air

blade holders are the standard equipment. The operator’s screen indicates the required fold roller gap adjustment. For sheet loading, the feed table automatically descends to an nozzles which blow air

Three perforating and two scoring operations are possible. A maximum of The operator then simply inserts the indicated number of sheets. ergonomically safe and easy loading height. laterally for smooth feeding

20 blades can be attached to the shaft. The fold roller system employs helical gears for quiet operation The AFC-744AKTSC can feed a maximum sheet size of 740 x of all sheet types can be

Center-cut is available for multiple-up jobs with the use of slitter blades. and cross couplings for quality folding. 1,100 mm (29.1" x 43.3"). adjusted.

Option A Wide Range of Optional Accessories Computerized Cross Folder AFC-744AKTSC

Round Pile Feeder Unit : RFU-74 Gluing Unit : CGU-50

Mobile Knife Fold Unit : MKU-54/54T The round pile feeder unit can feed 4- Folding, gluing, and edge trimming

page or 8-page signature, operations are performed efficiently.

The MKU-54 features the knife unit reverse function for upward or downward sheet delivery. curled/waved sheets, and milled-edge The gluing unit CGU-50 can produce

sheets from web printer. 8-page or 12-page glued booklets.

Two buckles below knife can be attached on the MKU-54T. (one buckle is standard.) The amount of glue can be adjusted

The speed of MKU-54/54T is fully synchronized with Horizon folder. Palette Feeder Unit : PFU-74 depending on the dot size of glue.

The computer controlled gluing unit

The MKU-CU Mobile Knife Fold Unit Conveyor is necessary The palette feeder unit accepts the

ensures neatly finished booklets.

piled sheet from the printing press to

when MKU-54/54T is connected with AFC-744AKTSC. maximize operator convenience and Gluing Unit Controller

The glue is suitable for recycling.

MKU-54/54T Major Specifications to minimize folder down time. Gluing

Max. 540(W) x 330(L) mm (21.2" x 12.9")

Sheet Size

Min. 160(W) x 100(L) mm (6.3" x 4.0") Gate Fold Buckle : GFB-74 Strip Trim Device : AF-ST6 Blades

Max. Folding Thickness Max. 2 mm (0.078") (Booklet of 40 pages [81 gsm])

Sheet Weight Range 35 to 220 gsm

Belt Speed 50 to 230 m/min. (164 to 754 ft./min.)

Voltage / Frequency 3-Phase 200 / 208 / 220 / 230 V, 50 / 60 Hz

3-Phase 200 V

1.3 / 1.5 A

3-Phase 208 V

Rated Current 50 / 60 Hz

3-Phase 220 V

1.3 / 1.4 A Scoring Blade Burst Blade 6 x 4 Slitter Blade

3-Phase 230 V

3-Phase 200 V 300 / 315 W

3-Phase 208 V 310 / 320 W

Power Consumption 50 / 60 Hz

3-Phase 220 V 320 / 325 W

3-Phase 230 V 325 / 330 W

Heat Output 950 kJ (230 kcal)

Available Folding Machine and Stitcher AFC-744AKTSC / AFC-742KSC / AFC-546AKTSC / AFC-544AKTSC / SPF-30 / SPF-20A / SPF-20 Perforation Blade Perforation Blade Perforation Blade

3.2 x 0.8 2.5 x 0.8 1.4 x 0.8

In-feed Height Highest Position : 970 mm (38.1") Lowest Position : 530 mm (20.9")

Delivery Height Highest Position : 855 mm (33.6") Lowest Position : 415 mm (16.4") The optional gate fold buckle provides Strip trimming is available for A wide variety of optional blades are

Machine Dimensions 1,100(W) x 800(D) x 1,350(H) mm (43.4" x 31.5" x 53.2") for precise, accurate gate folding. multiple-up jobs with slitter. available for various applications.

Machine Weight 200 kg (441 lb)

Press Stacker : PST-40 Press Stacking & Semi-auto Bundling Unit : TST-37

Maximum 440 mm (17.3") wide signature can be pressed. The first rollers remove the air and the second rollers powerfully compress the signatures for reduced

The first rollers remove the air and the second rollers powerfully compress the signatures for reduced bulk and tighter folds.

bulk and tighter folds. The TST-37 can be started or stopped from the AFC-744AKTSC/742KSC/546AKTSC/544AKTSC control console.

