Professional Documents

Culture Documents

Paper 132

Uploaded by

Devsoth NareshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paper 132

Uploaded by

Devsoth NareshCopyright:

Available Formats

EuroGeo4 Paper number 132

THE USE OF GEOCELLS IN ROAD CONSTRUCTIONS OVER SOFT SOIL: VERTICAL STRESS AND

FALLING WEIGHT DEFLECTOMETER MEASUREMENTS

Ansgar Emersleben1 & Norbert Meyer2

1

Institute of Geotechnical Engineering, Technology University of Clausthal. (e-mail: Ansgar.Emersleben@tuclausthal.de)

2

Institute of Geotechnical Engineering, Technology University of Clausthal. (e-mail: norbert.meyer@tu-clausthal.de)

Abstract: Geocells consist of a series of interconnected single cells that are manufactured from different types of

polymers. The geocells are expanded at the construction site and filled with soil. The cell walls completely encase the

infill material and provide all-round confinement to the soil. During vertical loading, hoop stresses within the cell

walls and earth resistance in the adjacent cells are mobilized which increases the stiffness and the load-deformation

behaviour of the soil. Thus the soil-geocell layers acts as a stiff mat and distribute the vertical traffic loads over a

much larger area of the subgrade soil. Large scale static load tests were carried out to evaluate the influence of a

geocell layer on the load-deformation behaviour of the soil. The test results show that a geocell layer increases the

bearing capacity of the infill materials up to three times compared to an unreinforced soil. The vertical stresses on the

soft subgrade, measured by eight earth pressure cells, where also reduced about 30 percent. To verify the results of

model tests in-situ field test where carried out within different road constructions. Earth pressure cells where installed

on the subgrade to measure the influence of the geocell layers on the stress distribution. After finishing the road

construction vehicle crossing tests with a 40-ton truck were carried out while the stresses on the subgrade where

measured. Compared to an unreinforced test section the stresses beneath the geocell layer were reduced by about 30

percent. In addition to vertical stress measurements, falling weight deflectometer (FWD) measurements were

conducted in reinforced and unreinforced test sections. The results show that the deflections measured in geocell

reinforced test section were significantly smaller than in the unreinforced section. Back calculated layer modules were

significantly higher in the geocell reinforced section compared to an unreinforced section.

Keywords: geocell, cellular system, earth reinforcement, field measurement, soil improvement, load tests

INTRODUCTION

Geocells are honeycomb interconnected cells that completely encase the soil and provide all-around confinement,

thus preventing the lateral spreading of the infill material. Due to the confinement of the soil the geocells increase the

stiffness and the load-deformation behaviour of gravel base layers and thereby reduce the deformation of the soil. The

soil-geocell layers act as a stiff mat, thus distributing the vertical traffic loads over a much larger area of the subgrade

soil.

Several model tests (e.g. Dash et al. 2001, 2003, Sitharam &Siressh 2005) have shown the positive effect of

geocells, made from different geogrids, on the load bearing capacity of soils. Meyer & Emersleben (2005a, 2005b,

2005c, 2006a, 2006b) and Mhaiskar & Mandal (1992) have evaluated the influence of industrially manufactured

geocells on the load-deformation behaviour of soils.

The use of geocells to stabilize unpaved road constructions is far from common, especially if suitable soils are not

available near the construction site (Ben Kurari 2000, Forsman et al. 1998, Leytland et al. 2006). The stabilization of

gravel base layers of asphalt paved road constructions over soft soils with geocells is an alternative technique to

reduce the deformation of the asphalt surface and to increase the stiffness of the main construction. Al Quadi &

Hughes (2000) reported an increase of the resilient modules of aggregate layers about two times due to the installation

of geocells within an asphalt paved road construction.

This paper reports the results of static load tests and in in-situ field tests. By means of vertical stress measurements

beneath the geocell layers and by means of falling weight deflectometer (FWD) measurements in geocell reinforced

test fields the positive influence of geocells was evaluated.

LARGE SCALE MODEL TESTS

Test Device

To evaluate the influence of geocells on the load bearing capacity of soil and the stress distribution large scale

model tests were carried out in a test box with internal dimensions of 2m length, 2m width and 2m height. Static load

is applied over a loading frame, and vertical loads up to 150 kN can be applied. The loads are applied by a hydraulic

jack and are transferred by a steel plate with a diameter of 30 cm to the soil.

