Professional Documents

Culture Documents

Em5500cxs Manual

Uploaded by

Navoprest ConstantaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Em5500cxs Manual

Uploaded by

Navoprest ConstantaCopyright:

Available Formats

06/03/17 11:58:36 32Z21600_006

CONTENTS

1. SAFETY INSTRUCTIONS ................................................................... 3

2. SAFETY LABEL LOCATIONS ............................................................. 5

CE mark and noise label location...................................................... 6

3. COMPONENT IDENTIFICATION........................................................ 7

4. PRE-OPERATION CHECK ................................................................. 11

5. STARTING THE ENGINE .................................................................. 15

High altitude operation

6. GENERATOR USE ............................................................................ 27

7. STOPPING THE ENGINE .................................................................. 33

8. MAINTENANCE ................................................................................ 35

9. TRANSPORTING/STORAGE............................................................ 42

10. TROUBLESHOOTING....................................................................... 44

11. SPECIFICATIONS.............................................................................. 47

12. INSTALLATION OF KIT PARTS ....................................................... 53

13. WIRING DIAGRAM ........................................................................... 60

14. MAJOR Honda DISTRIBUTOR ADDRESSES ................................. 65

06/03/17 11:58:23 32Z21600_003

Honda EM3100CXEM4500CXEM5500CX

EM4500CXSEM5500CXS

OWNERS MANUAL

Thee-SPECmark symbolizes environmentally

responsible technologies applied to Honda power

equipment, which contains our wish to preserve

nature for generations to come.

06/03/17 11:58:33 32Z21600_005

Thank you for purchasing a Honda generator.

This manual covers operation and maintenance of the EM3100CX

EM4500CXEM5500CXEM4500CXSEM5500CXS generators.

All information in this publication is based on the latest product

information available at the time of approval for printing.

Honda Motor Co., Ltd. reserves the right to make changes at any time

without notice and without incurring any obligation.

No part of this publication may be reproduced without written

permission.

This manual should be considered a permanent part of the generator

and should remain with it if it is resold.

Pay special attention to statements preceded by the following words:

Indicates a strong possibility of severe personal injury or

death if instructions are not followed.

Indicates a possibility of personal injury or equipment

damage if instructions are not followed.

Gives helpful information.

If a problem should arise, or if you have any questions about the

generator, consult an authorized Honda dealer.

Honda generator is designed to give safe and dependable service if

operated according to instructions. Read and understand the Owners

Manual before operating the generator. Failure to do so could result

in personal injury or equipment damage.

The illustration may vary according to the type.

06/03/17 11:58:43 32Z21600_007

1. SAFETY INSTRUCTIONS

To ensure safe operation

Honda generator is designed to give safe and

dependable service if operated according to

instructions.

Read and understand the Owners Manual

before operating the generator. Failure to do

so could result in personal injury or equipment

damage.

Exhaust gas contains poisonous carbon

monoxide. Never run the generator in an

enclosed area. Be sure to provide adequate

ventilation.

When installed inside, adequate ventilation

should be provided.

The muffler becomes very hot during

operation and remains hot for a while after

stopping the engine.

Be careful not to touch the muffler while it is

hot. Let the engine cool before storing the

generator indoors.

The engine exhaust system will be heated

during operation and remain hot immediately

after stopping the engine.

To prevent scalding, pay attention to the

warning marks attached to the generator.

06/03/17 11:58:55 32Z21600_008

To ensure safe operation

Gasoline is extremely flammable and

explosive under certain conditions.

Refuel in a well ventilated area with

the engine stopped.

Keep away from cigarette, smoke and

sparks when refueling the generator.

Always refuel in a well-ventilated

location.

Wipe up spilled gasoline at once.

Connections for standby power to a buildings

electrical system must be made by a qualified

electrician and must comply with all applicable laws

and electrical codes. Improper connections can allow

electrical current from the generator to back feed into

the utility lines. Such back feed may electrocute utility

company workers or others who contact the lines

during a power outage, and when utility power is

restored, the generator may explode, burn, or cause

fires in the buildings electrical system.

Always make a pre-operation inspection (page 11 ) before you start

the engine. You may prevent an accident or equipment damage.

Place the generator at least 1 m (3 ft) away from buildings or other

equipment during operation.

Operate the generator on a level surface.

If the generator is tilted, fuel spillage may result.

Know how to stop the generator quickly and understand operation

of all the controls. Never permit anyone to operate the generator

without proper instructions.

Keep children and pets away from the generator when it is in

operation.

Keep away from rotating parts while the generator is running.

The generator is a potential source of electrical shocks when

misused; do not operate with wet hands.

Do not operate the generator in rain or snow and do not let it get

wet.

06/03/17 11:59:05 32Z21600_009

2. SAFETY LABEL LOCATIONS

These labels warn you of potential hazards that can cause serious

injury. Read the labels and safety notes and precautions described in

this manual carefully.

If a label comes off or becomes hard to read, contact your Honda

dealer for a replacement.

READ OWNERS MANUAL

CONNECT CAUTION

FUEL CAUTION

EXHAUST CAUTION

HOT CAUTION

06/03/17 11:59:11 32Z21600_010

CE mark and noise label locations

NOISE LABEL

[Example:EM4500CX/CXS]

CE MARK

Manufacturer and address

Maximum

ambient temperature

Performance class

IP code

[Example:EM4500CXSB]

Maximum

altitude

Dry weight

06/03/17 11:59:18 32Z21600_011

3. COMPONENT IDENTIFICATION

ENGINE SWITCH

CONTROL PANEL

CHOKE ROD

AIR CLEANER

FUEL VALVE LEVER

OIL FILLER CAP

RECOIL STARTER GRIP

FUSE

ENGINE SERIAL NUMBER

OIL DRAIN BOLT

FUEL TANK CAP

FUEL GAUGE

SPARK PLUG CAP

FRAME SERIAL NUMBER

MUFFLER

Record the frame serial number and the engine serial number in the

space below. You will need these numbers when ordering parts.

Frame serial number:

Engine serial number:

06/03/17 11:59:23 32Z21600_012

CONTROL PANEL (B type)

EM3100CX

VOLTAGE SELECTOR SWITCH

CIRCUIT BREAKER

DC CIRCUIT PROTECTOR

ENGINE SWITCH

230 V RECEPTACLE

115 V RECEPTACLE

GROUND TERMINAL

DC OUTPUT TERMINAL

EM4500CXEM5500CX

EM4500CXSEM5500CXS

(CX type)

AUTO THROTTLE SWITCH

(CXS type)

VOLTAGE SELECTOR SWITCH

DC CIRCUIT PROTECTOR

230 V RECEPTACLE

ENGINE SWITCH

115 V RECEPTACLE

GROUND TERMINAL

CIRCUIT BREAKER

DC OUTPUT TERMINAL

06/03/17 11:59:28 32Z21600_013

(F, G, GW types)

EM3100CXEM4500CXEM5500CX

230 V RECEPTACLE

VOLT METER

DC CIRCUIT PROTECTOR

ENGINE SWITCH

GROUND TERMINAL

CIRCUIT BREAKER

DC OUTPUT TERMINAL

EM4500CXSEM5500CXS

CIRCUIT BREAKER

VOLT METER

DC CIRCUIT PROTECTOR

230 V RECEPTACLE

GROUND TERMINAL

AUTO THROTTLE SWITCH

ENGINE SWITCH

DC OUTPUT TERMINAL

06/03/17 11:59:33 32Z21600_014

Auto Throttle System (CXS Type)

The auto throttle system automatically reduces engine speed when all

loads are turned off or disconnected. When appliances are turned on

or reconnected, the engine returns to the rated speed.

ON:

Recommended to minimize fuel consumption and further

reduce noise levels when no load is applied to the generator.

OFF: The auto throttle system does not operate.

Recommended to minimize warm-up time when the generator

is started.

Leave the switch in the OFF position when using appliances that

require only momentary power, that have a power demand of

less than 1 ampere, or that have large startup power demands.