The PST-40 can be started or stopped from the AFC-744AKTSC/742KSC/546AKTSC/544AKTSC control console. The round belt change system at the in-feed section minimizes set-up time for change of sheet size.

The round belt change system at the in-feed section minimizes set-up time for change of sheet size. Pressed stacks are automatically transferred to the bundling section for optimum efficiency and labor savings.

The PST-40 can be operated independently of the folder for the pressing of saddle stitched booklets.

The height of the press unit is simply adjusted by the remote controller.

Operation Panel Rollers

The lamp illuminates in the event of The first rollers remove the air and the

Rollers In-feed Section misfeeding or mispressing. second rollers powerfully compress the

The first rollers remove the air and the Multiple sheets are firmly held with The TST-37 can start or stop the signatures for reduced bulk and tighter

second rollers powerfully compress the the round belts and transported to the operation of the AFC-744AKTSC/ folds.

signatures for reduced bulk and tighter press section continuously. 742KSC/546AKTSC/544AKTSC. Even a 32-page cross-fold can be

folds. The feed angle can be adjusted to the compressed powerfully.

The roller gap can be adjusted by sheet delivery from the folder. The roller gap can be easily adjusted by

inserting the sheets to be pressed.

Bundling Unit

inserting the sheets to be pressed.

A 16-page cross-fold can be compressed The bundling unit is manually

powerfully. operated so that the stack size and

bundling timing can be set

according to the folding speed.

For operator convenience, the

In-feed Section

Operation Panel folded sheets are always positioned The feed angle can be adjusted to the

Signatures can be offset separated at the center of the bundling section, sheet delivery from the folder.

individually or by group, depending and the plastic tape is prepared

on your job requirement. automatically.

PST-40 Major Specifications TST-37 Major Specifications

Model Press Stacker Adjustment Bolt Model Press Stacking & Semi-auto Bundling Unit Stack Capacity Set-up Setting by press guide position.

Main Body Fixing Method

Press Width Max. 440 mm (17.3") [Without offset : 470 mm (18.5")] Caster with Stopper Max. 370(W) x 260(L) mm (14.5" x 10.2") Preset Preset number of sheets setting on the folder are transferred to the bundling section when operating with the folder.

Signature Size

Press Length Min. 64 mm (2.5") Total Counter Sheet Count / Offset Count Min. 210(W) x 140(L) mm (8.3" x 5.6") Operation After arriving at set-up stack capacity, sheet feeding of the folder is stopped to transfer.

Operation Panel Transfer to Bundling Section

Production Speed Depends on fold device. Preset Counter Setting of the Number of Offset Sheets (0 to 9999) Production Speed 10,000 sheets/hr. Transfer Position Folded sheets are automatically positioned at the center of the bundling section.

Roller Speed Max. 210 m/min. (826.8"/min.) Voltage / Frequency Single Phase 200 / 220 / 230 V, 50 / 60 Hz Roller Speed Max. 180 m/min. (708.7"/min.) Compression Before Bundling Compression Power About 200 [N] (About 20 [Kgf])

In-feed Section Belt Change System Power Consumption 300 W, 50 Hz / 310 W, 60 Hz In-feed Section Belt Change System Unit Semi-Automatic

Bundling

(0

Number of Offset Sheets 1 sheet per setting to 9999 sheets) or All When Folded 1,200(W) x 795(D) x 1,230(H) mm (47.3" x 31.3" x 48.5") Air Remove Roller Gap is adjustable by inserting the instructed number of sheets. Bundle PP Band 12(W) mm (0.47")

Offset Press

Offset Amount 30 mm (1.1") When connecting to the parallel folding exit section : Press Roller Pressure Welding (Gap is adjustable by inserting the instructed number of sheets.) Total Counter / Error Lamp (No wrapping paper, Conveyor motor lock,

Operation Panel

Air Remove Roller Gap is adjustable by inserting the instructed number of sheets. 1,230(W) x 795(D) x 1,230(H) mm (48.5" x 31.3" x 48.5") Operation Intermittent operation only at in-feed time. Mis-transfer to bundling section, Mis-compression before bundling)

Press Conveyor

Press Roller Pressure Welding (Gap is adjustable by inserting the instructed number of sheets.) Machine Dimensions [When pulling out the receiving tray : 1,540(W) mm (60.7")] Belt Speed 0 to 12 m/min. (0" to 47.2"/min.) Voltage / Frequency 3-Phase 200 / 220 V, 50 / 60 Hz Single Phase 220 / 230 / 240 V, 50 / 60 Hz (for Europe)

