Professional Documents

Culture Documents

Mcaz Qis

Uploaded by

thembaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mcaz Qis

Uploaded by

thembaCopyright:

Available Formats

Medicines Control Authority of Zimbabwe

QUALITY INFORMATION SUMMARY (QIS)

FOREWORD

The Quality Information Summary (QIS) template should be completed to provide a condensed summary of

the key quality information for product dossiers (PDs) containing APIs of synthetic or semi-synthetic origin

and their corresponding products that are. submitted to the MCAZ for registration.

The QIS constitutes part of the registration PD. The QIS provides an accurate record of technical data in

the PD at the time of registration and thereafter serves as an official reference document during the course

of GMP inspections, and variation (amendment) assessments performed by the MCAZ. The QIS is a

condensed version of the Quality Overall Summary Product Dossier (QOS-PD) and represents the final,

agreed upon key information from the PD review (inter alia identification of the manufacturer(s), API/FPP

specifications, stability conclusions and relevant commitments).

The QIS template is structured to permit the rapid assembly of the QIS by copying requisite information

from the corresponding portions of the QOS-PD submitted with the original PD. It is acknowledged that the

numbering of the sections may not be entirely sequential. Those sections not considered necessary to be

included in the QIS have been removed (e.g. 2.3.S.5 Reference Standards or Materials) and the remaining

sections have retained their numbering to be consistent with the original PD.

For original PDs, the QIS should be provided in MS-Word format at the time of PD submission. The QIS

should be revised and submitted with the change history (see table at the end of the template) each time

additional data is provided during the assessment process. If no revision is necessary due to no change in

the information, a statement should be made to this effect in the covering letter. For amendments, the QIS

should be completed in its entirety (regardless of the proposed change), it should include information on all

strengths, with any changes highlighted and it should be provided at the time of submission of such

amendments.

When completing the QIS template, this covering Foreword should be deleted.

QUALITY INFORMATION SUMMARY (QIS)

<Dossier Reference Number(s) e.g. H999>

Page 1 of 12

(QIS) (2012-02-20)

Medicines Control Authority of Zimbabwe

INTRODUCTION

(a)

Summary of product information:

Non-proprietary name of the finished

pharmaceutical product (FPP)

Proprietary (Trade) name of the finished

pharmaceutical product (FPP)

International non-proprietary (generic)

name(s) of the active pharmaceutical

ingredient(s) (API(s)), including form (salt,

hydrate, polymorph)

Applicant name and address

Dosage form

Reference Number(s)

Strength(s)

Route of administration

Proposed indication(s)

Contact information

(b)

Name:

Phone:

Fax:

Email:

Administrative Summary:

Reference number e.g. H999

Applicants date of preparation or revision of the

QIS

Internal version and/or date of acceptance

(MCAZ use only)

Related dossiers (e.g. FPP(s) with the same API(s) submitted to the Prequalification Programme by

the applicant):

Reference

number

(eg H999)

Prequalified

(Y/N)

API, strength, dosage form

(eg. Abacavir (as sulphate) 300

mg tablets)

API manufacturer

(including address)

2.3.S DRUG SUBSTANCE (or ACTIVE PHARMACEUTICAL INGREDIENT (API)) (NAME,

MANUFACTURER)

Indicate which option applies for the submission of API information:

<Dossier Reference Number(s) e.g. H999>

Page 2 of 12

(QIS) (2012-02-20)

Medicines Control Authority of Zimbabwe

Name of API:

Name of API manufacturer:

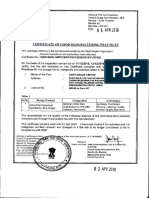

Certificate of suitability to the European Pharmacopoeia (CEP)

Full details in the PD

2.3.S.2 Manufacture (name, manufacturer)

2.3.S.2.1 Manufacturer(s) (name, manufacturer)

(a)

Name, address and responsibility (e.g. fabrication, packaging, labelling, testing,

storage) of each manufacturer, including contractors and each proposed production

site or facility involved in these activities:

Name and address

(including

block(s)/unit(s))

Responsibility

APIMF/CEP

number (if

applicable)

Letter of access

provided?

