Professional Documents

Culture Documents

DB Dbhs

Uploaded by

Avneet MaanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DB Dbhs

Uploaded by

Avneet MaanCopyright:

Available Formats

KIRLOSKAR END SUCTION PUMPS-TYPE DB/DBHS

Description

Shaft :

Range :

tensile steel shaft accurately machined and ground

Delivery size up to 150 mm

Capacity up to 550 m3/hr

Head up to 100 metres

Applications :

Suitable for Circulation of Water in Industries, AirConditioning Plant, Power Station, Mine Drainage,

Lift Irrigation, Sprinkler systems, Fire Fighting,

Booster service, pumping brine, alkaline solutions,

oils, benzene etc. for liquids having temperature in

the range of 100 C to 1000C.

Constructional Features :

These are single stage, single suction, horizontal

shaft type. They are made in accordance with DIN

24255. DBHS are similar to DB pumps but with heavy

duty bearings. Models are available to operate at

1450 rpm and 2900 rpm at 50 Hz and 1750 rpm and

3500 rpm at 60 Hz.

Casing :

End suction, volute type with top centreline

discharge. Suction and discharge nozzles as well

as the supporting feet are cast integral with the

casing.

Impeller :

Enclosed type and accurately balanced dynamically.

Hydraulically balanced by back vanes and for large

impellers by balancing holes and back wear rings.

Cut-sectional View

Alternatives Available

DB Pump-Mechanical Seal Arrangement

Three driving units cover complete range. The high

is supported by antifricition bearings. The shaft is

protected by shaft sleeve from wear in stuffing box

area.

Stuffing Box :

The stuffing box can be sealed by gland packing or

by mechanical seal.

Bearings :

Deep groove ball bearings are provided. Standard

lubrication is grease.

Oil lubrication against

requirement, only for DB pumps.

Direction of Rotation :

Clockwise viewed from driving end.

Drive :

Suitable for coupling with electric motors, engines

directly or through belt drives.

Material of Construction

Flanges :

Pump Casing

C.I.

C.I.

C.I.

C.I.

C.I.

Bronze/Ph.Br.

Casing Cover

C.I.

C.I.

C.I.

C.I.

C.I.

Bronze/Ph.Br.

Impeller

C.I.

Bronze

Ph. Br.

Bronze

Ph. Br.

Bronze/Ph.Br.

Wear Ring

C.I.

C.I.

Bronze

Bronze

Br.

Bronze

Shaft

C.S./St.St.

C.S./St.St.

C.S./St.St.

C.S./St.St.

St.St.

St.St.

Shaft Sleeve

St.St.

Br./St.St.

St.St.

Bronze/St.St.

Bronze

Bronze

Lantern Ring

C.I.

C.I.

C.I.

C.I./Bronze

C.I.

Bronze

Gland

C.I.

C.I.

C.I.

C.I./Bronze

C.I.

Bronze

Standard : Drilling as per DIN 2533 ND 16 for DB

Drilling as per ASA 125 for

DBHS pumps.

Optional : Drilling as per IS/BS/ASA/DIN available

with suitable pressure rating.

Material Standards

Equivalent International Standards

Material

IS

BS

ASTM

Cast Iron (C.I.)

IS 210 Gr. FG 260

BS 1452 Gr. 250

ASTM-A 48 CL 35

Carbon Steel (C.S.)

IS 1570 Gr. 45 C 8

BS 970 080 M 46

ASTM-A107 Gr. 1045

Stainless Steel (St. St.)

BS 970 410 S 21

ASTM-A 276A Type 410

Bronze

IS 318 Gr. LTB 2

BS 1400 LG 2C

ASTM-B62, B145 Alloy 4A

Phosphor Bronzer (Ph. Br.)

IS 28 Gr.1

Bs 1400 PB 4

KIRLOSKAR END SUCTION PUMPS-TYPE DB/DBHS

Description

Shaft :

Range :

tensile steel shaft accurately machined and ground

Delivery size up to 150 mm

Capacity up to 550 m3/hr

Head up to 100 metres

Applications :

Suitable for Circulation of Water in Industries, AirConditioning Plant, Power Station, Mine Drainage,

Lift Irrigation, Sprinkler systems, Fire Fighting,

Booster service, pumping brine, alkaline solutions,

oils, benzene etc. for liquids having temperature in

the range of 100 C to 1000C.

Constructional Features :

These are single stage, single suction, horizontal

shaft type. They are made in accordance with DIN

24255. DBHS are similar to DB pumps but with heavy

duty bearings. Models are available to operate at

1450 rpm and 2900 rpm at 50 Hz and 1750 rpm and

3500 rpm at 60 Hz.

Casing :

End suction, volute type with top centreline

discharge. Suction and discharge nozzles as well

as the supporting feet are cast integral with the

casing.

Impeller :

Enclosed type and accurately balanced dynamically.

Hydraulically balanced by back vanes and for large

impellers by balancing holes and back wear rings.

Cut-sectional View

Alternatives Available

DB Pump-Mechanical Seal Arrangement

Three driving units cover complete range. The high

is supported by antifricition bearings. The shaft is

protected by shaft sleeve from wear in stuffing box

area.

Stuffing Box :

The stuffing box can be sealed by gland packing or

by mechanical seal.

Bearings :

Deep groove ball bearings are provided. Standard

lubrication is grease.

Oil lubrication against

requirement, only for DB pumps.

Direction of Rotation :

Clockwise viewed from driving end.

Drive :

Suitable for coupling with electric motors, engines

directly or through belt drives.

Material of Construction

Flanges :

Pump Casing

C.I.

C.I.

C.I.

C.I.

C.I.

Bronze/Ph.Br.

