Professional Documents

Culture Documents

Ultrasonic Chemical Reactors

Uploaded by

Shrishma PaikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonic Chemical Reactors

Uploaded by

Shrishma PaikCopyright:

Available Formats

Ultrasonic Chemical Reactors

Ultrasonic Chemical Reactors

Igor I. Savin, Sergey N. Tsyganok, Andrey N. Lebedev, Student member, IEEE, Dmitry V. Genne,

Student Member, IEEE, Elena S. Smerdina, Student Member, IEEE

Biysk Technological Institute (branch) of Altay State Technical University after I.I. Polzunov, Biysk,

Russia

Abstract The article is devoted to different types ultrasonic

chemical reactors for laboratory and industrial using.

Experimental results are given.

from each other with intensity of ultrasonic oscillations

introducing into a fluid and possibility or impossibility of the

flowing processing [4,6] (fig. 1).

Index Termsultrasonic, sonochemistry, ultrasonic reactor,

cavitations.

I.INTRODUCTION

The present-day industrial enterprises continuously

increase tempo of industrial production. Usually, for this

purpose it is necessary to modernize or completely to change

the process flowsheet. It is widely known, that using of high

intensity ultrasonic oscillations allows intensifying many

technological processes, such as impregnating of composite

materials, drilling of brittle and extra-hard materials,

dissolution, extraction, emulsification, washing and clearing.

[1,2]

A plenty of researches being carried out at present moment

specify that speed of passing the majority of chemical

reactions increases under action of an acoustic field and that

some reactions do not pass without action of ultrasonic

oscillations [3-5].

Cavitation is considered as a major factor which influences

on reaction speed. The temperature inside cavitation bubbles

while collapsing attains approximately 5000 K, pressure

attains approximately 100 MPa and velocity of a collapse

attains about 400 km/h. At such bubble collapsing the

powerful shockwave [3] is created.

Providing of similar requirements is possible at intensity of

ultrasonic action from 100 W/cm2. Since the acoustic

oscillations of audio frequency and high intensity providing is

rather difficult, using of ultrasonic frequency oscillations

(above 20 kHz) obtains wide extending.

For implementation of such technological processes there

is a special class of technological apparatus called ultrasonic

reactors; and for providing researches of reaction passing

under action of acoustic oscillations there is a science called

acoustic chemistry.

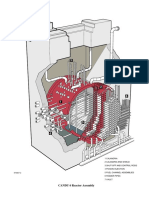

Figure 1 - Existing types of ultrasonic reactors [4]

The peak of ultrasonic action provides with the ultrasonic

reactor represented in figure 2.

Figure 2 - Embodiment and appearance of ultrasonic reactor UZOR

II.ULTRASONIC REACTORS FOR LABORATORY

Now there is a lot of ultrasonic reactors types, which differ

Such reactors are able to process about 300 ml of liquid

Ultrasonic Chemical Reactors

with intensity up to 200 W/cm2.

In cases when for experimental purpose it is enough to

process several tens of milliliters the ultrasonic apparatus for

processing liquid in test tubes is used. Distinguishing feature

of such apparatus is presence of two replaceable working

tools for a ultrasonic oscillatory system. One working tool is

intended for direct input of oscillations in the test tube, and

another one is for noncontact processing of liquids. The

working tool has shape of the hollow cylinder in which test

tube with reagents is placed, in space between walls of test

tube and the working tool there is a liquid through which

transmission of oscillations to test tube walls is carried out

(figure 3).

III.ULTRASONIC REACTORS FOR INDUSTRIAL APPLICATION

The major drawback of the foresaid reactors is the small

processing volume per unit of time. For laboratory it is not a

major drawback, but for the industrial applications the other

embodiment of the reactor is required. In this case, the

optimal solution is the flowing processing of liquid.

The laboratory of ultrasonic processes and apparatus

designs a lot of apparatus for the flowing processing of liquid

mediums with power from 400 VA up to 6000 VA (fig. 4).