AUTO THROTTLE SWITCH

OFF

ON

OFF

ON

10

06/03/17 11:59:43 32Z21600_015

4. PRE-OPERATION CHECK

Be sure to check the generator on a level surface with the engine

stopped.

1. Check the engine oil level.

Engine oil is a major factor affecting engine performance and service

life. Non-detergent oil and 2-stroke engine oil are not recommended.

Use 4-stroke motor oil that meets or exceeds the requirements for API

service classification SG, SF. Always check the API SERVICE label on

the oil container to be sure it includes the letter SG, SF.

SAE Viscosity Grades

AMBIENT TEMPERATURE

SAE 10W-30 is recommended for general, all-temperature use. Other

viscosities shown, in the chart may be used when the average

temperature in your area is within the indicated range.

1. Remove the oil filler cap and wipe the dipstick clean.

2. Check the oil level by inserting the dipstick in the filler hole without

screwing it in.

3. If the level is low, fill to the upper limit of the oil filler neck with the

recommended oil.

Running the engine with insufficient oil can cause serious engine

damage.

The Oil Alert System will automatically stop the engine before the oil

level falls below the safe limit. However, to avoid the inconvenience of

an unexpected shutdown, it is still advisable to visually inspect the oil

level regularly.

OIL FILLER HOLE

OIL FILLER CAP

UPPER LIMIT

DIPSTICK

11

06/03/17 11:59:50 32Z21600_016

2. Check the fuel level.

Use automotive unleaded gasoline with a Research Octane Number of

91 or higher (a Pump Octane Number of 86 or higher).

Never use stale or contaminated gasoline or an oil/gasoline mixture.

Avoid getting dirt or water in the fuel tank.

Gasoline is extremely flammable and is explosive under certain

conditions.

Refuel in a well-ventilated area with the engine stopped. Do not

smoke or allow flames or sparks in the area where the engine is

refueled or where gasoline is stored.

Do not overfill the fuel tank (there should be no fuel in the filler

neck). After refueling, make sure the tank cap is closed properly and

securely.

Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor

may ignite. If any fuel is spilled, make sure the area is dry before

starting the engine.

Avoid repeated or prolonged contact with skin or breathing of

vapor.

KEEP OUT OF REACH OF CHILDREN.

FUEL GAUGE

FULL

EMPTY

12

FUEL FILTER

MAXIMUM

FUEL LEVEL

06/03/17 12:00:00 32Z21600_017

Gasoline spoils very quicklr depending on factors such as light

exposure, temperature and time.

In worst cases, gasoline can be contaminated within 1 month.

Using contaminated gasoline can seriously damage the engine

(caburetor clogged, valve stuck).

Such damage due to spoiled fuel is disallowed from coverage by the

warrantry.

To avoid this please strictly follow these recommendations:

Only use specified gasoline.

To slow deterioration, keep gasoline in a certified fuel container.

If long storage (more than 1 month) is foreseen, drain fuel tank and

carburetor (page 43 ).

Gasolines containing alcohol

If you decide to use a gasoline containing alcohol (gasohol), be sure its

octane rating is at least as high as that recommended by Honda. There

are two types of gasohol: one containing ethanol, and the other

containing methanol.

Do not use gasohol that contains more than 10% ethanol. Do not use

gasoline containing methanol (methyl or wood alcohol) that does not

also contain cosolvents and corrosion inhibitors for methanol. Never

use gasoline containing more than 5% methanol, even if it has

cosolvents and corrosion inhibitors.

Fuel system damage or engine performance problems resulting

from the use of fuels that contain alcohol is not covered under the

warranty.

Honda cannot endorse the use of fuels containing methanol since

evidence of their suitability is as yet incomplete.

Before buying fuel from an unfamiliar station, try to find out if the

fuel contains alcohol, if it does, confirm the type and percentage of

alcohol used.

If you notice any undersirable operating symptoms while using a

gasoline that contains alcohol, or one that you think contains

alcohol, switch to a gasoline that you know does not contain alcohol.

13

06/03/17 12:00:05 32Z21600_018

3. Check the air cleaner.

Unsnap the air cleaner cover clips, remove the air cleaner cover, and

check the element.

Check the air cleaner elements to be sure they are clean and in good

condition.

Clean or replace the element if necessary. (see page 37 ).

Never run the engine without the air cleaner element. Rapid engine

wear will result from contaminants, such as dust and dirt, being

drawn through the carburetor, into the engine.

CLIP

ELEMENT

AIR CLEANER COVER

14

06/03/17 12:00:09 32Z21600_019

5. STARTING THE ENGINE

Make sure that the circuit breaker is OFF.

The generator may be hard to start if a load is connected.

OFF

OFF

CIRCUIT BREAKER

15

06/03/17 12:00:15 32Z21600_020

Electric starting (CXS type)

When starting the generator after adding fuel for the first time, after

long-term storage, or after running out of fuel, turn the fuel valve

lever to the ON position, then wait for 10 to 20 seconds before

starting the engine.

1. B type:

Set the Voltage Selector Switch to match the voltage requirements

for the application.

VOLTAGE SELECTOR SWITCH

230 V

115 V

2. Turn the fuel valve lever to the ON position.

OFF

ON

16

FUEL VALVE LEVER

06/03/17 16:55:42 32Z21600_021

3. Make sure the auto throttle switch is in the OFF position, or more

time will be required for warm up.

(F, G, GW types)

AUTO THROTTLE SWITCH

OFF

OFF

(B type)

AUTO THROTTLE SWITCH

OFF

OFF

17

06/03/17 12:00:24 32Z21600_022

4. Turn the engine switch to the START position and hold it there for 5

seconds or until the engine starts.

After the engine starts, let the engine switch return to the ON

position.

ON

START

ON

START

ENGINE SWITCH

Do not use the electric starter for more than 5 seconds at a time. If the

engine fails to start, release the switch and wait 10 seconds before

operating the starter again.

When the speed of the starter motor drops after a period of time, it is

an indication that the battery should be recharged.

18

06/03/17 16:55:48 32Z21600_023

5. If you wish to use the auto throttle system, turn the auto throttle

switch to the ON position after the engine has warmed up for 2 or 3

minutes.

(F, G, GW types)

AUTO THROTTLE SWITCH

ON

ON

(B type)

AUTO THROTTLE SWITCH

ON

ON

19

06/03/17 12:00:33 32Z21600_024

Manual starting

When starting the generator after adding fuel for the first time, after

long-term storage, or after running out of fuel, turn the fuel valve

lever to the ON position, then wait for 10 to 20 seconds before

starting the engine.

1. B type:

Set the Voltage Selector Switch to match the voltage requirements

for the application.

VOLTAGE SELECTOR SWITCH

230 V

115 V

2. Turn the fuel valve lever to the ON position.

OFF

ON

20

FUEL VALVE LEVER

06/03/17 12:00:38 32Z21600_025

3. CX type:

Pull the choke rod to the CLOSED position to start a cold engine.

Push the choke rod in the OPEN position to start a warm engine.

CXS type:

The auto choke will be closed if the engine is cold. If you want to

operate the choke manually, pull the choke rod out to the CLOSED

position.

OPEN

CLOSED

CLOSED

CHOKE ROD

21

06/03/17 16:55:53 32Z21600_026

4. CXS type:

Make sure the auto throttle switch is in the OFF position, or more

time will be required for warm up.

(F, G, GW types)

AUTO THROTTLE SWITCH

OFF

OFF

(B type)

AUTO THROTTLE SWITCH

OFF

OFF

22

06/03/17 12:00:46 32Z21600_027

5. Turn the engine switch to the ON position.

(CX type)

ENGINE SWITCH

ON

OFF

ON

OFF

(CXS type)

ON

OFF

ON

OFF

ENGINE SWITCH

23

06/03/17 12:00:52 32Z21600_028

6. Pull the starter grip lightly until you feel resistance, then pull the

starter grip briskly toward the arrow as shown below.

Do not allow the starter grip to snap back. Return it slowly by hand.

Do not let the starter rope rub against the generator body or the

rope will wear out prematurely.

