Professional Documents

Culture Documents

Regulador Pid Altivar PDF

Uploaded by

fernandez grOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Regulador Pid Altivar PDF

Uploaded by

fernandez grCopyright:

Available Formats

8000DB0701

10/2009

Raleigh, NC, USA

Data Bulletin

Altivar 61 Variable Speed Drive PID Function

Setup

Retain for future use.

Overview

This bulletin covers only the configuration of the parameters required to set

up the PID function; it assumes that all other motor parameters are set by

qualified personnel before the steps described in this example are

performed.

Due to the multitude of possible PID control configurations, this document

covers only the basic proportional-integral-derivative (PID) configuration on

a stand-alone Altivar 61 variable speed drive (ATV61) using an analog

input for control of the ATV61. This document does not describe an actual

configuration and is not a training document for PID control and

configuration. The values used are examples provided solely to illustrate the

PID function of the ATV61.

PID Control

The ATV61 offers proportional-integral-derivative (PID) control. When

programmed, the PID function compares the value of an analog input signal

(AI1 or AI2) to a set point. The PID loop adjusts the output frequency as

needed to correct the input signal, so that it equals the set point.

Presumption

This bulletin is written for individuals familiar with PowerSuite software user

and assumes familiarity with this software. If you are not familiar with this

software or ATV61 drive operation, please consult your system

administrator before attempting to set the parameters for the PID function

on an ATV61 drive.

Requirements

The following hardware and software is required:

Hardware

Altivar 61 variable speed drive with HMI V1.5

Software

PowerSuite software V2.5 or higher (optional)

Safety Information

Notice

2009 Schneider Electric All Rights Reserved

Read these instructions carefully, and look at the equipment to become

familiar with the device before trying to install, operate, or maintain it. The

following special messages may appear throughout this documentation or

on the equipment to warn of potential hazards, or to call attention to

information that clarifies or simplifies a procedure.

Altivar 61 Variable Speed Drive PID Function Setup

Safety Information

8000DB0701

10/2009

A lightning bolt or ANSI man symbol in a Danger or Warning safety label

on the equipment indicates an electrical hazard which, as indicated below,

can or will result in personal injury if the instructions are not followed.

The exclamation point symbol in a safety message in a bulletin indicates

potential personal injury hazards. Obey all safety messages introduced by

this symbol to avoid possible injury or death.

Symbol

Name

Lightning Bolt

ANSI Man

Exclamation Point

DANGER

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not

avoided, can result in death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not

avoided, can result in minor or moderate injury.

CAUTION

CAUTION, used without the safety alert symbol, indicates a potentially

hazardous situation which, if not avoided, can result in property damage.

Qualified Personnel

For the protection of personnel and equipment, a qualified person must

perform the procedures detailed in this bulletin.

A qualified person is one who has skills and knowledge related to the

construction and operation of this electrical equipment and the installation,

and has received safety training to recognize and avoid the hazards

involved. Refer to the most current release of NFPA 70E, Standard for

Electrical Safety in the Workplace, for safety training requirements.

In addition, the person must be:

Able to read, interpret, and follow the instructions and precautions in this

data bulletin and the other documentation referenced.

Able to use the required tools listed in this data bulletin in a safe and

correct manner.

2009 Schneider Electric All Rights Reserved

Altivar 61 Variable Speed Drive PID Function Setup

Safety Information

8000DB0701

10/2009

Before You Begin

Do not use this product on machinery lacking effective point-of-operation

guarding. Lack of effective point-of-operation guards on a machine can

result in serious injury to the operator of that machine.

.

WARNING

UNGUARDED MACHINERY CAN CAUSE SERIOUS INJURY

Do not use this software and related automation equipment on

equipment which does not have point-of-operation protection.

Do not reach into machinery during operation.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

This automation equipment and related software is used to control a variety

of industrial processes. The type or model of automation equipment suitable

for each application will vary depending on factors such as the control

function required, degree of protection required, production methods,

unusual conditions, and government regulations. In some applications,

more than one processor may be required, as when backup redundancy is

needed.

Only the user can be aware of all the conditions and factors present during

setup, operation, and maintenance of the machine; therefore, only the user

can determine the automation equipment and the related safeties and

interlocks which can be properly used. When selecting automation and

control equipment and related software for a particular application, the user

should refer to the applicable local and national standards and regulations.

The National Safety Councils Accident Prevention Manual (nationally

recognized in the United States of America) also provides much useful

information.

In some applications, such as packaging machinery, additional operator

protection such as point-of-operation guarding must be provided. This is

necessary if the operators hands and other parts of the body are free to

enter the pinch points or other hazardous areas and serious injury can

occur. Software products alone cannot protect an operator from injury.