Distinguishing feature of apparatus with power more than

2000 VA is use of the working tool with the extended

radiating surface. The working tool is the series joined

several step-radial concentrators; such form of the working

tool allows to extend the radiating surface in several times in

comparison with classical single- and two-half-wave

oscillatory systems. (fig. 5)

Figure 3 - The ultrasonic reactor for processing liquids in test tubes

Due to small volumes of the processing liquid it is possible

to achieve the intensity of ultrasonic action about 300 W/cm2.

a)

Figure 5 - The ultrasonic oscillatory system in technological volume

b)

c)

d)

e)

f)

a) ultrasonic apparatus MUSA (400 VA), b) ultrasonic apparatus Potok (630 VA), c) ultrasonic apparatus Crystal - 2 (1000 VA), d) ultrasonic apparatus

Potok-3 (1000 VA), e) ultrasonic apparatus Bulava, model 1000-3 (3000 VA), f) ultrasonic apparatus Bulava, model 1000-6 (6000 VA)

Figure 4 - Ultrasonic reactors of various powers

Ultrasonic Chemical Reactors

For providing super intensive action on liquid mediums, it

is promising to design the embodiment of ultrasonic reactor

for the flowing processing in form of truncated dodecahedron

with piezoceramic assemblies on its hexangular sides. Using

of such radiator embodiment will allow achieving the

intensity of 500 W/cm2 [7] (fig. 6).

procedures.

The sewage processing was provided with apparatus

Bulava, model 1000-3 (table 2), the represented results

show efficiency of ultrasonic oscillations using for water

purification.

TABLE 2

RESULTS OF SEWAGE PROCESSING WITH ULTRASONIC OSCILLATIONS OF HIGH INTENSITY

Water parameters

input

output

7,6

7,7

UEP

0,102

0,0577

Suspended matter

>2000

122,2

Solid residue

612,2

305,6

BPK5

1 - technological volume, 2 - ultrasonic transducer, 3 - the channel for delivery of

initial components and evacuation of reaction product, 4 - the piezoelectric

elements, 5 - reflective frequency- dropping patches.

Figure 6 - the Ultrasonic reactor of ultrahigh intensity

276

15,6

Permanganate oxidability

191,8

18,8

Ammonium

46,5

19,5

Phosphates

0,95

0,2

Sulfates

28,9

10,4

APAV

3,21

2,23

Nitrites, nitrates, clarity

below the rate

V.CONCLUSION

IV.EXPERIMENTAL RESEARCHES

The experimental researches on processing milk and

sewage with ultrasonic oscillations of high intensity have

been carried out using apparatuses designed.

By means of apparatus MUSA examination of influence

the ultrasonic oscillations on taste property, biological

parameters of milk and its storage stability was carried out.

Results of test have shown that the radiated milk is kept

longer than not processed one.

Thus the amount of bacteria in milk drops from initial

15000 unities to 5000 in the end of the first processing cycle

and to 1000 in the end of the third cycle (table 1).

The represented embodiments allow satisfying the

requirements both the industrial enterprises and the research

organizations. The presented experimental results confirm a

possibility and promising of using the ultrasonic technologies

both in industrial plants and laboratory researches.

REFERENCES

[1]

[2]

[3]

TABLE 1

RESULTS OF ULTRASONIC MILK PROCESSING

Experiment

Milk

Milk first cycle 2 minutes

Milk first cycle 5 minutes

Milk first cycle 10 minutes

Milk second cycle 2,5 minutes

Milk second cycle 7,5 minutes

Milk third cycle 2,5 minutes

Milk third cycle 7,5 minutes

Milk third cycle 10 minutes

amount of

bacteria

15000

10500

7000

5000

1000

6500

2000

1500

1000

Also it is determined that decrease in processing velocity

from 1 l/min to 0,5 l/min allows to essentially reduce quantity

of milk operation cycles to 1-2 with amount of bacteria in

milk 1000-2000 unities without losses of taste properties.

Changing in the amount of bacteria in milk on the second

cycle of processing are related with variation of productivity

from 1 l/min to 0,5 l/min.