When Operating

Model Horizontal Delivery Conveyor When connecting to the cross folding exit section : In-feed Height 440 to 680 mm (17.4" to 26.7") Power Consumption 1.2 kW, 50 Hz / 1.1 kW, 60 Hz 3.0 kW, 50 / 60 Hz (for Europe)

Conveyor

Belt Speed 0 to 12 m/min. (0" to 47.2"/min.) 1,490(W) x 795(D) x 1,230(H) mm (58.7" x 31.3" x 48.5") Wrapping Paper Thickness 1 to 2.5 mm (0.04" to 0.09") 1,550(W) x 1,100(D) x 1,130(H) mm (61.1" x 43.4" x 44.5")

Machine Dimensions

In-feed Height 400 to 950 mm (15.8" to 37.4") [Tilt Vertical Interval 240 mm (9.4")] [When pulling out the receiving tray : 1,800(W) mm (70.9")] Wrapping Paper Pile Height 45 mm (1.7") [Separate Reel : 665 x 460 x 525 mm (26.2" x 18.2" x 20.7")]

Main Body Lift Moves up and down by a motor. Machine Weight 280 kg (617.4 lb) Stack Capacity 600 sheets (64 gsm, 16-page cross fold) (With attachment : 150 sheets) Machine Weight 370 kg (815.9 lb) [Separate Reel : 30 kg (66.2 lb)]

Computerized Cross Folder AFC-744AKTSC

AFC-744AKTSC Major Specifications Machine Dimensions Unit : mm (inch)

Machine Structure 4KTTL (4 Buckles+Fold Knife+2 Buckles Below Knife+2nd Fold Knife)

With Flat Pile Feeder/Palette Feeder 740(W) x 1,100(L) mm (29.1" x 43.3") Parallel Fold Height = 1,617 (63.7")

Max. Sheet Size

With Round Pile Feeder 740(W) x 1,300(L) mm (29.1" x 51.1")

With Flat Pile Feeder 210(W) x 210(L) mm (8.3" x 8.3")

With Round Pile Feeder 210(W) x 297(L) mm (8.3" x 11.7")

Min. Sheet Size

With Palette Feeder 210(W) x 148(L) mm (8.3" x 5.9")

[Side Lay Guide Minimum Set Position : 82(W) mm (3.3")]

Sheet Weight Range 35 to 220 gsm 580 1,640

(22.9") Conveyor AFC-744AKTSC (64.6")

1st Buckle 55 to 560 mm (2.2" to 22") (Auto)

2nd Buckle 30 to 480 mm (1.2" to 18.8") (Auto)

3rd Buckle 30 to 480 mm (1.2" to 18.8") (Auto)

Buckle Fold Length 1,280 3,880

4th Buckle 30 to 330 mm (1.2" to 12.9") (Auto) (50.4") (152.8")

K1 Buckle Deflector (Replaceable with K2 buckle)

K2 Buckle 55 to 120 mm (2.2" to 4.7") (Manual Set-up) 8-page Cross Fold Height = 1,617 (63.7")

Max. 740(W) x 550(L) mm (29.1" x 21.6") 3,880

1st Knife (152.8")

Min. 160(W) x 100(L) mm (6.3" x 4")

Knife Fold Size

Max. 550(W) x 360(L) mm (21.6" x 14.1")

2nd Knife 1,234

Min. 160(W) x 100(L) mm (6.3" x 4") (48.6")

1,640 AFC-744AKTSC

With Flat Pile Feeder/Palette Feeder Air Suction Rotor & 1 Cylinder Separator Head (64.6")

Feeding Mechanism With Round Pile Feeder Air Suction Rotor & Front Blower & Side Blower 1 Cylinder Separator Head

(Feed interval and suction time are adjustable.)

Conveyor

With Flat Pile Feeder 750 mm (29.5") [within 600 kg (1,323 lb)] 1,280 3,030

Maximum Pile Height (50.4") (119.3")

With Palette Feeder 1,200 mm (47.2") (palette included) [within 1,000 kg (2,205 lb)]

Belt Speed 50 to 230 m (54 to 250 yd.)/min. [Knife Fold : 180 m (196 yd.)/min.]

