Professional Documents

Culture Documents

Chilled Ammonia

Uploaded by

nedian_2006Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chilled Ammonia

Uploaded by

nedian_2006Copyright:

Available Formats

P R E P R I N T ICPWS XV

Berlin, September 811, 2008

Chilled ammonia process for CO2 capture

Victor Dardea,b, Kaj Thomsena, Willy van Wellb and Erling Stenbya

Department of Chemical and Biochemical Engineering, Technical University of Denmark

b

Generation Department, Chemical & Materials, DONG Energy

Email: vid@kt.dtu.dk, kth@kt.dtu.dk, wilwe@dongenergy.dk, ehs@kt.dtu.dk

The chilled ammonia process for CO2 capture is a new and patented post-combustion technology that

offers good perspectives regarding the reduction of the emission of carbon dioxide from power plants. This

process was studied using a software based on the extended UNIQUAC model developed by Thomsen and

Rasmussen for the CO2-NH3-H2O system. This model is capable of describing accurately the vapor-liquidsolid equilibria and thermal properties for this system for a wide range of concentrations (up to 80 molal),

for a temperature in the range of 0-110C and for a pressure up to 100 bars.

Based on the equilibrium calculations and the information from the patent for the chilled ammonia process,

it has been possible to describe the composition of each stream, analyzing the solid, liquid and vapor phases.

Moreover, this study comprises calculations of the energy requirement in the absorber and the desorber,

based on the equilibrium calculation. The reference configuration which was used for the analysis shows

promising results regarding the energy consumption in the desorber compared to capture techniques using

aqueous alkanolamines.

Therefore, regarding the reduction objectives

endorsed by many governments, efforts are being

made to develop technologies allowing the

decrease of the emissions from the power plants.

Carbon dioxide capture implies separating the CO2

from the rest of the flue gases from a power plant

or a factory instead of releasing the CO2 in the

atmosphere. Several methods can be used to

capture CO2 from coal-fired power plants. Post

combustion techniques separate the carbon dioxide

from the flue gas after a traditional combustion

process. The main advantage of such technique is

that the combustion at the power plant is unaltered,

so the process can be implemented on existing

power plants. Amine solutions have been

commonly used for the commercial production of

CO2 and have been tested for CO2 capture on pilot

scale. However such technologies require a large

amount of energy, especially in the desorption part

of the process [4]. In addition, the use of amines

entails some problems related to solvent

degradation and corrosion [5, 6]. Therefore, new

alternatives for post-combustion capture are

searched for. Processes using aqueous ammonia as

solvent are promising alternatives. The ammonia

process is found in two variants, depending on the

temperature of absorption. The first variant

absorbs the CO2 at low temperature (2-10C) and

is therefore called chilled ammonia process. The

Introduction

The concentration of CO2 in the atmosphere

has constantly increased from 315 ppm in 1958 to

about 390 ppm in 2007 [1]. The Intergovernmental

Panel on Climate Change (IPCC) has concluded in

2007 that most of the observed increase in

globally averaged temperatures since the mid-20th

century is very likely due to the observed increase

in anthropogenic greenhouse gas concentrations

[2]. The consequences of global warming could be

very threatening. It has been studied that the

greenhouse effect is likely to increase the

frequency of extreme weather events, cause the

sea level to rise and modify the precipitation

pattern among many other effects. A rise of the

temperature would deeply modify the climate. It

would imply the appearance of climate refugees.

IPCC has estimated in 2007 that the number of

climate refugees in 2050 could reach 150 millions.

This phenomenon could also favor the spread of

diseases, especially in poor areas. Hence, the

reduction of the emission of greenhouse gas

represents one of the main challenges of the

coming years.

The proportion of carbon dioxide emissions

from power production is very significant in

industrialized countries. In Denmark, in 2004, they

represented 61% of the total CO2 emissions [3].

-1-

low temperature process has the advantage of

decreasing the ammonia slip in the absorber and

decreasing the flue gas volume. This process

allows precipitation of several ammonium

carbonate compounds in the absorber. The second

process absorbs CO2 at ambient temperature (2540C) and does not allow precipitation. This study

focuses on the chilled ammonia process for CO2

capture.

the cooling of the gas by using Direct Contact

Coolers (DCC). The number of DCC that are used

may vary. The temperature of the gas that leaves

the cooling subsystem is comprised between 0 and

10C. This stream contains low moisture and

almost no particulate matter, acidic or volatile

species. Indeed, the low temperature decreases the

vapor pressure of these compounds. It entails their

condensation into the water.

Then, the flue gas enters the CO2 capture and

regeneration subsystem. The process presents

some similarities with the capture process using

aqueous alkanolamines. It comprises two columns:

an absorber and a desorber. A schematic flow

sheet of this system is shown in Figure 1.