For this reason, the software cannot be substituted for or take the place of

point-of-operation protection.

Ensure that the appropriate safeties and mechanical/electrical interlocks

related to point-of-operation protection have been installed and are

operational before placing the equipment into service. All interlocks and

safeties related to point-of-operation protection must be coordinated with

the related automation equipment and software programming.

NOTE: Coordination of safeties and mechanical/electrical interlocks for

point-of-operation protection is outside the scope of the Function Block

Library, System User Guide, or other implementation referenced in this

documentation.

Start-up and Test

2009 Schneider Electric All Rights Reserved

Before using electrical control and automation equipment for regular

operation after installation, the system should be given a start-up test by

qualified personnel to verify correct operation of the equipment. It is

important that arrangements for such a check be made and that enough

time is allowed to perform complete and satisfactory testing.

Altivar 61 Variable Speed Drive PID Function Setup

Safety Information

8000DB0701

10/2009

CAUTION

EQUIPMENT OPERATION HAZARD

Verify that all installation and set up procedures have been completed.

Before operational tests are performed, remove all blocks or other

temporary holding means used for shipment from all component

devices.

Remove tools, meters, and debris from equipment.

Failure to follow these instructions can result in injury, or equipment

damage.

Follow all start-up tests recommended in the equipment documentation.

Store all equipment documentation for future references.

Software testing must be done in both simulated and real

environments.

Verify that the completed system is free from all short circuits and grounds,

except those grounds installed according to local regulations (according to

the National Electrical Code in the USA, for instance). If high-potential

voltage testing is necessary, follow recommendations in the equipment

documentation to prevent accidental equipment damage.

Before energizing equipment:

Operation and Adjustments

The following precautions are from the NEMA Standards Publication

ICS 7.1-1995 (English version prevails):

Related Documents

Remove tools, meters, and debris from equipment.

Close the equipment enclosure door.

Remove ground from incoming power lines.

Perform all start-up tests recommended by the manufacturer.

Regardless of the care exercised in the design and manufacture of

equipment or in the selection and rating of components, there are hazards

that can be encountered if such equipment is improperly operated.

It is sometimes possible to misadjust the equipment and thus produce

unsatisfactory or unsafe operation. Always use the manufacturers

instructions as a guide for functional adjustments. Personnel who have

access to these adjustments should be familiar with the equipment

manufacturers instructions and the machinery used with the electrical

equipment.

Only those operational adjustments actually required by the operator

should be accessible to the operator. Access to other controls should be

restricted to prevent unauthorized changes in operating characteristics.

If there are no documents recommended, this subsection can be removed.

Title of Documentation

Reference Number

Altivar 61 Programming Manual, Sections 1.5,

Inputs/Outputs Cfg and 1.7, Application Funct.

1760649

Addendum to Altivar 61 Variable Speed Drives Programming

30072-451-55

Manual,

Altivar 61 Variable Speed Drive Controllers, High

Horsepower, Simplified Guide,

30072-451-59

Altivar 61 Variable Speed Drive Controllers, Low

Horsepower, Simplified Guide,

30072-451-60

You can download these technical publications and other technical

information from our website at www.schneider-electric.us.

4

2009 Schneider Electric All Rights Reserved

Altivar 61 Variable Speed Drive PID Function Setup

Safety Information

8000DB0701

10/2009

Product Related Information

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E.

This equipment must be installed and serviced only by qualified

electrical personnel.

Turn off all power supplying this equipment before working on or inside

equipment. Disconnect the power at the processor and at the power

source.

Always use a properly rated voltage sensing device to confirm power is

off.

Replace all devices, doors and covers before turning on power to this

equipment.

Confirm that a proper ground connection exists before applying power

to the unit.

Use only the specified voltage when operating this equipment and any

associated products.

Failure to follow these instructions will result in death or serious

injury.

WARNING

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure

modes of control paths and, for certain critical control functions, provide

a means to achieve a safe state during and after a path failure.

Examples of critical control functions are emergency stop and

overtravel stop.

Separate or redundant control paths must be provided for critical control

functions.

System control paths may include communication links. Consideration

must be given to the implications of unanticipated transmission delays

or failures of the link. 1

Each implementation of an Altivar 31C drive must be individually and

thoroughly tested for proper operation before being placed into service.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

1. For additional information refer to NEMA ICS 1.1 (latest edition), Safety Guidelines for the

Application, Installation, and Maintenance of Solid State Control and to NEMA ICS 7.1 (latest

edition), Safety Standards for Construction and Guide for Selection, Installation and

Operation of Adjustable-Speed Drive Systems.