36,000 sheets/hr. [A4 (8.5" x 11") Parallel Fold] 580

Production Speed (22.9")

11,000 sheets/hr. [625(W) x 880(L) mm (24.6" x 34.6") 16-page Cross Fold]

Standard Fold Roller Combination of Urethane Foam (soft PU) Rubber and Steel Roller 16-page Cross Fold Height = 1,617 (63.7")

Roller Gap Adjustment Insert the instructed number of sheets into the gap adjust lever.

3,880

Cut : 10 mm (0.39") Blank : 4 mm (0.16") (152.8")

Parallel Fold

Bursting Cut : 4 mm (0.16") Blank : 2.5 mm (0.10")

Below Knife Cut : 9 mm (0.35") Blank : 3 mm (0.12") 1,234

AFC-744AKTSC (48.6")

Cut : 2.5 mm (0.10") Blank : 0.8 mm (0.03")

Perforation

Min. Line Distance : 66 mm (2.6") / Min. Line from Sheet Edge : 12 mm (0.48")

580

Scoring Scoring Width : 1 mm (0.04") (Depends on sheet type) (22.9") Conveyor

Cutters 3 pcs + 1 pc (Accessory) (Possible to add up to 14 pcs) 3,030

Automatic Setup Feed Guide Bar, Side Lay Guide, 1st to 4th Buckles, 1st and 2nd Knife Stoppers 1,280 (119.3")

(50.4")

Automatic Setup Accuracy Setting Dimension : +/-1 mm (0.04") / Round Accuracy : +/-0.1 mm (0.004")

1st Buckle Buckle Stopper and Swing-Arm Deflector

Deflectors

2nd to 4th Buckle Integrated Stopper / Deflector 32-page Cross Fold Height = 1,617 (63.7")

K1 Buckle (Below Knife) Deflector

K2 Buckle (Below Knife) Buckle Stopper and Swing-Arm Deflector

Parallel Fold, Short Fold, Open Gate Fold, Accordion Fold,

Zigzag (4 panel) Fold, Zigzag (5 panel) Fold, Letter Fold, Double Parallel Fold, 8-

Fold Patterns

page Cross Fold, 12-page Cross Fold, DL Fold, 16-page Transformation Fold,

16-page Cross Fold, 32-page Transformation Fold

Job Memory 100 Jobs

Flow 50 m3/hr. / 60 m3/hr. (With Round Pile Feeder)

Vacuum Pump Voltage / Frequency 3-Phase 230 / Y400 V +/- 10 % 50 / 60 Hz 5,940 (233.9")

Power Consumption 3.0 kW / 3.6 kW (50 / 60 Hz) 4,560 (179.6")

Voltage / Frequency 3-Phase 220 V, 60 Hz 400 V, 50 Hz

960

3-Phase 220 V 60 Hz 12.3 A (With Flat Pile Feeder) (37.8") AFC-744AKTSC+RFU-74 1,640

7.6 A (With Flat Pile Feeder) (64.6")

Rated Current

3-Phase 400 V 50 Hz 7.4 A (With Round Pile Feeder) 3,140 MKU-54

7.2 A (With Palette Feeder) (123.7") Height = 1,350 (53.2")

MKU-CU

3-Phase 220 V 60 Hz 4.1 kW (With Flat Pile Feeder)

Power Consumption TST-37 800

(Including Pump) 3.5 kW (With Flat Pile Feeder/Palette Feeder) MKU-54

3-Phase 400 V 50 Hz (31.5")

4.3 kW (With Round Pile Feeder)

Heat Output 5,800 kJ (1,390 kcal)

1,100

With Flat Pile Feeder 3,880(W) x 1,640(D) x 1,617(H) mm (152.8" x 64.6" x 63.7") 220 (43.4")

(8.7")

With Round Pile Feeder 4,560(W) x 1,640(D) x 1,617(H) mm (179.6" x 64.6" x 63.7")

Machine Dimensions Height = 1,230 (48.5") Height = 1,130 (44.5")

With Palette Feeder 3,960(W) x 1,640(D) x 1,617(H) mm (156.0" x 64.6" x 63.7")

Conveyor : 1,280(W) x 580(D) x 1,070(H) mm (50.4" x 22.9" x 42.2") 795

PST-40 1,100

Noise Level 86 dB [1,000(L) x 700(W) mm (39.4" x 27.6") -16-page cross fold- 64 gsm of sheet at maximum speed] (31.3") TST-37 (43.4")

1,718 kg (3,788 lb) / Conveyor : 81 kg (179 lb) /

With Flat Pile Feeder

Vacuum Pump : 66 kg (146 lb) / Transformer : 45 kg (99 lb) 1,230 (48.5") 1,550

Machine Weight

With Round Pile Feeder 1,950 kg (4,300 lb) 1,200 (47.3") (When folded) (61.1")

With Palette Feeder 1,800 kg (3,969 lb)

Manufactured by : Taiyo Seiki Co., Ltd.