To measure the heave and settlement on the soil surface five inductive displacement gauges were installed at

different distances from the centre of the load plate. For the determination of the stress distribution below the geocells,

eight earth pressure cells were installed at a depth of 35 cm. The earth pressure cells (EPC) with a diameter of 5 cm

and a maximum pressure capacity of 500 kN/m were aligned at different distances to the load plate.

EuroGeo4 Paper number 132

Materials

Soils

An artificial mixed soil called Glyben was used to simulate soft subgrade material. The soil consists of glycerine

and bentonite. The soil parameters depend on the rate of mixture. The soil was mixed in small portions, placed in the

test box and compacted. The main advantage of Glyben compared to other cohesive soils is that the soil parameters are

constant for a long time because the water or glycerine content is not changing. The mixed Glyben is not saturated and

has an undrained cohesion of cu = 15 kPa and a friction angle of u = 8. The stiffness modulus from axial

compression tests at relevant loads is about 5 MN/m.

Dry sand with a maximum particle size of 2 mm was used as infill material for the geocells as well as for the

unreinforced tests. The coefficient of uniformity (Cu) was 3.2 the coefficient of curvature (Cc) was 1.03. The

maximum and minimum void ratio of the sand is 0.45 and 0.34. The void ratio at infill density was 0.39. The friction

angle at infill density was 38.9. The sand was poured into the test box and compacted with a vibration plate

compactor.

Geocells

Two different types of geocells were used in the model tests. Geocell Typ 1 was made from high density

polyethylene (HDPE) with a density of 0.95 g/cm. Single cells are 210 mm long and 250 mm wide. Single cells with

a cell area of 262 cm were welded together to form a uniform geocell mattress. The geocells have seam strength,

depending on the height: 1150 N (10 cm height), 1725 N (15 cm height) and 2290 N (20 cm height). The cell walls are

perforated with 10 mm diameter holes. The total open area is 16 % of the cell wall area. The surface of the cell walls is

textured. Three different cell heights (h) of 10 cm, 15 cm and 20 cm were tested in the model tests while the

equivalent cell diameter (d0 = 23 cm) was constant in all tests.

Geocell Typ 2 was made from a thermally solidified non-woven geosynthetic with a tensile strength of 20.7

kN/m. The peel strength of the junction points is 10 kN/m and the shear strength is 13 kN/m. Three different cell

diameters (d0) of 16 cm, 22 cm and 30 cm were tested in the model tests at a constant cell height of h = 20 cm.

Test installation

After the walls of the test box were covered with foil and lubricant to minimize the friction between the soil and

the infill material, the subgrade layer was installed. Glyben was placed in the test box in 10 cm layers up to a height of

1 m. Afterwards the installation and adjustment of eight earth pressure cells took place. They were laid in a thin sand

bed at different distances to the load device, aligned and covered with sand. The layer thickness above the pressure

cells was selected to be equal in all tests. The distance between the pressure cells and the load plate was chosen to be

35 cm. Extensive preliminary tests indicate that a minimum distance of 15 cm between the pressure cells and the lower

edge of the geocells is necessary in order to measure a representative stress distribution in the ground. On the subgrade

material a non-woven with low tensile strength at high strains was placed over the soil to separate the subgrade and

infill material. The geocells were then placed on the non-woven. The geocells were stretched, adjusted with steel bars,

filled with dry sand and compacted by a vibrating plate compactor. The load plate and displacement gauges were

installed on the sand surface. The schematic experimental setup is shown in Figure 1.

Figure 1: Schematic diagram of test device.

EuroGeo4 Paper number 132

Static load was applied in steps. The number of applied load steps depended on the maximum bearing capacity of

the soil. Every load step was applied until no further settlement was observed.

TEST RESULTS

Load carrying capacity

The increase in load carrying capacity due to the provision of geocell layer is represented using a non-dimensional

load carrying factor (LCF).