RECOIL STARTER GRIP

7. Push the choke rod to the OPEN position as the engine warms up.

OPEN

CHOKE ROD

24

06/03/17 16:55:58 32Z21600_029

8. CXS type:

If you wish to use the auto throttle system, turn the auto throttle

switch to the ON position after the engine has warmed up for 2 or 3

minutes.

(F, G, GW types)

AUTO THROTTLE SWITCH

ON

ON

(B type)

AUTO THROTTLE SWITCH

ON

ON

25

06/03/17 12:01:00 32Z21600_030

High altitude operation

At high altitude, the standard carburetor air-fuel mixture will be

excessively rich. Performance will decrease, and fuel consumption will

increase.

High altitude performance can be improved by specific modifications

to the carburetor. If you always operate the generator at altitudes

higher than 1,500-meter (5,000 feet) above sea level, have your

authorized Honda dealer perform these carburetor modifications.

Even with suitable carburetor jetting, engine horsepower will decrease

approximately 3.5% for each 300-meter (1,000-foot) increase in altitude.

The affect of altitude on the horse power will be greater than this if no

carburetor modification is made.

Operation of the generator at an altitude lower than the carburetor is

jetted for may result in reduced performance, overheating, and

serious engine damage caused by an excessively lean air/fuel mixture.

26

06/03/17 12:01:10 32Z21600_031

6. GENERATOR USE

Be sure to ground the generator when the connected equipment is

grounded.

Connections for standby power to a buildings electrical system must

be made by a qualified electrician and must comply with all applicable

laws and electrical codes. Improper connections can allow electrical

current from the generator to backfeed into the utility lines. Such

backfeed may electrocute utility company workers or others who

contact the lines during a power outage, and when utility power is

restored, the generator may explode, burn, or cause fires in the

buildings electrical system.

Limit operation requiring maximum power (see pages 47 51 ) to

30 minutes.

For continuous operation, do not exceed the rated power (see

pages 47 51 ).

In either case, the total wattage of all appliances connected must be

considered.

Most appliance motors require more than their rated wattage for

startup.

Do not exceed the current limit specified for any one receptacle.

Do not connect the generator to a household circuit. This could

cause the damage to the generator or to electrical appliances in the

house.

Do not modify or use the generator for other purposes than it is

intended for. Also observe the following when using the generator.

Do not connect an extension to the exhaust pipe.

When an extension cable is required, be sure to use a tough rubber

sheathed flexible cable (IEC 245 or equivalent).

Limit length of extension cables; 60 m for cables of 1.5 mm and 100

m for cables of 2.5 mm . Long extension cables will lower usable

power due to resistance in the extension cable.

Keep the generator away from other electric cables or wires such as

commercial power supply lines.

27

06/03/17 12:01:19 32Z21600_032

AC Applications (B type)

Before connecting an appliance or power cord to the generator:

Make sure that it is in good working order. Faulty appliances or

power cords can create a potential for electrical shock.

If an appliance begins to operate abnormally, becomes sluggish or

stops suddenly, turn it off immediately. Disconnect the appliance,

and determine whether the problem is the appliance, or if the rated

load capacity of the generator has been exceeded.

Make sure that the electrical rating of the tool or appliance does not

exceed that of the generator. Never exceed the maximum power

rating of the generator. Power levels between rated and maximum

may be used for no more than 30 minutes.

Substantial overloading will open the main breaker. Exceeding the

time limit for maximum power operation or slightly overloading the

generator may not switch the main breaker or DC circuit protector OFF,

but will shorten the service life of the generator.

Limit operation requiring maximum power to 30 minutes.

Maximum power is:

EM3100CX: 3,100 VA

EM4500CX4500CXS: 4,500 VA

EM5500CX5500CXS: 5,500 VA

For continuous operation (longer than 30 minutes), do not exceed the

rated power.

Rated power is:

EM3100CX: 2,800 VA

EM4500CX4500CXS: 4,000 VA

EM5500CX5500CXS: 5,000 VA

The total power requirements (VA) of all appliances connected must

be considered. Appliance and power tool manufacturers usually list

rating information near the model number or serial number.

Be sure that all appliances are in good working order before

connecting them to the generator. If an appliance begins to operate

abnormally, becomes sluggish, or stops suddenly, turn off the

generator engine switch immediately. Then disconnect the appliance,

and examine it for signs of malfunction.

28

06/03/17 12:01:25 32Z21600_033

1. Set the Voltage Selector Switch to match the voltage requirements

for the appliance.

2. Start the engine (see page 15 ).

3. Switch the circuit breaker ON.

4. Plug in the appliance.

Most motorized appliances require more than their rated power for

startup.

VOLTAGE SELECTOR SWITCH

CIRCUIT BREAKER

29

06/03/17 12:01:32 32Z21600_034

DC Application

The DC output terminals may ONLY be used for charging 12 volt

automotive type batteries.

1. Connect the positive () battery cable to the generator positive ()

terminal.

2. Connect the other end of the positive () battery cable to the battery

positive () terminal.

DC CIRCUIT

PROTECTOR

POSITIVE TERMINAL

(RED)

NEGATIVE TERMINAL

(BLACK)

3. Connect the negative ( ) battery cable to the generator negative

() terminal.

4. Connect the other end of the negative () battery cable to the

battery negative () terminal.

5. Start the engine (see page 15 ).

To prevent the possibility of creating a spark near the battery,

connect charging cable first to the generator, then to the battery.

Disconnect cable first at the battery.

Before connecting charging cable to a battery that is installed in a

vehicle, disconnect the vehicles grounded battery cable. Reconnect

the vehicles grounded battery cable after the charging cables are

removed. This procedure will prevent the possibility of a short

circuit and sparks if you make accidental contact between a battery

terminal and the vehicles frame or body.

Do not attempt to start an automobile engine with the generator

still connected to the battery. The generator may be damaged.

Connect the positive battery terminal to the positive charging cord.

Do not reverse the charging cables, or serious damage to the

generator and/or battery may occur.

30

06/03/17 12:01:42 32Z21600_035

Batteries produce explosive gases: If ignited, and explosion can

cause serious injury or blindness. Provide adequate ventilation

when charging.

CHEMICAL HAZARD: Battery electrolyte contains sulfuric acid.

Contact with eyes or skin, even through clothing, may cause severe

burns. Wear a faceshield and protective clothing.

Keep flames and sparks away, and do not smoke in the area.

ANTIDOTE: If electrolyte gets into your eyes, flush thoroughly with

warm water for at least 15 minutes and call a physician

immediately.

POISON: Electrolyte is poison.

ANTIDOTE

External: Flush thoroughly with water.

Internal: Drink large quantities of water or milk.

Follow with milk of magnesia or vegetable oil, and call a

physician immediately.

KEEP OUT OF REACH OF CHILDREN.

The DC terminal may be used while the AC power is in use.

An overloaded DC circuit will trip the DC circuit protector (the yellow

indicator inside the clear circuit protector button will pop out).

If this happens, wait a few minutes before pushing in the circuit

protector to resume operation.

DC CIRCUIT

PROTECTOR

ON

NEGATIVE TERMINAL

(BLACK)

OFF

POSITIVE TERMINAL

(RED)

31

06/03/17 12:01:46 32Z21600_036

Oil Alert System

The Oil Alert system is designed to prevent engine damage caused by

an insufficient amount of oil in the crankcase. Before the oil level in the

crankcase falls below a safe limit, the Oil Alert system will

automatically shut down the engine (the engine switch will remain in

the ON position).

If the engine stops and will not restart, check the engine oil level (see

page 11 ) before troubleshooting in other areas.

32

06/03/17 12:01:53 32Z21600_037

7. STOPPING THE ENGINE

Stopping the Engine

To stop the engine in an emergency, turn the engine switch to the OFF

position.