Casing Cover

C.I.

C.I.

C.I.

C.I.

C.I.

Bronze/Ph.Br.

Impeller

C.I.

Bronze

Ph. Br.

Bronze

Ph. Br.

Bronze/Ph.Br.

Wear Ring

C.I.

C.I.

Bronze

Bronze

Br.

Bronze

Shaft

C.S./St.St.

C.S./St.St.

C.S./St.St.

C.S./St.St.

St.St.

St.St.

Shaft Sleeve

St.St.

Br./St.St.

St.St.

Bronze/St.St.

Bronze

Bronze

Lantern Ring

C.I.

C.I.

C.I.

C.I./Bronze

C.I.

Bronze

Gland

C.I.

C.I.

C.I.

C.I./Bronze

C.I.

Bronze

Standard : Drilling as per DIN 2533 ND 16 for DB

Drilling as per ASA 125 for

DBHS pumps.

Optional : Drilling as per IS/BS/ASA/DIN available

with suitable pressure rating.

Material Standards

Equivalent International Standards

Material

IS

BS

ASTM

Cast Iron (C.I.)

IS 210 Gr. FG 260

BS 1452 Gr. 250

ASTM-A 48 CL 35

Carbon Steel (C.S.)

IS 1570 Gr. 45 C 8

BS 970 080 M 46

ASTM-A107 Gr. 1045

Stainless Steel (St. St.)

BS 970 410 S 21

ASTM-A 276A Type 410

Bronze

IS 318 Gr. LTB 2

BS 1400 LG 2C

ASTM-B62, B145 Alloy 4A

Phosphor Bronzer (Ph. Br.)

IS 28 Gr.1

Bs 1400 PB 4

DBHS Pump

General Dimensions/Mounting Details

DB Pump

Typical Drawing

Typical Drawing

Dimension

PUMP

MODEL

Interchangeability of Components

NAME OF

TOTAL NO.

NO.

PART

OF PARTS

PUMP MODEL

32/13

40/13

50/13

65/13

32/16

40/16

50/16

32/20

40/20

65/16

80/16

50/20

65/20

32/26

40/26

50/26

80/20

100/20

65/26

80/26

100/26

125/26

65/32

80/32

100/32

125/32

150/32

100/40

125/40

150/40

PART

UNIT 30

UNIT 40

UNIT 50

105

PUMP CASING

30

2 3

4 5 6 7

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

151

IMPELLER

30

2 3

4 5 6 7

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

180

SHAFT

190

CASING RING

2 3

4 1 2 3

2 2 4 5 3 4

2 3 4

5 6 4 5

6 7 5

6 7 9 6 7 9

191

BACK WEAR

RING

3 2 2 4 2 5

220

CASING COVER

12

1 1

223

GLAND

227

LANTERN RING

240

BEARING

HOUSING

1 1

1 1 1 1

1 1 2 2 2 2

2 2 2

3 3 3 3

4 4 4

4 4 4 4 4 4

251

SUPPORT

FOOT

10

1 2

3 2 2 3

3 3 4 5 4 5

5 5 5

5 6 6 6

7 8 7

8 9 9 9 10 10

260

BEARING

270

BEARING COVER

310

SHAFT SLEEVE

320

IMPELLER KEY

321

COUPLING KEY

330

IMPELLER NUT

410

LOCK

WASHER

1 2 2 2

3 3 4 4 5 5

6 6 6

7 7 8 8

9 9 10 10 10 11 11 12 12 12

UNIT NO.

SUC. DEL.

h1

h2

PUMP MOUNTING DIMENSIONS

b c m1 m2 n1

n2 s

e1

sl

SHAFT END

d l t u

WT.