The cold flue gas enters the bottom of the

absorber while the CO2 lean stream enters the top

of it. As mentioned before, the temperature of the

flue gas should be between 0 and 10C. The CO2

lean stream is mainly composed of water,

ammonia and carbon dioxide. The mass fraction of

ammonia in the solvent is typically up to 28wt%.

The CO2 loading is defined as the ratio of the

number of mole of carbon dioxide and ammonia.

According to the patent, the CO2 lean stream

should have a CO2 loading comprised between

0.25 and 0.67, and preferably between 0.33 and

0.67.

The carbon dioxide is absorbed by the ammonia in

the absorber column. The pressure in the absorber

should be close to atmospheric pressure. The

CO2 capture using chilled ammonia

The use of chilled ammonia to capture carbon

dioxide was patented in 2006 by Eli Gal [7]. The

process is described in the patent.

Description of the patented process

The process requires several steps. First, the

purpose of the process is to absorb the carbon

dioxide at a low temperature. The patent indicates

a temperature range from 0 to 20C, and

preferably from 0 to 10C. Hence, it is first

necessary to cool down the flue gas that contains

the CO2. This is done by adding a cooling

subsystem at the entrance of the process. This

system also allows for cleaning of the gas before it

enters the absorber. It first consists of a reactor

used for gas desulphurization by using acid

absorbing reagent. Thanks to this system, a large

part of the contaminants initially present in the gas

may be removed. This cleaning step is followed by

Figure 1: Schematic flow sheet of the process

-2-

temperature should be in the range 0-20C, and

preferably 0-10C. This low temperature prevents

the ammonia from evaporating. In addition,

according to the patent, this low temperature is

supposed to enhance the mass transfer of CO2 to

the solution. A low CO2 loading increases the

vapor pressure of ammonia which implies its

evaporation. On the other hand, a high CO2

loading for the CO2 lean stream decreases the

efficiency of the absorption. Thus it was necessary

to define an optimized CO2 loading range. Under

the conditions described above and according to

the patent of the process, more than 90% of the

CO2 from the flue gas can be captured.

The cleaned gas stream can leave the absorber by

its top. This stream contains some residual

ammonia, which is washed out by using cold

water and an acidic solution. The treated stream is

reintroduced into the system. The cleaned gas

mainly contains Nitrogen, Oxygen and a low

concentration of carbon dioxide.

The CO2 rich stream leaves the bottom of the

absorber. It might be composed of a solid and a

liquid phase. Indeed, at this temperature and under

those conditions, the solubility limits may be

reached. Hence, the CO2 rich stream is a slurry. Its

CO2 loading is between 0.5 and 1, and preferably

between 0.67 and 1. The patent mentions that a

part of the CO2 rich stream could be recycled to

the absorber in order to increase the CO2 loading

of the CO2 rich stream by producing more solid.

The CO2 rich stream is then sent to a heat

exchanger where it is warmed, and then sent to the

desorber using a high pressure pump. Its

temperature reaches a range of 50-200C, and

preferably 100-150C. Its pressure is in the range

of 2-136 atmospheres. Under those conditions, the

emission of ammonia that could be implied by the

high temperature is reduced. The conditions cause

CO2 to separate from the solution. It leaves the top

of the desorber as a relatively clean and high

pressure stream. The water vapor and the

ammonia that is contained in this stream can be

recovered by cold washing, possibly using weak

acid to increase the washing efficiency.

The desorption reaction is endothermic, but the

energy that has to be supplied is much lower than

for MEA or other solvents according to the patent.

This energy highly depends on the composition of

the CO2 rich stream that enters the desorber.

Indeed, the composition of the solid phase, which

depends on the initial composition and on the

process conditions, has a strong influence on the

energy that has to be supplied. In addition, the

pure CO2 stream that is obtained with this process

is already at high pressure. Hence, a part of the

energy needed to compress this stream is saved.

Table 1 sums up the composition and the

process conditions that are described in the patent.

Table 1:

CO2

Lean

stream

Flue

gas

CO2

Rich

stream

Process conditions in the patent

Temperature Pressure

CO2

(C)

(atm)

loading

0-20

0-10

50-200

2-136

0.25-0.67

0.5-1

Description of the model

This study uses the extended UNIQUAC

thermodynamic model developed for the CO2NH3-H2O system by Thomsen and Rasmussen [8].

It calculates the activity coefficient for the liquid

phase using the extended UNIQUAC model, and

the gas phase fugacity using the Soave-RedlichKwong (SRK) equation for the volatile

compounds. [8] The model only requires binary

interaction parameters, UNIQUAC surface area

and volume parameters.

