Professional Documents

Culture Documents

Inoculation of Cast Iron

Uploaded by

arnaldorcr8646Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inoculation of Cast Iron

Uploaded by

arnaldorcr8646Copyright:

Available Formats

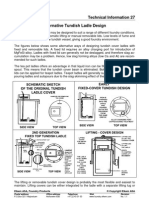

Technical Information 2

Inoculation of Cast Iron

Inoculation is a means of controlling the structure and properties of cast irons by increa-

sing the number of nucleation sites available for the growth of graphite flakes in grey irons

or graphite nodules in ductile irons. This reduces undercooling during eutectic solidification

thereby minimizing the risk of forming hard iron carbides or "chill" in the structure, parti-

cularly in thin sections.

An inoculant is a material added to the liquid iron just before casting that provides suitable

sites for the nucleation of graphite. The most effective inoculants are ferrosilicon alloys

containing small amounts of one or more of the elements Ca, Ba, Sr, Zr and/or Ce.

The micrographs and table below show examples of structures and properties obtained in

grey and ductile iron with and without the addition of an inoculant. As seen from the micro-

graphs, the uninoculated castings (left) contain large quantities of hard, brittle iron

carbides (cementite, Fe3C) and very poor graphite structures. The inoculated castings

(right) contain uniform structures of small, random oriented flakes (grey iron) and a large

number of small graphite nodules in a ferrite/pearlite matrix (ductile iron).

Graphite structure of uninoculated Graphite structure of inoculated grey

grey cast iron (100X). cast iron (100X).

Microstructure of uninoculated Microstructure of inoculated ductile

ductile cast iron (100X). cast iron (100X).

Elkem ASA, Foundry Products © Copyright Elkem ASA

Postal address Office address Telephone Web Revision

P.O.Box 5211 Majorstuen Hoffsveien 65B +47 22 45 01 00 www.foundry.elkem.com No. 2.1

NO-0302 Oslo Oslo Telefax Org. no. 20.03.2004

Norway Norway +47 22 45 01 52 NO 911 382 008 MVA

Technical Information 2 2

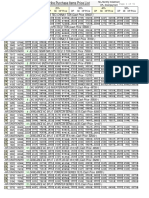

Typical properties of uninoculated compared to inoculated ductile iron.

Property Uninoculated Inoculated

Proof Strength Rp0.2 Not detected 200 - 400 MPa

Tensile Strength Rm < 300 MPa 350 - 800 MPa

Elongation A5 Not detected 3 - 30 %

Brinell Hardness HB > 600 140 - 300

2 2

Nodule Count 10 mm section < 50 per mm > 150 per mm

Microstructure ASTM Classification Carbidic Ferritic and/or Pearlitic

Important Benefits of Inoculation:

1. Eliminate the formation of hard, brittle iron carbides (cementite) often referred to as

"chill" in the structure and promote the formation of graphite during eutectic solidifi-

cation.

2. Improve machinability and mechanical properties and reduce variations due to

changes in section size.

3. Increase the number of graphite nodules in ductile irons thereby producing finer,

more uniform structures over a range of section thicknesses. Such structures

promote improved mechanical properties, a reduction in the segregation tendency

of some alloying or trace elements in the iron and give better machinability.

Note that certain iron conditions, for example initial sulphur content (grey iron), tempera-

ture and total “fade” time will affect the selection of a proprietary inoculant. Reference

should be made to Elkem Technical Information Sheets No. 15 and 16 before selecting an

inoculant for use.

For more detailed information on inoculation and proprietary inoculants see Elkem

Brochures:

"Cast Iron Inoculation",

"Foundrisil® Inoculant", and

"Superseed® Inoculant".

You might also like

- Common Metallurgical Defects in Ductile Cast IronDocument10 pagesCommon Metallurgical Defects in Ductile Cast IronsateeshkoriNo ratings yet

- Inoculation of Grey and Ductile Iron A Comparison of Nucleation Sites and Some Practical AdvisesDocument12 pagesInoculation of Grey and Ductile Iron A Comparison of Nucleation Sites and Some Practical AdvisesZody YtuNo ratings yet

- Common Metallurgical Defects in Ductile Cast IronDocument10 pagesCommon Metallurgical Defects in Ductile Cast IronsateeshkoriNo ratings yet