The inoculation of milk was made with Kessler and

Kmafanm mediums, produced by Obninsk-city on GOST

[4]

[5]

[6]

[7]

Khmelev V.N., Popova .V. Multiurpose ultrasonic apparatuses and their

application in conditions of small manufactures, agricultural and

housekeeping: the scientific monography / AltGTU. - Barnaul: AltGTU

Khmelev V.N., Barsukov R.V., Tsyganok S.N. "Drylling of brittle and

hard materials". Barnaul: AltGTU, 1999

Kenneth S. Suslick. "Sonochemistry" Kirk-Othmer Encyclodpedia of

Chemical Technology, Fourth Edition, vol. 26; John Willey&Sons, Inc.:

New York, 1998, pp.516-541

Design of Ultrasound Reactors: Choice of Working Conditions and Sound

Fields for Precipitation, Particle Fragmentation and Organometal

Reactions, Christian Horst, Yuh Shuh Chen, Jost Kruger, Ulrich

Kunz,Andreas Rosenplnter and Ulrich Hoffmann, Plenary Lecture.

M.G.Sulman Influence of ultrasound on catalysis processes, "Uspehi

Himii", 69(2), 2000, pp.178-191.

C.Horst, A.Lindermeir, U.Hoffman. Design of ultrasound reactors for

techical scale organometallic and electrochemical synthesis, TU HamburgHarburg Reports on Sanitary Engineering 35, 2002.

Ultrasonic Chemical Reactor, claim of Russian patent 2007101744/15

by 29.11.2006

Igor I. Savin, Ph.D (ultrasound)

principal engineer of MSIA

department of Biysk technological

institute. Laureate of Russian

Government

premium

for

achievements in science and

engineering. Area of scientific

interests is application of ultrasound

for

an

intensification

of

technological

processes.

IEEE

student member since 2001, IEEE

member since 2006.

Ultrasonic Chemical Reactors

Sergey N. Tsyganok was born in

Biysk, Russia, 1975. Now he is

Ph.D (Machinery), he received

degree on information measuring

engineering and technologies from

Altay State Technical University,

key specialist of electronics.

Laureate of Russian Government

premium for achievements in science

and engineering. His main research

interest are development of high

-effective multifunctional oscillators

for ultrasonic technological devices.

Andrey N. Lebedev (S'03) was

born in Kiselevsk, Russia in 1983.

He received degree on information

measuring

engineering

and

technologies

from

Biysk

Technological Institute of AltSTU.

He is post-graduate student of Biysk

Technological

Institute..

His

research interests is finite-element

modeling.

Genne V. Dmitry (S06) was born

in Biysk, Russia in 1982. He

received degree on information

measuring

engineering

and

technologies

from

Biysk

Technological Institute of AltSTU.

He is post-graduate student of Biysk

Technological Institute. His main

research interest are development of

high -power electronic generators for

ultrasonic technological devices.

Elena S. Smerdina (S06) was born in

Pobrade, Lithuania, 1983. She received

degree on Information science and

measuring engineering in Altay State

Technical University. Member of "Woman

in Engineering" IEEE work group since

2006.

You might also like

- Ultrasound in Synthetic Organic Chemistry: Timothy J. MasonDocument9 pagesUltrasound in Synthetic Organic Chemistry: Timothy J. MasonBandita DattaNo ratings yet

- Experimental Investigations On Ultrasound Mediated Particle BreakageDocument10 pagesExperimental Investigations On Ultrasound Mediated Particle BreakagekickNo ratings yet

- Sonication From Wikipedia, The Free Encyclopedia: UltrasonicDocument4 pagesSonication From Wikipedia, The Free Encyclopedia: UltrasonicJimmyNo ratings yet

- Acoustic Cavitation Theory and Equipment Design Principles For Industrial Applications of High Intensity Ultrasound by Alexey S. Peshkovsky and Sergei L. PeshkovskyDocument70 pagesAcoustic Cavitation Theory and Equipment Design Principles For Industrial Applications of High Intensity Ultrasound by Alexey S. Peshkovsky and Sergei L. PeshkovskyJuan Carlos CocaNo ratings yet

- BioreaktorDocument6 pagesBioreaktorMateusz 'Dareth' HoppeNo ratings yet

- 1 s2.0 S036031992100642X MainDocument22 pages1 s2.0 S036031992100642X MainmierdaNo ratings yet