User Comments

2009 Schneider Electric All Rights Reserved

We welcome your comments about this bulletin. You can reach us by e-mail

at oem.solutions@schneider-electric.com.

Altivar 61 Variable Speed Drive PID Function Setup

Using the Drive Controller HMI

Using the Drive Controller

HMI

8000DB0701

10/2009

For instructions on using the drive controller HMI, refer to the Altivar 61

Programming Manual, bulletin 1760649 . Be sure to press the navigation

button (Enter) to do the following:

Select the highlighted menu or parameter

Save the displayed value

Factory Default Settings

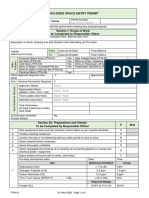

Table 1 shows the factory default settings. Ensure that these parameters

are set according to the configuration of your drive controller and motor.

Table 1:

Factory Default Settings

Macro-configuration

Pumps/fans

Motor frequency

50 Hz

Motor control type

Energy-saving, variable torque applications

Stop mode, normal

On deceleration ramp

Stop mode, in the event of a fault

Freewheel

Linear, acceleration, and deceleration ramps

3s

Low speed

0 Hz

High speed

50 Hz

Motor thermal current

Rated drive current

Standstill injection braking current

0.7 x rated drive current, for 0.5 s

Automatic starts after a fault

No

Switching frequency

2.5 kHz or 4 kHz, depending on the drive

controller rating

Logic inputs

Analog inputs

LI1

Forward (one operating direction), 2-wire

control on transition

LI2

Inactive (not assigned)

LI3

Switching of the 2nd speed reference

LI4

Fault reset

LI5, LI6

Inactive (not assigned)

AI1

1st speed reference, 010 Vdc

AI2

2nd speed reference, 020 mA

R1

The contact opens upon error detection

(drive off).

R2

The contact closes when the drive is

operating (drive running).

AO1

020 mA, inactive (not assigned)

Relay outputs

Analog output

2009 Schneider Electric All Rights Reserved

Altivar 61 Variable Speed Drive PID Function Setup

Setting the Access Level

8000DB0701

10/2009

Setting the Access Level

Set the access level to the drive configuration to either Advanced or Expert.

Using the HMI:

a. From the Main Menu, select ACCESS LEVEL.

b. Select ADVANCED or EXPERT, then press Enter.

Figure 1:

Setting the Access Level Using the HMI

Using PowerSuite software:

a. From the navigation pane on the left side of the screen, under

ATV61, select Access Level.

b. Select either Advanced access or Expert access from the drop-down

menu.

Figure 2:

Setting the Access Level Using the PowerSuite Software

Navigation Pane>ATV61>Access Level

Access Level

Drop-down Menu

2009 Schneider Electric All Rights Reserved

Altivar 61 Variable Speed Drive PID Function Setup

Setting the Drive Configuration Parameters

Setting the Drive

Configuration Parameters

8000DB0701

10/2009

Refer to Sections 1.5, Inputs/Outputs Cfg and 1.7, Application Funct. of

the Altivar 61 Programming Manual, Software Version 1.5, for detailed

descriptions and additional options available for configuring the ATV61.

Input Configuration

Setting the Wire Control

Set the wire control to two wire or three wire. The factory default setting is

2 wire [2C].

Using the HMI:

a. From the Main Menu, select

DRIVE MENT > INPUTS/OUTPUTS CFG > 2/3 WIRE CONTROL.

b. Select either 2 WIRE TYPE or 3 WIRE TYPE, then press Enter.

c. Press the Esc button.

Figure 3:

Setting the Wire Control Using the HMI

Using PowerSuite software:

a. Using the navigation pane on the left side of the screen, expand

Inputs/Outputs Configuration, then select Logical Inputs.

b. From the TCC 2 / 3 wire control drop-down menu, select the

appropriate wire control setting.

Figure 4:

Setting the Wire Control Using PowerSuite Software

2009 Schneider Electric All Rights Reserved

Altivar 61 Variable Speed Drive PID Function Setup

Setting the Drive Configuration Parameters

8000DB0701

10/2009

Logic Inputs

Configure logic inputs LI1 through LI6 according to the requirements of your

application.

Analog Inputs

Configure the analog input signal type as required (for example, 010 Vdc

or 420 mA).

NOTE: AI1 is a voltage only input; AI2 is configurable for voltage or current.

To set the AI1 parameters, follow the steps below. (To set the AI2

parameters, follow the same steps but select AI2 Configuration.)

Using the HMI:

a. From the Main Menu, select:

DRIVE MENU > 1.5 INPUTS/OUTPUTS CFG >

AI1 CONFIGURATION.