2.3.S.4 Control of the API (name, manufacturer)

2.3.S.4.1 Specification (name, manufacturer)

(a)

API specifications of the FPP manufacturer:

Standard (e.g. Ph.Int., Ph.Eur., BP, USP, House)

Specification reference number and version

Test

Acceptance criteria

Analytical procedure

(Type/Source/Version)

Description

Identification

Impurities

Assay

etc.

2.3.S.6 Container Closure System (name, manufacturer)

(a)

Description of the container closure system(s) for the storage and shipment of the API:

2.3.S.7 Stability (name, manufacturer)

<Dossier Reference Number(s) e.g. H999>

Page 3 of 12

(QIS) (2012-02-20)

Medicines Control Authority of Zimbabwe

2.3.S.7.1 Stability Summary and Conclusions (name, manufacturer)

(c)

Proposed storage conditions and re-test period:

Container closure system

Storage statement

Re-test period*

* indicate if a shelf-life is proposed in lieu of a re-test period (e.g. in the case of labile APIs)

2.3.P DRUG PRODUCT (or FINISHED PHARMACEUTICAL PRODUCT (FPP))

2.3.P.1 Description and Composition of the FPP

(a) Description of the FPP:

(b)

Composition of the FPP:

(i)

Component and

quality standard (and

grade, if applicable)

Composition, i.e. list of all components of the FPP and their amounts on a per

unit basis and percentage basis (including individual components of mixtures

prepared in-house (e.g. coatings) and overages, if any):

Function

Strength (label claim)

Quant.

per unit

Quant.

per unit

Quantity

per unit

<complete with appropriate title e.g. Core tablet, Contents of capsule, Powder for injection>

Subtotal 1

<complete with appropriate title e.g. Film-coating >

Subtotal 2

Total

(ii)

(c)

Composition of all components purchased as mixtures (e.g. colourants,

coatings, capsule shells, imprinting inks):

Description of accompanying reconstitution diluent(s), if applicable:

2.3.P.2.2.1 Formulation Development

(b)

Information on primary (submission, registration, exhibit) batches including

<Dossier Reference Number(s) e.g. H999>

Page 4 of 12

(QIS) (2012-02-20)

Medicines Control Authority of Zimbabwe

comparative bioavailability or biowaiver, stability, commercial:

(i) Summary of batch numbers:

Batch number(s) of the FPPs used in

Bioequivalence or biowaiver

Dissolution profile studies

Stability studies (primary batches)

packaging configuration I

packaging configuration II

Add/delete as many rows as necessary

Stability studies (production batches)

packaging configuration I

packaging configuration II

(Add/delete as many rows as necessary)

Validation studies (primary batches)

packaging configuration I

packaging configuration II

(Add/delete as many rows as necessary)

Validation studies (at least the first three

consecutive production batches)

or code(s)/version(s) for process validation

protocol(s)

<Dossier Reference Number(s) e.g. H999>

Page 5 of 12

(QIS) (2012-02-20)

Medicines Control Authority of Zimbabwe

(ii)

Summary of formulations and discussion of any differences:

Component and

quality standard

(e.g. NF, BP,

Ph.Eur, in-house)

Relevant batches

Comparative

bioavailability or

biowaiver

Stability

Process validation

Commercial

(2.3.P.1)

<Batch nos. and

sizes>

<Batch nos. and

sizes>

<Batch nos. and

sizes>

<Batch nos. and

sizes>

Theor.

quantity

per batch

Theor.

quantity

per

batch

Theor.

quantity

per

batch

Theor.

quantity

per

batch

<complete with appropriate title e.g. Core tablet, Contents of capsule, Powder for injection>

Subtotal 1

<complete with appropriate title e.g. Film-coating >

Subtotal 2

Total

2.3.P.3 Manufacture

2.3.P.3.1 Manufacturer(s)

(a)