- Ultrasound in Food Processing: Recent AdvancesFrom EverandUltrasound in Food Processing: Recent AdvancesMar VillamielNo ratings yet

- Sonochemistry (1617286524)Document290 pagesSonochemistry (1617286524)Hektor EktroposNo ratings yet

- Design Ultrasonic CleanerDocument33 pagesDesign Ultrasonic CleanercaxxvadgvadgfsNo ratings yet

- In Vitro Cryptosporidium Parvum: Pilot-Scale Evaluation of UV Reactors'e Cacy Against Infectivity of OocystsDocument7 pagesIn Vitro Cryptosporidium Parvum: Pilot-Scale Evaluation of UV Reactors'e Cacy Against Infectivity of OocystsSld AndyNo ratings yet

- Innovation in Food Technology by Professor Mohammed FaridDocument4 pagesInnovation in Food Technology by Professor Mohammed Faridlusitania rahma putriNo ratings yet

- Cavitación AcusticaDocument70 pagesCavitación AcusticaSANTIAGO ARIAS SIERRANo ratings yet

- Aquacultural Engineering: Hadas Mamane, Angelo Colorni, Ido Bar, Ido Ori, Noam MozesDocument9 pagesAquacultural Engineering: Hadas Mamane, Angelo Colorni, Ido Bar, Ido Ori, Noam MozesHassan AL-HilallyNo ratings yet

- Pollet - Importancia de Parametros de Ultrasonido TintasDocument12 pagesPollet - Importancia de Parametros de Ultrasonido TintasFabricio CarrilloNo ratings yet

- Sonochemistry and the Acoustic BubbleFrom EverandSonochemistry and the Acoustic BubbleFranz GrieserNo ratings yet

- Acoustic StimulationDocument9 pagesAcoustic StimulationPavin PiromNo ratings yet

- Article 2Document12 pagesArticle 2Hoàng Minh ÁiNo ratings yet

- Seminar ReportDocument21 pagesSeminar ReportEr Gaurav Agrawal100% (3)

- Ultrasound Review 1Document12 pagesUltrasound Review 1aliosarusNo ratings yet

- Ultrasound ChemistrDocument13 pagesUltrasound ChemistrNiravNo ratings yet

- Study On Treatment of Slaughterhouse Wastewater by Electro-Coagulation TechniqueDocument4 pagesStudy On Treatment of Slaughterhouse Wastewater by Electro-Coagulation TechniqueazerfazNo ratings yet

- Integrity Testing Laboratory Inc.: Ultrasonic Peening of Parts and Welded ElementsDocument5 pagesIntegrity Testing Laboratory Inc.: Ultrasonic Peening of Parts and Welded ElementsDickson LeongNo ratings yet

- Ultrasonics Sonochemistry: Dimitrios Tsalagkas, Rastislav Lagan A, Ida Poljanšek, Primoz Oven, Levente CsokaDocument8 pagesUltrasonics Sonochemistry: Dimitrios Tsalagkas, Rastislav Lagan A, Ida Poljanšek, Primoz Oven, Levente CsokaJulia LizNo ratings yet

- 8 - 2014 - Oil-Water De-Emulsification Using Ultrasonic Technology - ArticleDocument20 pages8 - 2014 - Oil-Water De-Emulsification Using Ultrasonic Technology - ArticlekjhdfNo ratings yet

- Water 12 02431 v2Document11 pagesWater 12 02431 v2subanandam567No ratings yet

- Applications of UltrasonicsDocument19 pagesApplications of UltrasonicsSara HNo ratings yet

- Preservation and Shelf Life Extension: UV Applications for Fluid FoodsFrom EverandPreservation and Shelf Life Extension: UV Applications for Fluid FoodsNo ratings yet

- Accepted Manuscript: Ultrasonics SonochemistryDocument23 pagesAccepted Manuscript: Ultrasonics SonochemistrySyaeful MalikNo ratings yet

- Accepted Manuscript: Ultrasonics SonochemistryDocument23 pagesAccepted Manuscript: Ultrasonics SonochemistrySyaeful MalikNo ratings yet