Adjust the AI1 MIN VALUE and AI1 MAX VALUE as required for your

device.

Figure 5:

Setting the Analog Inputs Using the HMI

Figure 6:

Setting the Analog Inputs Min and Max Value

Using PowerSuite software:

a. Using the navigation pane on the left side of the screen, expand

Inputs/Outputs configuration, then select Analogue inputs. Refer to

Figure 7 on page 10.

b. Under Configuration AI1, set the AI1 minimum value and

AI1 maximum value.

ExampleIf your device is a 210 Vdc input, set the AI1 minimum value

to 2 Vdc and the AI1 maximum value to 10 Vdc.

The values for the operating range are set in the PID function. See

Table 2 on page 10.

2009 Schneider Electric All Rights Reserved

Altivar 61 Variable Speed Drive PID Function Setup

Setting the Drive Configuration Parameters

8000DB0701

10/2009

Figure 7:

Setting the Analog Inputs Using PowerSuite Software

Table 2:

PID Regulator Parameter Assignments

HMI

PowerSuite Software

Description

PID Feedback Assignment

PIF PI fdbk assignment

Specify which analog input to set as the reference, either AI1 or AI2.

Min PID Feedback

PIF1 Minimum PID feedback

Specify the range of your input device. Among the possibilities are a range of: pressure

(0 20 psig), flow (0 500 gpm), or temperature (100 F 300 F).

Max PID Feedback

PIF2 Maximum PID feedback

For example, if an input device is scaled at 0 30 psig to 0 10 Vdc, set the

Min PID feedback to 0 and the Max PID feedback to 30.

Min PID Reference

PIP1 Minimum PID reference

Establish the limits to which the operator can adjust the setpoint.

Max PID Reference

PIP2 Maximum PID reference

In the above example, to limit the setpoints to a range of 12 16 psig, set the

Min PID reference to 12 and the Max PID reference to 16.

Act. Internal PID Ref.

PII Internal reference PI

Set the value to Yes. This enables the operator to enter a setpoint value directly into the drive

controller.

Internal PI Ref.

RPI Internal PI reference

Set the value to the desired setpoint.

PID Proportional Gain

RPG PI Proportional gain

PID Integral Gain

RIG Integral gain PI regulator

PID Derivative Gain

RDG PID derivative gain

PID Correct Reverse

PIC PID correction reverse

10

These values are relative to the loop characteristics; therefore, an experienced operator should

provide these values.

If you set this value to No, the speed of the motor increases when the error is positive

(for example, pressure control with a compressor).

If you set this value to Yes, the speed of the motor decreases when the error is positive

(for example, temperature controls using a cooling tower fan).

2009 Schneider Electric All Rights Reserved

Altivar 61 Variable Speed Drive PID Function Setup

Setting the Drive Configuration Parameters

8000DB0701

10/2009

PID Function Configuration

Configure the PID function as described in PID Regulator below.

NOTE: While configuring the PID loop, keep in mind that the

PID Regulator function does not allow negative values in the Internal PID

Reference setpoint. So when using negative values, configure your control

as a percentage.

If a temperature device is scaled at -100 to +300 F, enter

the Minimum PID Feedback as 0 (corresponding to -100 F) and the

Maximum PID Feedback as 100 (corresponding to +300 F). Then,

calculate the Internal PID Reference or setpoint as a percentage of the

range. For example, an 80 F setpoint is 45%; therefore, set the

Internal PID Reference to 45.

PID Regulator

Using the HMI:

a. From the Main Menu, select:

DRIVE MENU > APPLICATION FUNCT. > PID REGULATOR

b. From the PID REGULATOR menu, select the parameters shown in

Table 2 on page 10 and set the values according to the description.

Figure 8:

Setting the PID Regulator Parameters

2009 Schneider Electric All Rights Reserved

11

Altivar 61 Variable Speed Drive PID Function Setup

Data Bulletin

8000DB0701

10/2009

Using PowerSuite software:

a. Using the navigation pane on the left side of the screen, expand the

Applicative functions menu. Refer to Figure 9.

b. Select PID regulator and set the values of the parameters shown in

Table 2 on page 10 according to the description.

