Professional Documents

Culture Documents

Effects of Soaking On Yield and Quality of Agarwood Oil

Uploaded by

Nilamdeen Mohamed ZamilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effects of Soaking On Yield and Quality of Agarwood Oil

Uploaded by

Nilamdeen Mohamed ZamilCopyright:

Available Formats

Journal of Tropical Forest Science 24(4): 557564 (2012)

Nor Fazila K & Ku Halim KH

Effects of soaking on Yield and Quality of

Agarwood Oil

K Nor Fazila* & KH Ku Halim

Faculty of Chemical Engineering, Universiti Teknologi MARA, 40450 Shah Alam, Selangor Darul Ehsan, Malaysia

Received Mac 2012

Nor Fazila K & Ku Halim KH. 2012. Effects of soaking on yield and quality of agarwood oil. The aims

of this study were to investigate vaporisation temperature of agarwood oil, determine enlargement of wood

pore size, analyse chemical components in soaking solvents and examine the chemical composition of

agarwood oil extracted from soaked and unsoaked agarwood. Agarwood chips were soaked in two different

acids, namely, sulphuric and lactic acids for 168 hours at room temperature (25 C). Effects of soaking

were determined using thermogravimetric analysis (TGA), scanning electron microscope (SEM) and gas

chromatography-mass spectrum analysis. With regard to TGA curve, a small portion of weight loss was observed

between 110 and 200 C for agarwood soaked in lactic acid. SEM micrograph showed that the lactic acid-soaked

agarwood demonstrated larger pore size. High quality agarwood oil was obtained from soaked agarwood.

In conclusion, agarwood soaked in lactic acid with concentration of 0.1 M had the potential to reduce the

vaporisation temperature of agarwood oil and enlarge the pore size of wood, hence, improving the yield

and quality of agarwood oil.

Keywords: TGA analysis, SEM analysis, GC-MS analysis

Nor Fazila K & Ku Halim KH. 2012. Kesan rendaman terhadap hasil dan kualiti minyak gaharu.

Matlamat kajian ini adalah untuk menyiasat suhu pengewapan minyak gaharu, menentukan pembesaran

saiz liang kayu, menganalisis komponen kimia yang larut dalam pelarut rendaman dan mengkaji komposisi

kimia minyak gaharu yang diekstrak daripada kayu yang direndam dan yang tidak direndam dalam

pelarut. Serpihan kayu gaharu direndam dalam dua jenis asid iaitu asid sulfurik dan asid laktik pada

suhu bilik (25 C) selama 168 jam. Kesan rendaman ditentukan menggunakan analisis termogravimetrik

(TGA), mikroskop elektron pengimbas (SEM) dan analisis kromatografi gas spektrum jisim. Daripada graf

TGA, didapati sebahagian kecil daripada kehilangan berat diperhatikan pada suhu antara 110 C hingga

200 C bagi gaharu yang direndam dalam asid laktik. Mikrograf SEM menunjukkan bahawa gaharu yang

direndam dalam asid laktik menunjukkan saiz liang yang lebih besar. Minyak gaharu berkualiti tinggi

dapat diperoleh daripada gaharu yang direndam. Kesimpulannya, gaharu yang direndam dalam asid laktik

berkepekatan 0.1M mempunyai potensi untuk mengurangkan suhu pengewapan minyak gaharu dan

membesarkan saiz liang kayu. Justeru, hasil dan kualiti minyak gaharu dapat dipertingkatkan.

Introduction

Agarwood or scientifically known as Aquilaria

is the resinous hardwood native to South-East

Asia. There are 15 Aquilaria species in tropical

Asia. Natural distributions occur widely in South

and South-East Asia. Agarwood or commonly

called gaharu in Indonesia and Malaysia is a

fragrant resin that is produced by the hardwood

of Aquilaria species. Great demand for essential

oil from this species resulted in the depletion of

trees due to indiscriminate cutting. However, the

genus is listed and protected as an endangered

species internationally. Therefore, most countries

in South-East Asia are cultivating Aquilaria trees

to maintain agarwood products in a sustainable

manner. Resins can be formed by notching,

E-mail: norfazilakhairudin@yahoo.com

Forest Research Institute Malaysia

557

fungal infection, insect infestation or inoculation

either by chemical or biological methods

(Barden et al. 2002, Nor Azah et al. 2008, Rosli

2009). Agarwood is extensively used in incense,

pharmaceutical and perfumery industries.

Even though agarwood is an angiosperm, the

structure of agarwood is very unique whereby

a bundle of phloem is observed in the xylem

(Blanchette & Beek 2005). Parenchyma cells

were reported to produce resin or identified as

agarwood (Nobuchi & Siripatanadilok 1991).

Botany (1976) and Prachakul (1997) stressed

that resin did not only exist in parenchyma cells

but also in included-phloem tissue and ray cells.

The dark colour of agarwood indicates that the

Journal of Tropical Forest Science 24(4): 557564 (2012)

Nor Fazila K & Ku Halim KH

wood contains fragrant resin. Basically resins

have numerous chemical compounds such as

-guaiene, -bulnesene and -gurjunene (Nor

Azah et al. 2008, Wetwitayaklung et al. 2009,

Winarni & Waluyo 2009, Nizam & Mashitah

2010). A number of studies have found that the

compounds not only give odour, taste and colour

to wood but also act as a protector against insect

invasion (Rowell et al. 2005, Horvath 2006).

Several studies investigating the effect of

solvents on wood cell expansion have been

carried out. Soaking solvents play a role in

reducing the strength of cell walls and breaking

the oil glands. This eases extraction of chemical

components. For this purpose, a variety of

solvents were applied such as water (Rowell et

al. 2005, Stokke & Groom 2006), acid and alkali

(Rowell et al. 2005).

In commercial processing of agarwood oil,

no standard operating procedures were applied.