KG

32/13

32/16

32/20

32/26

25

25

25

25

50

50

50

50

32

32

32

32

80

80

80

100

360

360

360

360

112

132

160

180

140

160

180

225

50

50

50

65

14

14

14

14

100

100

100

125

70

70

70

95

190

240

240

320

140

190

190

250

14

14

14

14

100

100

110

110

14

14

14

14

267

267

267

267

24

24

24

24

50

50

50

50

27

27

27

27

8

8

8

8

100

100

100

100

28

34

41

59

40/13

40/16

40/20

40/26

25

25

25

25

65

65

65

65

40

40

40

40

80

80

100

100

360

360

360

360

112

132

160

180

140

160

180

225

50

50

50

65

14

14

14

14

100

100

100

125

70

70

70

95

210

240

265

320

160

190

212

250

14

14

14

14

100

100

110

110

14

14

14

14

267

267

267

267

24

24

24

24

50

50

50

50

27

27

27

27

8

8

8

8

100

100

100

100

29

36

44

61

50/13

50/16

50/20

50/26

25

25

25

25

65

65

65

65

50

50

50

50

100

100

100

100

360

360

360

360

132

160

160

180

160

180

200

225

50

50

50

65

14

14

14

14

100

100

100

125

70

70

70

95

240

265

265

320

190

212

212

250

14

14

14

14

100

110

110

110

14

14

14

14

267

267

267

267

24

24

24

24

50

50

50

50

27

27

27

27

8

8

8

8

100

100

100

100

32

38

46

63

65/13

65/16

65/20

65/26

65/32

25

25

25

35

35

80

80

80

80

80

65

65

65

65

65

100

100

100

100

125

360

360

360

470

470

160

160

180

200

225

180

200

225

250

280

65

65

65

80

80

14

14

14

16

16

125 95

125 95

125 95

160 120

160 120

280

280

320

360

400

212

212

250

280

315

14

14

14

18

18

110

110

110

110

110

14

14

14

14

14

267

267

267

342

342

24

24

24

32

32

50

50

50

80

80

27

27

27

35

35

8

8

8

10

10

100 39

100 43

100 52

140 81

140 100

80/16

80/20

80/26

80/32

25

35

35

35

100

100

100

100

80

80

80

80

125

125

125

125

360

470

470

470

180

180

200

250

225 65 14

250 65 14

280 80 16

315 80 16

125

125

160

160

95

95

120

120

320

345

400

400

250 14 110 14 267

280 14 110 14 342

315 18 110 14 342

315 18 110 14 342

24

32

32

32

50

80

80

80

27

35

35

35

8

10

10

10

100 53

140 70

140 91

140 107

100/20

100/26

100/32

100/40

35

35

35

45

125

125

125

125

100

100

100

10

125

140

140

140

470

470

470

530

200

225

250

280

280 80

280 80

315 80

355 100

160

160

160

200

120

120

120

150

360

400

400

500

280

315

315

400

18

18

18

23

110

110

110

110

14

14

14

14

342

342

342

370

32

32

32

42

80 35

80 35

80 35

110 45

10

10

10

12

140 85

140 103

140 116

140 177

125/26

125/32

125/40

35

45

45

150

150

150

125

125

125

140 470 250 355 80 16

140 530 280 355 100 18

140 530 315 400 100 18

160 120

200 150

200 150

400

500

500

315

400

400

18

23

23

110

110

110

14

14

14

342

370

370

32 80 35 10 140 110

42 110 45 12 140 151

42 110 45 12 140 188

150/32

150/40

45

45

200

200

150

150

160 530 280 400 100 18

160 530 315 450 100 18

200 150

200 150

550

550

450

450

23

23

110

110

14

14

370

370

42 110 45 12 140 170

42 110 45 12 140 205

16

16

16

18

DBHS Pump

General Dimensions/Mounting Details

DB Pump

Typical Drawing

Typical Drawing

Dimension

PUMP

MODEL

Interchangeability of Components

NAME OF

TOTAL NO.

NO.

PART

OF PARTS

PUMP MODEL

32/13

40/13

50/13

65/13

32/16

40/16

50/16

32/20

40/20

65/16

80/16

50/20

65/20

32/26

40/26

50/26

80/20

100/20

65/26

80/26

100/26

125/26

65/32

80/32

100/32

125/32

150/32

100/40

125/40

150/40

PART

UNIT 30

UNIT 40

UNIT 50

105

PUMP CASING

30

2 3

4 5 6 7

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

151

IMPELLER

30

2 3

4 5 6 7

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

180

SHAFT

190

CASING RING

2 3

4 1 2 3

2 2 4 5 3 4

2 3 4

5 6 4 5

6 7 5

6 7 9 6 7 9

191

BACK WEAR

RING

3 2 2 4 2 5

220

CASING COVER

12

1 1

223

GLAND

227

LANTERN RING

240

BEARING

HOUSING

1 1

1 1 1 1

1 1 2 2 2 2

2 2 2

3 3 3 3

4 4 4

4 4 4 4 4 4

251

SUPPORT

FOOT

10

1 2

3 2 2 3

3 3 4 5 4 5

5 5 5

5 6 6 6

7 8 7

8 9 9 9 10 10

260

BEARING

270

BEARING COVER

310

SHAFT SLEEVE

320

IMPELLER KEY

321

COUPLING KEY

330

IMPELLER NUT

410

LOCK

WASHER

1 2 2 2

3 3 4 4 5 5

6 6 6

7 7 8 8

9 9 10 10 10 11 11 12 12 12

UNIT NO.

SUC. DEL.

h1

h2

PUMP MOUNTING DIMENSIONS

b c m1 m2 n1

n2 s

e1

sl

SHAFT END

d l t u

WT.