- Nitrogen FissuresDocument1 pageNitrogen Fissuresarnaldorcr8646100% (1)

- Determining The Optimum Level of Inoculant Addition by Thermal Analysis - A Case Study, Ductile Iron News, Dec 2004Document8 pagesDetermining The Optimum Level of Inoculant Addition by Thermal Analysis - A Case Study, Ductile Iron News, Dec 2004arnaldorcr8646No ratings yet

- Compacted Iron ElkemDocument20 pagesCompacted Iron ElkemAmol ThakurNo ratings yet

- Heat Conservation in Liquid Iron, 2005-07-10Document5 pagesHeat Conservation in Liquid Iron, 2005-07-10arnaldorcr8646100% (1)

- Common Metallurgical Defects in Ductile Cast IronDocument10 pagesCommon Metallurgical Defects in Ductile Cast IronsateeshkoriNo ratings yet

- Inoculation of Heavy Section CastingsDocument2 pagesInoculation of Heavy Section Castingsarnaldorcr8646100% (1)

- In The Mould Nodular Is IngDocument2 pagesIn The Mould Nodular Is Ingarnaldorcr8646No ratings yet

- Magnesium Versus Sulphur in Ductile IronDocument2 pagesMagnesium Versus Sulphur in Ductile Ironarnaldorcr8646100% (2)

- Internal Shrinkage PorosityDocument1 pageInternal Shrinkage Porosityarnaldorcr8646100% (2)

- Magnesium Slag Defects in Ductile IronDocument1 pageMagnesium Slag Defects in Ductile Ironarnaldorcr8646100% (1)

- Slag Defects in Grey IronDocument1 pageSlag Defects in Grey Ironarnaldorcr8646100% (1)

- Hydrogen PinholesDocument1 pageHydrogen Pinholesarnaldorcr8646No ratings yet

- Carbon Monoxide Blowholes in Grey IronDocument1 pageCarbon Monoxide Blowholes in Grey Ironarnaldorcr8646No ratings yet

- Elkem 19 Aluminum in Cast IronDocument2 pagesElkem 19 Aluminum in Cast Ironmarcotulio123No ratings yet

- Selection of Inoculants For Grey Cast IronDocument2 pagesSelection of Inoculants For Grey Cast Ironarnaldorcr8646No ratings yet

- Selection of NodularizersDocument2 pagesSelection of Nodularizersarnaldorcr8646100% (2)

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronDocument2 pagesPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646No ratings yet

- Recommended Target Analysis For Grey IronDocument2 pagesRecommended Target Analysis For Grey Ironarnaldorcr8646No ratings yet

- Heat Conservation in Liquid IronDocument2 pagesHeat Conservation in Liquid Ironarnaldorcr8646No ratings yet

- Factors Influencing The Recovery and Addition of MagnesiumDocument4 pagesFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646No ratings yet

- Poor Nodularity in Ductile IronDocument2 pagesPoor Nodularity in Ductile Ironarnaldorcr864675% (4)

- Late Metal Stream InoculationDocument2 pagesLate Metal Stream Inoculationarnaldorcr8646No ratings yet

- Factors Influencing The Recovery and Addition of MagnesiumDocument4 pagesFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646No ratings yet

- The "Sandwich Pocket Process"Document2 pagesThe "Sandwich Pocket Process"arnaldorcr8646No ratings yet

- Selection of Inoculants For Ductile Cast IronDocument1 pageSelection of Inoculants For Ductile Cast Ironarnaldorcr8646100% (1)

- Fading of Nodularity in Ductile IronDocument2 pagesFading of Nodularity in Ductile Ironarnaldorcr8646100% (4)

- Alternative Tundish Ladle DesignDocument2 pagesAlternative Tundish Ladle Designarnaldorcr8646No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- HPDocument51 pagesHPKhan Basit KhanNo ratings yet

- Questions and Answers On Composite Materials and Structures: June 2017Document16 pagesQuestions and Answers On Composite Materials and Structures: June 2017airbuk doeingNo ratings yet

- Assiut Cement PlantDocument17 pagesAssiut Cement PlantMahmoud RashadNo ratings yet

- Mahaveer Agro Chemicals Manufacturer Agricultural FertilizersDocument10 pagesMahaveer Agro Chemicals Manufacturer Agricultural FertilizersDEEPAK SINGHNo ratings yet