Name, address and responsibility (e.g. fabrication, packaging, labelling, testing,

holder of the national manufacturing authorization of the FPP) of each manufacturer,

including contractors and each proposed production site or facility involved in

manufacturing and testing:

Name and address

(include block(s)/unit(s))

Responsibility

2.3.P.3.2 Batch Formula

(a)

List of all components of the FPP to be used in the manufacturing process and their

amounts on a per batch basis (including components of mixtures prepared in-house

(e.g. coatings) and overages, if any):

<Dossier Reference Number(s) e.g. H999>

Page 6 of 12

(QIS) (2012-02-20)

Medicines Control Authority of Zimbabwe

Strength (label claim)

Master production document

reference number and/or version

Proposed commercial batch size(s) (e.g.

number of dosage units)

Component and quality standard

(and grade, if applicable)

Quantity per

batch (e.g.

kg/batch)

Quantity per

batch (e.g.

kg/batch)

Quantity per

batch (e.g.

kg/batch)

<complete with appropriate title e.g. Core tablet, Contents of capsule, Powder for injection>

Subtotal 1

<complete with appropriate title e.g. Film-coating >

Subtotal 2

Total

2.3.P.3.3 Description of Manufacturing Process and Process Controls

(a)

Flow diagram of the manufacturing process:

(b)

Narrative description of the manufacturing process, including equipment type and

working capacity, process parameters:

2.3.P.3.4 Controls of Critical Steps and Intermediates

(a)

Summary of controls performed at the critical steps of the manufacturing process and

on isolated intermediates:

Step

(e.g. granulation, compression, coating)

Controls

2.3.P.3.5 Process Validation and/or Evaluation

(a)

Summary of the process validation and/or evaluation studies conducted and/or a

summary of the proposed validation protocol for the critical steps or critical assays

used in the manufacturing process (e.g. protocol number, parameters, results):

<Dossier Reference Number(s) e.g. H999>

Page 7 of 12

(QIS) (2012-02-20)

Medicines Control Authority of Zimbabwe

Document code(s) for the process validation protocol(s) and/or report(s) (including

reference number/version/date):

2.3.P.5 Control of FPP

2.3.P.5.1 Specification(s)

(a)

Specification(s) for the FPP:

Standard (e.g. Ph.Int., BP, USP, House)

Specification reference number and version

Test

Acceptance criteria

(release)

Acceptance criteria

(shelf-life)

Analytical procedure

(type/source/version)

Description

Identification

Impurities

Assay

etc.

2.3.P.7 Container Closure System

(a)

Description of the container closure systems, including unit count or fill size, container

size or volume:

Description

(including materials of

construction)

Strength

Unit count or fill size

Container size

2.3.P.8 Stability

2.3.P.8.1 Stability Summary and Conclusions

(c)

Proposed storage statement and shelf-life (and in-use storage conditions and in-use

period, if applicable):

Container closure system

<Dossier Reference Number(s) e.g. H999>

Storage statement

Page 8 of 12

Shelf-life

(QIS) (2012-02-20)

Medicines Control Authority of Zimbabwe

2.3.P.8.2 Post-approval Stability Protocol and Stability Commitment

(a)

Stability protocol for Primary stability batches (e.g. storage conditions (including

tolerances), batch numbers and batch sizes, tests and acceptance criteria, testing

frequency, container closure system(s)):

Parameter

Storage condition(s) (C, % RH)

Batch number(s) / batch size(s)

Tests and acceptance criteria

Details

Description

Moisture

Impurities

Assay

etc.

Testing frequency

Container closure system(s)

(b)

Stability protocol for Commitment batches (e.g. storage conditions (including

tolerances), batch numbers (if known) and batch sizes, tests and acceptance criteria,

testing frequency, container closure system(s)):

Parameter

Storage condition(s) (C, % RH)

Batch number(s) / batch size(s)

Tests and acceptance criteria

Details

<not less than three production batches in each container

closure system>

Description

Moisture

Impurities

Assay

etc.