The analysis of the CO2-NH3-H2O system

implies the study of several equilibrium processes.

The model is based on more than 2000

experimental data points on this system in the

IVC-SEP electrolyte data bank, including thermal

properties and solid-liquid equilibrium. The

following reactions must be considered.

Speciation equilibria

(1)

NH3 (aq)+H 2 O NH4+ +OH-

CO2 (aq)+H2O(l) HCO3- +H+

(2)

H 2 O(l) OH +H

(4)

HCO3- CO32- +H +

-

NH3(aq)+HCO NH2COO +H2O(l)

3

Vapor-liquid equilibria

-3-

(3)

(5)

CO2 (g) CO2 (aq)

(6)

H 2 O(g) H 2O(l)

(8)

NH3 (g) NH3 (aq)

software calculates the amounts of the different

species in the liquid phase, the pH, the bubble

point total pressure and partial pressures of water,

ammonia and carbon dioxide, the saturation index

of the 5 solids mentioned earlier, the enthalpy of

formation and the heat capacity of the liquid phase.

Hence, for a given molality, it is possible to obtain

the composition of the liquid phase, the nature and

the amount of the solid phases, the bubble point

total pressure, the composition of the bubble point

gas phase and the enthalpy of formation of the

stream. This last term is calculated by summing

the enthalpy of the liquid and solid phases,

knowing the standard enthalpy of formation of the

solids and the corresponding heat capacities.

(7)

Liquid-Solid equilibria

NH4+ +HCO3- NH4HCO3 (s)

(9)

NH4+ +NH2COO- NH2COONH4 (s)

(10)

2NH4+ +CO32- +H2O (NH4 )2CO3.H2O(s)

(11)

4NH4+ +CO32- +2HCO3- (NH4 )2CO3.2NH4HCO3(s) (12)

H 2O(l) H 2O(s)

(13)

Hence, five different solids can be formed

during the process:

Ammonium bicarbonate: NH4HCO3

Ammonium carbonate: (NH4)2CO3.H2O

Ammonium carbamate: NH2COONH4

Sesqui-carbonate: (NH4)2CO32NH4HCO3

Ice: H2O

Urea can also be formed at some temperatures

and compositions. Its formation is not included in

this study.

Figure 2 shows which solid phase can

precipitate

in

various

temperature

and

concentration ranges. Some experimental data are

marked in the diagram [9, 10, 11, 12].

Composition of the process streams

Based on the software and on the information

from the patent of the process, the equilibrium

composition of the different streams of the process

has been studied. The results shown here concern

the compositions of the streams in the absorber

and in the desorber. A typical initial mass fraction

of ammonia in the solvent is 28wt%. This value

has been used in this study.

In addition, in the absorber, the temperature

should be in the range of 0-20C, and preferably

0-10C. The CO2 loading of the CO2 lean stream

(lean CO2 loading) is in the range of 0.25-0.67,

and the one of the CO2 rich stream (Rich CO2

loading) in the range of 0.5-1. Therefore it seems

relevant to study the influence of the CO2 loading

from 0.25 to 0.77 by maintaining the temperature

at 10C and by using an initial mass fraction of

ammonia in the solvent of 28wt%. Hence, the

molality of ammonia in the solvent is 22.83

mol/kg H2O, and the molality of CO2 varies from

5.71 to 17.6 mol/kg H2O. The model is not

accurate for pressures higher than 100 bars that are

obtained for higher loadings. This equilibrium

study gives an overview of the species that appear

in the absorber. Figure 3, Figure 4 and Figure 5

respectively show the composition of the liquid

phase, the nature and amount of solid phases and

bubble point pressure of a 28wt% ammonia

solvent at a temperature of 10C as a function of

the CO2 loading.

10

9

NH3 /CO 2 mol ratio

Extended UNIQUAC

Jnecke (1929)

Terres & Weiser (1921)

Terres & Behrens (1928)

Guyer & Piechowicz (1944)

NH2 COONH4

8

7

6

5

4

3

2

NH4HCO3

1

0

(NH4)2CO32NH4HCO3

(NH4)2CO3 H2 O

10

20

30

40

50

Temperature, C

60

70

80

90

100

Figure 2: Phase diagram of the CO2-NH3-H2O

system [8]

Hence, the model is capable of describing

accurately the vapor-liquid-solid equilibria and

thermal properties for the CO2-NH3-H2O system

for a wide range of concentration (up to 80 molal

NH3), for a temperature in the range of 0-110C

and for a pressure range up to 100 bars.