Distillers usually soak the wood in water for a

few days up till two months. To date effects of

the immersion technique on the vaporisation

temperature and pore size enlargement of

agarwood have not been studied extensively. Most

publications focused only on the extraction of

chemical compounds from agarwood (Nor Azah

et al. 2008, Wetwitayaklung et al. 2009, Winarni &

Waluyo 2009, Nizam & Mashitah 2010). Winarni

and Waluyo (2009) extracted agarwood oil from

unsoaked wood. Thus, only a small amount of

extractive was obtained. Conversely, numerous

chemical components were extracted from

agarwood that was soaked in water for more than

three days (Wetwitayaklung et al. 2009, Nizam &

Mashitah 2010). Therefore, soaking is significant

in improving chemical components extracted

and yield of essential oil.

Hypothetically, the degradation of wood cell

wall would enlarge the pore size. The objectives

of this study were to determine effects of soaking

method on vaporisation temperature of essential

oil and the enlargement of agarwood pore size.

These would increase the yield of essential oil

and extract the active ingredients in agarwood.

The study on soaking solvents was carried out

to better understand the diffusion of chemical

components through open wood pores as a

result of soaking. Unsoaked agarwood acted as

control. Chemical compositions of agarwood oil

were analysed using gas chromatography-mass

spectrum (GC-MS) and the yield was calculated

in order to compare the quality of oils extracted

from soaked and unsoaked agarwood.

Forest Research Institute Malaysia

558

materials and Methods

Plant materials and reagents

The heterogeneous ground agarwood species

Aquilaria malaccensis used in this research was

obtained from the forest of Temerloh, Pahang,

West Malaysia. Chemicals such as sulphuric acid

(9598%), lactic acid (88%) and hexane (95%)

used were of commercial grades.

Soaking with solvents

Ground agar wood samples were soaked in

two solutions of 0.1 M lactic acid and 0.1 M

sulphuric acid. Soaking process was performed

at room temperature (25 C) for 168 hours. The

agarwood samples which were soaked in solvents

were dried for 24 hours in an oven at 50 C. For

assessment using scanning electron microscope

(SEM), agarwood was cut into 1 cm (length)

1 cm (width) 0.1 cm (height) before being

soaked in solvents.

Thermogravimetry analysis (TGA)

Wood is essentially composed of hemicellulose,

cellulose, lignin and extractives (Wiedenhoeft

& Miller 2005, Shebani et al. 2009). Each

component has its own temperature profile which

can be interpreted from thermogravimetric

and derivative thermogravimetric cur ves.

However, the present research focused only

on the vaporisation temperature of agarwood

extractives. The temperature obtained is very

practical as guidance to distillers in setting

temperature for the extraction process. This

practice was conducted with a Mettler Toledo

analyser. The experiment was carried out with

20 mg of agarwood samples, heated from 30 to

900 C at a rate of 10 C min-1 under nitrogen

gas flow of 60 mL min-1.

Scanning electron microscopy analysis

Non-coated agarwood samples were introduced to

SEM with magnification of 500 times. The changes

in the structure of agarwood especially average

pore size were measured and compared.

Hydrodistillation

Two hundred grams of each sample were

subjected to hydrodistillation (Zulbadli et al.

Journal of Tropical Forest Science 24(4): 557564 (2012)

Nor Fazila K & Ku Halim KH

2011). The agarwood samples were extracted

with 1.5 L of water for 12 hours. Following

this, mixtures of oils and water collected were

separated using a separation funnel by adding

hexane in a ratio of 1:2. Then, the hexane was

separated using rotar y evaporator at 60 C.

Evaporation of hexane under reduced pressure

gave the agarwood oil, which was weighed to

determine the yield of oil.

Yield

of oil (%) = agarwood oil (g)

100%

agarwood chips (g)

Gas chromatography-mass spectrometry

(GC-MS) analysis

GC-MS was used to identify chemical compounds

of agarwood which were dispersed in the solvents

during the immersion process through open

wood pores and chemical components extracted

from soaked and unsoaked samples. Since acids

could not be injected directly to GC-MS, the

soaking solvents were mixed with hexane in a

separation funnel in the ratio of 1:2. Two layers

of liquid were formed, whereby hexane which was

lighter would float on top of the acid. Hexane was

collected and analysed via GC-MS.

The GC-MS analyses were performed via

Varian 450 gas chromatograph with attached

Varian 240 mass spectrometer. This apparatus

was equipped with DB-1 capillar y column

(30 m 0.25 mm film thickness 0.25 m).

Injector temperature was set at 230 C and oven

temperature was programmed between 50 and

230 C at a rate of 3 C min-1. Injection volume

was 1 L with split ratio 20:1. Helium was used

as carrier gas and the flow rate was set at 1 mL

min-1 (Nizam & Mashitah 2010).

Results and discussion

Effect of soaking on the vaporisation

temperature of agarwood oil

Figure 1a depicts the weight loss (thermogravimetric) cur ves of unsoaked agar wood

samples and agarwood soaked in lactic acid and

sulphuric acid. Figure 1b represents the derivative

thermogravimetric curves.

All agarwood samples revealed a small amount

of weight loss at temperatures ranging from 40

to 100 C due to evaporation of moisture (Figure

1a). Agarwood soaked in sulphuric acid showed

Forest Research Institute Malaysia

559

the highest moisture loss which was 6.5% as

visibly shown in Figure 1b. It occurred due to the

characteristic of sulphuric acid as an excellent

dehydrating agent. Agarwood which was soaked

in sulphuric acid was volatile at about 100 C,

followed by agarwood soaked in lactic acid and

unsoaked sample at temperatures of 110 and

170 C respectively. A possible explanation for

this might be due to the break up of parenchyma

cells as a result of immersion, thus easing wood

components to volatilise. Apparently, all samples

except for agarwood soaked in sulphuric acid

showed rapid weight loss between 50 and 60% at

temperatures 200 to 400 C. Conversely, agarwood

soaked in sulphuric acid displayed a large

vaporisation temperature range starting from

110 to 500 C with weight loss of 55%.

Derivative thermogravimetric curve gave a

clear picture of the weight loss comparison for all

agarwood samples. One unanticipated finding

was that there was weight loss of 4.14% at

temperatures 110 to 200 C for agar wood

soaked in lactic acid. It could be presumed as

vaporisation of agarwood oil. As mentioned in

previous studies, the yield of essential oil obtained

was between 0.03 and 4.43% (Wetwitayaklung

et al. 2009, Winarni & Waluyo 2009, Nizam &

Mashitah 2010). However, no weight loss was

displayed by unsoaked samples within that range

of temperature. With regard to agarwood soaked

in sulphuric acid, there was abrupt decline at

100 to 300 C. Obviously, agarwood soaked in

sulphuric acid exhibited the highest weight loss

of 32.6%. The weight loss could be referred to

as the degradation of salts that were formed

from the reaction between sulphuric acid and

agarwood components.