LCF =

r,(s)

u,(s)

[ ]

The LCF is defined as the ratio of the footing pressure with geocells at a given settlement r,(s) to the corresponding

pressure of the unreinforced soil at the same settlement u,(s). The calculated load carrying factors for two different test

series are presented in Figure 2. Test series A was conducted with geocell typ 1 to measure the influence of the

geocell height on the load-deformation behaviour and test series B was carried out with geocell typ 2 to measure the

influence of different cell diameters on the load-deformation behaviour.

The load carrying factors were calculated up to load a of 400 kN/m respectively up to a settlement of 16 mm. At

this settlement the ultimate bearing capacity of the unreinforced sand was reached.

Figure 2: Load carrying factors for test series A (typ 1, d = 230 mm) and test series B (typ 2, h = 200 mm).

The load carrying capacity increases with increasing cell height and decreasing cell diameter. Depending on

geocell height and diameter, the load carrying capacity could be improved up to 1.5 times due to the reinforcement of

dry sand with geocells. Further improvement will occur at higher settlement and loads because the ultimate bearing

capacity of unreinforced sand could not be increased while the ultimate bearing capacity of the reinforced sand was

not reached at a load of 400 kN/m.

Vertical stresses

During static load tests vertical stresses on the subgrade were measured with eight pressure cells at different

distances from the load plate. To avoid influences on the stress distribution resulting from measured peak stresses in

single pressure cells the stresses of two pressure cells, which are lying next to each other, were averaged according to

the following equation.

epc,i =

epc,i + epc,i +1

Vertical stresses were measured in every test. Exemplary the results of tests with 20 cm height and 23 cm in

diameter geocells typ 1 are presented in Figure 3b for different loads. Vertical stresses measured in the

corresponding unreinforced test are presented in Figure 3a.

The stresses that are measured in the unreinforced soil are significantly higher than those measured in the geocell

reinforced soil at the same load. A stress reduction between 30% and 36% can be observed depending of the applied

load. Similar results were observed for different cell heights and cell diameters.

In the unreinforced soil the stresses are more concentrated in the area of the load plate while the stresses in the

geocell reinforced soil are distributed over a larger area. These results indicate that the geocell layer acts like a stiff

matt and distributes the footing load over a larger area thus reducing the vertical stresses directly beneath the load

plate. This effect increases with increasing load. Similar results were observed by Dash et al. (2003). The influence of

different cell heights and cell diameters on the magnitude of vertical stresses was marginal.

3

EuroGeo4 Paper number 132

Figure 3: Measured vertical stresses on subgrade, unreinforced sand (l) and geocell typ1 reinforced sand (r).

IN-SITU TEST FIELDS

To verify the results of large scale model tests, two different in-situ tests fields were carried out. Geocells were

placed within the gravel base layers of two different asphalt paved road constructions. To measure the vertical stresses

on the subgrade the test sections were instrumented with earth pressure cells. After the road constructions were

finished vehicle crossing tests were carried out while the stresses on the subgrade were measured. In addition falling

weight deflectometer (FWD) measurements were conducted.

Reconstruction of the road K-23

The existing road K-23 consisted in the upper part of an approximately 20 cm thick asphalt layer. Below the

asphalt layer there was a 15 cm gravel base layer. The underlying ground consisted of sandy clay with low bearing

capacity. At both sides of the street a drainage channel was located a small distance from the pavement over the whole

length of the road to drain the adjacent agricultural areas. The existing road had to be reconstructed since a large

number of cracks have appeared on the road and lane grooves in the outer areas of the pavement have developed.

Because of the close proximity of the drainage channels to the road the lateral support of the pavement was

insufficient, deformations of the outer road areas have taken place and rutting has occurred due to traffic.

The main reconstruction concept of the existing road consists of stabilization of the road foundations. In addition a

new bituminous asphalt pavement is placed on the existing road surface.

First of all the existing asphalt layers were removed at the sides of the road to a width of between one and two

meters. After that, the gravel and the soil beneath the asphalt layers were removed to a depth of 70 cm. After

compaction of the subgrade material a new 70 cm thick gravel layer with a maximum particle size of 32 mm was

placed in layers of 15 to 25 cm thickness. An approximately 1 m wide band in the middle of the road was not rebuilt at

all. In this part of the road only the existing cracks were filled. When the gravel layers at the road sides were built up

completely a 17.5 cm thick new asphalt pavement was applied over the whole width of the road (Figure 4).

