Professional Documents

Culture Documents

Escalator Inspection Report

Uploaded by

a_salehiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Escalator Inspection Report

Uploaded by

a_salehiCopyright:

Available Formats

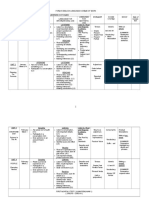

Minnesota Department of Labor and Industry

Construction Codes and Licensing Division

Elevator Inspections

443 Lafayette Road North

St. Paul, MN 55155-4341

Phone: (651) 284-5071

Fax: (651) 284-5749

www.dli.mn.gov

Reset

Escalator Inspection Report

PRINT IN INK or TYPE

LOCATION

COUNTY

ADDRESS

CITY

NORMAL DIRECTION OF TRAVEL:

ESCALATOR SERVES

OWNER ID NO.

STATE

ZIP CODE

STATE ID NO.

UP

DOWN

UP AND DOWN

LEVEL TO

LEVEL

ASME Inspection Standard to be applied for this unit: Year of Installation

People per hour (pph) Total travel (ft) Rated speed (fpm)

NOTES:

Step Skirt Performance Index

Has the escalator skirt been cleaned?

Yes

Did the index polycarbonate test specimen meet the following criteria:

Material:

Polycarbonate without fillers.

No

Yes

No

Is all equipment calibrated and current?

Yes

No Color: Natural, no pigments.

Yes

No

Was the unit tested in the normal direction of travel?

Yes

No Finish: Glossy (roughness less than 0.32 uin.

Yes

No

Was the applied load 25 lbf?

Yes

Did it deviate more than +/- 2.5 lbf?

Yes

No Area in contact with skirt plane: 4.5+/-0.5in2 and

at least 0.03in thick.

No

Yes

No

Is the distributed load area between 3in2 & 6in2

Yes

Does this unit have skirt deflection devices?

At what intervals was the index recorded?

No Specification: GE Lexan 100 series or equivalent

polycarbonate.

No

Yes

No

Yes

Left

What were the Step/Skirt Performance Index measurements?

How many readings per side were taken during the test? (Identified when looking up from the bottom on

the unit.)

CHOOSE ONE OF THE FOLLOWING THREE ITEMS as described in ASME A17.1a 2005 Item 8.6.8.3.3

Right

Left

Right

Condition 1: All units range < 15

Condition 2: Escalators installed under ASME A17.1a-2002 and later editions Range: < .25 with skirt deflection devices.

Condition 3: Escalators installed under ASME A17.1-2000 and earlier editions Range: < .4 with skirt deflection devices.

Did the escalator meet one of the applicable conditions above using the highest measurement obtained?

Yes

No

Have all readouts been attached to this form? Must be submitted for each test, properly labeled and dated?

Yes

No

DID THE UNIT PASS ALL TESTING REQUIREMENTS PRIOR TO BEING RETURNED TO SERVICE?

Brake Lining Condition:

Machine Room Light:

Broken Drive Chain Device:

Machine Room Stop Switches:

Broken Step Chain:

Missing Step Device:

Comb Step Impact Devices:

Reversal Stop Device:

Demarcation Lighting:

Reverse Phase Relay:

Disconnected Motor Device:

Rolling Shutter Device:

Drain in Bottom for Outside Escalators:

Signage:

Drain Chain Tension:

Skirt Switches:

Emergency Stop Buttons:

Speed Governor:

Handrail Chain Tension:

Step Chain Tension:

LH

RH

Handrail Entry Device:

Step Level Device:

LH

RH

Handrail Monitoring Device:

Step Rollers:

Top

Bottom

Landing Plate Switches:

Step Upthrust Device: Top

Lockable Fused Disconnect/CircuitBre

Step Upthrust Device: Bottom

Yes

No

Machine Room Cover Switches:

Top

Bottom

Top

Top

Bottom

Bottom

LH

RH

LH

LH

RH

RH

Tandem Operation Interlock Device:

COMPANY CONDUCTING TEST

NAME OF PERSON CONDUCTING TEST

ADDRESS

SIGNATURE OF PERSON CONDUTING TEST

CITY

STATE

ZIP CODE DATE

This material can be made available in different forms, such as large print, Braille or on a tape. To request, call 1-800-342-5354 (DIAL-DLI) Voice or

TDD (651) 297-4198.