Effect of soaking on pore size

Figure 2 depicts the structure of agar wood

samples examined by SEM at magnification of

500 times. Figure 2a shows the image of unsoaked

agarwood. The average pore size of this sample

was 9.09 m. Apparently, the pore sizes were small

and cell walls were not deformed. Presumably,

chemical components were difficult to escape.

Therefore, soaking agarwood prior to extraction

of essential oil is crucial.

Figures 2b and c show considerable changes

in morphology for soaked samples. Figure 2b

clearly displays that the pore size is expanded to

18 m when agarwood is soaked in lactic acid.

Journal of Tropical Forest Science 24(4): 557564 (2012)

Nor Fazila K & Ku Halim KH

100

(a)

Weight (%)

80

No soaking

60

Sulphuric acid

40

20

0

Lactic acid

100

200

300 400 500 600

Temperature (C)

700

800

900

700

800

900

Temperature (C)

Derivative weight (%/min)

0

0

-0.2

-0.4

-0.6

-0.8

-1.0

-1.2

-1.4

-1.6

-1.8

100

200

300

400

500

600

(b)

Sulphuric acid

No soaking

Lactic acid

Figure 1 (a) Thermogravimetric curve and (b) derivative thermogravimetric curve for

agarwood at heating rate of 10 C min-1

It is interesting to note that the pore size for

agarwood soaked in lactic acid was augmented

greatly. This could be due to the effect of

microbial activities in lactic acid, significantly

degrading wood components. Furthermore,

extensive soaking period allowed the bacteria to

acclimatise aggressively in the soaking mixture.

These findings further supported the findings

of Rowell et al. (2005) who found that cell wall

structure degraded when the wood was exposed

to acids for a long time. Conversely, the pore

size of agarwood became smaller than that of

unsoaked wood when the wood was soaked in

sulphuric acid. The phenomenon was perceived

in Figure 2c with an average pore size of 8.61 m.

This could be due to elimination of hydrogen

and oxygen atoms from carbohydrates contained

in agar wood, leaving behind carbon atoms

(Shakhashiri 1989). Thus, carbon atoms might

Forest Research Institute Malaysia

560

obstruct the pores of agarwood and distract the

extraction of agarwood oil.

Effect of soaking on the diffusion of chemical

components in immersion solvents

Table 1 shows the chemical components that

are extracted from the agar wood during

immersion process. As expected, there were

more chemical components found in lactic acid

compared with sulphuric acid. However, the

percentage of components extracted were not

as high as components extracted with sulphuric

acid. Most of the compounds that diffused

in lactic acid such as -guaiene, -selinene

and -gurjunene could influence the unique

odour of agarwood oil. The major components

extracted in lactic acid and sulphuric acid

Journal of Tropical Forest Science 24(4): 557564 (2012)

Nor Fazila K & Ku Halim KH

(a) Transverse section of

unsoaked agarwood

(b) Transverse section of agarwood

soaked in lactic acid

(c) Transverse section of agarwood

soaked in sulphuric acid

Figure 2

Scanning electron micrographs of unsoaked and soaked agarwood

were -gurjunene (0.818%) and benzaldehyde

(0.856%) respectively.

Effect of soaking on the yield of extract

Comparison between soaked and unsoaked

samples based on yield of agarwood oil extracted

using hydrodistillation is shown in Table 2.

Higher yield was obtained from soaked agarwood

compared with unsoaked samples. The findings

of this study were consistent with those of Rashid

and Zuhaidi (2011) and Pornpunyapat et al.

(2011). They found that soaking could rupture

the parenchyma cells, hence facilitating diffusion

of oil from the fractured oil glands. Agarwood

soaked in acids gave significantly greater yield

of oil than the control. Our findings seemed to

contrast with other researchers who found that

the yield of essential oil derived from agarwood

soaked in water was between 0.03 and 4.43%

(Wetwitayaklung et al. 2009, Winarni & Waluyo

2009, Nizam & Mashitah 2010). This could

be due to the effect of acid on the agarwood

Forest Research Institute Malaysia

561

structure. Furthermore, distillation of acidsoaked agarwood samples within the shorter

period gave extraordinary oil yield. It could be

proven by comparing the current study with

research done by Wetwitayaklung et al. (2009)

who obtained only 0.2% oil yield from 168 hours

distillation of 15 kg of agarwood soaked in water.

On the other hand, in the present study, oil yield

obtained was higher, i.e. 4.74 to 6.78%, extracted

from 0.2 kg soaked agar wood samples for

12 hours.

Isolation of agarwood oil from unsoaked and

soaked agarwood by hydrodistillation

The volatile components obtained from the

extraction of various agar wood samples are

shown in Table 3. The greatest numbers of volatile

components were obtained from soaked samples.

Agar wood soaked in lactic acid isolated the

highest number of compounds. This accorded

with earlier obser vations using SEM, which

showed that the pore size of agarwood soaked

Journal of Tropical Forest Science 24(4): 557564 (2012)

Table 1

Chemical components of agarwood diffused in immersion solvents

Compound

Nor Fazila K & Ku Halim KH

Immersion solvent

Retention time

(min)

Lactic acid (%)

Sulphuric acid (%)

4-phenyl-2-butanone

17.40

0.258

0.609

Benzaldehyde

5.80

0.856

Caryophellene oxide

35.50

0.401

0.728

-Guaiene

37.50

0.175

-Selinene

35.60

0.401

-Gurjunene

44.50

0.818

denotes data not available

Table 2

Comparison of yield percentage of agarwood

oil extracted via hydrodistillation

Sample

Yield (%)

Unsoaked

1.72

Soaked in lactic acid

4.74

Soaked in sulphuric acid

6.78

in lactic acid was much bigger than the rest,

thus facilitating compounds escaping from the

oil glands.