- Mayer-2016-Fatigue & Fracture of Engineering Materials & StructuresDocument27 pagesMayer-2016-Fatigue & Fracture of Engineering Materials & StructuresmohamadNo ratings yet

- Research: Wisconsin Department of Natural ResourcesDocument20 pagesResearch: Wisconsin Department of Natural ResourcesFrancoGarbarinoRiffoNo ratings yet

- Final Seminar Report 1Document23 pagesFinal Seminar Report 1Anakha Nair0% (1)

- Ultrasonic Production of Nano-Size Dispersions and EmulsionsDocument7 pagesUltrasonic Production of Nano-Size Dispersions and EmulsionsCatalin DucuNo ratings yet

- Khaire2020-Improved Sonocrystallization of LactoseDocument11 pagesKhaire2020-Improved Sonocrystallization of Lactosesuki chandranNo ratings yet

- Ultrasonics Sonochemistry. 2004, 11, 5-8Document4 pagesUltrasonics Sonochemistry. 2004, 11, 5-8JESUS DAVID BOLA‹O JIMENEZNo ratings yet

- YttrrtDocument9 pagesYttrrtImad AghilaNo ratings yet

- Agua ElectrolizadaDocument10 pagesAgua ElectrolizadaJohnnyJavierJiménezLópezNo ratings yet

- Microcontroller Based High Voltage Pulse Electric Field Generator For PasteurizationDocument3 pagesMicrocontroller Based High Voltage Pulse Electric Field Generator For Pasteurizationijsret0% (1)

- Engineering Journal Monitoring of Bubble Formation During The Boiling Process Using Acoustic Emission SignalsDocument7 pagesEngineering Journal Monitoring of Bubble Formation During The Boiling Process Using Acoustic Emission SignalsEngineering JournalNo ratings yet

- Gonze, Environmental TechnologyDocument19 pagesGonze, Environmental TechnologyMarwen EsselmiNo ratings yet

- Ultrasonic HomogenizerDocument4 pagesUltrasonic HomogenizerOsvaldoNo ratings yet

- Ultrasonic Sound and Its ApplicationsDocument12 pagesUltrasonic Sound and Its ApplicationsbukyaravindarNo ratings yet

- Water Supply Lab ManualDocument108 pagesWater Supply Lab ManualMuhammadNo ratings yet

- Go Gate 2002Document9 pagesGo Gate 2002shivam aggarwalNo ratings yet

- Term Project - Geodynamics and Multi-SensingDocument9 pagesTerm Project - Geodynamics and Multi-Sensinghandikajati kusumaNo ratings yet

- Adsorption of Copper Ions in Aqueous Media Using Tea Waste and Sawdust As An AdsorbentDocument6 pagesAdsorption of Copper Ions in Aqueous Media Using Tea Waste and Sawdust As An AdsorbentIJIRSTNo ratings yet

- Review Ultrasoud Yao 2019Document20 pagesReview Ultrasoud Yao 2019KatNo ratings yet

- WO Nanoparticle-Based Conformable PH SensorDocument9 pagesWO Nanoparticle-Based Conformable PH Sensor18015 Asfia RifaNo ratings yet

- Instrumentation and Equipment ListDocument148 pagesInstrumentation and Equipment ListAnonymous zCqjvFRNo ratings yet

- Optimizing Sludge Dewatering Efficiency With Ultrasonic TreatmentDocument9 pagesOptimizing Sludge Dewatering Efficiency With Ultrasonic TreatmentnirupamadastaneNo ratings yet

- A Novel Process To Isolate Fibrils From Cellulose Fibers by High-Intensity UltrasonicationDocument6 pagesA Novel Process To Isolate Fibrils From Cellulose Fibers by High-Intensity UltrasonicationQuyên NguyễnNo ratings yet

- ManuscriptDocument9 pagesManuscriptCélio MarquesNo ratings yet

- Sonocrystallization - The Use of Ultrasound For Improved Industrial Crystallization PDFDocument10 pagesSonocrystallization - The Use of Ultrasound For Improved Industrial Crystallization PDFJessica FengkaiNo ratings yet

- Surface Micromachined Capacitive Ultrasonic TransducersDocument13 pagesSurface Micromachined Capacitive Ultrasonic TransducersArjun CheruvathurNo ratings yet