In one part of the road an alternative road reconstruction was used, using typ 1 geocells. 20 cm high geocells

with a diameter of 23 cm were installed on a length of approximately 500 m directly below the asphalt layer (Figure

4).

Figure 4: Different reconstruction section, road K-23.

In this section, first of all the existing 20 cm thick asphalt course was removed. After that the base course,

consisting of a 40 cm gravel layer, was also removed until the subgrade was reached. Load plate tests on the subgrade

4

EuroGeo4 Paper number 132

gave an Ev2-value of 20 MN/m. After the Subgrade was compacted, earth pressure cells were installed on the

subgrade. After the installation of earth pressure cells a new 15 cm thick gravel layer 0/22 mm was built up and

compacted. In one section a non-woven was installed on the surface of the gravel layer. The geocells were placed on

top of the non-woven. After the installation of the geocells they were filled with gravel with a maximum particle size

of 22 mm until the old road surface was reached, then the infill material was compacted (Figure 5). Another section

was built up without geocells in the same way.

Figure 5: Installation of geocell layer directly beneath the asphalt surface.

When the installation of the geocell mattress had been finished the new 17.5 cm asphalt course was applied. The

asphalt course consists of a 10 cm thick base course 0/32 mm, a 4 cm thick binder layer 0/16 mm and a 3.5 cm thick

wearing layer of SMA 0/8 mm.

After installation of the gravel base course on the earth pressure cells, plate load tests were carried out while the

stresses on the subgrade were measured. The measured stresses in the geocell stabilized test section 1 were about 50 %

percent smaller than in the unreinforced test section 3.

In addition to plate load tests initial vehicle crossing tests were performed on the 25 cm thick gravel layer. During

crossing of a grader vertical stresses of 120 kN/m were measured on the subgrade in the unreinforced test section 3

while only 75 kN/m could be measured on the subgrade in geocell reinforced test section 1.

Vehicle Crossing tests and vertical stress measurements

After the asphalt surface course was reconstituted further measurements were conducted to take account of any

further compaction of the asphalt layers and the underlying soil due to the increased traffic load. In this case controlled

vehicle crossing tests were carried out. A heavy truck with five axles and a weight of approximately 41 tons crossed

the road at different speeds. During truck crossing the stresses in the underground were measured by the installed earth

pressure cells. The stresses measured at a crossing speed of 40 km/h are presented in Figure 6.

Figure 6: Results of truck crossing tests, crossing speed 40 km/h.

The measured peak values (1) and (2) result from the crossing of the single axles of the truck, the double peak

values (3) result from crossing of semi-trailer.

The results clearly confirm the results of previous tests. The stresses that are measured in the geocell reinforced

tests section are significantly lower than those which are measured in the unreinforced section. The average stress

reduction on the subgrade due to the installation of the geocell layer in the gravel base layer is approximately 30%.

5

EuroGeo4 Paper number 132

Similar results could also be observed at other crossing speeds. Both the stresses in the reinforced and also in the

unreinforced section decrease with increasing crossing speed.

Falling weight measurements (FWD)

In addition to vertical stress measurements falling weight deflectometer (FWD) measurements were carried out

after the road construction was loaded by traffic for a longer time.

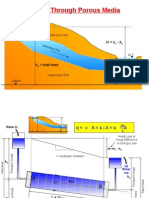

The FWD is a dynamic measuring instrument, which measures the reaction of the pavement structure to a defined

load impulse. To measure the pavement reaction a falling weight falls from a defined height on a rubber-puffersystem. The dynamic load impulse of 50 kN is transferred into the pavement structure by a load plate with a diameter

of 30 cm. The size and duration of the load impulse broadly correspond with those due to the passage of a truck.

The pavement reaction is measured at the road surface, in the form of deflections, by nine geophones. The

geophones are aligned at different distances from the load plate. The deflections and the form of the deflection bowl

are the base for the evaluation of the bearing capacity and the stiffness of individual base layers and also for the total

pavement structure (Figure 7).

Figure 7: Schematic diagram of falling-weight-deflectometer (FWD) measurements (FGSV, 2004).