Certified in Dec. 1997 Certified in Jan. 1999

The machine design and specifications are subject to change without any notice.

Distributed by

Trademark of American Soybean Association

Printed on 100% Recycled Paper

Standard Finishing Systems, 10 Connector Road, Andover, MA 01810 (877) 404-4460 www.standardfinishing.com

510 Kuze Ooyabu-cho, Minami-ku, Kyoto, 601-8206, Japan Phone : +81-(0)75-934-6700, Fax : +81-(0)75-934-6708, www.horizon.co.jp

040803/SN/744AKT/02E/SV

You might also like

- Cityline ExpressDocument4 pagesCityline Expresssunil kambleNo ratings yet

- Titan 265 - 230 - 200 - Challenge MachineryDocument4 pagesTitan 265 - 230 - 200 - Challenge MachineryTravis MendozaNo ratings yet

- 2012 Own and BT in Parts GBPDocument51 pages2012 Own and BT in Parts GBPabed sabbaghNo ratings yet

- User ElantrixDocument11 pagesUser Elantrixwdanel2428No ratings yet

- Catalogo Botoes EatonDocument348 pagesCatalogo Botoes EatonxixiaucamruNo ratings yet

- Duplo DB-200 Instruction Manual Perfect Binding DB-200Document18 pagesDuplo DB-200 Instruction Manual Perfect Binding DB-200Javier Rivera100% (1)

- Screen FTR 3035 3050Document5 pagesScreen FTR 3035 3050Artur Gustavo100% (1)

- Keyence FS-V22 使用說明Document4 pagesKeyence FS-V22 使用說明Lúcio M Miranda LimaNo ratings yet

- Samsung Xpress SL-M2885FW - SL-M2870FD - ETS - Parts.Document28 pagesSamsung Xpress SL-M2885FW - SL-M2870FD - ETS - Parts.Júlio Cesar Guimarães de SouzaNo ratings yet

- Elantrix DX User's ManualDocument30 pagesElantrix DX User's ManualCesar AugustoNo ratings yet

- ACS200 User ManualDocument58 pagesACS200 User ManualJulian Toro GarzonNo ratings yet

- Stahl HMI Operating InstructionsDocument60 pagesStahl HMI Operating InstructionsJaysonNo ratings yet

- 52di Esm-2Document109 pages52di Esm-2Vance IbzNo ratings yet

- KBA Rapida 164: The Peak Performance Class in Large FormatDocument32 pagesKBA Rapida 164: The Peak Performance Class in Large FormatszopuchNo ratings yet

- Catalog Piese INTROMA-ZD-2SR StandardDocument17 pagesCatalog Piese INTROMA-ZD-2SR StandardAnonymous 2MRGC0w1100% (1)

- Polar 191030 em Emc Mon Technical TrainingDocument62 pagesPolar 191030 em Emc Mon Technical TrainingYves KingNo ratings yet

- ELAU SB Servo Motor Kullanma KilavuzuDocument124 pagesELAU SB Servo Motor Kullanma KilavuzuVAN AN NGUYENNo ratings yet

- Manuals and SchemesDocument8 pagesManuals and SchemesRishi jain0% (1)

- DUPLO DF-777 Service ManualDocument136 pagesDUPLO DF-777 Service Manualyuiop890No ratings yet

- BST 10 (D / CD ) Service Manual 4 - Parts List: ImportantDocument21 pagesBST 10 (D / CD ) Service Manual 4 - Parts List: Importantbelpapel100% (2)

- KBA Rapida 75pro Broschuere enDocument24 pagesKBA Rapida 75pro Broschuere enMedyouNo ratings yet

- Samsung Mx-hs8000 PartsDocument16 pagesSamsung Mx-hs8000 PartsBálint MészárosNo ratings yet