KG

32/13

32/16

32/20

32/26

25

25

25

25

50

50

50

50

32

32

32

32

80

80

80

100

360

360

360

360

112

132

160

180

140

160

180

225

50

50

50

65

14

14

14

14

100

100

100

125

70

70

70

95

190

240

240

320

140

190

190

250

14

14

14

14

100

100

110

110

14

14

14

14

267

267

267

267

24

24

24

24

50

50

50

50

27

27

27

27

8

8

8

8

100

100

100

100

28

34

41

59

40/13

40/16

40/20

40/26

25

25

25

25

65

65

65

65

40

40

40

40

80

80

100

100

360

360

360

360

112

132

160

180

140

160

180

225

50

50

50

65

14

14

14

14

100

100

100

125

70

70

70

95

210

240

265

320

160

190

212

250

14

14

14

14

100

100

110

110

14

14

14

14

267

267

267

267

24

24

24

24

50

50

50

50

27

27

27

27

8

8

8

8

100

100

100

100

29

36

44

61

50/13

50/16

50/20

50/26

25

25

25

25

65

65

65

65

50

50

50

50

100

100

100

100

360

360

360

360

132

160

160

180

160

180

200

225

50

50

50

65

14

14

14

14

100

100

100

125

70

70

70

95

240

265

265

320

190

212

212

250

14

14

14

14

100

110

110

110

14

14

14

14

267

267

267

267

24

24

24

24

50

50

50

50

27

27

27

27

8

8

8

8

100

100

100

100

32

38

46

63

65/13

65/16

65/20

65/26

65/32

25

25

25

35

35

80

80

80

80

80

65

65

65

65

65

100

100

100

100

125

360

360

360

470

470

160

160

180

200

225

180

200

225

250

280

65

65

65

80

80

14

14

14

16

16

125 95

125 95

125 95

160 120

160 120

280

280

320

360

400

212

212

250

280

315

14

14

14

18

18

110

110

110

110

110

14

14

14

14

14

267

267

267

342

342

24

24

24

32

32

50

50

50

80

80

27

27

27

35

35

8

8

8

10

10

100 39

100 43

100 52

140 81

140 100

80/16

80/20

80/26

80/32

25

35

35

35

100

100

100

100

80

80

80

80

125

125

125

125

360

470

470

470

180

180

200

250

225 65 14

250 65 14

280 80 16

315 80 16

125

125

160

160

95

95

120

120

320

345

400

400

250 14 110 14 267

280 14 110 14 342

315 18 110 14 342

315 18 110 14 342

24

32

32

32

50

80

80

80

27

35

35

35

8

10

10

10

100 53

140 70

140 91

140 107

100/20

100/26

100/32

100/40

35

35

35

45

125

125

125

125

100

100

100

10

125

140

140

140

470

470

470

530

200

225

250

280

280 80

280 80

315 80

355 100

160

160

160

200

120

120

120

150

360

400

400

500

280

315

315

400

18

18

18

23

110

110

110

110

14

14

14

14

342

342

342

370

32

32

32

42

80 35

80 35

80 35

110 45

10

10

10

12

140 85

140 103

140 116

140 177

125/26

125/32

125/40

35

45

45

150

150

150

125

125

125

140 470 250 355 80 16

140 530 280 355 100 18

140 530 315 400 100 18

160 120

200 150

200 150

400

500

500

315

400

400

18

23

23

110

110

110

14

14

14

342

370

370

32 80 35 10 140 110

42 110 45 12 140 151

42 110 45 12 140 188

150/32

150/40

45

45

200

200

150

150

160 530 280 400 100 18

160 530 315 450 100 18

200 150

200 150

550

550

450

450

23

23

110

110

14

14

370

370

42 110 45 12 140 170

42 110 45 12 140 205

16

16

16

18

Cross Sectional View

DB Pump

DBHS Pump

Typical Drawing

36

32/20

50

32

75

385

160

176

50

14

100

70

240

190

14

100

14

290

50

1.11

1/4

48

40/13

65

40

75

385

112

135

50

14

100

70

210

160

14

100

14

290

50

1.11

1/4

33

65

40

75

385

132

155

50

14

100

70

240

190

14

100

14

290

50

1.11

1/4

38

40/20

65

40

95

385

160

175

50

14

100

70

265

212

14

110

14

290

50

1.11

1/4

50/13

65

50

95

385

132

155

50

14

100

70

240

190

14

100

14

290

50

1.11

1/4

36

50/16

65

50

95

385

160

175

50

14

100

70

265

212

14

110

14

290

50

1.11

1/4

42

65/13

80

65

95

385

160

175

65

14

125

95

280

212

14

110

14

290

50

1.11

1/4

41

32/26

50

32

95

498

180

221

65

14

125

95

320

250

14

110

14

378 1.3/8

75

1.513 5/16

73

40/26

65

40

95

498

180

220

65

14

125

95

320

250

14

110

14

378 1.3/8

75

1.513 5/16

75

50/20

65

50

95

498

160

195

50

14

100

70

265

212

14

110

14

378 1.3/8

75

1.513 5/16

61

50/26

65

50

95

498

180

220

65

14

125

95

320

250

14

110

14

378 1.3/8

75

1.513 5/16

77

65/16

50

65

95

498

160

195

65

14

125

95

280

212

14

110

14

378 1.3/8

75

1.513 5/16

61

65/20

40

80/16

100

49

TOTAL NO.