Testing Frequency

Container Closure System(s)

(c)

Stability protocol for Ongoing Batches (e.g. storage conditions (including tolerances),

number of batches per strength and batch sizes, tests and acceptance criteria, testing

frequency, container closure system(s)):

Parameter

Storage condition(s) (C, % RH)

Batch size(s), annual allocation

Tests and acceptance criteria

Details

<at least one production batch per year (unless none is

produced that year) in each container closure system >

Description

Moisture

<Dossier Reference Number(s) e.g. H999>

Page 9 of 12

(QIS) (2012-02-20)

Medicines Control Authority of Zimbabwe

Parameter

Details

Impurities

Assay

etc.

Testing frequency

Container closure system(s)

2.3.P.8.3 Stability Data

(c)

Bracketing and matrixing design for commitment and/or continuing (i.e. ongoing)

batches, if applicable:

WRITTEN COMMITMENTS OF THE MANUFACTURER

API

If applicable (primary stability study commitment):

The Applicant (or API manufacturer) undertook in writing (date of letter of commitment) to continue longterm testing of <INN of API> for a period of time sufficient to cover the whole provisional re-test period

(period ending month/year) and to report any significant changes or out-of-specification results immediately

to MCAZ for the following batches :

<Batch numbers, manufacturing dates, batch size, primary packing materials>

If applicable (commitment stability studies):

Since stability data on three production scale batches were not provided with the application, the remaining

number of production scale batches should be put on long-term stability testing and the data should be

provided as soon as available. Any significant changes or out-of-specification results should be reported

immediately to MCAZ. The approved stability protocol should be used for commitment batches.

API option 2 - CEP

The Applicant provided a commitment in writing (date of letter of commitment) to inform MCAZ in the

event that the CEP is withdrawn. Note that withdrawal will require additional consideration of the API data

requirements to support the dossier.

API option 3 - full details in the PD (ongoing stability study commitment)

The Applicant undertook in writing (date of letter of commitment) a commitment regarding ongoing

stability studies. Unless otherwise justified, at least one batch per year of the product will be included in

the stability programme (unless none is produced during that year). The stability protocol will be that

which was approved for primary batches (or the protocol was submitted for assessment). Out-ofspecification results or significant atypical trends should be investigated. Any confirmed significant

change, out-of-specification result, or significant atypical trend should be reported immediately to MCAZ.

The possible impact on batches on the market should be considered in consultation with MCAZ

inspectors.

FPP

If applicable (primary stability study commitment):

The Applicant undertook in writing (date of letter of commitment) to continue long-term testing of < FPP

reference number, trade name (INN of API), strength, pharmaceutical form> for a period of time sufficient

<Dossier Reference Number(s) e.g. H999>

Page 10 of 12

(QIS) (2012-02-20)

Medicines Control Authority of Zimbabwe

to cover the whole provisional shelf-life (period ending month/year) and to report any out-of-specification

results or significant changes immediately to WHO for the following batches :

<Batch numbers, manufacturing dates, batch size, primary packing materials >

If applicable (commitment stability studies):

Since stability data on three production scale batches was not provided with the application, the Applicant

undertook in writing, (date of letter of commitment) to put the remaining number <e.g. additional two (2)>

production scale batches of < FPP reference number, trade name (INN of API), strength, pharmaceutical

form, primary packing material> on long-term stability testing. Any out-of-specification results or

significant changes during the study should immediately be reported to MCAZ. The approved stability

protocol should be used for commitment batches.

If applicable (the proposed commercial batch size is 200 000 units (x units) or less)

The Applicant undertook in writing (date of letter of commitment) to place the first three batches of any

production size larger than x units on stability. The stability protocol will be that which was approved for

primary batches (or the protocol was submitted for assessment). Out-of-specification results or significant

atypical trends will be investigated. Any confirmed significant change, out-of-specification result, or

significant atypical trend will be reported immediately to MCAZ.

