Professional Documents

Culture Documents

Construction Materials 01

Uploaded by

Châu TúCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction Materials 01

Uploaded by

Châu TúCopyright:

Available Formats

1/22/2013

Materials for infrastructures

Department of Civil Engineering Mar. 15, 2012

International University - VNU HCMC

1. Building:

Columns:

Floor:

Wall:

Window:

Formwork:

CE210IU-Constructions Materials

Concrete, steel bars, mortar,

Concrete, steel bars, mortar, gypsum

Brick, mortar, concrete, big stone,

wood, alumina, glass, steel bar,

Steel frame, wooden plate/bar,

Overview of the course

Nguyen Dinh Hung Dr. Eng.

Materials for infrastructures

2. Road:

- Pavement: Asphalt concrete, concrete, brick

- Base:

big stone, aggregate,

- Subbase: Soil, sand,

Accidents in constructions

Materials for infrastructures

3. Bridge:

Concrete, steel bars, prestressing steel, steel frame, asphalt concrete,

brick , wood, big stone,

Introduction to the course

1. Evaluation

In-class quizzes, class participation and learning attitude: 10 - 30%

One midterm exam: 20 - 40%

One comprehensive final exam: 30 - 50%

Final score = 30%(midterm) + 30%(report and others) + 40% (final exam)

2. Textbook

Michael S. Mamlouk and John P. Zaniewski, Materials for Civil and

Construction Engineers, Prentice Hall, 2005.

Sailing Tower in Ha Tinh

Workshop in Binh Duong

Can Tho bridge (Sept. 26, 2007)

3. Reference books:

Steven H. Kosmatka, Beatrix Kerkhoff, and William C.

Panarese, Design and Control of Concrete Mixtures, 14th Ed., Portland

Cement Association, 2008.

Neil Jackson and Ravindra K. Dhir, Civil engineering materials, 4th

Ed, Palgrave Macmillan, 1996.

Phng Vn L v cc tc gi, Gio trnh vt liu xy dng, NXB Gio

dc, 2000.

Phm Duy Hu, Ng Xun Qung v Mai nh Lc, Gio trnh Vt

liu xy dng, NXB Giao Thng Vn Ti

Palau bridge (Sept. 26, 1996)

1/22/2013

Content for the course

Plan

Design

Construction

Maintenance

Department of Civil Engineering Mar. 15, 2012

International University - VNU HCMC

Demolition

1. Concrete

Aggregate: stone, gravel, sand

Cement, water (bonding)

Admixture: Lime stone, fibers, fly ash, rice husk slag, blast-furnace

slag, gypsum, ice, silica fume, glass,

Mixture proportion, concrete properties,

2. Steel

Normal reinforcing bar, prestressing tendon/strand, steel plate,

3. Asphalt concrete

Aggregate: stone, gravel, sand, lime stone,

Bitumen materials (bonding)

Mixture proportion

4. Other materials

Brick, wood, mortar and grout (sand, cement, lime, water), composite

materials, paint coating and cladding materials,

Keyword: Properties of construction materials!

What is concrete?

CE210U-Constructions Materials

Concrete

Nguyen Dinh Hung Dr. Eng.

Introduction to the course

Concrete is a composite construction material

composed primarily of aggregate, cement

, water and others (admixture) .

Aggregate: crushed stone, gravel, sand

Cement, water (bonding)

Coarse and Fine Aggregate and

Admixture: Lime stone, fibers, fly ash, rice husk

slag, blast-furnace slag, gypsum, ice, silica

fume, glass,

Water

v Strong in compression

v Week in tension

v Easier in making shape

Aggregate (course and fine)

10

1. Source: Natural aggregate

Aggregate (course and fine)

2. Source: Artificial aggregate

Lead shot aggregate

Crushed stone

Gravel

Crushed sand

burned expanded clay aggregate

Pumice stone

Blast Furnace Slag (BFS)