To evaluate the influence of the geocell layer within the mineral base course, falling weight deflectometer

measurements were carried out on both the geocell reinforced section (test section 1, Figure 4) as well as on the

unreinforced section (test section 2, Figure 4). Additional measurements were conducted in a test section with standard

reconstruction of 70 cm gravel base course (test section 3, Figure 5).

The average values of measured deflections and back calculated layer modulus are presented in Figure 8. The

calculation of the layer modulus was based upon the theory of the elastic half space and on multi-layer models (Ullitz,

1998). The results show that the highest deflections and lowest layer modulus were measured in the unreinforced test

section with a base layer of 40 cm gravel. Both the deflections and the layer modulus of the unreinforced test section

with 70 cm thick gravel base layer and the geocell reinforced test section were very similar. The deflections of these

test fields were about 15 percent lower and the layer modulus about 10 percent higher than those of the unreinforced

test section with a 40 cm gravel base layer.

Figure 8: Results of FWD-measurements.

Therefore a stabilization of 40 cm mineral base course with 20 cm height geocells, placed in the upper part of the

6

EuroGeo4 Paper number 132

base layer, has a comparable effect to a 70 cm thick unreinforced gravel base layer with similar boundary conditions.

The FWD measurements conducted confirm the results of the vertical stress measurements.

Reconstruction of the road K-637

To verify the results of large scale model tests and the results of in-situ field measurements during the

reconstruction of the road K-23 a further test field was carried out. The road K-637 had to be widened and stabilized,

since the road was to be used as an access road during construction of a highway.

The main reconstruction concept of the existing road comprised a widening of the road shoulders of approximately

two meters. In addition a new bituminous asphalt pavement was placed on the existing road surface. First of all the

existing soil at the sides of the road was removed to a width between one and two meters until a depth of 50 cm was

reached. After compaction of the subgrade material a new 40 cm thick hydraulic bound base layer (HBB) was placed

in layers of 20 cm thickness. Every HBB-layer was compacted with a vibrating plate compactor. The middle of the

existing road was not rebuilt. In this part of the road only the existing cracks were filled. When the HBB-layers at the

road sides were completed an 18 cm thick layer of new asphalt pavement was applied over the whole width of the

road.

In one part of the road an alternative road reconstruction was carried out, using three different stabilization

methods. Four test fields, each 5 m long, were carried out. In one test section geocells were built in within the mineral

base layer (test section 1, Figure 9). A further road section (test section 3, Figure 9) is stabilized with a 20 cm thick

hydraulic bonded base layer. As a reference, test section (test section 2, Figure 9) remains unreinforced. In this section

a 40 cm thick mineral base layer is build in beneath the asphalt pavement. An overview of the test fields and their

construction is shown in Figure 9.

Figure 9: Test section K-637.

In test sections 1, 2 and 3 dynamic earth pressure cells were installed directly on the subgrade material. During and

after the road construction vehicle crossing tests were carried out. The stress measurements during crossing tests

verify the results of in-situ field tests during construction of the road K-23. The vertical stresses in the geocell

reinforced section were about 30 % lower than the stresses which were measured in the unreinforced test section.

Because of its higher stiffness the 20 cm hydraulic bonded base layer could reduce the vertical stresses about 22 %

compared to the geocell reinforced test section. No stresses were measured in test section 4.

Falling weight deflectometer measurements were also carried out. The measured deflections in the geocell

reinforced section were smaller than those measured in the unreinforced section. A further reduction could be

observed in test sections 3 and 4, were 20 cm and 40 cm thick hydraulic bonded base layers were placed beneath the

asphalt pavement. With increasing height of HBB-layer the deflections were decreasing.

The highest back calculated layer modulus could be observed in the HBB-layers while the modulus of the

unreinforced test section was the smallest. The modulus of the geocell reinforced section is smaller than those of the

HBB-layers but higher than the modulus of the unreinforced section.

If the vertical stress measurements and the FWD measurements are summarized, a very good agreement between

the vertical stresses and deformations can be observed. With increasing layer modules the deformation and the vertical

stresses are decreasing (Figure 10).

The investigations conducted confirm the results of large scale model tests as well as the test results of in-situ test

fields of road K 23.