The major compounds (chromatogram area

> 1%) for unsoaked agar wood were dibutyl

phthalate, eudesma-5,11(13)-dien-8,12-olide and

dodecanoic acid. Furfural, 4-phenyl-2-butanone,

vanillin, dibutyl phthalate, eudesma-5,11(13)dien-8,12-olide and dodecanoic acid were

detected as the major compounds of oil extracted

from agarwood soaked in lactic acid. The findings

for agar wood soaked in sulphuric acid were

slightly different, whereby furfural, 5-methyl2-furancarboxaldehyde, 4-phenyl-2-butanone,

vanillin, dibutyl phthalate and dodecanoic acid

were identified as major compounds.

Nevertheless, dibutyl phthalate and

eudesma-5,11(13)-dien-8,12-olide were not

the fragrant agents. It is interesting to note

that furfural, 4-phenyl-2-butanone, 5-methyl-2furancarboxaldehyde, vanillin and dodecanoic

acid contribute to the unique odour of agarwood

oil. The pherobase database website El-Sayed

(2011) and the good scents Company website

(Company TGS 2012) have described the odour

characteristics of some chemical components:

vanillin (sweet), furfural (woody, almond, sweet,

fruity, flower y), 4-phenyl-2-butanone (floral

jasmine, herbal fruity, balsam) and 5-methyl2-furancarboxaldehyde (caramel, burnt sugar,

Forest Research Institute Malaysia

562

spicy, acid, coffee). However, the findings of the

current study did not support those of previous

studies (Nor Azah et al. 2008, Nizam & Mashitah

2010). Previous researchers had reported that

-bulnesene, kusunol, -guaiene, -agarofuran,

jinkoh eremol, oxo-agarospirol, selina-3,11dien-9-one and guaia-1(10),11-dien-15,2-olide

were marker compounds of A. malaccensis oil. A

possible explanation for this might be that some

of the compounds such as -guaiene, -selinene

and -gurjunene were diffused into immersion

solvents during soaking. Meanwhile the pore size

of unsoaked agarwood was too small as analysed

using SEM. Perhaps, the 12-hour extraction was

not enough to isolate the marker compounds.

Conclusions

Agar wood oil that existed in samples which

were soaked in lactic acid was volatile at low

temperature of 110 C. The results indicated that

agarwood soaked in lactic acid gave a remarkable

impact in reducing energy consumption in the

agarwood oil processing.

Agar wood soaked in lactic acid caused

extraordinary enlargement of pore size with

average of 18 m. This could provide better

condition for the extraction process by facilitating

the diffusion of either solvent or chemical

component through the enlarged pores.

High yield and greatest numbers of chemical

compounds were obtained from agar wood

soaked in lactic acid.

References

Barden A, Anak NA, Mulliken T & Song M. 2002. Heart

of the matter: agarwood use and trade and cites

implementation for Aquilaria malaccensis. http://

awsassets.wwf.org.my/downloads/agarwood.pdf.

Journal of Tropical Forest Science 24(4): 557564 (2012)

Table 3

Comparison of volatile oil components extracted from unsoaked and soaked agarwood

Compound

3-hexanone

Methyl isobutyl ketone

2-hexanone

Furfural

5-methyl-2-furancarboxaldehyde

Benzaldehyde

4-phenyl-2-butanone

3,4-dimethoxyphenol

Vanillin

2-methyl-4-chromone

4-(4-methoxyphenyl)-2-butanone

-gurjunene

Aromadendrene

-selinene

-guaiene

Velleral

Caryophelene oxide

-gurjunene

Valencene

Dibutyl phthalate

Aromadendrene oxide (2)

Eudesma-5,11(13)-dien-8,12-olide

Dodecanoic acid

Nor Fazila K & Ku Halim KH

Retention time

(min)

3.56

3.60

3.61

4.19

7.55

7.55

19.04

22.08

23.68

28.67

29.64

35.58

38.29

40.99

41.15

41.30

42.20

43.35

44.62

44.94

49.36

51.29

54.32

Unsoaked

0.49

0.29

0.37

0.18

0.37

0.28

26.76

0.54

5.69

4.64

(% Area)

Lactic acid

0.09

0.12

5.69

0.70

3.79

1.33

0.20

0.42

0.46

0.32

0.40

0.75

0.63

0.16

0.49

40.98

0.51

5.38

10.97

Sulphuric acid

0.13

0.16

19.16

2.45

2.51

0.89

2.02

0.20

0.24

0.49

0.22

0.53

30.91

0.33

2.98

Compounds listed here are based on the relative peak area > 0.1%; denotes data not available

Blanchette RA & Beek HHv. 2005. United States of America

Patent No. US 6,848,211 B2.

Botany K. 1976. A preliminary attempt at unravelling the

secret of the oleoresin formation in the wood of

Aquilaria sinensis (Lour.) Gilg. Journal of Integrative

Plant Biology 18: 287292.

Company TGS. 2012. The Good Scents Company is introducing

perflavor y. http://www.thegoodscentscompany.

com.

El-Sayed. 2011. The pherobase: database of pheromones and

semiochemicals. http://www.pherobase.com/.

Horvath AL. 2006. Solubility of structurally complicated

materials: I. Wood. Journal of Physical and Chemical

Reference Data 35: 7792.

Nizam TS & Mashitah MY. 2010. Chemical composition of

volatile oils of Aquilaria malaccensis (Thymelaeaceae)

from Malaysia. Natural Product Communications 5:

14.

Nobuchi T & Siripatanadilok S. 1991. Preliminary observation

of Aquilaria crassna wood associated with the

formation of aloeswood. Bulletin of Kyoto University

Forest: 226235.

Nor Azah MA, Chang YS, Mailina J, Said AA, Husni SS,

Hasnida HN & Yasmin YN. 2008. Comparison of

chemical profiles of selected gaharu oils from

Peninsular Malaysia. The Malaysian Journal of

Analytical Science 12: 338340.

Forest Research Institute Malaysia

563

Pornpunyapat J, Chetpattananondh P & Tongurai C. 2011.

Mathematical modeling for extraction of essential oil

from Aquilaria crassna by hydrodistillation and quality

of agarwood oil. Bangladesh Journal of Pharmacology

6: 1824.