Ongoing stability study commitment

The Applicant undertook in writing (date of letter of commitment) a commitment regarding ongoing

stability studies. Unless otherwise justified, at least one batch per year of the product manufactured in

every primary packaging type will be included in the stability programme (unless none is produced during

that year). The stability protocol will be that which was approved for primary batches (or the protocol was

submitted for assessment). Out-of-specification results or significant atypical trends should be

investigated. Any confirmed significant change, out-of-specification result, or significant atypical trend

should be reported immediately to MCAZ. The possible impact on batches on the market should be

considered in consultation with MCAZ inspectors.

If applicable (validation of production batches)

Since validation data on production scale batches of not less than three (3) consecutive batches of <FPP

reference number, trade name (INN of API), strength, pharmaceutical form, primary packing material>

were not provided with the application, the Applicant submitted a written commitment (date of letter of

commitment) that a validation report in accordance with the details of the validation protocol provided in

the dossier would be made available as soon as possible for evaluation by assessors or for verification by

the MCAZ inspection team. The approved validation protocol should be used for commitment batches.

<Dossier Reference Number(s) e.g. H999>

Page 11 of 12

(QIS) (2012-02-20)

Medicines Control Authority of Zimbabwe

Change History

Date of preparation of original QIS:

Date of revised

version

Section (e.g.

S.2.1)

<Dossier Reference Number(s) e.g. H999>

Revision

Page 12 of 12

(QIS) (2012-02-20)

You might also like

- Quality Information Summary (Qis)Document12 pagesQuality Information Summary (Qis)Arham AhmedNo ratings yet

- 2.25 PA CTD Jun11 v3Document38 pages2.25 PA CTD Jun11 v3Snezana Smileva LazovaNo ratings yet

- Pe 008 4 Site Master File Copy1 PDFDocument8 pagesPe 008 4 Site Master File Copy1 PDFCamilo SuárezNo ratings yet

- Scale Up and Postapproval Changes (Supac) Guidance For Industry: A Regulatory NoteDocument9 pagesScale Up and Postapproval Changes (Supac) Guidance For Industry: A Regulatory NoteAKKAD PHARMANo ratings yet

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- Mcaz QosDocument27 pagesMcaz QosthembaNo ratings yet

- Drug Master FileDocument4 pagesDrug Master FileTHE SMURFSNo ratings yet

- Photostability Testing Guidelines Impact on Generic DrugsDocument11 pagesPhotostability Testing Guidelines Impact on Generic DrugsHaroon RasheedNo ratings yet

- Checklist RDC 200 2017Document5 pagesChecklist RDC 200 2017Quéle MeneguettiNo ratings yet

- CTD Dossier Preparation: K. Srikantha Reddy K. Srikantha ReddyDocument46 pagesCTD Dossier Preparation: K. Srikantha Reddy K. Srikantha ReddyashwanNo ratings yet

- Essential SMF GuideDocument12 pagesEssential SMF Guidechemist_tmaNo ratings yet

- Generic Product DevelopmentDocument25 pagesGeneric Product DevelopmentChairman Pharmaceutical SciencesNo ratings yet

- Eneric: G G D DDocument75 pagesEneric: G G D Dlalooprasad15No ratings yet

- Canadian-GMPs For DrugsDocument100 pagesCanadian-GMPs For DrugsAnil Kumar GuptaNo ratings yet

- PIRIMS - Operations Manual Ver. 1.1 - Pharmaceutical CompanyDocument38 pagesPIRIMS - Operations Manual Ver. 1.1 - Pharmaceutical CompanyBilal AhmadNo ratings yet

- Regulatory Guidelines To Medical DevicesDocument8 pagesRegulatory Guidelines To Medical Devicesdeeksha kinjavdekarNo ratings yet

- SUB 00029-B03 v2.0Document63 pagesSUB 00029-B03 v2.0clauss789hotmailcomNo ratings yet

- FDA Approval Process for Generic Drugs Seminar TranscriptDocument16 pagesFDA Approval Process for Generic Drugs Seminar TranscriptTawfeeq BA AbbadNo ratings yet

- Hatch-Waxman Act & Paragraph IV LitigationDocument23 pagesHatch-Waxman Act & Paragraph IV LitigationParag MehtaNo ratings yet