CONCLUSIONS

To determine the influence of a geocell layer on the load-settlement behavior and the vertical stresses on the subgrade,

large scale model tests were conducted. The results have shown that the geocell layer reduced the vertical stresses on

the subgrade about 30 %, distributed the vertical loads over a larger area and improved the bearing capacity of the

infill material between 1.1 and 1.7 times.

EuroGeo4 Paper number 132

Figure 10: Results of FWD measurements K 637.

In addition to the model tests, two different in-situ test fields were constructed during the reconstruction of the

roads K-23 and K-637. Vehicle crossing tests have shown that in the geocell reinforced test sections the vertical

stresses on the subgrade were reduced about 30% compared to the unreinforced section. FWD measurements have

shown that the geocell layer increased the layer modulus of the gravel base layer and decreased the deflections on the

surface. The results of the in-situ tests confirmed the results of the large scale model tests. With increasing soil

stiffness, e.g. due to installation of geocells or a hydraulic bonded base layer, the vertical stresses on the subgrade and

the deflections on the surface were reduced and the layer modulus were increased.

REFERENCES

Al-Quadi I.L. & Hughes J.J. 2000. Field evaluation of geocell use in flexible pavements. Transportation Research

Record (TRB) H. 1709, S. 26 - 35

Ben Kurari K. 2000. Implementation of geocells in low bearing capacity roads. Proceedings of the 2nd European

Geosynthetics Conference, Session7A , S. 365 -368, Bologna

Dash S.K., Krishnaswamy N.R. & Rajagopal, K. 2001. Bearing capacity of strip footings supported on geocellreinforced sand. Geotextiles and Geomembranes, Volume: 19, Issue: 4, S. 235-256, June, 2001

Dash S.K., Sireesh S. & Sitharam T.G 2003. Model studies on circular footing supported on geocell reinforced sand

underlain by soft clay. Geotextiles and Geomembranes, Volume: 21, Issue: 4, S. 197-219

Forschungsgesellschaft fr Straen - und Verkehrswesen, FGSV Arbeitspapier "Tragfhigkeit" Teil C2 "FWD,

Auswertung und Bewertung", AK 4.8.2, Entwurf Stand Februar 2004

Forsman J., Slunga E. & Lahtinen P. 1998. Geogrid and Geocell Reinforced Secondary Road over Deep Peat Deposit.

Proceedings of the 6th International Conference on Geosynthetics, Vol. 2, S. 773-778, Atlanta

Leytland I.V., Aliver Y.A. & Bubnovsky V.V. 2006. Experience on using plastic geocells in the construction of roads

under conditions of the arctic of Russia. Proceedings of the 8th international Geosynthetic Conference, S. 705

708, Yokohama

Meyer N. & Emersleben A. 2005a. Mechanisches Verhalten von bewehrten Bden mit Geozellen. 9. Informationsund Vortragstagung ber "Geokunststoffe in der Geotechnik", Sonderheft der Geotechnik, S. 49 - 55.

Meyer, N. & Emersleben A. 2005b. Mechanisches Verhalten von bewehrten Bden mit Geozellen. Symposium

Geotechnik Verkehrswegebau und Tiefgrndungen, Schriftenreihe Geotechnik, Universitt Kassel Heft 18, S. 93

112

Meyer, N. & Emersleben A. 2005c. Einsatz von Geozellen im Verkehrswegebau. Tiefbau Ingenieurbau

Straenbau (TIS) Heft 11, S. 32 37

Meyer, N. & Emersleben A. 2006a. Bodenstabilisierung mit Geozellen im Straenbau. 21. Christian Veder

Kolloquium (CVK) Neue Entwicklungen der Baugrundverbesserung, Heft 28, S. 85-101 Technische Universitt

Graz (TUG)

Meyer, N. & Emersleben A. 2006b. Stabilisierung von mineralischen Tragschichten mit Geozellen. Tiefbau Heft 11,

S. 634 640

Mhaiskar S.Y. & Mandal, J.N. 1992. Soft Clay Subgrade stabilisation using Geocells. Geotechnical special

publications, Vol. 30, S. 1092 1103, New York, American Society of Civil Engineers, ASCE

Ullidtz, P. 1998. Modelling Flexible Pavement Response and Performance. Polyteknisk Forlag, Lyngby.