P rachakul M. 1997. Anatomy of normal wood and

abnormal wood of Kristsanaa tree (Aquilaria

crassna Pierre ex H. Lec.). MSc thesis, Kasetsart

University, Bangkok.

Rashid AMA & Zuhaidi YA (eds). 2011. Tapping the Wealth

from Karas (Aquilaria malaccensis) Tree. Forest

Research Institute Malaysia, Kepong.

Rosli Y. 2009. Gaharu: Wang Tumbuh di atas Pokok. Jundi

Resources, Kuala Lumpur.

Rowell RM, Pettersen R, Han JS, Rowell JS & Tshabalala

MA. 2005. Cell wall chemistry. Pp 3655 in Rowell

RM (ed) Handbook of Wood Chemistr y and wood

composites. CRC Press, Boca Raton.

Shakhashiri BZ. 1989. Chemical Demonstrations: a Handbook

for Teachers of Chemistry. The University of Wisconsin

Press, Madison.

Shebani AN, Reenen AJv & Meinckenm. 2009. The effect of

wood extractives on the thermal stability of different

woodLLDPE composites. Thermochimica Acta 481:

5256.

Stokke DD & Groom LH. 2006. Characterization of the cellulosic

cell wall. Blackwell Publication, Ames.

Journal of Tropical Forest Science 24(4): 557564 (2012)

Nor Fazila K & Ku Halim KH

Wetwitayaklung P, Thavanapong N & Charoenteeraboon

J. 2009. Chemical constituents and antimicrobial

activity of essential oil and extracts of heartwood

of Aquilaria crassna obtained from water distillation

and supercritical fluid carbon dioxide extraction.

Silpakorn University Science and Technology Journal 3:

2533.

Wiedenhoeft AC & Miller RB. 2005. Structure and function

of wood. Pp 932 in Rowell RM (ed) Handbook

of wood chemistry and wood composites. CRC Press,

Boca Raton.

Forest Research Institute Malaysia

Winarni I & Waluyo TK. 2009. Technology processing on

particular Indonesian non-timber forest products

for enhancing their added values. Pp 17 in XIII

World Forestry Congress. 1823 October 2009, Buenos

Aires.

Z ulbadli N, A lwi H & H amid KHK. 2011. Momordica

charantia extraction by using pressurized boiling

system and compounds identification through gas

chromatography mass spectrometry. International

Journal of Engineering and Technology 11: 7984.

564

You might also like

- Column Design With ExcelDocument40 pagesColumn Design With ExcelMatiur Rahman BasumNo ratings yet

- Angle DesignDocument245 pagesAngle DesignGian CarloNo ratings yet

- By Ehsan Khazeni, Iran: Admin@tashtar - IrDocument7 pagesBy Ehsan Khazeni, Iran: Admin@tashtar - IrNilamdeen Mohamed ZamilNo ratings yet

- By Ehsan Khazeni, Iran: Admin@tashtar - IrDocument7 pagesBy Ehsan Khazeni, Iran: Admin@tashtar - IrNilamdeen Mohamed ZamilNo ratings yet

- Bsava Protect PosterDocument1 pageBsava Protect PosterNilamdeen Mohamed ZamilNo ratings yet

- Product List Vet PDFDocument6 pagesProduct List Vet PDFNilamdeen Mohamed Zamil75% (4)

- Solubility PDFDocument36 pagesSolubility PDFAshwin Narayan100% (1)

- Defects in Stainless SteelDocument31 pagesDefects in Stainless SteelPrabhakar Kattula80% (5)

- Wood VinegarDocument7 pagesWood VinegarAdrian MausigNo ratings yet

- Alkyd ResinDocument7 pagesAlkyd ResinSandip AgrawalNo ratings yet

- Compressor Anti-Surge ValveDocument2 pagesCompressor Anti-Surge ValveMoralba SeijasNo ratings yet

- Slide 1: No-Churn TelecomDocument11 pagesSlide 1: No-Churn Telecomleongladxton100% (1)

- SRU Presentation For NewDocument47 pagesSRU Presentation For Newviettanct100% (3)

- GenMath11 Q1 Mod26 Domain and Range of Logarithmic Functions 08082020Document19 pagesGenMath11 Q1 Mod26 Domain and Range of Logarithmic Functions 08082020Charity Myrh Pasquin ArzagaNo ratings yet

- Potassium in Water by Atomic Absorption Spectrophotometry: Standard Test Method ForDocument4 pagesPotassium in Water by Atomic Absorption Spectrophotometry: Standard Test Method ForhydrogenperoksideNo ratings yet

- (En) Evaluation of Optimal Conditions For Crude Palm Oil Bleaching On Locally Prepared Activated Carbon Using Rsm-Ga and A Hybrid Ann-GaDocument15 pages(En) Evaluation of Optimal Conditions For Crude Palm Oil Bleaching On Locally Prepared Activated Carbon Using Rsm-Ga and A Hybrid Ann-GaAli MulhakimNo ratings yet

- Optimization of Bleaching Parameters ofDocument6 pagesOptimization of Bleaching Parameters ofLangkuk Moses TaraNo ratings yet

- ST1508 020Document7 pagesST1508 020Dewala KutaNo ratings yet

- Formation and Characterization of Paint Based On Alkyd Resin Derivative of Ximenia Americana (Wild Olive) Seed OilDocument11 pagesFormation and Characterization of Paint Based On Alkyd Resin Derivative of Ximenia Americana (Wild Olive) Seed OilUlfahanny RachsetyaNo ratings yet

- Acid Value ASTM MethodDocument18 pagesAcid Value ASTM MethodLaras Wahyu SetyaningrumNo ratings yet

- Optimization of Palma - Based Wax Esters Production - Statistical Design of ExperimentsDocument10 pagesOptimization of Palma - Based Wax Esters Production - Statistical Design of Experimentsmarcelotoledo1No ratings yet

- Jurnal Bahan Alam TerbarukanDocument8 pagesJurnal Bahan Alam TerbarukanMuhamad Zunanda AjiNo ratings yet

- Linxing Yao JAOCS 2010Document9 pagesLinxing Yao JAOCS 2010Satyam BhuyanNo ratings yet