OF PARTS

PUMP MODEL

UNIT 25

UNIT 35

UNIT 45

105

PUMP CASING

30

3 4

9 10

11 12 13 14 15 16 17 18 19

20 21 22 23 24 25 26 27 28 29 30

151

IMPELLER

30

3 4

9 10

11 12 13 14 15 16 17 18 19

20 21 22 23 24 25 26 27 28 29 30

180

SHAFT

190

CASING RING

3 4

3 4

6 4

5 6

1 1

4 4

5 6

6 7

9 10 10 10

3

6

7 9

65

95

498

180

220

65

14

125

95

320

250

14

110

14

378 1.3/8

75

1.513 5/16

68

220

CASING COVER

10

80

120

498

180

220

65

14

125

95

320

250

14

110

14

378 1.3/8

75

1.513 5/16

71

223

GLAND

227

LANTERN RING

240

BEARING

HOUSING

1 1

2 2

3 3

3 3

4 4

251

SUPPORT

FOOT

2 3

4 4

4 4

4 5

8 8

260

BEARING

270

BEARING COVER

310

SHAFT SLEEVE

320

IMPELLER KEY

321

COUPLING KEY

330

IMPELLER NUT

80

65

95

498

200

245

80

16

160

120

360

280

18

110

14

378 1.3/8

75

1.513 5/16

83

100

80

120

498

180

245

65

14

125

95

345

280

14

110

14

378 1.3/8

75

1.513 5/16

78

80/26

100

80

120

498

200

275

80

16

160

120

400

315

18

110

14

378 1.3/8

75

1.513 5/16

101

100/20

125

100

120

498

200

275

80

16

160

120

360

280

18

110

14

378 1.3/8

75

1.513 5/16

95

65/32

80

65

120

530

225

275

80

16

160

120

400

315

18

110

14

379 1.5/8 100

1.79

129

3/8

80/32

100

80

120

530

250

310

80

16

160

120

400

315

18

110

14

379 1.5/8 100

1.79

3/8

100/26

125

100

135

530

225

275

80

16

160

120

400

315

18

110

14

379 1.5/8 100

1.79

3/8

125

100

135

530

250

310

80

16

160

120

400

315

18

110

14

379 1.5/8 100

1.79

3/8

142

125

100

135

530

280

350

100

18

200

150

500

400

23

110

14

379 1.5/8 100

1.79

3/8

180

125/26

150

125

135

530

250

350

80

16

160

120

400

315

18

110

14

379 1.5/8 100

1.79

3/8

140

125/32

150

125

135

530

280

350

100

18

200

150

500

400

23

110

14

379 1.5/8 100

1.79

3/8

161

125/40

150

125

135

530

315

395

100

18

200

150

500

400

23

110

14

379 1.5/8 100

1.79

3/8

195

150/32

200

150

155

530

280

395

100

18

200

150

550

450

23

110

14

379 1.5/8 100

1.79

3/8

190

150/40

200

150

155

530

315

445

100

18

200

150

550

450

23

110

14

379 1.5/8 100

1.79

3/8

212

50

NAME OF

PART

80

80/20

100/40

PART

NO.

100

65/26

100/32

Interchangeability of Components

150/40

30

1/4

125/40

1/4

1.11

100/40

1.11

50

150/32

50

125/32

290

80/32

290

14

100/32

14

100

65/32

100

14

125/26

14

190

80/26

40

240

100/26

190

70

65/26

70

100

80/20

100

14

Typical Drawing

WT.

KG

100/20

14

50

50/26

50

156

u in

40/26

136

132

30

SHAFT END

l

t in

32/26

112

385

d in

65/20

385

75

50/20

75

32

s1

40/20

32

50

e1

32/20

50

32/16

80/16

32/13

40/16

PUMP MOUNTING DIMENSIONS

c

m1

m2

n1

n2

65/16

50/16

h2

40/16

h1

32/16

65/13

50/13

UNIT

NO. SUC. DEL.

40/13

PUMP

MODEL

32/13

Dimensions

All dimensions are in mm unless specified otherwise.

131

140

123

410

LOCK

WASHER

Cross Sectional View

DB Pump

DBHS Pump

Typical Drawing

36

32/20

50

32

75

385

160

176

50

14

100

70

240

190

14

100

14

290

50

1.11

1/4

48

40/13

65

40

75

385

112

135

50

14

100

70

210

160

14

100

14

290

50

1.11

1/4

33

65

40

75

385

132

155

50

14

100

70

240

190

14

100

14

290

50

1.11

1/4

38

40/20

65

40

95

385

160

175

50

14

100

70

265

212

14

110

14

290

50

1.11

1/4

50/13

65

50

95

385

132

155

50

14

100

70

240

190

14

100

14

290

50

1.11

1/4

36

50/16

65

50

95

385

160

175

50

14

100

70

265

212

14

110

14

290

50

1.11

1/4

42

65/13

80

65

95

385

160

175

65

14

125

95

280

212

14

110

14

290

50

1.11

1/4

41

32/26

50

32

95

498

180

221

65

14

125

95

320

250

14

110

14

378 1.3/8

75

1.513 5/16

73

40/26

65

40

95

498

180

220

65

14

125

95

320

250

14

110

14

378 1.3/8

75

1.513 5/16

75

50/20

65

50

95

498

160

195

50

14

100

70

265

212

14

110

14

378 1.3/8

75

1.513 5/16

61

50/26

65

50

95

498

180

220

65

14

125

95

320

250

14

110

14

378 1.3/8

75

1.513 5/16

77

65/16

50

65

95

498

160

195

65

14

125

95

280

212

14

110

14

378 1.3/8

75

1.513 5/16

61

65/20

40

80/16

100

49

TOTAL NO.