Sitharam T.G. & Siressh S. 2005. Behavior of embedded footings supported on geogrid cell reinforced foundation

beds. Geotechnical testing journal Vol. 28, No. 5, S. 1-12

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- TrtrereDocument2 pagesTrtrereDevsoth NareshNo ratings yet

- Design of Dams - Seepage ControlDocument55 pagesDesign of Dams - Seepage ControlDevsoth NareshNo ratings yet

- Screenshot 2021-11-05 at 1.21.59 PMDocument19 pagesScreenshot 2021-11-05 at 1.21.59 PMDevsoth NareshNo ratings yet

- Buy Black Sneakers Online Sneakers For Men UrbanshoreDocument1 pageBuy Black Sneakers Online Sneakers For Men UrbanshoreDevsoth NareshNo ratings yet

- Seepage Through Porous Media: H Total HeadDocument20 pagesSeepage Through Porous Media: H Total HeadDevsoth NareshNo ratings yet

- The Robotic RevolutionDocument26 pagesThe Robotic RevolutionDevsoth NareshNo ratings yet

- File: UC - No.G1/ /2018-19: Submitted SirDocument1 pageFile: UC - No.G1/ /2018-19: Submitted SirDevsoth NareshNo ratings yet

- Notes SheetDocument2 pagesNotes SheetDevsoth NareshNo ratings yet

- Act BillsDocument2 pagesAct BillsDevsoth NareshNo ratings yet

- Soil NailingDocument2 pagesSoil NailingDevsoth NareshNo ratings yet

- AGS 2013-1 Article 5Document13 pagesAGS 2013-1 Article 5Devsoth NareshNo ratings yet

- Fci - Admit CardDocument3 pagesFci - Admit CardDevsoth Naresh100% (1)

- 03 Jul 201502071915Document5 pages03 Jul 201502071915Devsoth NareshNo ratings yet

- Nhess 9 459 2009Document9 pagesNhess 9 459 2009Devsoth NareshNo ratings yet

- Failures in Pavements - JNTU COE HyderabadDocument40 pagesFailures in Pavements - JNTU COE HyderabadDevsoth NareshNo ratings yet

- DAMS 1unit Part2Document53 pagesDAMS 1unit Part2Devsoth NareshNo ratings yet

- 2015fin MS65Document9 pages2015fin MS65Devsoth NareshNo ratings yet

- Expansive Soils 20-02-2015Document49 pagesExpansive Soils 20-02-2015Devsoth NareshNo ratings yet

- DetailsDocument1 pageDetailsDevsoth NareshNo ratings yet

- 1-MIS, DeO, Messanger CRP,, Attendance of April and May 1.6.15Document8 pages1-MIS, DeO, Messanger CRP,, Attendance of April and May 1.6.15Devsoth NareshNo ratings yet

- Opx 1 TJTPDocument8 pagesOpx 1 TJTPDevsoth NareshNo ratings yet

- Ground Improvement TechniquesDocument17 pagesGround Improvement Techniquesjs kalyana rama100% (1)

- A Case Study On The Performance of Embankments On Treated Soft Ground (2003) - Thesis (69 (Document69 pagesA Case Study On The Performance of Embankments On Treated Soft Ground (2003) - Thesis (69 (Julio Humberto Díaz RondánNo ratings yet

- Case History of GEEDocument2 pagesCase History of GEEDevsoth NareshNo ratings yet

- Soil Mechanics Lab ManualDocument22 pagesSoil Mechanics Lab ManualDevsoth NareshNo ratings yet

- GT 1Document8 pagesGT 1Devsoth NareshNo ratings yet

- Lecture 01Document17 pagesLecture 01Devsoth NareshNo ratings yet

- 6 TH-53Document6 pages6 TH-53Devsoth NareshNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Plusco428 Wireline Products 28 Vis Honey Oil With Inhibitor For Pressure ApplicationDocument7 pagesPlusco428 Wireline Products 28 Vis Honey Oil With Inhibitor For Pressure ApplicationebeNo ratings yet

- Direct Energy Conversion Methods for Improving Fusion Reactor EfficiencyDocument4 pagesDirect Energy Conversion Methods for Improving Fusion Reactor EfficiencyPavan Kumar BittuNo ratings yet