A software based on the model was used in

this study. Based on the temperature and the

molalities of carbon dioxide and ammonia, the

-4-

0.2

NH3(aq)

NH4+

CO3-HCO3NH2COO-

0.15

Mole fraction

the ammonium bicarbonate solid phase. The

composition of the solution and the pH are very

stable when it is present while they change rapidly

as soon as it disappears. Figure 4 shows that at

10C, there is a solid phase present at all CO2

loadings higher than 0.25. For loadings higher

than 0.5, two solids are present: ammonium

carbonate and ammonium bicarbonate. For

loadings lower than 0.5, the only solid is

ammonium carbonate. This result is in agreement

with the phase diagram presented in Figure 2,

which shows that increasing the loading entails the

formation of ammonium bicarbonate and the

decrease of the amount of ammonium carbonate.

Figure 5 shows that at low CO2 loadings, the mole

fraction of ammonia in the gas phase is very high.

Therefore, it is likely that some ammonia is swept

along in the pure gas stream that leaves the

absorber. Hence, a washing section must be

considered to limit the emission of ammonia.

A similar study was performed to analyze the

composition of the stream in the desorber. The

same initial mass fraction of ammonia was chosen

(28wt%). According to the patent, the desorption

preferably occurs at temperatures in the range of

100-150C. The CO2 loading decreases in the

stripper as the carbon dioxide is desorbed there.

The influence of this parameter on the

composition of the stream in the stripper is studied

in the following paragraphs. A temperature of

120C was chosen in the study. The CO2 loading

was varied from 0.25 to 0.77.

Composition of the liquid phase

Ammonia 28wt%, Temperature 10C

0.1

0.05

0.25

0.29

0.33

0.40

CO2 loading

0.50

0.67

Figure 3: Composition of the liquid phase of a

28wt% ammonia solvent with a

temperature of 10C as a function of

the CO2 loading

Nature and amount of solid phases

Ammonia 28wt%, Temperature 10C

Number of mol

14

12

(NH4)2CO3H2O

10

NH4HCO3

8

6

4

2

0

0.25

0.29

0.33

0.40

CO2 loading

0.50

0.67

Figure 4: Nature and amount of solid phases of a

28wt% ammonia solvent with a

temperature of 10C as a function of

the CO2 loading

Bubble point pressures

Ammonia 28wt%, Temperature 10C

0.25

Total

H2O

NH3

NH3(aq)

NH4+

HCO3NH2COOCO2 (aq)

0.2

0.1

0.05

0

Composition of the liquid phase

Ammonia 28wt%, Temperature 120C

0.25

CO2

0.15

mole fraction

Pressure (bar)

0.2

0.25

0.29

0.33

0.40

CO2 loading

0.50

0.67

0.15

0.1

0.05

Figure 5: Bubble point pressures of a 28wt%

ammonia solvent with a temperature of

10C as a function of the CO2 loading

0.23

0.26

0.30

0.36

CO2 loading

0.43

0.56

0.77

Figure 6: Composition of the liquid phase of a

28wt% ammonia solvent with a

temperature of 120C as a function of

CO2 loading

It can be seen from Figure 3 that the CO2

loading has a very significant influence on the

composition of the liquid phase. The discontinuity

that is observed corresponds to the appearance of

-5-

Energy requirement

Ammonia 28wt%, Temperature 120C

Pressure (bar)

1000

100

The energy requirement is a key parameter of a

capture process. Indeed, one of the main problems

related to the use of capture techniques on a large

scale is the cost of the process. This cost is

strongly linked to the energy that has to be

supplied to ensure the desorption. The use of

ammonia is supposed to lower the energy

requirement. This study focuses first on the energy

requirement in the absorber. As the absorption of

carbon dioxide by ammonia is an exothermic

reaction, some energy is produced in the absorber.

A reference configuration has been set up to assess

this energy production. In this configuration, it is

assumed that 100% of the carbon dioxide from the

flue gas is absorbed by the solvent. The major

assumptions are included in Table 2.

Total

H2O

NH3

CO2

10

0,

27

0,

29

0,

30

0,

32

0,

34

0,

37

0,

40

0,

43

0,

48

0,

53

0,

59

0,

67

0,

77

1

CO2 loading

Figure 7: Bubble point pressures of a 28wt%

ammonia solvent with a temperature of

120C as a function of the CO2 loading

Composition of the gas phase

Ammonia 28wt%, Temperature 120C

1.2

H2O

NH3

CO2

Mole fraction

1

0.8

Table 2: Description of the absorber reference

configuration

0.6

0.4

NH3

initial

wt%

0.2

0

0.26

0.30

0.36

CO2 loading

0.43

0.56

0.77

28

Figure 8: Composition of the bubble point gas

phase of a 28wt% ammonia solvent

with a temperature of 120C as a

function of the CO2 loading

T CO2

Lean

stream

10C

T CO2

Rich

stream

10C

T

flue

gas

10C

Lean

CO2

loading

0.333

Rich

CO2

loading

0.667

The energy requirement in the absorber

expressed in kJ/kg CO2 absorbed was then

calculated according to the following formula:

ERabs =

No solid phase appears at this high temperature.