OF PARTS

PUMP MODEL

UNIT 25

UNIT 35

UNIT 45

105

PUMP CASING

30

3 4

9 10

11 12 13 14 15 16 17 18 19

20 21 22 23 24 25 26 27 28 29 30

151

IMPELLER

30

3 4

9 10

11 12 13 14 15 16 17 18 19

20 21 22 23 24 25 26 27 28 29 30

180

SHAFT

190

CASING RING

3 4

3 4

6 4

5 6

1 1

4 4

5 6

6 7

9 10 10 10

3

6

7 9

65

95

498

180

220

65

14

125

95

320

250

14

110

14

378 1.3/8

75

1.513 5/16

68

220

CASING COVER

10

80

120

498

180

220

65

14

125

95

320

250

14

110

14

378 1.3/8

75

1.513 5/16

71

223

GLAND

227

LANTERN RING

240

BEARING

HOUSING

1 1

2 2

3 3

3 3

4 4

251

SUPPORT

FOOT

2 3

4 4

4 4

4 5

8 8

260

BEARING

270

BEARING COVER

310

SHAFT SLEEVE

320

IMPELLER KEY

321

COUPLING KEY

330

IMPELLER NUT

80

65

95

498

200

245

80

16

160

120

360

280

18

110

14

378 1.3/8

75

1.513 5/16

83

100

80

120

498

180

245

65

14

125

95

345

280

14

110

14

378 1.3/8

75

1.513 5/16

78

80/26

100

80

120

498

200

275

80

16

160

120

400

315

18

110

14

378 1.3/8

75

1.513 5/16

101

100/20

125

100

120

498

200

275

80

16

160

120

360

280

18

110

14

378 1.3/8

75

1.513 5/16

95

65/32

80

65

120

530

225

275

80

16

160

120

400

315

18

110

14

379 1.5/8 100

1.79

129

3/8

80/32

100

80

120

530

250

310

80

16

160

120

400

315

18

110

14

379 1.5/8 100

1.79

3/8

100/26

125

100

135

530

225

275

80

16

160

120

400

315

18

110

14

379 1.5/8 100

1.79

3/8

125

100

135

530

250

310

80

16

160

120

400

315

18

110

14

379 1.5/8 100

1.79

3/8

142

125

100

135

530

280

350

100

18

200

150

500

400

23

110

14

379 1.5/8 100

1.79

3/8

180

125/26

150

125

135

530

250

350

80

16

160

120

400

315

18

110

14

379 1.5/8 100

1.79

3/8

140

125/32

150

125

135

530

280

350

100

18

200

150

500

400

23

110

14

379 1.5/8 100

1.79

3/8

161

125/40

150

125

135

530

315

395

100

18

200

150

500

400

23

110

14

379 1.5/8 100

1.79

3/8

195

150/32

200

150

155

530

280

395

100

18

200

150

550

450

23

110

14

379 1.5/8 100

1.79

3/8

190

150/40

200

150

155

530

315

445

100

18

200

150

550

450

23

110

14

379 1.5/8 100

1.79

3/8

212

50

NAME OF

PART

80

80/20

100/40

PART

NO.

100

65/26

100/32

Interchangeability of Components

150/40

30

1/4

125/40

1/4

1.11

100/40

1.11

50

150/32

50

125/32

290

80/32

290

14

100/32

14

100

65/32

100

14

125/26

14

190

80/26

40

240

100/26

190

70

65/26

70

100

80/20

100

14

Typical Drawing

WT.

KG

100/20

14

50

50/26

50

156

u in

40/26

136

132

30

SHAFT END

l

t in

32/26

112

385

d in

65/20

385

75

50/20

75

32

s1

40/20

32

50

e1

32/20

50

32/16

80/16

32/13

40/16

PUMP MOUNTING DIMENSIONS

c

m1

m2

n1

n2

65/16

50/16

h2

40/16

h1

32/16

65/13

50/13

UNIT

NO. SUC. DEL.

40/13

PUMP

MODEL

32/13

Dimensions

All dimensions are in mm unless specified otherwise.

131

140

123

410

LOCK

WASHER

Family Curve of DB/DBHS Pump at

1450 rpm 50Hz

Family Curve of DB/DBHS Pump at

2900 rpm 50Hz

Family Curve of DB/DBHS Pump at

1750 rpm 60Hz

Family Curve of DB/DBHS Pump at

3500 rpm 60Hz

As we are constantly endeavouring to improve the performance of our products/equipment, we reserve the right to make alterations

from time to time and as such our products/equipment may differ from that detailed in this publication. For latest information you may

get in touch with our Regional Sales Offices.

CORPORATE OFFICE :

UDYOG BHAVAN, TILAK ROAD,

PUNE - 411 002 (INDIA)

PHONE : (020) 444 4444

FAX : (020) 4444198, 4440156

Email : kblin@kbl.co.in

Web Site : http://www.kirloskars.com

WORKS : KIRLOSKARVADI 416 308.

DIST. SANGLI

PHONE : (02346) 22301-5 FAX : (02346) 22311

Enquiries may be directed to the nearest Regional Sales Office.

Regional Sales Offices : Ahmedabad, Bangalore, Baroda, Bhubaneswar, Calcutta,

Chennai, Jaipur, Kochi, Lucknow, Mumbai, Nagpur, New Delhi, Pune, Ranchi,

Secunderabad.

DB 092100

KIRLOSKAR BROTHERS LIMITED

PRINTING DIVISION, PUNE 411 038.

KIRLOSKAR

BROTHERS

LIMITED

You might also like

- Definition and Details of FlangesDocument23 pagesDefinition and Details of Flangesvishan2kNo ratings yet

- Chapter-3 Cylinder Heads, Cylinders & LinersDocument18 pagesChapter-3 Cylinder Heads, Cylinders & LinersRam KumarNo ratings yet

- LG LFX31945 Refrigerator Service Manual MFL62188076 - Signature2 Brand DID PDFDocument95 pagesLG LFX31945 Refrigerator Service Manual MFL62188076 - Signature2 Brand DID PDFplasmapete71% (7)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Rsi r2 Super Rsi FaqDocument14 pagesRsi r2 Super Rsi FaqChandrasekar Chandramohan100% (1)

- D W G 1Document1 pageD W G 1Avneet MaanNo ratings yet

- Structural Design Basis ReportDocument31 pagesStructural Design Basis ReportRajaram100% (1)

- 12 Step Worksheet With QuestionsDocument26 pages12 Step Worksheet With QuestionsKristinDaigleNo ratings yet

- Dimensional Engineering Part3Document10 pagesDimensional Engineering Part3Avneet MaanNo ratings yet

- DB Pump CurvesDocument70 pagesDB Pump CurvesMusheer Basha75% (12)

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet

- Governance Operating Model: Structure Oversight Responsibilities Talent and Culture Infrastructu REDocument6 pagesGovernance Operating Model: Structure Oversight Responsibilities Talent and Culture Infrastructu REBob SolísNo ratings yet

- Gaseous Hydrogen Piping SpecificationDocument5 pagesGaseous Hydrogen Piping SpecificationAndri DoemeriNo ratings yet

- HOS (Heavy Oilfield Separable Compressor) BrochureDocument6 pagesHOS (Heavy Oilfield Separable Compressor) BrochureakamalapuriNo ratings yet

- Strategic Management SlidesDocument150 pagesStrategic Management SlidesIqra BilalNo ratings yet

- 06 SCT Extended PDFDocument40 pages06 SCT Extended PDFSlobodan Antic100% (2)

- Control Choke Valve 9000Document8 pagesControl Choke Valve 9000sabi_shi100% (2)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- 5steps To Finding Your Workflow: by Nathan LozeronDocument35 pages5steps To Finding Your Workflow: by Nathan Lozeronrehabbed100% (2)