- NTS GAT Test Sample Paper of PharmacyDocument12 pagesNTS GAT Test Sample Paper of PharmacyNational Testing Service77% (13)

- ALS Minerals Service Schedule USDDocument44 pagesALS Minerals Service Schedule USDGAUCHEX697355No ratings yet

- GEAS 1 - Chemistry - 2Document4 pagesGEAS 1 - Chemistry - 2Leoneil Angelo AbreuNo ratings yet

- Mitsubishi AcDocument28 pagesMitsubishi AcZeeshanNo ratings yet

- Bob Kimmel CV Expert Witness Plastic PackagingDocument11 pagesBob Kimmel CV Expert Witness Plastic PackagingBob KimmelNo ratings yet

- Guggenheim PDFDocument11 pagesGuggenheim PDFAll about NBJNo ratings yet

- Stirling EngineDocument14 pagesStirling EngineShivakumar Ainapur100% (1)

- Notes On Electricity For Grade 6Document4 pagesNotes On Electricity For Grade 6Robert Hooke100% (1)

- Venturi EffectDocument21 pagesVenturi Effectmuhammad ridNo ratings yet

- Spectrophotometry - Absorbance SpectrumDocument3 pagesSpectrophotometry - Absorbance SpectrumSom PisethNo ratings yet

- The Nuclear Reactions Involved in The Synthesis of New ElementsDocument3 pagesThe Nuclear Reactions Involved in The Synthesis of New ElementsChristian Isip67% (3)

- Powder Coating at HomeDocument9 pagesPowder Coating at Homepakde jongko100% (1)

- A Dictionary of ColoursDocument528 pagesA Dictionary of ColoursMohammed Mahfouz78% (9)

- TOA DKK Water Quality Sensor Xseries PreDocument12 pagesTOA DKK Water Quality Sensor Xseries PrealdiniNo ratings yet

- Austenitic Stainless SteelDocument3 pagesAustenitic Stainless SteelGeorge MarkasNo ratings yet

- International Atomic Energy Agency - Production of Yellow Cake and Uranium Fluorides (Panel Proceedings) (1981, IAEA) PDFDocument368 pagesInternational Atomic Energy Agency - Production of Yellow Cake and Uranium Fluorides (Panel Proceedings) (1981, IAEA) PDFZia KhanNo ratings yet

- Light in August EssayDocument7 pagesLight in August Essayppggihnbf100% (2)

- Grade 10 - ch2, 100Document2 pagesGrade 10 - ch2, 100NayLinNo ratings yet

- PHYS 1220 Coulomb's Law and Electric Fields SolutionsDocument20 pagesPHYS 1220 Coulomb's Law and Electric Fields SolutionsHüthâifâ AbdérahmânNo ratings yet

- Toluene: Safety Data SheetDocument10 pagesToluene: Safety Data SheetLiaHerlianaNo ratings yet

- Injections and Implanted Drug ProductsDocument3 pagesInjections and Implanted Drug ProductsHAROLD TANNo ratings yet

- S4 PDFDocument9 pagesS4 PDFAbhilash ReddyNo ratings yet

- C78IA009EN A ViscoQC Yield PointDocument2 pagesC78IA009EN A ViscoQC Yield Pointjomoro29No ratings yet

- 연습문제 SolutionDocument156 pages연습문제 Solution박민지No ratings yet

- Inclusion Compounds & Cyclodextrins: Presented By: Kunal Goyal Pt.B.D. Sharma Univ. Health Sci. RohtakDocument23 pagesInclusion Compounds & Cyclodextrins: Presented By: Kunal Goyal Pt.B.D. Sharma Univ. Health Sci. Rohtakgkunal991No ratings yet

- MRES216 Physical Techniques For The Study of Biological SystemsDocument10 pagesMRES216 Physical Techniques For The Study of Biological SystemsSaurabh ShineNo ratings yet

- Comet Assay: From Wikipedia, The Free EncyclopediaDocument11 pagesComet Assay: From Wikipedia, The Free EncyclopediasuryasivNo ratings yet

- Magnitude of Magnetic Field Inside Hydrogen Atom ModelDocument6 pagesMagnitude of Magnetic Field Inside Hydrogen Atom ModelChristopher ThaiNo ratings yet