- Classify Your Medical DeviceDocument3 pagesClassify Your Medical DeviceChris HartoyoNo ratings yet

- Marketing Authorisation Application Maa Pre Submission Meeting Request Form Human - enDocument25 pagesMarketing Authorisation Application Maa Pre Submission Meeting Request Form Human - ensridevi100% (1)

- NEWS CENTER Maine (NCM) Sent A List of Questions To The FDA and These Were Their ResponsesDocument2 pagesNEWS CENTER Maine (NCM) Sent A List of Questions To The FDA and These Were Their ResponsesNEWS CENTER MaineNo ratings yet

- Minutes of 244th Meeting of Registration BoardDocument268 pagesMinutes of 244th Meeting of Registration BoardSarfarazpk1100% (2)

- Good Pharmacovigilance Guidelines For Registration HoldersDocument63 pagesGood Pharmacovigilance Guidelines For Registration HoldersHaider HakimNo ratings yet

- The Common Technical Document-Quality (CTD-Q) : George Wade EMEA February 2008Document14 pagesThe Common Technical Document-Quality (CTD-Q) : George Wade EMEA February 2008deepmankarNo ratings yet

- Compilation of Community Procedures in Inspections and Exchange of InformationDocument6 pagesCompilation of Community Procedures in Inspections and Exchange of InformationDaoNo ratings yet

- Abnormal Returns and Cash Flows in Pharmaceutical M&A PDFDocument61 pagesAbnormal Returns and Cash Flows in Pharmaceutical M&A PDFJoachim_91No ratings yet

- Bromelain MonographDocument5 pagesBromelain MonographLizbeth Aura CebrianNo ratings yet

- 202727orig1s000 Lanzoprazole 15Document164 pages202727orig1s000 Lanzoprazole 15giovanni zegarraNo ratings yet

- FDA Audit Checklist: Preparing for Inspection DayDocument2 pagesFDA Audit Checklist: Preparing for Inspection Daydrs_mdu48No ratings yet

- Ich, Who and Supac GuidelinesDocument66 pagesIch, Who and Supac GuidelinesHaroon RasheedNo ratings yet

- WHO Certificate E120 2019Document4 pagesWHO Certificate E120 2019Risen ChemicalsNo ratings yet

- Oman-Guideline On Good Pharmacovigilance PracticesDocument30 pagesOman-Guideline On Good Pharmacovigilance PracticesAmrNo ratings yet

- An Initiative Under The ICH: Europe, Japan and USADocument14 pagesAn Initiative Under The ICH: Europe, Japan and USAPavan KumarNo ratings yet

- FDA Warning Letter Details CGMP ViolationsDocument7 pagesFDA Warning Letter Details CGMP ViolationsChandan ShahNo ratings yet

- Operational Manual: DGYF-S500 Type Electromagnet Induction Sealing MachineDocument8 pagesOperational Manual: DGYF-S500 Type Electromagnet Induction Sealing MachineHaroldNo ratings yet

- Pharma Industry: Vipul Murarka Vibhuti SharmaDocument37 pagesPharma Industry: Vipul Murarka Vibhuti SharmaVipul MurarkaNo ratings yet

- Biosimilars ManuDocument6 pagesBiosimilars ManuIshan GhaiNo ratings yet

- Comparative Study of Dossier File Submission Process of Drug Product in Usa and EuropeDocument19 pagesComparative Study of Dossier File Submission Process of Drug Product in Usa and EuropeSeemab Amjad RoyNo ratings yet

- Pharmacovigilance Responsibilities of Medicine Sponsors: Australian Recommendations and RequirementsDocument44 pagesPharmacovigilance Responsibilities of Medicine Sponsors: Australian Recommendations and RequirementsResmy JoseNo ratings yet

- Pharmaceutical Country Profile PeruDocument147 pagesPharmaceutical Country Profile PeruNethcy JapNo ratings yet

- Formulario Validacion Procesos Version 7.1Document9 pagesFormulario Validacion Procesos Version 7.1Santiago CastrillonNo ratings yet