Concrete sand

11

fill sand

Glass

Aggregate for normal concrete:

1200 to 1760 kg/m3

Aggregate for light weight concrete:

560 to 1120 kg/m3

Aggregate for heavy concrete:

>1760 kg/m3

1/22/2013

12

Basic aggregate properties

Aggregate size distribution (ASTM C136-96a)

14

Aggregate size distribution

13

15

100

100

90

80

90

80

70

60

50

Upper limit

40

30

Lower limit

Test

20

10

0

Percent passing (%)

Percent passing (%)

Shape of course aggregate

70

60

50

Upperlimit

40

30

Lower limit

Test

20

10

0

10

100

0.01

sieve size (mm)

10

sieve size (mm)

Coarse aggregate

Fine aggregate

If test aggregate is outside of limit lines, some aggregate needs to add to

meet Specifications.

sieve

Fine aggregate

0.1

Coarse aggregate

Amount of aggregate is passed through on

sieve (in weight).

Maximum size aggregate: (important) related

to tensile strength of concrete

Aggregate size distribution

Fineness Modulus (FM): obtained by adding the total percentage of the

sample of an aggregate retained on each of a specified series of

sieves, and dividing the sum by 100.

16

Toughness, Hardness, and Abrasion Resistance

Aggregate abrasion characteristics are

important because the constituent aggregate

must resist crushing, degradation and

disintegration during mixing cement concrete

or asphalt concrete and service

Aggregate: made dry (110C) then cooling

and measured 5000(g) or 10000 (g)

Steel balls: 6 or 12 balls

500 or 1000 revolutions

Sieve: No.12 (1.7mm)

Measure: retaining mass (g) after making

dry

Loss = (

FM of sand = 2.3 to 3.1. FM of coarse aggregate >3.1. Other should

check and wash aggregate. Therefore, FM is control quality and cost of

product

17

M Original - M Final

M Original

) 100

TCVN 7572-12:2006

1/22/2013

Typical L.A. Abrasion Loss Values

Rock Type

18

Moisture content and weights (ASTM C 127)

19

L.A. Abrasion Loss (by

percent weight)

General Values

Hard, igneous rocks

10

Soft limestones and

sandstones

60

Dry state (bond dry): aggregate contains no moisture.

Ranges for specific rocks

Basalt

10 17

In an air dry condition: aggregate may have some moisture (normal condition)

Dolomite

18 30

Gneiss

33 57

Saturated surfacedry (SSD) condition: water penetrated into aggregate but its

surface is dry. This water will not participate in the reaction with cement.

Granite

27 49

Limestone

19 30

Quartzite

20 35

Moisture content and weights (ASTM C 127)

Absorption: is defined as the moisture content in the SSD condition.

Free moisture content: water in surface of aggregate. This water will participate

in the reaction with cement.

20

Moisture content and weights (ASTM C 127)

WS

Dry weight (WS): wash dust then oven-dry to a constant mass (less then 0.1% in

weight) at 110C (230F) after cooling 3 hours.

Saturated surfacedry (SSD) weight (WP): put clean aggregate into water with 24

hours in normal condition. Remove the aggregate from the water and roll it in a large

absorbent cloth until all visible films of water are removed. Wipe the larger particles

individually (use in determining distribution of aggregate for concrete).

M =

Percent free moisture: M A =

Unit weights: dry, saturated surface-dry, wet and saturated conditions (kg/m3)

Moisture content and weights (ASTM C 127)

22

Absorption

W - WS

100%

WS

Wet weight: is defined as weight of aggregate in wet (normal condition) .

Saturated weight: is defined as weight of aggregate in saturated condition.

WP

W

Moisture content

AM =

WP - WS

100%

WS

21

WM

Moisture content

M =

WM - WS

100%

WS

= 0: use to cast concrete

< 0: put more water

> 0: reduce water

Strength and modulus

23

Important properties: tensile and compressive strengths, modulus.