Figure 9:

Configuring the PID Function Using PowerSuite Software

Schneider Electric

8001 Knightdale Blvd

Knightdale, NC 27545 USA

(oem.solutions@us.schneider-electric.com)

www.schneider-electric.us

12

Altivar is a registered trademark of Schneider Electric. Other trademarks used herein are the

property of their respective owners.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

2009 Schneider Electric All Rights Reserved

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Assuring Food Safety and Quality: Guidelines for Strengthening National Food Control SystemsDocument130 pagesAssuring Food Safety and Quality: Guidelines for Strengthening National Food Control SystemsPedro CampeloNo ratings yet

- Witness Protection Act: Laws of KenyaDocument29 pagesWitness Protection Act: Laws of KenyaDiana WangamatiNo ratings yet

- Task 1Document11 pagesTask 1sheraz ahmadNo ratings yet

- 09 South Africa PPC Cement Full ReportDocument28 pages09 South Africa PPC Cement Full ReportLorena MartínezNo ratings yet

- Fire Risk Assessment Guidance and TemplatesDocument20 pagesFire Risk Assessment Guidance and TemplatesKakira Lions ClubNo ratings yet

- Safety Engineering Techniques Hazard IDDocument20 pagesSafety Engineering Techniques Hazard IDSasidhar ThamilNo ratings yet

- Discussion Paper - Decommissioning Offshore Petroleum Infrastructure in Commonwealth Waters 2018Document95 pagesDiscussion Paper - Decommissioning Offshore Petroleum Infrastructure in Commonwealth Waters 2018Ross WaringNo ratings yet

- Cosmetics Safety Guideline Risk AssessmentDocument40 pagesCosmetics Safety Guideline Risk AssessmentromicaNo ratings yet

- GP 48-04Document27 pagesGP 48-04snikraftar1406No ratings yet

- PTW-01 Enclosed Space Entry Permit (1601608066)Document4 pagesPTW-01 Enclosed Space Entry Permit (1601608066)jayNo ratings yet

- Method Statement of HACKING WORKS ON CONCRETE WALL FOR LIFTDocument3 pagesMethod Statement of HACKING WORKS ON CONCRETE WALL FOR LIFTfaizbukhari100% (2)

- Standard Deliverable List For Feasibility Conceptual FEED Detailed DesignDocument190 pagesStandard Deliverable List For Feasibility Conceptual FEED Detailed Designkere_hore00740% (5)

- Fuses Glasses and CeramicDocument5 pagesFuses Glasses and CeramicAbhijit JanaNo ratings yet

- Azul de metileno-MSDSDocument6 pagesAzul de metileno-MSDSAlejandroNo ratings yet

- Section 5 Health SafetyDocument6 pagesSection 5 Health SafetyArbaz AhmedNo ratings yet

- DatasheetDocument6 pagesDatasheetBruno Miguel Brandão RibeiroNo ratings yet

- JSA-Construction Right of WayDocument3 pagesJSA-Construction Right of Wayfrancis_e_tan100% (5)

- Engineering Standards - Sp10Document29 pagesEngineering Standards - Sp10alexokorieNo ratings yet

- Daily Situational Report: Republic of The Philippines Department of The Interior and Local GovernmentDocument4 pagesDaily Situational Report: Republic of The Philippines Department of The Interior and Local GovernmentBfpcar K PasilNo ratings yet

- nhp002 PDFDocument36 pagesnhp002 PDFMichael SilalahiNo ratings yet

- 600a 35kv Class BT Tap Connector System Installation Instructions Mn650003enDocument20 pages600a 35kv Class BT Tap Connector System Installation Instructions Mn650003endixonNo ratings yet

- Septic Tank Design Computation PDFDocument7 pagesSeptic Tank Design Computation PDFCyril Abad DelfinNo ratings yet

- On-Scene Commander (OSC) and Emergency Control Centre (ECC) Training - ProposalDocument30 pagesOn-Scene Commander (OSC) and Emergency Control Centre (ECC) Training - ProposalAhmad Nazri Mokhtar100% (4)

- 1250 Black SDSDocument4 pages1250 Black SDSkwerwaNo ratings yet

- Risk Assesment FOR CONCRETEDocument12 pagesRisk Assesment FOR CONCRETEAnwar MohiuddinNo ratings yet

- Ahmed - Pinger CISSP Assignment 1 IEC - ODFDocument3 pagesAhmed - Pinger CISSP Assignment 1 IEC - ODFAhmed HussainNo ratings yet

- HSE-RA-040 Marble Fixing Rev 0Document12 pagesHSE-RA-040 Marble Fixing Rev 0عمروNo ratings yet

- F RA 24 Circular SawDocument2 pagesF RA 24 Circular SawAnnie BosmanNo ratings yet

- 10-Personal Emergency Evacuation Plan PEEPDocument6 pages10-Personal Emergency Evacuation Plan PEEPArsh AlamNo ratings yet

- Internal safety assessment report for Shyam TechDocument14 pagesInternal safety assessment report for Shyam TechDwitikrushna RoutNo ratings yet