1. Turn the circuit breaker to the OFF position.

CIRCUIT BREAKER

ON

OFF

OFF

2. Turn the engine switch to the OFF position.

(CX type)

(CXS type)

OFF

ON

ON

ON

OFF

ON

OFF

OFF

ENGINE SWITCH

33

06/03/17 12:01:57 32Z21600_038

3. Turn the fuel valve lever to the OFF position.

FUEL VALVE LEVER

OFF

ON

34

06/03/17 12:02:08 32Z21600_039

8. MAINTENANCE

The purpose of the maintenance and adjustment schedule is to keep

the generator in the best operating condition.

Inspect or service as scheduled in the table below.

Shut off the engine before performing any maintenance. If the engine

must be run, make sure the area is well ventilated. The exhaust

contains poisonous carbon monoxide gas.

Use genuine Honda parts or their equivalent. The use of replacement

parts which are not of equivalent quality may damage the generator.

Maintenance Schedule

REGULAR SERVICE PERIOD (3)

Performed at every indicated

month or operating hour interval,

whichever comes first.

ITEM

Check Level

Engine oil

Change

Check

Air filter

Clean

Clean

Sediment cup

Check-adjust

Spark plug

Replace

Check-adjust

Valve clearance

Clean

Combustion

chamber

Clean

Fuel tank and filter

Check

Fuel tube

Each use

First

month

or

20 Hrs.

Every

Every

Every

year

3 months 6 months

or

or

or

50 Hrs. 100 Hrs. 300 Hrs.

(1)

(2)

After every 500 Hrs. (2)

(2)

Every 2 years (Replace if necessary) (2)

(1) Service more frequently when used in dusty areas.

(2) These items should be serviced by your servicing dealer, unless you have the proper tools

and are mechanically proficient. Refer to Honda shop manual for service procedures.

(3) For commercial use, log hours of operation to determine proper maintenance intervals.

35

06/03/17 12:02:15 32Z21600_040

1. CHANGING OIL

Drain the oil while the engine is still warm to assure rapid and

complete draining.

1. Remove the drain bolt and sealing washer, remove the oil filler cap,

and drain the oil.

2. Reinstall the drain bolt and sealing washer. Tighten the bolt securely.

3. Refill with the recommended oil (see page 11 ) and check the oil level.

Oil capacity: 1.10 (1.16 US qt , 0.97 Imp qt)

SEALING WASHER

UPPER LIMIT

OIL DRAIN BOLT

OIL FILLER CAP

Wash your hands with soap and water after handling used oil.

Please dispose of used motor oil in a manner that is compatible with

the environment. We suggest you take it in a sealed container to your

local service station for reclamation. Do not throw it in the trash or

pour it on the ground.

36

06/03/17 12:02:26 32Z21600_041

2. AIR CLEANER SERVICE

A dirty air cleaner will restrict air flow to the carburetor. To prevent

carburetor malfunction, service the air cleaner regularly. Service more

frequently when operating the generator in extremely dusty areas.

Do not use gasoline or low flash point solvents for cleaning. They are

flammable and explosive under certain conditions.

Never run the engine without the air cleaner element. Rapid engine

wear will result from contaminants, such as dust and dirt, being

drawn through the carburetor, into the engine.

1. Unsnap the air cleaner cover clips, remove the air cleaner cover, and

remove the element.

CLIP

ELEMENT

AIR CLEANER COVER

ELEMENT

2. Wash the air cleaner element in a solution of household detergent

and warm water, then rinse thoroughly, or wash in nonflammable or

high flashpoint solvent. Allow the air cleaner element to dry

thoroughly.

3. Soak the air cleaner element in clean engine oil and squeeze out the

excess oil. The engine will smoke during initial startup if too much

oil is left in the air cleaner element.

4. Reinstall the air cleaner element and the cover.

pr op er ly

hooked

improperly

hooked

CLIP

ELEMENT

AIR CLEANER COVER

37

06/03/17 12:02:34 32Z21600_042

3. FUEL SEDIMENT CUP SERVICE

Gasoline is extremely flammable and is explosive under certain

conditions. Do not smoke or allow flames or sparks in the area.

The sediment cup prevents dirt or water which may be in the fuel tank

from entering the carburetor. If the engine has not been run for a long

time, the sediment cup should be cleaned.

1. Turn the fuel valve lever to the OFF position. Remove the sediment

cup, O-ring, and filter.

2. Clean the sediment cup and filter in nonflammable or high flash

point solvent.

3. Reinstall the filter, O-ring, and sediment cup.

4. Turn the fuel valve lever to the ON position and check for leaks.

After installing the sediment cup, be sure to tighten it securely. Check

for fuel leaks and make sure the area is dry before starting the engine.

FUEL VALVE LEVER

OFF

FILTER

O-RING

SEDIMENT CUP

38

06/03/17 12:02:44 32Z21600_043

4. SPARK PLUG SERVICE

Recommended spark plugs: BPR5ES (NGK)

W16EPR-U (DENSO)

To ensure proper engine operation, the spark plug must be properly

gapped and free of deposits.

If the engine has been running, the muffler will be very hot. Be careful

not to touch the muffler.

1. Remove the spark plug cap.

2. Clean any dirt from around the spark plug base.

3. Use a spark plug wrench to remove the spark plug.

SPARK PLUG WRENCH

SPARK PLUG CAP

SIDE ELECTRODE

4. Visually inspect the spark plug.

Discard it if the insulator is

cracked, chipped or fouled.

5. Measure the plug gap with a

feeler gauge.

Correct as necessary by carefully

bending the side electrode.

The gap should be:

0.700.80 mm (0.0280.031 in)

0.700.80 mm

(0.0280.031 in)

SEALING WASHER

39

06/03/17 12:02:48 32Z21600_044

6. Make sure that the sealing washer is in good condition, and thread

the spark plug in by hand to prevent cross-threading.

7. After the spark plug is seated, tighten with a spark plug wrench to

compress the washer.

If installing a new spark plug, tighten 1/2 turn after the spark plug seats

to compress the washer. If reinstalling a used spark plug, tighten 1/8 to

1/4 turn after the spark plug seats.

The spark plug must be securely tightened. An improperly

tightened plug can become very hot and possibly damage the

generator.

Never use a spark plug with an improper heat range.

40

06/03/17 12:02:54 32Z21600_045

5. FUSE REPLACEMENT

(CXS type)

If the fuse is blown, the starter motor will not work until it is replaced.

1. Turn the engine switch to the OFF position.

2. Remove the fuse holder cover and replace the fuse.

The specified fuse is 10A.

FUSE HOLDER

If frequent fuse failure occurs, determine the cause and correct the

problem before attempting to operate the generator further.

Never use a fuse with a different rating from that specified. Serious

damage to the electrical system or fire may result.

41

06/03/17 12:03:01 32Z21600_046

9. TRANSPORTING/STORAGE

When transporting the generator:

Do not overfill the tank.

Do not operate the generator while it is on a vehicle. Take the

generator off the vehicle and use it in a well ventilated place.

Avoid a place exposed to direct sunlight when putting the

generator on a vehicle. If the generator is left in an enclosed

vehicle for many hours, high temperature inside the vehicle could

cause fuel to vaporize resulting in a possible explosion.

Do not drive on a rough road for an extended period with the

generator on board. If you must transport the generator on a

rough road, drain the fuel from the generator beforehand.

Take care not to drop or strike the generator when transporting.

Do not place heavy object on the generator.

When transporting the generator by loading it on to a vehicle, secure

to the generator frame as shown.

42

06/03/17 12:03:07 32Z21600_047

Storage

1. Drain the carburetor by losening the drain screw. Drain the gasoline

into a suitable container.

Gasoline is extremely flammable and is explosive under certain

conditions. Perform this task in a well ventilated area with the engine

stopped. Do not smoke or allow flames or sparks in the area during

this procedure.

DRAIN SCREW

2. Change the engine oil (refer to page 36 ).

3. Remove the spark plug, and pour about a tablespoon of clean

engine oil into the cylinder. Turn the engine several revolutions

slowly with the recoil starter to distribute the oil, then reinstall the

spark plug.