It is difficult and rare to determine important properties of aggregate by test

(monolithic sample with diameter of 50mm , 100 mm in high no crack, no bulk

layer, no special vein).

Tensile strength: 0.7 to 16 MPa.

ft =

2P

pDL

Compressive strength: 35 to 350 MPa.

fc =

P

A

Young Modulus

P

E=

d

P: Applied load (N)

D, A, L: Diameter (mm), area (mm2)

and length (mm) of sample

d: displacement (mm)

1/22/2013

Water

24

Department of Civl Engineering

International University VNU HCMC

Thank you for your kind attention!

You might also like

- Technical Design/ Detailed Design For Construction: Date Description RevDocument6 pagesTechnical Design/ Detailed Design For Construction: Date Description RevChâu TúNo ratings yet

- Association With Azmeel, Abu-Nayyan& Saudi Tumpane Excavation Weekly Inspection Checklist Site Location: Excation Depth: Excavation Width: Soil TypeDocument1 pageAssociation With Azmeel, Abu-Nayyan& Saudi Tumpane Excavation Weekly Inspection Checklist Site Location: Excation Depth: Excavation Width: Soil TypeChâu TúNo ratings yet

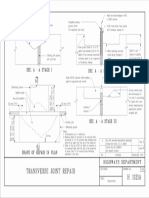

- Transverse Joint RepairDocument1 pageTransverse Joint RepairChâu TúNo ratings yet

- Session2 Generalsafetyrequirements 150927084710 Lva1 App6891 PDFDocument76 pagesSession2 Generalsafetyrequirements 150927084710 Lva1 App6891 PDFChâu TúNo ratings yet

- Checklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingDocument11 pagesChecklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingChâu TúNo ratings yet

- PVC Installation GuideDocument3 pagesPVC Installation GuideChâu TúNo ratings yet

- Al Mussafah A Al Mussafah Ahalia Hospital Al Mussafah Ahalia HospitalDocument4 pagesAl Mussafah A Al Mussafah Ahalia Hospital Al Mussafah Ahalia HospitalChâu TúNo ratings yet

- Aluminum Form Work SystemDocument18 pagesAluminum Form Work SystemChâu TúNo ratings yet

- (Xaydung360.Vn) 01 BoQ Interial Works The NASSIMDocument27 pages(Xaydung360.Vn) 01 BoQ Interial Works The NASSIMChâu TúNo ratings yet

- RC Cadd 1Document1 pageRC Cadd 1Châu TúNo ratings yet

- Phaàn 3: Thieát Keá Thi CoângDocument14 pagesPhaàn 3: Thieát Keá Thi CoângChâu TúNo ratings yet

- 2014 Deqs Chap1 2Document84 pages2014 Deqs Chap1 2Châu TúNo ratings yet

- Ho Chi Minh City International UniversityDocument2 pagesHo Chi Minh City International UniversityChâu TúNo ratings yet

- Elevated TanksDocument8 pagesElevated TanksChâu TúNo ratings yet

- Ho Chi Minh City International UniversityDocument2 pagesHo Chi Minh City International UniversityChâu TúNo ratings yet

- DEqs Midterm Exam 10 11Document2 pagesDEqs Midterm Exam 10 11Châu TúNo ratings yet

- Introduction To Computing For Engineers: Cell Arrays and ExamplesDocument9 pagesIntroduction To Computing For Engineers: Cell Arrays and ExamplesChâu TúNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2 TensionDocument28 pages2 TensionRICKY IVANNo ratings yet

- Interfaces KelloggDocument16 pagesInterfaces KelloggUrrNo ratings yet

- Service Manual: Model Code - Kib19Bp3-CmgDocument11 pagesService Manual: Model Code - Kib19Bp3-Cmgpravin jadavNo ratings yet