EL003 (10/08)

You might also like

- Concord Infinity II Residential Elevator Instal & Service SearchableDocument128 pagesConcord Infinity II Residential Elevator Instal & Service SearchableHongquan SuNo ratings yet

- Caroline Tierney's Dirth Nasty Sex Fantasy PDFDocument15 pagesCaroline Tierney's Dirth Nasty Sex Fantasy PDFSarah DuffyNo ratings yet

- 02.04.19 ITP Inspection PlanDocument11 pages02.04.19 ITP Inspection PlanWinNo ratings yet

- ABRSM TheoryDocument24 pagesABRSM TheoryJane Haddad83% (6)

- Elevator Maintenance Check List Sample OTIS PDFDocument2 pagesElevator Maintenance Check List Sample OTIS PDFSohail100% (3)

- Building Great Sentences - Exploring The Writer's Craft by Brooks Landon - ReviewDocument5 pagesBuilding Great Sentences - Exploring The Writer's Craft by Brooks Landon - Reviewi KordiNo ratings yet

- Elevator Commissioning Guide: Quickly Complete Installation & TestingDocument30 pagesElevator Commissioning Guide: Quickly Complete Installation & TestingtoufikNo ratings yet

- JSA For Elevator InstallationDocument11 pagesJSA For Elevator InstallationHamid RazaNo ratings yet

- Passenger & Freight Elevator Pre-Inspection Checklist 2014 - FinalDocument3 pagesPassenger & Freight Elevator Pre-Inspection Checklist 2014 - FinalMostafa MohmmedNo ratings yet

- Case Against Balancing ValvesDocument4 pagesCase Against Balancing Valvesa_salehiNo ratings yet

- WIRING DIAGRAM ELEVATOR PANELDocument28 pagesWIRING DIAGRAM ELEVATOR PANELGogik AntoNo ratings yet

- Well Testing Wireless Data AcquisitionDocument8 pagesWell Testing Wireless Data Acquisitiona_salehiNo ratings yet

- FM200Document18 pagesFM200a_salehiNo ratings yet

- ElevatorsDocument6 pagesElevatorssenthilNo ratings yet

- Elevator Modernization Case StudyDocument22 pagesElevator Modernization Case Studyvaratharajank100% (1)

- Rx8 Engine Workshop ManualDocument80 pagesRx8 Engine Workshop Manualfrj83No ratings yet

- Elevator Control Wiring and Simple Configuration: Button ModeDocument7 pagesElevator Control Wiring and Simple Configuration: Button ModeAgnelo FernandesNo ratings yet

- Operation and MaintenanceDocument41 pagesOperation and Maintenancegajendrabanshiwal8905100% (2)

- Ut Id 30-8-0 1 Nce NCT Diagnostic ToolDocument19 pagesUt Id 30-8-0 1 Nce NCT Diagnostic ToolAlex GonzalezNo ratings yet

- Drawworks Technology CatalogDocument20 pagesDrawworks Technology Cataloga_salehi100% (1)

- Escalator OptionsDocument2 pagesEscalator Optionsjk.dasguptaNo ratings yet

- Methodology LiftDocument5 pagesMethodology LiftBala Vtec100% (1)

- Rogers Fire Dept Elevator Rescue ProceduresDocument4 pagesRogers Fire Dept Elevator Rescue ProceduresAisah Nursani0% (1)

- Diagnostic Check Sheets PDFDocument15 pagesDiagnostic Check Sheets PDFLuisYFer1No ratings yet

- Technical Offer For Gearless Passenger Lift: LG Elevator Co,. LTDDocument7 pagesTechnical Offer For Gearless Passenger Lift: LG Elevator Co,. LTDAntr HasanNo ratings yet

- Elevator Maintenance Check ListDocument6 pagesElevator Maintenance Check ListSohailNo ratings yet

- Bss2 Practical EscalatorDocument7 pagesBss2 Practical EscalatorJanet100% (1)

- Load Testing of LiftsDocument4 pagesLoad Testing of LiftsahmedNo ratings yet

- Elevator Violation CodesDocument31 pagesElevator Violation CodesAnonymous YzSzB0rpNKNo ratings yet