- Extraction and Identification of Bioactive Compounds From Agarwood LeavesDocument6 pagesExtraction and Identification of Bioactive Compounds From Agarwood LeavesAdrians SAFNo ratings yet

- Encapsulation of Sea Buckthorn Kernel Oil in Modified StarchesDocument5 pagesEncapsulation of Sea Buckthorn Kernel Oil in Modified StarchesNicolas AvendañoNo ratings yet

- Synthesis of Alkyd Resin Via Alcoholysis-Polyesterification Process Using Modified Avocado Seed Oil As A Potential Source of Raw MaterialDocument9 pagesSynthesis of Alkyd Resin Via Alcoholysis-Polyesterification Process Using Modified Avocado Seed Oil As A Potential Source of Raw MaterialIlham Kiki ShahilaNo ratings yet

- Physico-Chemical Characterization of Algal Oil - Kumar-2011 PDFDocument5 pagesPhysico-Chemical Characterization of Algal Oil - Kumar-2011 PDFrinkanNo ratings yet

- Synthesis of Alkyd Resin Modified With Waste Palm Cooking Oil As Precursor Using Pretreatment With Zeolite AdsorbentDocument4 pagesSynthesis of Alkyd Resin Modified With Waste Palm Cooking Oil As Precursor Using Pretreatment With Zeolite AdsorbentIlham Kiki ShahilaNo ratings yet

- Synthesis and Evaluation of Performance Characteristics of Rubber Seed Oil-Modified Short and Medium Alkyd ResinsDocument7 pagesSynthesis and Evaluation of Performance Characteristics of Rubber Seed Oil-Modified Short and Medium Alkyd ResinsijsidonlineinfoNo ratings yet

- Jurnal Enzim IndonesiaDocument7 pagesJurnal Enzim IndonesiaMarina Rosa AnggraeniNo ratings yet

- 10 1111@jfpp 13592Document11 pages10 1111@jfpp 13592serge ndomouNo ratings yet

- Gas Chromatography Mass Spectrometry Couple With Quadrupole Time-Of-Flight (GC-QTOF MS) As A Powerful Tool For Profiling of Oxygenated Sesquiterpenes in Agarwood OilDocument9 pagesGas Chromatography Mass Spectrometry Couple With Quadrupole Time-Of-Flight (GC-QTOF MS) As A Powerful Tool For Profiling of Oxygenated Sesquiterpenes in Agarwood OilRiza RinjaniNo ratings yet

- Beneficiation of Local Clay To Improve Its Performance in Adsorption of Carotene Pigments and Volatiles in The Bleaching of Palm OilDocument8 pagesBeneficiation of Local Clay To Improve Its Performance in Adsorption of Carotene Pigments and Volatiles in The Bleaching of Palm OilinventionjournalsNo ratings yet

- Synthesis Characterisation and Antimicrobial Evalu PDFDocument5 pagesSynthesis Characterisation and Antimicrobial Evalu PDFShreya RoyNo ratings yet

- Engineering Journal Biodiesel Production by Using CaO-Al2O3 Nano CatalystDocument7 pagesEngineering Journal Biodiesel Production by Using CaO-Al2O3 Nano CatalystEngineering JournalNo ratings yet

- (C) Extraction of Agarwood Using Supercritical (Thailand Mahidol University)Document5 pages(C) Extraction of Agarwood Using Supercritical (Thailand Mahidol University)asiapowerdriveNo ratings yet

- Full Characterisation of Crambe Abyssinica Hochst. Seed OilDocument6 pagesFull Characterisation of Crambe Abyssinica Hochst. Seed Oilwillian01No ratings yet

- Preliminary Chemical Analysis of Shea Butter Tree (Butyrospermum Parkii) LatexDocument9 pagesPreliminary Chemical Analysis of Shea Butter Tree (Butyrospermum Parkii) LatexInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Amansea Clay JournalDocument20 pagesAmansea Clay Journalcn.nwekeNo ratings yet

- Otra AlternativaDocument4 pagesOtra AlternativaKevin SalvatierraNo ratings yet

- ARTICULODocument6 pagesARTICULOKaterine CoralNo ratings yet

- Synthesis of Alkyd Resin From Non-Edible Jatropha Seed OilDocument6 pagesSynthesis of Alkyd Resin From Non-Edible Jatropha Seed OilDonald_12No ratings yet

- 2016, Supercritical Extraction of Sunflower Oil PDFDocument13 pages2016, Supercritical Extraction of Sunflower Oil PDFAmit RaiNo ratings yet

- tmpB2AD TMPDocument4 pagestmpB2AD TMPFrontiersNo ratings yet

- Extraction, Characterization of African Pear (Dacryodes Surface Coating DriersDocument9 pagesExtraction, Characterization of African Pear (Dacryodes Surface Coating DriersocmainNo ratings yet

- Production of Sunflower Oil Methyl Esters by Optimized Alkali-Catalyzed MethanolysisDocument4 pagesProduction of Sunflower Oil Methyl Esters by Optimized Alkali-Catalyzed MethanolysisMáximo Décimo MeridioNo ratings yet

- Romero-Hernadez 2021Document10 pagesRomero-Hernadez 2021Lorenth ArgüellesNo ratings yet

- Reduction of Peroxide Value in Used Palm Cooking Oil Using Bagasse AdsorbentDocument7 pagesReduction of Peroxide Value in Used Palm Cooking Oil Using Bagasse AdsorbentDeneshVijayNo ratings yet

- Compositional Characteristics of Sour Cherry Kernel and Its Oil PDFDocument6 pagesCompositional Characteristics of Sour Cherry Kernel and Its Oil PDFGeorgiana AndreeaNo ratings yet

- Journal of Food Engineering: Sarina Sulaiman, A.R. Abdul Aziz, Mohamed Kheireddine ArouaDocument7 pagesJournal of Food Engineering: Sarina Sulaiman, A.R. Abdul Aziz, Mohamed Kheireddine ArouaJonnah Faye MojaresNo ratings yet

- Effect of The NCO-OH Ratio On The Properties of Mesua Ferrea L Seed Oilmodified Polyurethane Resins.Document8 pagesEffect of The NCO-OH Ratio On The Properties of Mesua Ferrea L Seed Oilmodified Polyurethane Resins.aikhang teohNo ratings yet