- The Effect of Ultrasonic Water Treatment On The CHDocument11 pagesThe Effect of Ultrasonic Water Treatment On The CHBianca LeyvaNo ratings yet

- 10.1515 - Cdbme 2021 2100Document4 pages10.1515 - Cdbme 2021 2100Zu TranNo ratings yet

- Telemicroscopy Erosion Measurements of 5Document7 pagesTelemicroscopy Erosion Measurements of 5Sanico PrulliNo ratings yet

- Journal of Food Engineering: Jonathan O'Sullivan, Brian Murray, Cal Flynn, Ian NortonDocument8 pagesJournal of Food Engineering: Jonathan O'Sullivan, Brian Murray, Cal Flynn, Ian NortonJeniferMejiaNo ratings yet

- Ultrasonics in EndodonticsDocument35 pagesUltrasonics in Endodonticsmuchlis fauzi100% (1)

- ApplicationDocument5 pagesApplicationArljarica PabunanNo ratings yet

- LV 2008Document4 pagesLV 2008Shrishma PaikNo ratings yet

- 1 s2.0 0040603185854484 Main PDFDocument6 pages1 s2.0 0040603185854484 Main PDFShrishma PaikNo ratings yet

- A Combined Use of Optical Microscopy X R PDFDocument11 pagesA Combined Use of Optical Microscopy X R PDFShrishma PaikNo ratings yet

- Particle Reentrainment From Fibrous FiltersDocument12 pagesParticle Reentrainment From Fibrous FiltersShrishma PaikNo ratings yet

- CANDU6 Reactor Assembly PDFDocument1 pageCANDU6 Reactor Assembly PDFShrishma PaikNo ratings yet

- Crystal Habit and Phase Attribution of U (Vi) Oxides in A Gelation ProcessDocument7 pagesCrystal Habit and Phase Attribution of U (Vi) Oxides in A Gelation ProcessShrishma PaikNo ratings yet

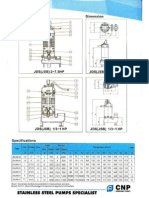

- Reactors IndiaDocument1 pageReactors IndiaShrishma PaikNo ratings yet

- Understand The Basics of Centrifugal Pump Operations (CEP)Document5 pagesUnderstand The Basics of Centrifugal Pump Operations (CEP)Ari Firmansyah100% (1)

- OStiDocument20 pagesOStiShrishma PaikNo ratings yet

- Zinc PhosphateDocument10 pagesZinc PhosphateShrishma PaikNo ratings yet

- Three Phase FlowDocument12 pagesThree Phase FlowShrishma PaikNo ratings yet

- Cement ModelDocument15 pagesCement ModelShrishma PaikNo ratings yet

- A Brief Description of NDTDocument22 pagesA Brief Description of NDTranjana3006No ratings yet

- Broadband PlansDocument2 pagesBroadband PlansShrishma PaikNo ratings yet

- Centrifugal PumpsDocument15 pagesCentrifugal PumpsVignaesh SubramaniamNo ratings yet

- Pit PumpDocument1 pagePit PumpShrishma PaikNo ratings yet

- Nalco Ion ExchangeDocument8 pagesNalco Ion ExchangeZiauddin ChawdhryNo ratings yet

- 1 s2.0 S0009250907003053 MainDocument10 pages1 s2.0 S0009250907003053 MainShrishma PaikNo ratings yet

- Heat Transfer in Rotary KilnDocument10 pagesHeat Transfer in Rotary KilnShrishma PaikNo ratings yet

- Physical Properties of Uranium Process Solutions byDocument15 pagesPhysical Properties of Uranium Process Solutions byShrishma PaikNo ratings yet

- Thorium 1Document1 pageThorium 1Shrishma PaikNo ratings yet

- 04 Todd CRESP 2009 Presentation Separations ToddDocument36 pages04 Todd CRESP 2009 Presentation Separations ToddShrishma PaikNo ratings yet