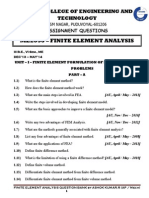

- Assignment Booklet Me2353 Finite Element Analysis Dec 2013 May 2014Document85 pagesAssignment Booklet Me2353 Finite Element Analysis Dec 2013 May 2014Ashok Kumar Rajendran100% (9)

- The Holographic Universe - Simulation Hypothesis - CrystalinksDocument29 pagesThe Holographic Universe - Simulation Hypothesis - CrystalinkssalatieNo ratings yet

- Catalogo GIACOMINIDocument45 pagesCatalogo GIACOMINIIsrael Silva Hgo.No ratings yet

- CHEG320 Electrochemistry LecturesDocument114 pagesCHEG320 Electrochemistry LecturesqalanisNo ratings yet

- Jeppiaar SRR Engineering College: Title: Smart Wearble Health Monitoring For Patient/Elder PeopleDocument12 pagesJeppiaar SRR Engineering College: Title: Smart Wearble Health Monitoring For Patient/Elder PeopleKurushNishanthNo ratings yet

- Manufacturer'S Test Certificate: National Builtech Trading and Contracting CoDocument1 pageManufacturer'S Test Certificate: National Builtech Trading and Contracting CoQc QatarNo ratings yet

- IQ RF MappingDocument14 pagesIQ RF Mappingsatcom_77No ratings yet

- Esc101: Fundamentals of Computing: 2011-12-Monsoon SemesterDocument6 pagesEsc101: Fundamentals of Computing: 2011-12-Monsoon SemesterMukesh Kumar DewraNo ratings yet

- WBNR La Auto BCM SpanishDocument41 pagesWBNR La Auto BCM SpanishHaragopal KrishnaNo ratings yet

- One JanDocument69 pagesOne JanDeep PatelNo ratings yet

- Statistical Process Control & Cost of QualityDocument114 pagesStatistical Process Control & Cost of QualityAshraf S. Youssef100% (2)

- Specification Sheets PDFDocument6 pagesSpecification Sheets PDFVu TongNo ratings yet

- Olefins-All Product CatalogDocument28 pagesOlefins-All Product Catalogayon_hossen242No ratings yet

- DsPIC33F - 01 - IntroductionDocument8 pagesDsPIC33F - 01 - IntroductionLau SandovalNo ratings yet

- Mov BiffiDocument177 pagesMov BiffiSKNo ratings yet

- 240-109607332 Eskom Plant Labelling Abbreviation StandardDocument638 pages240-109607332 Eskom Plant Labelling Abbreviation StandardiabhuaNo ratings yet

- Brige Lauching Cap 1 PDFDocument16 pagesBrige Lauching Cap 1 PDFAnonymous VkzquW39No ratings yet

- Operation Guide MSBDocument8 pagesOperation Guide MSBMao RathanithNo ratings yet

- Connections For Hydraulic Fluid Power and General Use - Hose FittingsDocument22 pagesConnections For Hydraulic Fluid Power and General Use - Hose FittingsОлег СоловьевNo ratings yet

- Omfb MTC 11.12.23Document2 pagesOmfb MTC 11.12.23obviousplatinum2No ratings yet

- PC W130B 09 EUDocument272 pagesPC W130B 09 EUОблачноNo ratings yet

- Yale PD2, C85, D85Document28 pagesYale PD2, C85, D85LGWILDCAT73No ratings yet

- SMA LACB Flyer Update BID21 ENDocument4 pagesSMA LACB Flyer Update BID21 ENadilsonrodriguesNo ratings yet

- Excel ExercisesDocument37 pagesExcel ExercisesBERNIELLE DAVE FALDASNo ratings yet

- Assign Chap 8Document3 pagesAssign Chap 8nishedhNo ratings yet

- 5209 Aerospace T SealDocument20 pages5209 Aerospace T SealNicolasSuchNo ratings yet

- Const Estimate Made EasyDocument31 pagesConst Estimate Made EasyLorenzo SerranoNo ratings yet