It can be seen from Figure 7 that the pressure can

reach high values, especially when the CO2

loading is high. It should be noticed a logarithmic

scale is used for the ordinate axis. Figure 8 shows

that for high CO2 loading, the mole fraction of

carbon dioxide in the gas phase is very close to 1.

The CO2 rich stream that enters the stripper has a

high CO2 loading. Hence, this figure shows that at

high temperature, it is possible to get a pressurized

and nearly pure CO2 stream. The use of a

condenser and a washing section allow the

cleaning of the pure CO2 stream from water and

ammonia. Hence, some energy savings can be

made during the compression of the CO2 stream

before it is transported and sequestrated.

H CO2Rich + HCleaned gas - H CO2Lean - H Flue gas

Amount of CO2 in flue gas * MW(CO2)

For the reference configuration, the energy

requirement in the absorber is -2100 kJ/kg CO2

absorbed. Hence, this study shows that a large

amount of cooling water has to be used in order to

maintain a low temperature of absorption. The

energy requirement in the desorber was studied as

well as the influence of several parameters on the

energy requirement. Figure 9 shows a schematic

flow sheet of the stripping part of the process. This

study takes into account the amounts of water and

ammonia that are swept along in the gas phase and

eventually enter the desorber after the pure CO2

stream passes through the condenser and the

washing section.

A reference configuration has been set up

according to the information from the patent. The

main assumptions are summed up in Table 3.

-6-

Energy requirement (kJ/kg CO2

captured)

4000

3000

2000

1000

0,56

0,59

0,63

0,67

Rich CO2 loading

0,71

0,77

2200

2100

2000

38

0.

16

5000

0,53

2300

Ammonia initial mass fraction

The energy requirement decreases for an initial

mass fraction of ammonia from 0.16 to 0.28, and

increases for higher mass fraction. This increase

might be explained by the appearance of a

precipitate in the CO2 rich stream according to the

equilibrium calculations.

The influence of the temperature of both the

lean and the CO2 rich stream on the energy

requirement has been studied. The equilibrium

calculations show a linear relationship between

those temperatures and the energy requirement,

with a slope of -42.6 kJ/(kg CO2 K) for the rich

stream and 39.6 kJ/(kg CO2 K) for the lean stream.

The CASTOR project that consists of a pilot

capture plant using aqueous alkanolamines

resulted in an energy consumption in the stripper

of about 3700 kJ/kg CO2 captured, with a capture

6000

0,50

2400

Figure 11: Energy requirement as a function of the

initial mass fraction of ammonia

7000

2500

0.

18

The desorption process actually uses more energy

than calculated as the fact that the efficiency of the

reboiler is not optimal is not taken into account in

this study. Then, different parameters were

modified individually in order to assess their

influence. Figure 7 shows the influence of the rich

CO2 loading on the energy requirement in the

desorber.

2600

0.

4

H CO2Lean + H Pure CO2 - H CO2Rich - H NH3/H2O condenser

ERdes =

Amount of CO2 in pure CO2stream * MW(CO2 )

2700

36

The energy requirement in the stripper is

calculated according to the following formula. It is

expressed in kJ/kg CO2 captured.

2800

0.

Energy Requirement (kJ/kg CO2

captured)

Figure 9: Flow sheet of the stripper

0.

25C

0.

34

0.67

0.

3

T H2 O +

NH3 from

condenser

0.

32

0.33

Rich

CO2

loading

0.

28

110C

Lean

CO2

loading

0.

26

80C

T

Pure

CO2

22

110C

T

CO2

Rich

0.

24

28

T

CO2

Lean

0.

2

NH3

init

wt%

Figure 10 shows that the energy requirement

gets very high for low CO2 loadings of the rich

stream. Thus it is necessary to ensure that the rich

loading is high in order to reduce the energy

consumption in the stripper. For the reference

configuration, i.e. for a rich loading of 0.67, the

energy requirement is about 2300 kJ/kg CO2

captured. The temperature approach is defined as

the difference between the temperature of the lean

and of the CO2 rich stream that leaves and enters

the desorber. It must be noticed that this

configuration is not optimized, especially

regarding the very high temperature difference in

the stripper (30C).

Figure 11 shows the influence of the initial

mass fraction of ammonia in the solvent on the

energy requirement in the stripper. The mass

fraction has been varied from 0.16 to 0.4.