- Thorium 1Document1 pageThorium 1Shrishma PaikNo ratings yet

- Moldova N 2015Document8 pagesMoldova N 2015Suissi AnisNo ratings yet

- Classwork 4 Naming AlkanesDocument3 pagesClasswork 4 Naming AlkanesclaraNo ratings yet

- BSC Chemistry Syllabus 2016-17 NewDocument20 pagesBSC Chemistry Syllabus 2016-17 NewSwapnil RamukNo ratings yet

- The Coke Oven by Product Plant 07-22-2021Document9 pagesThe Coke Oven by Product Plant 07-22-2021Thiruvengadam SNo ratings yet

- Chapter 2 RevisionDocument8 pagesChapter 2 RevisionRose Angelyn JuanichNo ratings yet

- Bindzil PDFDocument1 pageBindzil PDFmaheshNo ratings yet

- WS Grade 10 IG Chemistry 23-24 - Revision For UT1Document4 pagesWS Grade 10 IG Chemistry 23-24 - Revision For UT1SiyaNo ratings yet

- 3 060713 English Compendium PDFDocument391 pages3 060713 English Compendium PDFMarcelino Vargas QueaNo ratings yet

- 323 Ta Aerosil200 PDFDocument2 pages323 Ta Aerosil200 PDFelektron2010No ratings yet

- Silicone Rubber PropertiesDocument15 pagesSilicone Rubber PropertiesSh.nasirpurNo ratings yet

- Trends in Analysis of Gunshot Residue For Forensic PurposesDocument9 pagesTrends in Analysis of Gunshot Residue For Forensic PurposesKatteryne Salinas M.No ratings yet

- MINERALSDocument90 pagesMINERALSlyjohnjoel maglacasNo ratings yet

- Sulfuric Acid and John Harrison: The Chemical Revolution in AmericaDocument5 pagesSulfuric Acid and John Harrison: The Chemical Revolution in Americajmd540No ratings yet

- Exercise (2) - Stoikhiometri - Rev.Document2 pagesExercise (2) - Stoikhiometri - Rev.GelvinNo ratings yet

- Chemical Surface Deposition of Cds Ultra Thin Films From Aqueous SolutionsDocument26 pagesChemical Surface Deposition of Cds Ultra Thin Films From Aqueous SolutionsAnnisa TurrahmahNo ratings yet

- Anion Ide: Monoatomic: Change Ending ToDocument24 pagesAnion Ide: Monoatomic: Change Ending TodjkedslNo ratings yet

- BioplasticsDocument15 pagesBioplasticsHonie Liane Tagose VillamorNo ratings yet

- PV Physical Pharmaceutics 4th SemDocument82 pagesPV Physical Pharmaceutics 4th SemSejal ShirgaveNo ratings yet

- Modul 4-Basic ChemDocument10 pagesModul 4-Basic ChemSaravanan ManiamNo ratings yet

- Naming Compounds - EditedDocument17 pagesNaming Compounds - EditedAngel Joy CATALAN (SHS)No ratings yet

- Gamal A. HamidDocument90 pagesGamal A. HamidDaniel VargasNo ratings yet

- IJCRT2005279Document4 pagesIJCRT2005279Harshit AhirNo ratings yet

- Lehninger Principles of Biochemistry Test Bank CH 3pdfDocument17 pagesLehninger Principles of Biochemistry Test Bank CH 3pdfMcLovin LUNo ratings yet

- Solution and Bulk PolymerizationDocument7 pagesSolution and Bulk PolymerizationLuan GabrielNo ratings yet

- PQ Sodium Silicates: Liquids and SolidsDocument20 pagesPQ Sodium Silicates: Liquids and Solidsandrei12320003181No ratings yet

- Article PDFDocument40 pagesArticle PDFAhmed YounisNo ratings yet

- Carbozinc 11: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbozinc 11: Selection & Specification Data Substrates & Surface PreparationClarkFedele27No ratings yet

- CRDF 1Document46 pagesCRDF 1sakumar5678100% (1)

- 2019 Specimen Paper 3 PDFDocument20 pages2019 Specimen Paper 3 PDFLindokunhle MabuzaNo ratings yet

- Science - Adh1853 SMDocument44 pagesScience - Adh1853 SMgetahun esubalewNo ratings yet