- Optimization of The Soxhlet Extraction of Oil From Safou Pulp (Dacryodes Deulis)Document6 pagesOptimization of The Soxhlet Extraction of Oil From Safou Pulp (Dacryodes Deulis)yohannesNo ratings yet

- IJASR - Physico-Chemical Properties of Marking NutDocument8 pagesIJASR - Physico-Chemical Properties of Marking NutTJPRC PublicationsNo ratings yet

- Storage Stability of α-tocopherol Extracted from Heated and Un-heated Palm Oil MesocarpDocument10 pagesStorage Stability of α-tocopherol Extracted from Heated and Un-heated Palm Oil MesocarpTanwarat ChaikaewNo ratings yet

- Molecular Distillation For Recovering Tocopherol and Fatty Acid Methyl Esters From Rapeseed Oil Deodoriser DistillateDocument9 pagesMolecular Distillation For Recovering Tocopherol and Fatty Acid Methyl Esters From Rapeseed Oil Deodoriser DistillateSrđan TufegdžićNo ratings yet

- Jurnal Urea Formaldehyde 1Document9 pagesJurnal Urea Formaldehyde 1Afriyanti RosmadianaNo ratings yet

- Transesterification and Physical Properties of Fatty Acid Methyl Ester From Rubber Seed Oil.Document7 pagesTransesterification and Physical Properties of Fatty Acid Methyl Ester From Rubber Seed Oil.hanifahNo ratings yet

- A Study of The Effect of Palm Oil On The Properties of A New Alkyd ResinDocument8 pagesA Study of The Effect of Palm Oil On The Properties of A New Alkyd ResinUsama AwadNo ratings yet

- Akmar 22 1 20Document9 pagesAkmar 22 1 20Becky LawnsNo ratings yet

- Extraction of Oil From Algae For Biodiesel ProductDocument8 pagesExtraction of Oil From Algae For Biodiesel ProductAbdisa GemechuNo ratings yet

- Alkyd Based Resin From Non Drying Oil 2014 Procedia EngineeringDocument11 pagesAlkyd Based Resin From Non Drying Oil 2014 Procedia EngineeringMuhammad FurqanNo ratings yet

- Behavior of Flavor Release From Emulsified D-Limonene in Spray-Dried Powders With Various Wall MaterialsDocument7 pagesBehavior of Flavor Release From Emulsified D-Limonene in Spray-Dried Powders With Various Wall MaterialsHermawan Dwi AriyantoNo ratings yet

- Comparison Study of Rubber Seed Shell and Kernel (Hevea: Brasiliensis) As Raw Material For Bio-Oil ProductionDocument8 pagesComparison Study of Rubber Seed Shell and Kernel (Hevea: Brasiliensis) As Raw Material For Bio-Oil ProductionGrace ApriliaNo ratings yet

- 3130-6400-1-RV Edit TEADocument9 pages3130-6400-1-RV Edit TEAMuhammad NopriyansyahNo ratings yet

- Synthesis and Characterization of Styrenated Rubber Seed Oil AlkydDocument6 pagesSynthesis and Characterization of Styrenated Rubber Seed Oil AlkydDeacy SulaimanNo ratings yet

- Demulsif SaltDocument12 pagesDemulsif SaltLidiya KirilovaNo ratings yet

- Methyl Ester Synthesis of Crude Palm Oil Off GradeDocument11 pagesMethyl Ester Synthesis of Crude Palm Oil Off GradeDiar RickiNo ratings yet

- 0101-2061-Cta-Fst43317 Tablas de Acidez, Segun AlmacenamientoDocument7 pages0101-2061-Cta-Fst43317 Tablas de Acidez, Segun AlmacenamientoMANUEL JULCANo ratings yet

- BioRes 09 2 2382 Salem AA Stem Wood Bark Extract Delonix Regia 5238Document14 pagesBioRes 09 2 2382 Salem AA Stem Wood Bark Extract Delonix Regia 5238Cassandruh jennerNo ratings yet

- Egg Shell Waste-Catalyzed Transesterification of Mustard Oil: Optimization Using Response Surface Methodology (RSM)Document6 pagesEgg Shell Waste-Catalyzed Transesterification of Mustard Oil: Optimization Using Response Surface Methodology (RSM)Tanjina azadNo ratings yet

- Optimization of Biodiesel Production From Non-Edible Seeds Of0Gul MohrDocument9 pagesOptimization of Biodiesel Production From Non-Edible Seeds Of0Gul MohrINUWA LAMIDONo ratings yet

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesFrom EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNo ratings yet

- Application Form For The Registration of Importers & ExportersDocument4 pagesApplication Form For The Registration of Importers & ExportersNilamdeen Mohamed ZamilNo ratings yet

- Bajaj Pulsar Discover - XLSX 0Document9 pagesBajaj Pulsar Discover - XLSX 0Nilamdeen Mohamed ZamilNo ratings yet

- Series Centrifugal Pump With Flanged Connection: LimitsDocument5 pagesSeries Centrifugal Pump With Flanged Connection: LimitsNilamdeen Mohamed ZamilNo ratings yet

- Early Journal Content On JSTOR, Free To Anyone in The WorldDocument23 pagesEarly Journal Content On JSTOR, Free To Anyone in The WorldNilamdeen Mohamed ZamilNo ratings yet

- Terms & Conditions For Lounge Access and Excess Baggage ( )Document2 pagesTerms & Conditions For Lounge Access and Excess Baggage ( )Nilamdeen Mohamed ZamilNo ratings yet

- Importers Drugs1 2016Document2 pagesImporters Drugs1 2016Nilamdeen Mohamed ZamilNo ratings yet

- Matrix Magic SquaresDocument31 pagesMatrix Magic SquaresNilamdeen Mohamed Zamil100% (1)

- Antibiotics PDFDocument4 pagesAntibiotics PDFNilamdeen Mohamed ZamilNo ratings yet