- KEROI Well ServicesDocument13 pagesKEROI Well Servicesa_salehiNo ratings yet

- Checklist For Escalator Inspection PDFDocument1 pageChecklist For Escalator Inspection PDFthanggimme.phanNo ratings yet

- Hyundai Elevator Preventive Maintenance ProcedureDocument19 pagesHyundai Elevator Preventive Maintenance ProcedureTrebor Santos100% (2)

- Elevator ChecklistDocument3 pagesElevator ChecklistNguyễn Thế PhongNo ratings yet

- 380V Electrical Drawing PDFDocument34 pages380V Electrical Drawing PDFMujianaNo ratings yet

- Rimary Repair-FinalDocument136 pagesRimary Repair-FinalTroubleshooting100% (1)

- Alanis Morissette - Jagged Little Pill LyricsDocument15 pagesAlanis Morissette - Jagged Little Pill LyricsPattyaa100% (1)

- Fellowship - Playbook 3Document44 pagesFellowship - Playbook 3Bubba McBimbam100% (1)

- Escalator Instruction-Manual KindmoverDocument32 pagesEscalator Instruction-Manual KindmoverengkankwNo ratings yet

- ARD SystemDocument9 pagesARD Systemshobhitec20095807No ratings yet

- The Divine Mercy PRAYER AND CHAPLETDocument3 pagesThe Divine Mercy PRAYER AND CHAPLETBeni Brendz Quizon JanairoNo ratings yet

- Technical Manual Quality Tubing PDFDocument52 pagesTechnical Manual Quality Tubing PDFOrlando PuentesNo ratings yet

- 4 Hyundai High Speed Elevator Catalogue - Speed Up To 6 MPSDocument15 pages4 Hyundai High Speed Elevator Catalogue - Speed Up To 6 MPSRIZALNo ratings yet

- Bearings in Twin Screw CompressorsDocument108 pagesBearings in Twin Screw Compressorsa_salehi100% (1)

- Installation and Operating Instructions Overspeed Governor Type 7/8/9Document16 pagesInstallation and Operating Instructions Overspeed Governor Type 7/8/9RuiNo ratings yet

- Electric Lift Testing Commissioning SheetDocument5 pagesElectric Lift Testing Commissioning Sheetamal_post100% (2)

- Otis E MotionDocument2 pagesOtis E MotionFERNSNo ratings yet

- Checklist For Inspection of Escalators PDFDocument1 pageChecklist For Inspection of Escalators PDFAry Putra100% (1)

- Car Elevators SpecDocument34 pagesCar Elevators Specmohammad ghassanNo ratings yet

- Checklist Lift PDFDocument4 pagesChecklist Lift PDFSean Chan100% (1)

- ARES Escalator BDocument2 pagesARES Escalator BGutmonarchNo ratings yet

- Schindler Handrail MaintenanceDocument9 pagesSchindler Handrail Maintenancea_salehi100% (1)

- Escalator: Installation ManualDocument53 pagesEscalator: Installation ManualSamih AlraghbanNo ratings yet

- Short StoriesDocument4 pagesShort StoriesJoana CalvoNo ratings yet

- Step-by-Step Planning for Escalators and Moving WalksDocument21 pagesStep-by-Step Planning for Escalators and Moving WalksYusup SNo ratings yet

- HLP-A100 Operating Manual PDFDocument207 pagesHLP-A100 Operating Manual PDFGuillermo HernándezNo ratings yet

- Sri+Bhakti-Ratnakara+ 28not+complete 29 PDFDocument316 pagesSri+Bhakti-Ratnakara+ 28not+complete 29 PDFJuan ChavezNo ratings yet

- Hospital List March 92012Document198 pagesHospital List March 92012Prashant Ingawale100% (1)

- Festo-Close Loop HydraulicsDocument356 pagesFesto-Close Loop HydraulicsGiorgio MackenzieNo ratings yet

- Elevator Five Year Safety Test FormDocument2 pagesElevator Five Year Safety Test FormTaufiq Omar HasanNo ratings yet

- Escalator Load Test On Initial InspectionDocument2 pagesEscalator Load Test On Initial InspectionAry Putra100% (1)