- BiosimilarsDocument22 pagesBiosimilarsMichel HalimNo ratings yet

- Marketing History Declaration Template and Safety Declaration TemplateDocument8 pagesMarketing History Declaration Template and Safety Declaration TemplateChannarong ChathaenNo ratings yet

- GMPJBK1 Scribd Uploaded JBK 001Document9 pagesGMPJBK1 Scribd Uploaded JBK 001Jaya Bir KarmacharyaNo ratings yet

- Srilaksmi 2017 Regulatory Requirements For Registration of API in US and EU PDFDocument17 pagesSrilaksmi 2017 Regulatory Requirements For Registration of API in US and EU PDFhira darNo ratings yet

- 2013-12 QP Template Imp PDFDocument3 pages2013-12 QP Template Imp PDFMarcM77No ratings yet

- Funded Non-Interventional Registry AgreementDocument31 pagesFunded Non-Interventional Registry AgreementMEDNo ratings yet

- Chile 09 q3 WPMDocument80 pagesChile 09 q3 WPMhormiga777No ratings yet

- Promise Pharma LabsDocument7 pagesPromise Pharma LabsprinceamitNo ratings yet

- ICH Q3C Residual SolventsDocument40 pagesICH Q3C Residual SolventsRiccardo TorelliNo ratings yet

- Assay and Dissolution EtoricoxibDocument8 pagesAssay and Dissolution Etoricoxibsesilia dyah novitrianiNo ratings yet

- Risk Management PlanDocument4 pagesRisk Management PlanprabhatgoaNo ratings yet

- Bsi MD Clinical Masterclass PMCF Under MDR Webinar 160322 en GBDocument61 pagesBsi MD Clinical Masterclass PMCF Under MDR Webinar 160322 en GBada wangNo ratings yet

- European Journal of Biomedical AND Pharmaceutical SciencesDocument14 pagesEuropean Journal of Biomedical AND Pharmaceutical SciencesSACHIN BHASKAR NARKHEDENo ratings yet

- Biopharmaceuticals Are Among The Most Sophisticated and ElegantDocument8 pagesBiopharmaceuticals Are Among The Most Sophisticated and ElegantRuza MazlanNo ratings yet

- Generic Drug ApprovalDocument17 pagesGeneric Drug Approvalshamma shahulhameedNo ratings yet

- Nonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsFrom EverandNonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsWilliam J. BrockNo ratings yet

- Portfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesFrom EverandPortfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesPete HarpumNo ratings yet

- Kiwi FarmingDocument8 pagesKiwi FarmingthembaNo ratings yet

- Veterinary Guidelines FinalDocument63 pagesVeterinary Guidelines FinalthembaNo ratings yet

- Audit Checklist SOPDocument43 pagesAudit Checklist SOPthemba100% (4)

- mc8 FormDocument6 pagesmc8 FormthembaNo ratings yet

- Metronidazole and Disulfirum ReactionDocument7 pagesMetronidazole and Disulfirum ReactionthembaNo ratings yet

- Mcaz Guideline On Biowaivers Rev1 - Aug 2009Document5 pagesMcaz Guideline On Biowaivers Rev1 - Aug 2009thembaNo ratings yet

- Mcaz QosDocument27 pagesMcaz QosthembaNo ratings yet

- Mcaz Guideline On Submission of Documentation For Interchangeability - Rev0 - Aug 09Document5 pagesMcaz Guideline On Submission of Documentation For Interchangeability - Rev0 - Aug 09thembaNo ratings yet

- List For Bcs ClassificationDocument3 pagesList For Bcs Classificationthemba67% (3)

- Berno 1Document24 pagesBerno 1Try AdipradanaNo ratings yet

- MJV Pharma and Medical SuppliesDocument2 pagesMJV Pharma and Medical SuppliesMervin BocatcatNo ratings yet

- Scnausea Protocol 1mar2012Document6 pagesScnausea Protocol 1mar2012Afra FitrianitaNo ratings yet