- Magic Squares, Continued: V. Using One of The Magic Squares You Created Using Digits (0-8), Perform The FollowingDocument3 pagesMagic Squares, Continued: V. Using One of The Magic Squares You Created Using Digits (0-8), Perform The FollowingNilamdeen Mohamed ZamilNo ratings yet

- Automatic Self-Priming Pump With Brass Impeller CoverDocument4 pagesAutomatic Self-Priming Pump With Brass Impeller CoverNilamdeen Mohamed ZamilNo ratings yet

- General Conditions of Sale Relating To Internet Sales by Pipa To ConsumersDocument8 pagesGeneral Conditions of Sale Relating To Internet Sales by Pipa To ConsumersNilamdeen Mohamed ZamilNo ratings yet

- Burg GraffDocument2 pagesBurg GraffNilamdeen Mohamed ZamilNo ratings yet

- 1119827169eijerkamp and Heremans-CeustersDocument4 pages1119827169eijerkamp and Heremans-CeustersNilamdeen Mohamed ZamilNo ratings yet

- Our Lord! Send Salutations Upon Muhammad, The Untaught Prophet, Upon His Family and Send (Continuous) Peace.Document1 pageOur Lord! Send Salutations Upon Muhammad, The Untaught Prophet, Upon His Family and Send (Continuous) Peace.Nilamdeen Mohamed ZamilNo ratings yet

- Folder 2009 JosDocument1 pageFolder 2009 JosNilamdeen Mohamed ZamilNo ratings yet

- LDteamDocument1 pageLDteamNilamdeen Mohamed ZamilNo ratings yet

- Product List VetDocument6 pagesProduct List VetNilamdeen Mohamed Zamil100% (2)

- Du$27as For The ToiletDocument1 pageDu$27as For The ToiletNilamdeen Mohamed ZamilNo ratings yet

- Olympic 2008 Part 2Document1 pageOlympic 2008 Part 2Nilamdeen Mohamed ZamilNo ratings yet

- Etiquette Before SleepingDocument1 pageEtiquette Before SleepingNilamdeen Mohamed ZamilNo ratings yet

- Her Bots 2008Document1 pageHer Bots 2008Nilamdeen Mohamed ZamilNo ratings yet

- CatalogDocument18 pagesCatalogNilamdeen Mohamed ZamilNo ratings yet

- "Our Lord!: Sit and Drink With The Right Hand Animals Standing and DrinkingDocument1 page"Our Lord!: Sit and Drink With The Right Hand Animals Standing and DrinkingNilamdeen Mohamed ZamilNo ratings yet

- When Leaving The HomeDocument1 pageWhen Leaving The HomeNilamdeen Mohamed ZamilNo ratings yet

- Marcel SangersDocument20 pagesMarcel SangersNilamdeen Mohamed ZamilNo ratings yet

- Enabling Arabic Input: Yping in Rabic IndowsDocument6 pagesEnabling Arabic Input: Yping in Rabic IndowsNilamdeen Mohamed ZamilNo ratings yet

- Fiitjee Fiitjee Fiitjee Fiitjee: Fortnightly Assessment QuizDocument8 pagesFiitjee Fiitjee Fiitjee Fiitjee: Fortnightly Assessment QuizIshaan BagaiNo ratings yet

- Chapter 2 Approaches To Software DesignDocument25 pagesChapter 2 Approaches To Software DesigntarunkakkarNo ratings yet

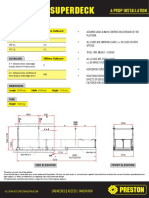

- SuperDeck All ModelsDocument12 pagesSuperDeck All Modelsarthur chungNo ratings yet

- Report OmarDocument14 pagesReport OmarYasir KhursheedNo ratings yet

- Class 10 Science Chapter 2 Revision NotesDocument16 pagesClass 10 Science Chapter 2 Revision NotesKriish RatnaniNo ratings yet

- Surveying PDFDocument215 pagesSurveying PDFShaira Mae Cañedo100% (1)

- Kitar FosforusDocument4 pagesKitar FosforusMohd Hakimi MD Setapa100% (1)

- Experiment 08-A2dDocument3 pagesExperiment 08-A2dapi-277396867No ratings yet

- DeskView Client 6 45 enDocument166 pagesDeskView Client 6 45 enRazvan22081997No ratings yet

- Quantum Computing: Exercise Sheet 1: Steven Herbert and Anuj DawarDocument2 pagesQuantum Computing: Exercise Sheet 1: Steven Herbert and Anuj DawarJuan DiegoNo ratings yet

- Chapter 6: Fatigue Failure: Introduction, Basic ConceptsDocument21 pagesChapter 6: Fatigue Failure: Introduction, Basic ConceptsNick MezaNo ratings yet

- Nilfisk 2016Document12 pagesNilfisk 2016Ilham HamidNo ratings yet

- Fujitsu APMDocument2 pagesFujitsu APMLuis D100% (1)

- RS 385SHDocument3 pagesRS 385SHshahpinkalNo ratings yet

- Corrosion Properties of Copper Nickel Alloys in Chlorinated Sea WaterDocument14 pagesCorrosion Properties of Copper Nickel Alloys in Chlorinated Sea WaterArunNo ratings yet

- Dell's Guide To Server Basics: Click On The Questions Below To Learn More About Servers: 1. 2. 3. 4. 4.1. 4.2. 4.3. 5. 6Document11 pagesDell's Guide To Server Basics: Click On The Questions Below To Learn More About Servers: 1. 2. 3. 4. 4.1. 4.2. 4.3. 5. 6rameshNo ratings yet

- Decompiled With CFR ControllerDocument3 pagesDecompiled With CFR ControllerJon EricNo ratings yet

- Lab Guide #2 Coulombs LawDocument3 pagesLab Guide #2 Coulombs LawJoriel CruzNo ratings yet

- PLCC-28: FeaturesDocument5 pagesPLCC-28: Features肖磊No ratings yet

- Model 793.00 System SoftwareDocument750 pagesModel 793.00 System SoftwareMichel Zarzosa RojasNo ratings yet

- LISTA PRECIOS CORPORATIVOS - Garantia en Partes de Diez (10) MesesDocument10 pagesLISTA PRECIOS CORPORATIVOS - Garantia en Partes de Diez (10) MesesJavier DavidNo ratings yet