0.

Table 3: Description of the stripper reference

configuration

0,83

Figure 10: Energy requirement as a function of the

loading of the CO2 rich stream

-7-

efficiency of 90%. [13] Hence, this study shows

that based on the equilibrium calculations, the use

of ammonia as a solvent is a way to very

significantly decrease this energy consumption in

the desorber. In addition, the configuration studied

here can be optimized to reduce the energy

requirement. This could be done by decreasing the

temperature approach in the desorber. Moreover,

as mentioned above, the CO2 stream that is

obtained at the end of the process is pressurized

when ammonia is used, which would result in

additional energy savings during compression of

the carbon dioxide. However, it must be noticed

that this study does not take into account the

additional energy required to lower the

temperature of both the flue gas and the CO2 lean

stream entering the absorber, or any other form of

increase of the energy consumption during the

process.

is pressurized. From an energetic point of view, a

reference configuration was used to assess the

energy requirement both in the absorber and in the

desorber. Based on equilibrium calculations and

assuming an efficiency of the reboiler of 100%,

this study showed that the chilled ammonia

process allows for a significant reduction of the

energy consumption in the desorber compared to

the energy consumption of the process using

aqueous alkanolamines.

Acknowledgement

The results of this study were obtained during

a 3-month study financed by DONG Energy and

Vattenfall followed by an industrial PhD with

DONG Energy. The authors want to thank Moritz

Kpcke for discussions, and the Danish ministry

of Science, Technology and Innovation for

financial support during the industrial PhD.

Summary and conclusion

Literature

The CO2 capture process using chilled

ammonia is a post combustion process that has

been patented in 2006. It consists of absorbing the

carbon dioxide from the flue gas of a power plant

at low temperature (0-20C) using ammonia as

solvent. The cooling of the flue gas is

accomplished by using Direct Contact Coolers. In

this temperature range precipitation occurs in the

absorber. The desorption is made at high

temperature (100-200C).

A software based on the extended UNIQUAC

model was used to describe the equilibrium of the

CO2-NH3-H2O system. This model is valid for

temperatures in the range 0-110C and for

molalities in the range 0-80mol/kg H2O. Thanks to

the indications from the patent, it was possible to

describe the composition of the different streams.

This study showed the presence of precipitates in

the absorber, and the formation of ammonium

bicarbonate from the ammonium carbonate present

in the CO2 lean stream. The equilibrium

calculation of the gas phase in the absorber shows

a high mole fraction of ammonia. Hence, some

cleaning subsystems at the top of the absorber

should be considered in order to avoid the

emission of ammonia. It was also shown that the

pure CO2 stream that leaves the desorber column

[1]

[2]

[3]

[4]

[5]

[6]

[7]

-8-

Keepling CD, Scripps Institution of

Oceanography, San Diego (2007)

IPCC, Special Report on Carbon dioxide

Capture and Storage (2006)

Denmarks 4th National Communication to

the United Nations Framework Convention

on Climate Change and Report on

Demonstrable Progress under the Kyoto

Protocol (2005)

Freguia S and Rochelle GT, Modeling of

CO2 capture by aqueous Monoethanolamine.

AIChE Journal 49: 1676-1686 (2003).

Reza J and Trejo A, Degradation of Aqueous

Solutions of Alkanolamine Blends at High

Temperature, under the Presence of CO2 and

H2S. Chemical engineering Communications

193: 129-138 (2006)

Lawal O, Bello A, Idem R, The role of

methyl

diethanolamine

(MDEA)

in

preventing the oxidative degradation of CO2

loaded

and

concentrated

aqueous

monoethanolamine (MEA)-MDEA blends

during CO2 absorption from flue gases.

Industrial & Engineering chemistry research

44: 1874-1896 (2005)

Gal E, Ultra cleaning combustion gas

including the removal of CO2, World

Intellectual

Property,

Patent

WO

2006022885 (2006)

[8]

[9]

[10]

[11]

[12]

[13]

Thomsen K, Rasmussen P, Modeling of

Vapor-liquid-solid equilibrium in gasaqueous electrolyte system. Department of

Chemical Engineering, IVC-SEP, Technical

University

of

Denmark,

Chemical

Engineering Science 54, 1787-1802 (1999)

Jnecke E, ber das System H2O, CO2 und

NH3. Zeitschrift fuer Elektrochemie, 39:

332-334 + 716-728 (1929)

Terres E and Weiser H, Beitrag zur Kenntnis

der Ammoniak-Kohlensureverbindungen

im Gleigewicht mit ihren wsserigen

Lsungen. Zeitschrift fuer Elektrochemie 27:

177-193 (1921)