4. Slowly pull the starter grip until resistance is felt. At this point, the

piston is coming up on its compression stroke and both the intake

and exhaust valves are closed. Storing the engine in this position

will help to protect it from internal corrosion.

Align the notch on the starter pulley

with the hole at the top of recoil starter.

43

06/03/17 12:03:18 32Z21600_048

10. TROUBLESHOOTING

When the engine will not start:

Is there fuel in

the tank?

NO

Refill the fuel

tank.

NO

Add the

recommended

oil.

YES

Is there enough

oil in the engine?

YES

Is the spark plug

in good

condition?

NO

Readjust gap

and dry the

spark plug.

Replace it if

necessary.

YES

Is the fuel

reaching the

carburetor?

YES

If the engine still

does not start,

take the

generator to an

authorized

Honda dealer.

44

NO

Clean the fuel

sediment cup.

To check:

1) Turn off the engine switch and loosen the

drain screw (see page 43 ).

2) Turn the fuel valve to ON. Fuel should flow

from the drain when the fuel valve is

turned ON.

06/03/17 12:03:23 32Z21600_049

[CXS Type]

Starter motor does not turn round;

The fuse is blown.

YES

Replace the fuse.

(See page 41 )

NO

Battery is discharge.

YES

Charge a battery.

NO

If the starter motor

still does not turn

round, take the

generator to an

autorized Honda

dealer.

45

06/03/17 12:03:28 32Z21600_050

No electricity at the AC receptacles:

Is the circuit

breaker ON?

NO

Turn the circuit

breaker ON.

YES

Check the electrical

appliance or

equipment for any

defects.

NO DEFECTS

DEFECTS

46

Take the generator

to an authorized

Honda generator

dealer.

Replace the

electrical

appliance or

equipment.

Take the

electrical

appliance or

equipment to an

electrical shop

for repair.

06/03/17 12:03:44 32Z21600_051

11. SPECIFICATIONS

Dimensions and Weight

Model

Description code

Length

Width

Height

Dry weight

EM3100CX

EARC

680 mm (26.8 in)

530 mm (20.9 in)

545 mm (21.5 in)

73.0 kg (160.9 lbs)

Engine

Model

Engine type

Displacement

Bore Stroke

Compression ratio

Engine speed

Cooling system

Ignition system

Oil capacity

Fuel tank capacity

Spark plug

GX240K1

4-stroke, overhead valve, single cylinder

243 cm (14.8 cu-in)

73 58 mm (2.9 in 2.3 in)

8.2:1

3,000 rpm

Forced air

Transistorized magneto

1.10 (1.16 US qt , 0.97 Imp qt)

25 (6.6 US gal , 5.5 Imp gal)

BPR5ES (NGK)

W16EPR-U (DENSO)

Generator

AC

output

Model

Type

Rated Voltage (V)

Rated Frequency (Hz)

Rated Ampere (A)

Rated Output (kVA)

Max. Output (kVA)

DC rated output

EM3100CX

B

115/230

F, G, GW

230

50

24.3/12.2

12.2

2.8

3.1

Only for charging 12 V

automotive batteries.

12 V, 8 A

47

06/03/17 12:03:49 32Z21600_052

Noise

Model

Type

Sound pressure level (LpA)

According to 98/37/EC

EM3100CX

B, F, G, GW

78 dB

Microphone point

CONTROL

PANEL

Center

1.60 m

1.0 m

Guaranteed sound power level

(LWA) Tested by 2000/14/EC

96 dB

Specifications are subject to change without notice.

48

06/03/17 12:04:06 32Z21600_053

Dimensions and Weight

Model

Description code

Length

Width

Height

Dry weight

EM4500CX

EASC

680 mm (26.8 in)

530 mm (20.9 in)

545 mm (21.5 in)

86.0 kg (189.6 lbs)

EM4500CXS

EATC

880 mm (34.6 in)

530 mm (20.9 in)

545 mm (21.5 in)

94.0 kg (207.2 lbs)

Engine

Model

Engine type

Displacement

Bore Stroke

Compression ratio

Engine speed

Cooling system

Ignition system

Oil capacity

Fuel tank capacity

Spark plug

GX340K1

4-stroke, overhead valve, single cylinder

338 cm (20.6 cu-in)

82 64 mm (3.2 in 2.5 in)

8.0:1

3,000 rpm

Forced air

Transistorized magneto

1.10 (1.16 US qt , 0.97 Imp qt)

25 (6.6 US gal , 5.5 Imp gal)

BPR5ES (NGK)

W16EPR-U (DENSO)

Generator

AC

output

Model

Type

Rated Voltage (V)

Rated Frequency (Hz)

Rated Ampere (A)

Rated Output (kVA)

Max. Output (kVA)

DC rated output

EM4500CXEM4500CXS

F, G, GW

B

115/230

230

50

34.8/17.4

17.4

4.0

4.5

Only for charging 12 V

automotive batteries.

12 V, 8 A

49

06/03/17 12:04:12 32Z21600_054

Noise

Model

Type

Sound pressure level (LpA)

According to 98/37/EC

EM4500CXEM4500CXS

B, F, G, GW

80 dB

Microphone point

CONTROL

PANEL

Center

1.60 m

1.0 m

Guaranteed sound power level

(LWA) Tested by 2000/14/EC

97 dB

Specifications are subject to change without notice.

50

06/03/17 12:04:28 32Z21600_055

Dimensions and Weight

Model

Description code

Length

Width

Height

Dry weight

EM5500CX

EAUC

680 mm (26.8 in)

530 mm (20.9 in)

545 mm (21.5 in)

88.0 kg (194.0 lbs)

EM5500CXS

EAVC

880 mm (34.6 in)

530 mm (20.9 in)

545 mm (21.5 in)

96.0 kg (211.6 lbs)

Engine

Model

Engine type

Displacement

Bore Stroke

Compression ratio

Engine speed

Cooling system

Ignition system

Oil capacity

Fuel tank capacity

Spark plug

GX390K1

4-stroke, overhead valve, single cylinder

389 cm (23.7 cu-in)

88 64 mm (3.5 in 2.5 in)

8.0:1

3,000 rpm

Forced air

Transistorized magneto

1.10 (1.16 US qt , 0.97 Imp qt)

25 (6.6 US gal , 5.5 Imp gal)

BPR5ES (NGK)

W16EPR-U (DENSO)

Generator

AC

output

Model

Type

Rated Voltage (V)

Rated Frequency (Hz)

Rated Ampere (A)

Rated Output (kVA)

Max. Output (kVA)

DC rated output

EM5500CXEM5500CXS

B

F, G, GW

115/230

230

50

43.5/21.7

21.7

5.0

5.5

Only for charging 12 V

automotive batteries.

12 V, 8 A

51

06/03/17 12:04:33 32Z21600_056

Noise

Model

Type

Sound pressure level (LpA)

According to 98/37/EC

EM5500CXEM5500CXS

B, F, G, GW

80 dB

Microphone point

CONTROL

PANEL

Center

1.60 m

1.0 m

Guaranteed sound power level

(LWA) Tested by 2000/14/EC

97 dB

Specifications are subject to change without notice.

52

06/03/17 12:04:40 32Z21600_057

12. INSTALLATION OF KIT PARTS

STANDARD KIT PARTS

Battery Tray Kit (CXS type)

1. Install the battery guard on the frame.

Set the battery tray on the battery guard and tighten the bolts.

2. Route the starter cable under the tank and connect it to the starter

solenoid.

3. Connect the ground cable to the generator rear housing.

4. Set the battery on the battery tray and secure with the battery

bracket.

Connect the starter cable to the battery positive () terminal first,

then to the negative () terminal. When disconnecting, disconnect

at the battery negative () terminal first.

5. Install the battery guard plate on the battery guard.

53

06/03/17 12:04:47 32Z21600_058

CABLE TIE

STARTER SOLENOID

STARTER CABLE

(positive)

GROUND

CABLE

STARTER

CABLE

GROUND

CABLE

CABLE

TIE

BATTERY

BRACKET

BATTERY

Use a battery rated at

12V835AH or more

()

()

BATTERY

GUARD

BATTERY

GUARD

BATTERY

GUARD PLATE

54

BATTERY

TRAY

06/03/17 12:04:57 32Z21600_059

OPTIONAL KIT PARTS

2 Wheel Type

Handle Installation

Install the right and left handles on the generator upper frame using

the brackets and 4 flange bolts.