- Pharmacology of Antipyretic DrugsDocument19 pagesPharmacology of Antipyretic DrugsPretty HiaNo ratings yet

- PT SEHAT BERSAMA SEJAHTERA Price ListDocument20 pagesPT SEHAT BERSAMA SEJAHTERA Price ListApotek C 8No ratings yet

- Drug Study - IBRANCEDocument3 pagesDrug Study - IBRANCEKian HerreraNo ratings yet

- Musculoskeletal PharmacologyDocument18 pagesMusculoskeletal PharmacologyBLEEMAGE100% (2)

- Handbook of Pharmaceutical Generic Development Vol 12 Part 2Document236 pagesHandbook of Pharmaceutical Generic Development Vol 12 Part 2Pablo Atapuma100% (7)

- Daftar Obat Baksos KosongDocument9 pagesDaftar Obat Baksos Kosongkus miniNo ratings yet

- Pediatric Dosage CalculationsDocument1 pagePediatric Dosage CalculationsDianne MacaraigNo ratings yet

- Vims-Vas Final SeptDocument115 pagesVims-Vas Final SeptR Lamb D LeonNo ratings yet

- Drug Dosage and IV Rates Calculations PDFDocument6 pagesDrug Dosage and IV Rates Calculations PDFvarmaNo ratings yet

- Draft European Union Herbal Monograph Aesculus Hippocastanum L Cortex Revision 1 enDocument7 pagesDraft European Union Herbal Monograph Aesculus Hippocastanum L Cortex Revision 1 enAmineNo ratings yet

- The Truth About CBDDocument34 pagesThe Truth About CBDapi-458412381No ratings yet

- RibavirinDocument2 pagesRibavirinAnonymous 6u2S47fbxnNo ratings yet

- LECTURE 3 - Pharmacology of VasoconstrictorsDocument27 pagesLECTURE 3 - Pharmacology of VasoconstrictorsKIH 20162017No ratings yet

- VICEDocument8 pagesVICEMariel CortezNo ratings yet

- Complete Drug FormularyDocument96 pagesComplete Drug FormularyRPh Krishna Chandra JagritNo ratings yet

- Name of Sleeping Pill in Bangladesh - Google Search PDFDocument1 pageName of Sleeping Pill in Bangladesh - Google Search PDFPrati ShahanazNo ratings yet

- The Side Effects of Common Psychiatric DrugsDocument40 pagesThe Side Effects of Common Psychiatric DrugsSFLD0% (1)

- Pfizer COVID vaccine preparation and administration guideDocument3 pagesPfizer COVID vaccine preparation and administration guideL Jossenel Mejido-AñanoNo ratings yet

- Available Medicine at Pharmacy of THQ Hospital Jampur District Rajanpur Date:03.03.2020Document2 pagesAvailable Medicine at Pharmacy of THQ Hospital Jampur District Rajanpur Date:03.03.2020Kashif AhmadNo ratings yet

- Pharmacology ReviewersDocument5 pagesPharmacology ReviewersNeisha Halil VillarealNo ratings yet

- Lessening Pain Through Continuous IV MorphineDocument23 pagesLessening Pain Through Continuous IV MorphineKatrina Cruz Yambao100% (2)

- Navigation Search THC (Disambiguation) : TetrahydrocannabinolDocument14 pagesNavigation Search THC (Disambiguation) : TetrahydrocannabinolVictor Vacariu100% (1)

- CNS Stimulants and Hallucinogenic Drugs EffectsDocument21 pagesCNS Stimulants and Hallucinogenic Drugs EffectsGeorgios PlethoNo ratings yet

- DexamethasoneDocument3 pagesDexamethasoneWina Siska Purnama BurmanNo ratings yet

- Drug Card BenadrylDocument1 pageDrug Card BenadryljackNo ratings yet

- Benzo PowerpointDocument21 pagesBenzo Powerpointapi-300457344No ratings yet

- Thesis On Topical Drug Delivery SystemDocument7 pagesThesis On Topical Drug Delivery Systemjuliemoralesomaha100% (2)