Terres E and Behrens H, Zur Kenntnis des

physikalisch-chemischen Grundlagen der

Harnstoffsynthese

aus

Ammoniak,

Kohlensure und Wasser. Zeitschrift fuer

Physikalische Chemie 139: 693-716 (1928)

Guyer

A

and

Piechowicz

T,

Lsungsgleichgewichte

in

wssringen

Systemen. Das System CO2-NH3-H2O bei

20-50. Helvitica Chimica Acta 27: 858-867

(1944)

Knudsen JN, Vilhelmsen, Jensen JN, Biede O,

Castor SP2: Experiments on Pilot Plant,

CASTOR-ENCAP-CACHET-DYNAMIS

common Technical Training Workshop

22-24 January 2008

-9-

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Flow Measurement in Pipes and Ducts PDFDocument38 pagesFlow Measurement in Pipes and Ducts PDFAhmad AryNo ratings yet

- 11 Refrigeration CyclesDocument18 pages11 Refrigeration CyclesHussamNo ratings yet

- AC For Mechanical EngineeringDocument77 pagesAC For Mechanical EngineeringHasen Yunne ShemsiNo ratings yet

- Cryogenics EngineeringDocument174 pagesCryogenics EngineeringGomathi Sankar100% (1)

- A Systematic Study On Wetting Properties of Solids With Differnrent Chemistry and RoughnessDocument31 pagesA Systematic Study On Wetting Properties of Solids With Differnrent Chemistry and RoughnesssharonNo ratings yet

- Excess Air CalculationDocument11 pagesExcess Air CalculationKarthic Keyan50% (2)

- Atmospheric Crude FractionatorDocument3 pagesAtmospheric Crude Fractionatornedian_2006No ratings yet

- The Nalco Water HandbookDocument2 pagesThe Nalco Water Handbookarikraja40% (5)

- 2013 TSX MaintenanceDocument2 pages2013 TSX Maintenancenedian_2006No ratings yet

- Personalized Mortgage ReportDocument3 pagesPersonalized Mortgage Reportnedian_2006No ratings yet

- NoviesDocument1 pageNoviesnedian_2006No ratings yet

- Boiler Water Treatment External PDFDocument4 pagesBoiler Water Treatment External PDFnedian_2006No ratings yet

- Missing Shipment PDFDocument1 pageMissing Shipment PDFnedian_2006No ratings yet

- Chemical Compatibility ChartDocument52 pagesChemical Compatibility Chartusamamalik1989No ratings yet

- Dear Applicant,: For Appointment of Canadian Health Assessment, We Need For All Applicant ExactlyDocument1 pageDear Applicant,: For Appointment of Canadian Health Assessment, We Need For All Applicant Exactlynedian_2006No ratings yet

- Vaporizer MBDocument4 pagesVaporizer MBnedian_2006No ratings yet

- Ethical Theories and PrinciplesDocument22 pagesEthical Theories and Principlesnedian_2006No ratings yet

- Conditions of Nomination SIDocument2 pagesConditions of Nomination SInedian_2006No ratings yet

- A) Water Treatment Plant Operation Vol. I Seventh Edition-Csus B) Water Treatment Plant Operation Vol. II Sixth Edition - CsusDocument1 pageA) Water Treatment Plant Operation Vol. I Seventh Edition-Csus B) Water Treatment Plant Operation Vol. II Sixth Edition - Csusnedian_2006No ratings yet

- Swoop AirDocument95 pagesSwoop Airnedian_2006No ratings yet

- Job Posting PC FSJ 2017 V2Document2 pagesJob Posting PC FSJ 2017 V2nedian_2006No ratings yet

- RE: Vapour Pressure Specification Update #2Document9 pagesRE: Vapour Pressure Specification Update #2nedian_2006No ratings yet

- Tri P10Document10 pagesTri P10Dvd Davide La CruzNo ratings yet

- 02 K Charts - AE+SIDocument4 pages02 K Charts - AE+SInedian_2006No ratings yet

- CosstDocument23 pagesCosstnedian_2006No ratings yet

- #2Document11 pages#2nedian_2006No ratings yet

- CoostDocument737 pagesCoostnedian_2006No ratings yet

- RE: Vapour Pressure Specification Update #2Document9 pagesRE: Vapour Pressure Specification Update #2nedian_2006No ratings yet

- 2009Document8 pages2009nedian_2006No ratings yet

- #2Document11 pages#2nedian_2006No ratings yet

- ReadmeDocument1 pageReadmenedian_2006No ratings yet

- 3823 RetallackDocument14 pages3823 Retallacknedian_2006No ratings yet

- 11 7755 Bro Mbo FinalDocument3 pages11 7755 Bro Mbo Finalnedian_2006No ratings yet