Wheel Kit Installation

1. Install the two wheels on the axle shaft using the washers and cotter

pins.

2. Install the axle assembly on the generator using four 8 16 mm

flange bolts and 8 mm flange nuts.

3. Install the two stands on the under frame using four 8 16 mm

flange bolts.

TORQUE: 2429 Nm (2.43.0 kgfm , 1722 lbfft)

GENERATOR

SIDE

816 mm FLANGE BOLT (4)

LEFT UPPER HANDLE ASSY

RIGHT UPPER

HANDLE ASSY

LONGER

RIGHT HANDLE BRACKET

LEFT HANDLE BRACKET

816 mm FLANGE BOLT (4)

816 mm FLANGE BOLT (4)

20 mm WASHER (2)

4.030 mm COTTER PIN (2)

AXLE

WHEEL (2)

STAND (2)

8 mm FLANGE NUT (4)

55

06/03/17 12:05:04 32Z21600_060

4 Wheel Type

1. Install the lock plate and four wheels on the wheel shaft using the

washers and cotter pins.

Install the left wheel shaft on the left side nearest the engine.

2. Install the wheel shaft assembly on the generator using eight 8 16

mm hex. bolts and 8 mm flange nuts.

TORQUE: 2429 Nm (2.43.0 kgfm , 1722 lbfft)

GENERATOR

SIDE

816 mm HEX. BOLT (8)

LONGER

WHEEL (4)

RIGHT WHEEL SHAFT

LEFT WHEEL SHAFT

20mm PLAIN WASHER (4)

LOCK PLATE

428 mm SPLIT PIN (4)

8 mm FLANGE NUT (8)

56

06/03/17 12:05:09 32Z21600_061

Hanger Kit Installation

1. Position the hanger at the generators balance point as shown below.

2. Fit the end tabs of the hanger through the bracket slots, and bolt the

brackets to the hanger and tighten securely.

TORQUE: 2429 Nm (2.43.0 kgfm , 1722 lbfft)

816 mm FLANGE BOLT (4)

HANGER

HANGER BRACKET (2)

280 mm (11 in)

HANGER

GENERATOR

SIDE

57

06/03/17 12:05:15 32Z21600_062

[CXS type]

Remote Control Kit

1. Remove the blind 6-P connector from the back of the control panel.

2. Connect the remote control cable to the back of the control panel

and remote control box.

3. Install the two cable ties as shown.

REMOTE CONTROL

CABLE

CABLE TIES

REMOTE CONTROL

CABLE

REMOTE CONTROL BOX

Connect the blind connector when not using the remote control.

Engine will not start unless the blind connector is connected.

58

06/03/17 12:05:22 32Z21600_063

PILOT LAMP

START SWITCH

STOP SWITCH

Starting the engine with remote control

1. Turn the fuel valve to the ON position.

2. Turn the engine switch to the ON position.

3. Press the start switch untill the pilot lamp comes on.

Stopping the engine with remote control

1. Press the stop switch.

2. Turn the engine switch to the OFF position.

3. Turn the fuel valve lever to the OFF position.

59

06/03/17 12:05:25 32Z21600_064

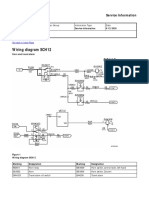

13. WIRING DIAGRAM

ACOR

AC, NF

ATS

ATSw

ATU

AVR

BAT

CB

CBxB

ChC

CP

D

DC, D

DC, NF

DC, T

DC, W

EgB

EgCU

EgSw

F

ExW

FW

FCS

GeB

GT

IgC

MW

OAU

OLSw

RCB

RCC

S

SP

SSw

STSw

SV

T

VM

VSSw

60

AC Output Receptacle

AC Noise Filter

Auto Throttle Solenoid

Auto Throttle Switch

Auto Throttle Unit

Auto Voltage Regulator

Battery

Circuit Breaker

Control Box Block

Charge Coil

Circuit Protector

Diode

DC Diode

DC Noise Filter

DC Terminal

DC Winding

Engine Block

Engine Control Unit

Engine Switch

Fuse

Exciter Winding

Field Winding

Fuel Cut Solenoid

Generator Block

Ground Terminal

Ignition Coil

Main Winding

Oil Alert Unit

Oil Level Switch

Remote Control Block

Remote Control Cable

Starter

Spark Plug

Start Switch

Stop Switch

Solenoid Valve

Thermistor

Volt Meter

Voltage Selector Switch

06/03/17 12:05:30 32Z21600_065

Bl

Y

Bu

G

R

W

Br

O

Lb

Lg

P

Gr

BLACK

YELLOW

BLUE

GREEN

RED

WHITE

BROWN

ORANGE

LIGHT BLUE

LIGHT GREEN

PINK

GRAY

ENGINE SWITCH

EM3100CXEM4500CXEM5500CX

IG

E

FS

OFF

ON

EM4500CXSEM5500CXS

IG

E

OFF

ON

START

LO

BAT

ST

FS

61

06/03/17 12:05:38 32Z21600_066

EM3100CXEM4500CXEM5500CX (B Type)

62

06/03/17 12:05:48 32Z21600_067

EM4500CXSEM5500CXS (B Type)

63

06/03/17 12:05:55 32Z21600_068

EM3100CXEM4500CXEM5500CX (F, G, GW Type)

64

06/03/17 12:06:04 32Z21600_069

EM4500CXSEM5500CXS (F, G, GW Type)

65

06/03/17 12:06:26 32Z21600_070

14. MAJOR Honda DISTRIBUTOR ADDRESSES

For European

NAME OF FIRM (COMPANY)

Honda (U.K.) Limited

Honda Europe Power Equipment S.A.

Honda Motor Europe (North) GmbH.

Honda Belgium H.V.

Honda Italia Industriale S.P.A.

Honda (Suisse) S.A.

Honda Nederland B.V.

Honda Austria G.M.B.H.

Honda Power Equipment Sweden AB

Honda Produtos De Fora, Portugal, S.A.

Berema A/S

66

ADDRESS

470 London Road, Slough,

Berkshire, SL38QY,

TEL: FAX:

Tel: 01753-590-590

Fax: 01753-590-000

United Kingdom

Pole 45 Rue des Chataigniers

45140 Ormes

Tel: 2-38-65-06-00

Fax: 2-38-65-06-02

France

Spredlinger, Landstrae 166

D-63069 Offenbach/Main

Germany

Tel: 069-83-09-0

Fax: 069-83-09-519

Wijngaardveld 1, 9300 Aalst

Belgium

Via della Cecchignola, 5/7

00143 ROMA

Tel: 053-725-111

Fax: 053-725-100

Tel: 06-54928-1

Fax: 06-54928-400

Route des Moulires 10

Case postale Ch 1214

Vernier-Geneve, Switzerland

Capronilaan 1

Tel: 022-341-22-00

Fax: 022-341-09-72

1119 NN Schiphol-Rijk

Netherlands

Honda Strasse 1 A-2351

Wiener Neudorf

Fax: 020-7070001

Austria

Vstkustvgen 17

202 15 Malm,

Sweden

Tel: 020-7070000

Tel: 223-66-900

Fax: 223-66-4130

Tel: 040-600 23 00

Fax: 040-600 23 19

Lugar da Abrunheira

S. Pedro de Penaferrim

2710 Sintra, Portugal

Berghagan 5, Langhus

Tel: 351-1-9150374

Fax: 351-1-9111021

Box 454, 1401 Ski

Norway

Fax: 64-86-05-49

Tel: 64-86-05-00

06/03/17 12:06:48 32Z21600_071

For European (continued)

NAME OF FIRM (COMPANY)

OY Brandt AB

TIMA PRODUCTS A/S

Greens

Automocion Canarias S.A.