- Preliminary: Fagor Automation, S.CoopDocument32 pagesPreliminary: Fagor Automation, S.CoopRogério PereiraNo ratings yet

- 52di Esm-1Document116 pages52di Esm-1Vance IbzNo ratings yet

- CR85-X - Manual - 2007-12-07 3.0Document527 pagesCR85-X - Manual - 2007-12-07 3.0Elias JardimNo ratings yet

- As 48117 KV-H20S H40S Um - GB WW 0025-1Document202 pagesAs 48117 KV-H20S H40S Um - GB WW 0025-1Tuấn NguyễnNo ratings yet

- Spellman PDFDocument254 pagesSpellman PDFLê HoàngNo ratings yet

- SVC Manual SL-M337x 387x 407xDocument176 pagesSVC Manual SL-M337x 387x 407xDJ LEDMANNo ratings yet

- DCD300 ServoamplifierDocument31 pagesDCD300 ServoamplifierPaun Al100% (1)

- Laboo Operation ManualDocument83 pagesLaboo Operation ManualMrDaytimeNo ratings yet

- Flowpet 5GDocument56 pagesFlowpet 5GOoi Ban JuanNo ratings yet

- Cato Edition: Anaesthetic WorkstationDocument148 pagesCato Edition: Anaesthetic WorkstationEcole Acharaf100% (1)

- MassicotDocument7 pagesMassicotJuan Sanchez GutierraNo ratings yet

- Pdvol (PR13) - 3kva-225v-Premium 19 12 14Document1 pagePdvol (PR13) - 3kva-225v-Premium 19 12 14Elenilson Fernandes100% (1)

- Sucofeed RF Cables H&SDocument12 pagesSucofeed RF Cables H&SRahul GoudNo ratings yet

- Heidelberg SM 74 - 5 H: Curriculum Vitae of The Machine Reference Number: 20059Document2 pagesHeidelberg SM 74 - 5 H: Curriculum Vitae of The Machine Reference Number: 20059Magros TamNo ratings yet

- POLAR - Cutting in PracticeDocument24 pagesPOLAR - Cutting in PracticePetrtmNo ratings yet

- Telemecanique Altivar28 Manual PDFDocument74 pagesTelemecanique Altivar28 Manual PDFqlx4No ratings yet

- Data SheetDocument16 pagesData SheetΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNo ratings yet

- EMC2 User ManualDocument175 pagesEMC2 User ManualJuhasz GaborNo ratings yet

- инструкцияDocument60 pagesинструкцияVladimir100% (1)

- Smart: Intelligent Relay Hardware ManualDocument190 pagesSmart: Intelligent Relay Hardware ManualDragan LugonićNo ratings yet

- Enthrone 29Document6 pagesEnthrone 29Adam Muhamad AliNo ratings yet

- Design & Implementation of Motion Controller For Industrial Paper Cutting MachineDocument7 pagesDesign & Implementation of Motion Controller For Industrial Paper Cutting MachineEditor IJRITCCNo ratings yet

- Duplo DC-645 Instruction ManualDocument106 pagesDuplo DC-645 Instruction ManualpfequipNo ratings yet

- Viper22a Equivalent PDFDocument16 pagesViper22a Equivalent PDFXande Nane Silveira0% (1)

- Markem Imaje SmartLase Range DS HQ A1Document4 pagesMarkem Imaje SmartLase Range DS HQ A1shahrear sultan100% (1)

- Siemens Micromaster Eco ManualDocument181 pagesSiemens Micromaster Eco ManualMohammad Imtiaz ChowdhuryNo ratings yet

- AC6000 8000S 8300 UsersManual EDocument60 pagesAC6000 8000S 8300 UsersManual EInversiones JapesaNo ratings yet

- Acopos PDFDocument19 pagesAcopos PDFHoàng Mỹ NguyễnNo ratings yet

- Cross Reference Atmel Vs XilinxDocument14 pagesCross Reference Atmel Vs XilinxjassadNo ratings yet

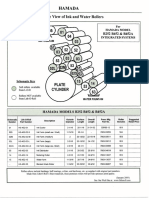

- Hamada:, Rtnhjt-O-A R.R. View WaterDocument10 pagesHamada:, Rtnhjt-O-A R.R. View WaterXaqani AxmedovNo ratings yet