- Code of Ethics For Civil Engineers PiceDocument3 pagesCode of Ethics For Civil Engineers PiceEdwin Ramos Policarpio100% (3)

- SDS ERSA Rev 0Document156 pagesSDS ERSA Rev 0EdgarVelosoCastroNo ratings yet

- Dimensional Engineering PDFDocument71 pagesDimensional Engineering PDFAvneet MaanNo ratings yet

- MGH PTF CatalogDocument16 pagesMGH PTF CatalogWawanW36No ratings yet

- Milliken AWWA Swing Check ValveDocument8 pagesMilliken AWWA Swing Check ValveDiego Fernando PerdomoNo ratings yet

- Vertical Sump PumpDocument6 pagesVertical Sump Pumpsahildhingra100% (1)

- WKM DynaSeal 370D4 PDFDocument40 pagesWKM DynaSeal 370D4 PDFAlfredo MedinaNo ratings yet

- Goulds Vertical Turbine PumpDocument16 pagesGoulds Vertical Turbine PumpAnanto Veryadesa100% (2)

- Valves Pipe Fittings DimensionsDocument37 pagesValves Pipe Fittings DimensionstsoheilNo ratings yet

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocument8 pagesTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4No ratings yet

- Valves & ControlsDocument16 pagesValves & ControlseborresonNo ratings yet

- SREBRSuperH Plug ValvesDocument39 pagesSREBRSuperH Plug ValvesFAZUL412100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Características Técnicas Bombas Mark IIIDocument60 pagesCaracterísticas Técnicas Bombas Mark IIIBORISINHO2975No ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- CVC Steel Valvulas LunkenheimerDocument28 pagesCVC Steel Valvulas LunkenheimerAlex WilmerNo ratings yet

- Globe ValvesDocument12 pagesGlobe ValvesVivekanandan VaiyapuriNo ratings yet

- Neral Capítulo.9 PDFDocument24 pagesNeral Capítulo.9 PDFtrinoNo ratings yet

- DSM PDFDocument8 pagesDSM PDFSlobodan AnticNo ratings yet

- Needle Cages and Roller Cages: ConstructionDocument12 pagesNeedle Cages and Roller Cages: ConstructionMohan Kumar MathrubaiNo ratings yet

- Parker Series 2A Air CylinderDocument36 pagesParker Series 2A Air Cylindersdey26No ratings yet

- Aggregate Testing - TecnotestDocument16 pagesAggregate Testing - TecnotestKate HayesNo ratings yet

- FSV03Document24 pagesFSV03elangopi89No ratings yet

- 11422Document10 pages11422balajivangaruNo ratings yet

- STP CatalogueDocument37 pagesSTP CataloguemmkattaNo ratings yet

- Iso 9001 CertifiedDocument4 pagesIso 9001 CertifiedLuis R. Salas SotoNo ratings yet

- MOSBrochure PDFDocument6 pagesMOSBrochure PDFabisaNo ratings yet

- rc61180 b09Document9 pagesrc61180 b09eww08No ratings yet

- 175 PSI WWP Iron Body Gate ValvesDocument1 page175 PSI WWP Iron Body Gate ValvestremendousNo ratings yet

- Saint Gobain Sluice ValvesDocument2 pagesSaint Gobain Sluice ValveskibzeamNo ratings yet

- HydrantDocument10 pagesHydrantjdsa123No ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- Butterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetDocument2 pagesButterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetWattsNo ratings yet

- Catalog ParkerDocument230 pagesCatalog Parkeringerash_mic9067% (3)

- New Storage Tanks Design GuidelinesDocument6 pagesNew Storage Tanks Design GuidelinespaaryNo ratings yet

- WWW Flosteer Com Check ValveDocument6 pagesWWW Flosteer Com Check ValveMashudi FikriNo ratings yet

- Aurora 340 DsDocument4 pagesAurora 340 DsdesuyaNo ratings yet

- Aurora PumpsDocument12 pagesAurora PumpsM Alim Ur RahmanNo ratings yet

- Crown-Fusion Brochure Flanged Floaters 2Document14 pagesCrown-Fusion Brochure Flanged Floaters 2claudio godinezNo ratings yet

- Crown-Fusion Brochure Flanged Floaters 2 CompressedDocument14 pagesCrown-Fusion Brochure Flanged Floaters 2 Compressedclaudio godinezNo ratings yet

- Check Valves With Tilting DiscDocument2 pagesCheck Valves With Tilting DiscSamir RawalNo ratings yet

- Gate Valve CataogueDocument4 pagesGate Valve CataogueAditya B. RyantoNo ratings yet

- 31261Document7 pages31261Athirah Amer HamzahNo ratings yet

- SolidEdge Piping Library ST2 Tcm1023-21382Document60 pagesSolidEdge Piping Library ST2 Tcm1023-21382kpm_2486No ratings yet

- Technical Bulletin: Valtek Mark One Control ValvesDocument20 pagesTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzNo ratings yet

- Ball Valves - Metal SeatedDocument6 pagesBall Valves - Metal Seatedmetasoniko2014No ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- Asco S V7394R5Document16 pagesAsco S V7394R5Jorge Jarpa VNo ratings yet

- Phased Out Products: Gear Pumps and Motors General ProductsDocument18 pagesPhased Out Products: Gear Pumps and Motors General ProductsAndrei VladNo ratings yet

- Properties of Material2Document1 pageProperties of Material2Avneet MaanNo ratings yet