- Pressure Molding & Vacuum Forming Processes ExplainedDocument22 pagesPressure Molding & Vacuum Forming Processes ExplainedRik PtlNo ratings yet

- Filament Winding Process GuideDocument17 pagesFilament Winding Process GuideCharaf Leo100% (1)

- Analysis of Metal Bearing Ores and Related Materials For Carbon, Sulfur, and Acid-Base CharacteristicsDocument24 pagesAnalysis of Metal Bearing Ores and Related Materials For Carbon, Sulfur, and Acid-Base CharacteristicsEric GozzerNo ratings yet

- Composite Propane Cylinder Fire Safety RiskDocument19 pagesComposite Propane Cylinder Fire Safety RiskOoNo ratings yet

- PENGARUH QUENCHING DAN TEMPERING TERHADAP SIFAT BAJA S45CDocument14 pagesPENGARUH QUENCHING DAN TEMPERING TERHADAP SIFAT BAJA S45CRefi RahmaliaNo ratings yet

- Silcone Glass Cloth Tech SheetDocument1 pageSilcone Glass Cloth Tech SheetOdo AsuNo ratings yet

- Eaton Capri Ade4f Datasheet Inch en UsDocument2 pagesEaton Capri Ade4f Datasheet Inch en UsqsdfqsoqzfuiNo ratings yet

- Sarten Volcable Clevelam CLE SGM 40 TR - SPMDocument29 pagesSarten Volcable Clevelam CLE SGM 40 TR - SPMRicardo Del Castillo VillacortaNo ratings yet

- Installation Guidance For Cement Rotary Kiln (LKB)Document20 pagesInstallation Guidance For Cement Rotary Kiln (LKB)Waka OngetiNo ratings yet

- FH FH: Horizontal Basket StrainerDocument1 pageFH FH: Horizontal Basket StrainerjechurchNo ratings yet

- One Point LessonDocument8 pagesOne Point LessonVenkatesanNo ratings yet

- Sepuran® N Module 4": in NM /H at 7 Barg 25°CDocument2 pagesSepuran® N Module 4": in NM /H at 7 Barg 25°CsanjaigNo ratings yet

- Graphenstone TDS - MortarBase-Premium - 2018Document2 pagesGraphenstone TDS - MortarBase-Premium - 2018Nicholas ThengNo ratings yet

- Physical Science Quarter 3 Week 2: Not For SaleDocument7 pagesPhysical Science Quarter 3 Week 2: Not For SaleChristien Kate GonzalesNo ratings yet

- Flyer Non-Return-Valves Edition07 20-04-2018 ENDocument12 pagesFlyer Non-Return-Valves Edition07 20-04-2018 ENЊегош ТешановићNo ratings yet

- Cambridge IGCSE: Combined Science 0653/62Document16 pagesCambridge IGCSE: Combined Science 0653/62septina restuNo ratings yet

- Balluff Chemical ResistanceDocument17 pagesBalluff Chemical ResistanceHéctor Eduardo Hernández LópezNo ratings yet

- Acids, Bases and IndicatorsDocument12 pagesAcids, Bases and IndicatorsDavyieNo ratings yet

- Polyols and Polyurethanes From Renewable Sources: Past, Present and Future-Part 1: Vegetable Oils and Lignocellulosic BiomassDocument22 pagesPolyols and Polyurethanes From Renewable Sources: Past, Present and Future-Part 1: Vegetable Oils and Lignocellulosic BiomassDevarshi ModiNo ratings yet

- Palpadores M2 RENISHAWDocument8 pagesPalpadores M2 RENISHAWJosevi Jiménez MerinoNo ratings yet

- 649 1 PDFDocument239 pages649 1 PDFZainul AbideenNo ratings yet

- TORQWIN Screw CatalogDocument8 pagesTORQWIN Screw Catalogjoel borlandNo ratings yet

- WS2032D3Document4 pagesWS2032D3Luis David Méndez MirandaNo ratings yet

- MO-114D/104D: Instruction ManualDocument32 pagesMO-114D/104D: Instruction Manualmikail2008No ratings yet

- AMIF Sanitary Design ChecklistsDocument12 pagesAMIF Sanitary Design ChecklistsGustavoNo ratings yet

- Hot Water SupplyDocument56 pagesHot Water SupplyVismithaNo ratings yet