- Manuales Catalogos Siemens NCZ 01.03 IngDocument117 pagesManuales Catalogos Siemens NCZ 01.03 Ingtmsxpto100% (3)

- PLC Xinje ModelosDocument25 pagesPLC Xinje ModelosLeonardoNo ratings yet

- EPM - 07 - 07S - Manual - ENTESDocument4 pagesEPM - 07 - 07S - Manual - ENTESAhmed Mohamed Kamal El-DeenNo ratings yet

- BRKARC 3147 IOS XE TroubleshootingDocument211 pagesBRKARC 3147 IOS XE TroubleshootingAdriana MitsovaNo ratings yet

- BRKDCN 1645Document62 pagesBRKDCN 1645Chafik KaNo ratings yet

- Cat LandscapeDocument2 pagesCat LandscapeDOMINICNo ratings yet

- Introduction To Infiniband: Executive SummaryDocument20 pagesIntroduction To Infiniband: Executive SummarySunjay JoseNo ratings yet

- MGI dp60PRODocument4 pagesMGI dp60PROKBR Graphics CanadaNo ratings yet

- MGI-KBR AdJan10Document1 pageMGI-KBR AdJan10KBR Graphics CanadaNo ratings yet

- Specifications: Titan 265/230/200Document4 pagesSpecifications: Titan 265/230/200KBR Graphics CanadaNo ratings yet

- Horizon Stitch Liner 5500Document8 pagesHorizon Stitch Liner 5500KBR Graphics Canada100% (1)

- KBA Genius52uv enDocument8 pagesKBA Genius52uv enKBR Graphics CanadaNo ratings yet

- KBARapida Large Format 130-142-162 EnglDocument8 pagesKBARapida Large Format 130-142-162 EnglKBR Graphics CanadaNo ratings yet

- KBA-Rapida106SPC T Part EnglDocument8 pagesKBA-Rapida106SPC T Part EnglKBR Graphics CanadaNo ratings yet

- Horizon PF 40Document3 pagesHorizon PF 40KBR Graphics CanadaNo ratings yet

- KBA-Rapida 75 I Part EnglDocument8 pagesKBA-Rapida 75 I Part EnglKBR Graphics CanadaNo ratings yet

- Horizon SB 07Document3 pagesHorizon SB 07KBR Graphics CanadaNo ratings yet

- Horizon HOF20 eDocument2 pagesHorizon HOF20 eKBR Graphics CanadaNo ratings yet

- Horizon SPF20 FC 20Document5 pagesHorizon SPF20 FC 20KBR Graphics CanadaNo ratings yet

- Horizon SPF 200ADocument2 pagesHorizon SPF 200AKBR Graphics CanadaNo ratings yet

- Horizon HT30Document3 pagesHorizon HT30KBR Graphics CanadaNo ratings yet

- Horizon AF 566T4FDocument7 pagesHorizon AF 566T4FKBR Graphics CanadaNo ratings yet

- HorizonBQ 270CBinderDocument2 pagesHorizonBQ 270CBinderKBR Graphics CanadaNo ratings yet

- Horizon AFC 564A 566ADocument6 pagesHorizon AFC 564A 566AKBR Graphics CanadaNo ratings yet

- Horizon HCM1 Case Binding BRDocument2 pagesHorizon HCM1 Case Binding BRKBR Graphics CanadaNo ratings yet

- GraphicWhizard Baum BrochureDocument2 pagesGraphicWhizard Baum BrochureKBR Graphics CanadaNo ratings yet

- Horizon HCB 2 Case BindingDocument2 pagesHorizon HCB 2 Case BindingKBR Graphics CanadaNo ratings yet

- Challenge Drill MS 10ADocument4 pagesChallenge Drill MS 10AKBR Graphics CanadaNo ratings yet

- Challenge Spartan185AEPDocument1 pageChallenge Spartan185AEPKBR Graphics CanadaNo ratings yet

- Challenge-Drills - JO and JFDocument2 pagesChallenge-Drills - JO and JFKBR Graphics CanadaNo ratings yet

- Challenge Padding Press Handy PadderDocument2 pagesChallenge Padding Press Handy PadderKBR Graphics CanadaNo ratings yet

- Horizon AF 406Document7 pagesHorizon AF 406KBR Graphics Canada0% (1)

- Challenge Drill Handy DrillDocument2 pagesChallenge Drill Handy DrillKBR Graphics CanadaNo ratings yet