- MPDocument1 pageMPAvneet MaanNo ratings yet

- Datum QuizDocument1 pageDatum QuizAvneet MaanNo ratings yet

- Manuf ProcDocument1 pageManuf ProcAvneet MaanNo ratings yet

- BDocument1 pageBAvneet MaanNo ratings yet

- Properties of Material1Document1 pageProperties of Material1Avneet MaanNo ratings yet

- Properties of Material3Document1 pageProperties of Material3Avneet MaanNo ratings yet

- Datum FsDocument1 pageDatum FsAvneet MaanNo ratings yet

- Definition FSCDocument1 pageDefinition FSCAvneet MaanNo ratings yet

- Dimensional Engineering Part2Document10 pagesDimensional Engineering Part2Avneet MaanNo ratings yet

- Datum Reference Frame: Tertiary Datum Plane Secondary Datum PlaneDocument1 pageDatum Reference Frame: Tertiary Datum Plane Secondary Datum PlaneAvneet MaanNo ratings yet

- Six Degree of FreedomDocument1 pageSix Degree of FreedomAvneet MaanNo ratings yet

- Netzsch Pump 12KDocument1 pageNetzsch Pump 12KAvneet MaanNo ratings yet

- Dimensional Engineering Part1Document10 pagesDimensional Engineering Part1Avneet MaanNo ratings yet

- MTechDesignEngineering Jan2017Document2 pagesMTechDesignEngineering Jan2017Avneet MaanNo ratings yet

- BlenderDocument1 pageBlenderAvneet MaanNo ratings yet

- Mahindra Truxo 25Document1 pageMahindra Truxo 25Avneet MaanNo ratings yet

- MTechDesignEngineering Jan2017Document2 pagesMTechDesignEngineering Jan2017Avneet MaanNo ratings yet

- CBD 2516Document1 pageCBD 2516Avneet MaanNo ratings yet

- A AaaaaaaaaaaaaaaaaaaaaaaaDocument1 pageA AaaaaaaaaaaaaaaaaaaaaaaaAvneet MaanNo ratings yet

- Good Knowledge of Powertrain Development Process and SystemsDocument1 pageGood Knowledge of Powertrain Development Process and SystemsAvneet MaanNo ratings yet

- What Is BIW - 11111111111111Document1 pageWhat Is BIW - 11111111111111Avneet MaanNo ratings yet

- What Is BIW - PDFDocument2 pagesWhat Is BIW - PDFAvneet MaanNo ratings yet

- A0Y2U4 - Attachment 99999999999999Document1 pageA0Y2U4 - Attachment 99999999999999Avneet MaanNo ratings yet

- A0Y2U4 - Attachment 99999Document1 pageA0Y2U4 - Attachment 99999Avneet MaanNo ratings yet

- What Is BIW - PDFDocument2 pagesWhat Is BIW - PDFAvneet MaanNo ratings yet

- A0Y2U4 - Attachment 99Document1 pageA0Y2U4 - Attachment 99Avneet MaanNo ratings yet

- بتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Document5 pagesبتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Batool MagedNo ratings yet

- Object Oriented ParadigmDocument2 pagesObject Oriented ParadigmDickson JohnNo ratings yet

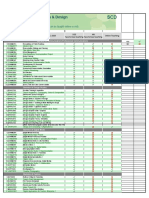

- SCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Document2 pagesSCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Nguyễn Hồng AnhNo ratings yet

- Regulasi KampenDocument81 pagesRegulasi KampenIrWaN Dompu100% (2)

- Spectroscopic Methods For Determination of DexketoprofenDocument8 pagesSpectroscopic Methods For Determination of DexketoprofenManuel VanegasNo ratings yet

- Technical Sheet Racloflex NTDocument2 pagesTechnical Sheet Racloflex NTAnthony AngNo ratings yet

- Accessoryd-2020-07-31-185359.ips 2Document20 pagesAccessoryd-2020-07-31-185359.ips 2Richard GarciaNo ratings yet

- Section 1 Company Overview StandardsDocument34 pagesSection 1 Company Overview StandardsChris MedeirosNo ratings yet

- Transfert de Chaleur AngDocument10 pagesTransfert de Chaleur Angsouhir gritliNo ratings yet

- Ethernet/Ip Parallel Redundancy Protocol: Application TechniqueDocument50 pagesEthernet/Ip Parallel Redundancy Protocol: Application Techniquegnazareth_No ratings yet

- Sony x300 ManualDocument8 pagesSony x300 ManualMarcosCanforaNo ratings yet

- Hard DiskDocument9 pagesHard DiskAmarnath SahNo ratings yet

- 'Causative' English Quiz & Worksheet UsingEnglish ComDocument2 pages'Causative' English Quiz & Worksheet UsingEnglish ComINAWATI BINTI AMING MoeNo ratings yet

- A Short Survey On Memory Based RLDocument18 pagesA Short Survey On Memory Based RLcnt dvsNo ratings yet

- Blackberry: Terms of Use Find Out MoreDocument21 pagesBlackberry: Terms of Use Find Out MoreSonu SarswatNo ratings yet

- Job Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeDocument16 pagesJob Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeNaveen KumarNo ratings yet

- Sheet-Metal Forming Processes: Group 9 PresentationDocument90 pagesSheet-Metal Forming Processes: Group 9 PresentationjssrikantamurthyNo ratings yet

- Puma PypDocument20 pagesPuma PypPrashanshaBahetiNo ratings yet

- Tomb of Archimedes (Sources)Document3 pagesTomb of Archimedes (Sources)Petro VourisNo ratings yet

- TM Mic Opmaint EngDocument186 pagesTM Mic Opmaint Engkisedi2001100% (2)

- Static Electrification: Standard Test Method ForDocument10 pagesStatic Electrification: Standard Test Method Forastewayb_964354182No ratings yet