- PILLAR Elevator Catalogue 2019Document29 pagesPILLAR Elevator Catalogue 2019Ardi FebyNo ratings yet

- District of Columbia: 1. Elevator - Inside of CarDocument2 pagesDistrict of Columbia: 1. Elevator - Inside of Carunsuckdcmetro0% (2)

- General EscalatorDocument65 pagesGeneral EscalatorMạnh HùngNo ratings yet

- Passenger Lift Specification for New Airport in Timor LesteDocument3 pagesPassenger Lift Specification for New Airport in Timor LesteSAYYID ALKAHFI AGIT PRAKOSONo ratings yet

- Safety Tips Escalator TravelatorDocument3 pagesSafety Tips Escalator TravelatorZulhilmiIbrahimNo ratings yet

- ARCODE EU-Type Examination CertificateDocument1 pageARCODE EU-Type Examination CertificateMazen Alhouseen100% (1)

- Tabulasi Neraca Limbah b3Document3 pagesTabulasi Neraca Limbah b3Winda Fitri RahayuNo ratings yet

- Variable Voltage Variable Frequency Motor Drive ManualDocument11 pagesVariable Voltage Variable Frequency Motor Drive ManualKhaled ZakariaNo ratings yet

- Electric Dumbwaiter Installation ProposalDocument2 pagesElectric Dumbwaiter Installation ProposalTempwell company Naga Branch0% (1)

- Creating a new history with machine room-less elevatorsDocument20 pagesCreating a new history with machine room-less elevatorsTaimoor Ahmed100% (1)

- 19010493-SC - A00 - 19010493 - ME320LNnew Series Elevator AC Drive - 20161121Document145 pages19010493-SC - A00 - 19010493 - ME320LNnew Series Elevator AC Drive - 20161121Ks BharathiyarNo ratings yet

- Metis Joymore: Compact Machine Room ElevatorDocument14 pagesMetis Joymore: Compact Machine Room ElevatorjackyNo ratings yet

- Ard Based Elevator Control SystemDocument7 pagesArd Based Elevator Control SystemIRJIENo ratings yet

- Nice 7000Document120 pagesNice 7000Syed iliyasNo ratings yet

- SIEPC80000045C SigmaV User Manual Design Maintenance Rotational MotorDocument402 pagesSIEPC80000045C SigmaV User Manual Design Maintenance Rotational MotorNguyễn Hữu Tuân100% (1)

- Operation & Maintenance of LiftDocument40 pagesOperation & Maintenance of Liftaung kokoNo ratings yet

- Test of Escalator Safety DevicesDocument1 pageTest of Escalator Safety Devicesa_salehiNo ratings yet

- Troubleshoot ECU SystemsDocument9 pagesTroubleshoot ECU SystemsdiemnganNo ratings yet

- Data SheetDocument3 pagesData SheetMostafa MohmmedNo ratings yet

- Ims Kendrion Control Power Line Control Solenoids enDocument8 pagesIms Kendrion Control Power Line Control Solenoids ena_salehiNo ratings yet

- Braking Performance Analysis of An Escalator System Using Multibody Dynamics Simulation TechnologyDocument7 pagesBraking Performance Analysis of An Escalator System Using Multibody Dynamics Simulation Technologya_salehiNo ratings yet

- IMI HB-2-Balancing of Distribution SystemsDocument68 pagesIMI HB-2-Balancing of Distribution SystemsAbey VettoorNo ratings yet

- 51-DAA26231G Auxiliary BrakeDocument5 pages51-DAA26231G Auxiliary Brakea_salehiNo ratings yet

- High Pressure Mixed Flow FanDocument22 pagesHigh Pressure Mixed Flow Fana_salehiNo ratings yet

- NSK CAT E1102m A20-23 PDFDocument2 pagesNSK CAT E1102m A20-23 PDFChetan PrajapatiNo ratings yet

- Cimberio Balancing Valves Eng-Gb Rev0Document35 pagesCimberio Balancing Valves Eng-Gb Rev0appukkiliNo ratings yet

- The Conceptual Design of High Pressure ReversibleDocument12 pagesThe Conceptual Design of High Pressure Reversiblea_salehiNo ratings yet