- Challenge Folder Medalist 870Document2 pagesChallenge Folder Medalist 870KBR Graphics CanadaNo ratings yet

- Configuring Hyper-V: This Lab Contains The Following Exercises and ActivitiesDocument9 pagesConfiguring Hyper-V: This Lab Contains The Following Exercises and ActivitiesMD4733566No ratings yet

- Admission: North South University (NSU) Question Bank Summer 2019Document10 pagesAdmission: North South University (NSU) Question Bank Summer 2019Mahmoud Hasan100% (7)

- World Trends in Municipal Solid Waste ManagementDocument11 pagesWorld Trends in Municipal Solid Waste ManagementNeima EndrisNo ratings yet

- 20235UGSEM2206Document2 pages20235UGSEM2206Lovepreet KaurNo ratings yet

- Bilateral Transfer of LearningDocument18 pagesBilateral Transfer of Learningts2200419No ratings yet

- LQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQDocument5 pagesLQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQSAJAL KOIRALANo ratings yet

- ISO-50001-JK-WhiteDocument24 pagesISO-50001-JK-WhiteAgustinusDwiSusantoNo ratings yet

- 61annual Report 2010-11 EngDocument237 pages61annual Report 2010-11 Engsoap_bendNo ratings yet

- 2011 Burris CatalogDocument56 pages2011 Burris CatalogMario Lopez100% (1)

- NCRA Membership InformationDocument1 pageNCRA Membership Informationbkharkreader1301No ratings yet

- Evidence MODULE 1 Evidence DefinitionDocument8 pagesEvidence MODULE 1 Evidence Definitiondave BarretoNo ratings yet

- CUIT 201 Assignment3 March2023Document2 pagesCUIT 201 Assignment3 March2023crybert zinyamaNo ratings yet

- 1st Unseen Passage For Class 5 in EnglishDocument7 pages1st Unseen Passage For Class 5 in EnglishVibhav SinghNo ratings yet

- 19 Uco 578Document20 pages19 Uco 578roshan jainNo ratings yet

- Ad For Guru Ned'S Enlightenment Masterclass 1 of 33Document33 pagesAd For Guru Ned'S Enlightenment Masterclass 1 of 33ElliuggNo ratings yet

- Medrano, Rene LynnDocument2 pagesMedrano, Rene LynnRene Lynn Labing-isa Malik-MedranoNo ratings yet

- Group 4 - When Technology and Humanity CrossDocument32 pagesGroup 4 - When Technology and Humanity CrossJaen NajarNo ratings yet

- HP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningDocument2 pagesHP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningParesh BabariaNo ratings yet

- T54125ADocument64 pagesT54125ARaúl FroddenNo ratings yet

- Brp-Rotax Chassis Approval FormDocument3 pagesBrp-Rotax Chassis Approval Formdelta compNo ratings yet

- Kunst 1600 Case AnalysisDocument3 pagesKunst 1600 Case AnalysisrakeshNo ratings yet

- Measures of Indicator 1Document2 pagesMeasures of Indicator 1ROMMEL BALAN CELSONo ratings yet

- Module 1 Supply Chain Management in Hospitality IndustryDocument39 pagesModule 1 Supply Chain Management in Hospitality IndustryHazelyn BiagNo ratings yet

- Paper Ed Mid TermDocument2 pagesPaper Ed Mid Termarun7sharma78No ratings yet

- Zgouras Catherine Team Together 1 Teachers BookDocument257 pagesZgouras Catherine Team Together 1 Teachers Booknata86% (7)

- PH-01 (KD 3.1) Filling Out Forms (PG20) - GFormDocument4 pagesPH-01 (KD 3.1) Filling Out Forms (PG20) - GFormLahita AzizahNo ratings yet

- THE BASIC TYPES OF SPEECHES PPTDocument14 pagesTHE BASIC TYPES OF SPEECHES PPTKevin BanezNo ratings yet

- Mathematics4 q4 Week4 v4Document11 pagesMathematics4 q4 Week4 v4Morales JinxNo ratings yet

- Solar-range-brochure-all-in-one-Gen 2Document8 pagesSolar-range-brochure-all-in-one-Gen 2sibasish patelNo ratings yet

- Void Engineers (Convention: Mage The Ascension)Document6 pagesVoid Engineers (Convention: Mage The Ascension)Beth0% (1)