(AUCASA)

The Associated Motors Company Ltd.

Two Wheels Ltd.

General Automotive Co., S.A.

BG Technik s.r.o

ADDRESS

Tuupakantie 4

SF-01740, Vantaa

TEL: FAX:

Tel: 90-895-501

Fax: 90-878-5276

Finland

Trnfalkevej 16, Postboks 511

DK 2650 Hvidovre

Tel: 31-49-17-00

Fax: 36-77-16-30

Denmark

Polig. Industrial Congost

08530, La Garriga

(Barcelona), Spain

Tel: 93-871-84-50

Fax: 93-871-81-80

Apartado de Correos, num 206

Santa Cruz de Tenerife

Canary Island

148, Rue DArgens, Msida

Tel: 922-61-13-50

Fax: 922-61-13-44

Malta

Crosslands Business Park,

Ballymount Road, Dublin 12,

Ireland

Fax: 356-340473

Tel: 4602111

Fax: 4566539

P.O. Box 1200, 101 73 Athens

Greece

Radlick 117/520

158 01 Praha 5

Tel: 346-5321

Fax: 346-7329

Tel: 2-5694 573

Fax: 2-5694 571

Tel: 356-333001

Czech Republic

Aries Power Equipment Ltd.

01-493 Warszawa, ul Wroclawska

25a

Poland

Tel: 22-685 17 06

Fax: 22-685 16 03

MO. TOR. PEDO Ltd.

2040 Buda-rs, Kamaraerdei-t 3.

Hungary

Tel: 23-444-971

Fax: 23-444-972

ADDRESS

1954-1956 Hume Highway

Campbelifield Victoria 3061

TEL: FAX:

Tel: (03) 9270 1111

Fax: (03) 9270 1133

For Australian

NAME OF FIRM (COMPANY)

Honda Australia Motorcycle and Power

Equipment Pty. Ltd

67

EM3100CX-36Z21601 05.8.25 11:20 AM 1

GENERATOR

EM3100CXEM4500CXEM5500CX

EM4500CXSEM5500CXS

36Z21602

36Z21601

00X36-Z21-6020

EU1

00X36-Z21-6010

DIC

197

Bk

12mm

CX1

CXS1

C Honda Motor Co., Ltd. 2004

HC

Printed in China

OWNER'S MANUAL

MANUEL DE L'UTILISATEUR

BEDIENUNGSANLEITUNG

MANUAL DE EXPLICACIONES

EM3100CX-EM5500CXS O/M_36Z21601

You might also like

- Honda Generator Ex1000Document45 pagesHonda Generator Ex1000Blaire ReynoldsNo ratings yet

- Gener. Inverter. KGE3000ti Manual de Servicio PDFDocument35 pagesGener. Inverter. KGE3000ti Manual de Servicio PDFManuel Sierra100% (1)

- Engine Control Module (Ecm) : Connector (E100 K)Document11 pagesEngine Control Module (Ecm) : Connector (E100 K)Ham NgoNo ratings yet

- Kge 3000 T I Service ManualDocument35 pagesKge 3000 T I Service ManualVianeyNo ratings yet

- Wiring Diagram SCH12: Service InformationDocument2 pagesWiring Diagram SCH12: Service InformationPreett Rajin MenabungNo ratings yet

- ABB IE3 Process Performance CatalogueDocument12 pagesABB IE3 Process Performance Cataloguehardik033No ratings yet

- Goodrive20 Series Inverter - V1.5Document155 pagesGoodrive20 Series Inverter - V1.5Jhoompieer VFNo ratings yet

- Zx200-5a 4hk1 Engine Manuel (Workshop)Document575 pagesZx200-5a 4hk1 Engine Manuel (Workshop)Halil KaraNo ratings yet

- Silicon Power Transistor: Data SheetDocument5 pagesSilicon Power Transistor: Data Sheetibnu2malkanNo ratings yet

- Kipor generator shop manual guide to specifications, wiring diagrams and repairDocument38 pagesKipor generator shop manual guide to specifications, wiring diagrams and repairantoniomecpt100% (1)

- Kipor IG1000Document54 pagesKipor IG1000Brandon PhelpsNo ratings yet

- DSEP100 PC Software ManualDocument30 pagesDSEP100 PC Software ManualSon DoNo ratings yet

- SDLG B876F B877F Operation & Maintenance ManualDocument138 pagesSDLG B876F B877F Operation & Maintenance Manualvicmart3030No ratings yet

- Volvo Tad650-750 Electric ManualDocument176 pagesVolvo Tad650-750 Electric ManualMouloud Derrahi100% (1)

- JAC Light Truck HFC1040Document50 pagesJAC Light Truck HFC1040Jose Simonetti100% (1)

- CD5540F-YB5515 Tier 3 SM 198-04Document412 pagesCD5540F-YB5515 Tier 3 SM 198-04RaphaelNo ratings yet

- Omron Programming ManualDocument1,175 pagesOmron Programming ManualHaroDavidNo ratings yet

- 115ZV 2 (EU Trouble)Document114 pages115ZV 2 (EU Trouble)ManulNo ratings yet

- Operation & Safety, Service & Maintenance & Illustrated Parts Manual SupplementDocument68 pagesOperation & Safety, Service & Maintenance & Illustrated Parts Manual SupplementSebastian Alejandro RománNo ratings yet

- Instruction ManualDocument28 pagesInstruction ManualpapagunzNo ratings yet

- Power OneDocument136 pagesPower Oneatul patelNo ratings yet

- PC450 (LC, HD) - 8 UEN02647-00 TroubleshootingDocument364 pagesPC450 (LC, HD) - 8 UEN02647-00 Troubleshootingdatphuong100% (1)

- Sharp Aquos 40-Inch HDTV LCD User ManualDocument32 pagesSharp Aquos 40-Inch HDTV LCD User ManualoneoftheworstNo ratings yet

- Riso ComColor 9150 Technical ManualDocument1,540 pagesRiso ComColor 9150 Technical ManualTiago sotto mayorNo ratings yet

- Bosch S3-S6 Car Batteries for Cars & Asian VehiclesDocument10 pagesBosch S3-S6 Car Batteries for Cars & Asian Vehiclessimon_someone217No ratings yet

- Mitsubishi PLC FX1S-FX1N-FX2N Series Programming Manual (PDFDrive) PDFDocument466 pagesMitsubishi PLC FX1S-FX1N-FX2N Series Programming Manual (PDFDrive) PDFHandi KsciNo ratings yet

- Engine SlobberingDocument1 pageEngine Slobberingbauhaus10No ratings yet

- Bac06 Series (BAC06A/BAC06V) Switch-Type Battery Charger: User ManualDocument6 pagesBac06 Series (BAC06A/BAC06V) Switch-Type Battery Charger: User ManualJermaine PeñaNo ratings yet

- JM ETACS Technical OverviewDocument26 pagesJM ETACS Technical Overviewlartsim115100% (1)

- HITACHI Evcavator Fault Codes DTC & Troubleshooting PDFDocument401 pagesHITACHI Evcavator Fault Codes DTC & Troubleshooting PDFAfsar's SonNo ratings yet

- SED MAN GC2599 002 Manual For GC2599 ControllerDocument78 pagesSED MAN GC2599 002 Manual For GC2599 ControllerkrishnaNo ratings yet

- Maintenance by Garr BhuwaDocument8 pagesMaintenance by Garr BhuwaejazNo ratings yet

- Faults and AlarmsDocument35 pagesFaults and Alarmsvzprele100% (1)

- Generator Model: P 200: Prime Power 200 KVA 160 KWDocument4 pagesGenerator Model: P 200: Prime Power 200 KVA 160 KWMuhammad AtifNo ratings yet

- SEKN5005 Deutsch C TIPS PDFDocument7 pagesSEKN5005 Deutsch C TIPS PDFJoko SukarionoNo ratings yet