- Balancing Valve TBV - EN - MAINDocument8 pagesBalancing Valve TBV - EN - MAINa_salehiNo ratings yet

- 10 DrawworksDocument5 pages10 Drawworksa_salehiNo ratings yet

- Test of Escalator Safety DevicesDocument1 pageTest of Escalator Safety Devicesa_salehiNo ratings yet

- SKF Rolling Bearings InformationDocument117 pagesSKF Rolling Bearings InformationchoongzjNo ratings yet

- Pg05f05te PDFDocument8 pagesPg05f05te PDFa_salehiNo ratings yet

- Broch Siei-Areg Overview en LowDocument28 pagesBroch Siei-Areg Overview en Lowa_salehiNo ratings yet

- Hydronic Heating SystemDocument50 pagesHydronic Heating Systema_salehiNo ratings yet

- Fujitec Handrail MaintenanceDocument2 pagesFujitec Handrail Maintenancea_salehiNo ratings yet

- Wireless InstrumentDocument12 pagesWireless Instrumenta_salehi100% (2)

- Pg05f05te PDFDocument8 pagesPg05f05te PDFa_salehiNo ratings yet

- Sensors Switches Traction ElevatorsDocument5 pagesSensors Switches Traction ElevatorsFERNSNo ratings yet

- Esc Out DoorDocument1 pageEsc Out Doora_salehiNo ratings yet

- Contemporary World QuizDocument16 pagesContemporary World QuizPrincess Jhoie Corpuz0% (1)

- Human LyricsDocument7 pagesHuman LyricsËçël EcelNo ratings yet

- NURSE UNIFORMDocument9 pagesNURSE UNIFORMawhie dg.masikkiNo ratings yet

- Language and Literature DP 2 - 2019-2020Document29 pagesLanguage and Literature DP 2 - 2019-2020Shuaib MohamedNo ratings yet

- Form 5 English Scheme of Work SummaryDocument8 pagesForm 5 English Scheme of Work SummaryMazLinaNo ratings yet

- Understanding English TextsDocument7 pagesUnderstanding English TextsQiirunNo ratings yet

- Paket 9 Big UsbnDocument13 pagesPaket 9 Big UsbnMia Khalifa100% (1)

- Sync Your Ipad With Linux PDFDocument0 pagesSync Your Ipad With Linux PDFricardox28No ratings yet

- Pradosham: An Important Saivite Worship Ritual Observed in Lord Shive Temples in IndiaDocument4 pagesPradosham: An Important Saivite Worship Ritual Observed in Lord Shive Temples in IndiaMUTHUSAMY RNo ratings yet

- A Phonological Study of Elision in Standard English and Standard ArabicDocument20 pagesA Phonological Study of Elision in Standard English and Standard Arabicvote nctNo ratings yet

- Advocacy PamphletDocument2 pagesAdvocacy Pamphletapi-449004464No ratings yet

- Huawei Sne Mobile Phone User Guide - (Emui9.0.1 - 01, En-Uk, Normal)Document68 pagesHuawei Sne Mobile Phone User Guide - (Emui9.0.1 - 01, En-Uk, Normal)FarzadNo ratings yet

- ETHICSDocument7 pagesETHICSMaribeth TantiadoNo ratings yet

- Chapter 2 Digital Image FundamantelsDocument58 pagesChapter 2 Digital Image FundamantelsVimal KumarNo ratings yet

- Article 9 - Visual Merchandising Window DisplayDocument7 pagesArticle 9 - Visual Merchandising Window DisplayManoranjan DashNo ratings yet

- The Martian AnalysisDocument6 pagesThe Martian AnalysisalecNo ratings yet

- Church Mass ScheduleDocument2 pagesChurch Mass ScheduleKonrad MigrasoNo ratings yet

- HOW LONG CHORDS by Charlie Puth @Document3 pagesHOW LONG CHORDS by Charlie Puth @Jon Rainiel JimenezNo ratings yet

- Mies Vander o HeDocument16 pagesMies Vander o HeTushar JainNo ratings yet

- Reception of The Holy OilsDocument2 pagesReception of The Holy OilsSaitama SenseiNo ratings yet