- #3 PDFDocument8 pages#3 PDFnedian_2006No ratings yet

- Cleaningcalendar: Kindly Cross Mark You Name After You Done Your TurnDocument1 pageCleaningcalendar: Kindly Cross Mark You Name After You Done Your Turnnedian_2006No ratings yet

- FormulaDocument4 pagesFormulanedian_2006No ratings yet

- Viscosity Correction ChartDocument1 pageViscosity Correction ChartPítty Jonathan JaramilloNo ratings yet

- Intro Steady Flow Compressible Fluids EnglishDocument2 pagesIntro Steady Flow Compressible Fluids EnglishOda DemissieNo ratings yet

- Open Pan EvaporatorDocument5 pagesOpen Pan EvaporatorAshish Verma0% (3)

- Cosmoplast CPVC Pipes & Fittings: Description Size U. Price (DHS) CPVC Pipes According To ASTM F441 - SCH80Document3 pagesCosmoplast CPVC Pipes & Fittings: Description Size U. Price (DHS) CPVC Pipes According To ASTM F441 - SCH80Shaik Mohamed Haja MaideenNo ratings yet

- Experiment No. 5 1Document6 pagesExperiment No. 5 1JunNo ratings yet

- L.2.1 - Matter - Properties and ChangesDocument5 pagesL.2.1 - Matter - Properties and ChangesH DNo ratings yet

- Ae 223 Prelim Module No. 3Document14 pagesAe 223 Prelim Module No. 3Noel Gaddi Jr.0% (1)

- Nitrogen Phosphorus Detector TheoryDocument3 pagesNitrogen Phosphorus Detector TheoryVarun Kumar100% (1)

- Buoyancy and Archimedes Principle - 2023-3Document29 pagesBuoyancy and Archimedes Principle - 2023-3Jenny ZhangNo ratings yet

- JT Plants: PC LiquidsDocument2 pagesJT Plants: PC LiquidsJimenez ArgenisNo ratings yet

- Heat and Mass Transfer Process in Exhaust Wet ScrubberDocument5 pagesHeat and Mass Transfer Process in Exhaust Wet ScrubberGracylla RoseNo ratings yet

- Week 2 - Physical-ScienceDocument2 pagesWeek 2 - Physical-ScienceKayla TiquisNo ratings yet

- Pure Substances: Vapor-Liquid Critical PointDocument3 pagesPure Substances: Vapor-Liquid Critical PointNihad S ZainNo ratings yet

- Geology 446 Hydrology-Hydrogeology Part I of The Lecture Notes. Significance of Water.Document76 pagesGeology 446 Hydrology-Hydrogeology Part I of The Lecture Notes. Significance of Water.Harbinder SinghNo ratings yet

- Rota Meter Flow-MeasurementDocument18 pagesRota Meter Flow-MeasurementMudit BhatiaNo ratings yet

- Chapter 5. Introduction To Gas-Bearing, Aqueous Fluid InclusionsDocument59 pagesChapter 5. Introduction To Gas-Bearing, Aqueous Fluid InclusionsGosia CegiełkaNo ratings yet

- Applications of Thermodynamics To Flow Processes: Che 406 Chemical Engineering ThermodynamicsDocument24 pagesApplications of Thermodynamics To Flow Processes: Che 406 Chemical Engineering ThermodynamicsJAN JERICHO MENTOYNo ratings yet

- RefrigerationDocument163 pagesRefrigerationali105No ratings yet

- AGA Report No.3-2000 Part 2 - Orifice Metering of Natural Gas and Other Related Hydrocarbon FluidsDocument80 pagesAGA Report No.3-2000 Part 2 - Orifice Metering of Natural Gas and Other Related Hydrocarbon Fluidspras_fistek100% (1)

- Csmgem Example ProblemsDocument8 pagesCsmgem Example Problemsh0s0No ratings yet

- 978 1 4419 9979 5 - BookBackMatterDocument35 pages978 1 4419 9979 5 - BookBackMatterVivek AnandNo ratings yet

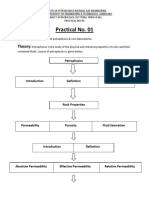

- Petrophysics (Lab Experiment 01)Document5 pagesPetrophysics (Lab Experiment 01)amaar siyalNo ratings yet

- Chapter Five: Centrifugal Compressors, Fans and BlowersDocument21 pagesChapter Five: Centrifugal Compressors, Fans and BlowerstemesgenNo ratings yet

- Solucionario Química Capitulo 12 - Whitten - 10 EdiciónDocument21 pagesSolucionario Química Capitulo 12 - Whitten - 10 EdiciónDanielNo ratings yet