- CPT Cirprotec V OVERVOLTAGE AND SURGE PROTECTION PDFDocument44 pagesCPT Cirprotec V OVERVOLTAGE AND SURGE PROTECTION PDFSitiSaodahNo ratings yet

- Njr2-D Series Soft Starter: Instruction ManualDocument21 pagesNjr2-D Series Soft Starter: Instruction ManualNguyen Van ChungNo ratings yet

- DCA-25ESK: DenyoDocument1 pageDCA-25ESK: DenyoAdeelNo ratings yet

- Markon Generator ManualDocument52 pagesMarkon Generator ManualjuanlukaNo ratings yet

- Kenwood - TK-2160 - 3160 Service ManualDocument42 pagesKenwood - TK-2160 - 3160 Service ManualcornelisjjNo ratings yet

- 70ZV 2 (EU Trouble)Document115 pages70ZV 2 (EU Trouble)Halil KaraNo ratings yet

- BE (Body Electrical System)Document37 pagesBE (Body Electrical System)RomusNo ratings yet

- Fuse DiagramDocument206 pagesFuse DiagramRandy JenkinsNo ratings yet

- Bosch Alternator 1994 Volvo TroubleshootingDocument4 pagesBosch Alternator 1994 Volvo TroubleshootingbbruneaucaNo ratings yet

- Delphi 150 series Load Pin installation manualDocument31 pagesDelphi 150 series Load Pin installation manualMuhmmad Masrur MushfiqueNo ratings yet

- 115ZV 2 (EU Trouble)Document114 pages115ZV 2 (EU Trouble)Halil Kara100% (1)

- PC340LC (NLC) - 7 UEN00262-00 Structure, Function & Maintenance StandardDocument240 pagesPC340LC (NLC) - 7 UEN00262-00 Structure, Function & Maintenance StandarddatphuongNo ratings yet

- (SM Eng) PC340 LC (NLC) - 6K (EEAM008007)Document323 pages(SM Eng) PC340 LC (NLC) - 6K (EEAM008007)НиколайNo ratings yet

- Technical Description Hydraulic Excavator Operating Weight 35,9 - 40,7Document16 pagesTechnical Description Hydraulic Excavator Operating Weight 35,9 - 40,7LiebherrNo ratings yet

- Awp Family Brochure 2017Document20 pagesAwp Family Brochure 2017Gautam PkNo ratings yet

- Sop-09-Washing of Motor Winding With CTCDocument3 pagesSop-09-Washing of Motor Winding With CTCOSAMANo ratings yet

- Service Manual For Luna Series DC InverterDocument73 pagesService Manual For Luna Series DC Invertercmorley5057No ratings yet

- SE220LCDocument2 pagesSE220LCAriel Quezada100% (1)

- PASX710 SP CatalogueDocument67 pagesPASX710 SP CatalogueLuis Antonio Chiapas GarciaNo ratings yet

- Grupo Honda Eb12dDocument53 pagesGrupo Honda Eb12dmilerk100% (1)

- Honda EM 3500 XDocument56 pagesHonda EM 3500 XDokhtar SaidiNo ratings yet

- Honda Engine ManualDocument45 pagesHonda Engine ManualFlavianNo ratings yet

- Petrol Generator Manual CLARKEDocument34 pagesPetrol Generator Manual CLARKEThabo NgidiNo ratings yet

- IG1000 Operation ManualDocument40 pagesIG1000 Operation ManualDan KillkennyNo ratings yet

- 3.II BO23-User - Documentation-V6Document65 pages3.II BO23-User - Documentation-V6Ranjeet SinghNo ratings yet

- Service Manual Fujitsu Nocria AWYZ 14-18-LBCDocument14 pagesService Manual Fujitsu Nocria AWYZ 14-18-LBCNo Surrender No RetreatNo ratings yet

- D400 Hardware Users Guide R1.2Document122 pagesD400 Hardware Users Guide R1.2valkm2306No ratings yet

- Dptexxxxs / Dptexxxx: 3-Wire Differential Pressure Transmitters With Current and Voltage OutputDocument4 pagesDptexxxxs / Dptexxxx: 3-Wire Differential Pressure Transmitters With Current and Voltage OutputMario Mô Ri ANo ratings yet

- AirCell Catalog RadiatingDocument18 pagesAirCell Catalog RadiatingthuandinhqhNo ratings yet

- Coarse Feed ValveDocument34 pagesCoarse Feed ValveRahmat Yusuf0% (1)

- Chapter - 03: Memory-mapped I/O and I/O device interfacingDocument42 pagesChapter - 03: Memory-mapped I/O and I/O device interfacingJoseph JohnNo ratings yet

- Electromagnetic Radiation: Visible LightDocument39 pagesElectromagnetic Radiation: Visible LightgeethaNo ratings yet

- Window Function ComparisonsDocument7 pagesWindow Function ComparisonsHaripriya RadhakrishnanNo ratings yet

- Recent Research Papers in Electronics and CommunicationDocument6 pagesRecent Research Papers in Electronics and Communicationgw2x60nw100% (1)

- WorldSkills Mobile Robotics Collection Shanghai 2021Document2 pagesWorldSkills Mobile Robotics Collection Shanghai 2021Jorge CastañoNo ratings yet

- Instruction Manual For AT7328/7340 Dual Channel OscilloscopeDocument12 pagesInstruction Manual For AT7328/7340 Dual Channel OscilloscopeanswetNo ratings yet

- Arnel Villanueva Quillopo: Work ExperienceDocument2 pagesArnel Villanueva Quillopo: Work Experienceanon_846849419No ratings yet

- Popcorn Hour A-110 NMT Quickstart GuideDocument1 pagePopcorn Hour A-110 NMT Quickstart GuideTalynOne100% (1)

- Effect of Slots On Performance of The Microstrip Patch AntennaDocument7 pagesEffect of Slots On Performance of The Microstrip Patch AntennaAnonymous XZUyueNNo ratings yet

- Computers Formative AssessmentDocument22 pagesComputers Formative AssessmentPritika SachdevaNo ratings yet

- Sl. No State Resume Sent Date Candidate Name Contact No. Mail ID QualificationDocument6 pagesSl. No State Resume Sent Date Candidate Name Contact No. Mail ID QualificationAswathi SNo ratings yet

- TMPA 8823-5VA4 Service Manual: IC Functions and I2C Bus ControlDocument16 pagesTMPA 8823-5VA4 Service Manual: IC Functions and I2C Bus ControlAndy AnsahNo ratings yet

- How To Install WM 10 On Unsupported PhoneDocument6 pagesHow To Install WM 10 On Unsupported PhoneTomi ArdianaNo ratings yet

- Cisco Prime Support DevicesDocument181 pagesCisco Prime Support DevicesjoNo ratings yet

- Electrical System p9000Document50 pagesElectrical System p9000tazjuan1No ratings yet

- Eltek CTE20415.002 PDFDocument18 pagesEltek CTE20415.002 PDFDmiNo ratings yet

- Pack Hot Manual Et-12-ManualDocument17 pagesPack Hot Manual Et-12-ManualamalfarhanaNo ratings yet

- The Spectra Precision EPOCH 50 GNSS ReceiverDocument3 pagesThe Spectra Precision EPOCH 50 GNSS ReceiverSubaElemer-EmanuelNo ratings yet

- Configuracion Switch H3CDocument43 pagesConfiguracion Switch H3CjonathanortizmNo ratings yet

- Innovation Strategy Mapping ValueDocument23 pagesInnovation Strategy Mapping ValueSantanu KararNo ratings yet

- Ome56640e3 RC1800F2Document40 pagesOme56640e3 RC1800F2okanNo ratings yet

- Excellent Inverters Operation Manual: We Are Your Excellent ChoiceDocument71 pagesExcellent Inverters Operation Manual: We Are Your Excellent ChoicephaPu4cuNo ratings yet

- Good VLSI Design Test Power TutorialDocument1,515 pagesGood VLSI Design Test Power TutorialprakashthamankarNo ratings yet

- Chemistry Practical GuideDocument14 pagesChemistry Practical GuideOmar HashemNo ratings yet