Professional Documents

Culture Documents

Concrete Pavement Design Details and Construction Practices Companion Workbook

Uploaded by

robert_salas_14Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Pavement Design Details and Construction Practices Companion Workbook

Uploaded by

robert_salas_14Copyright:

Available Formats

Concrete Pavement Design Details

and Construction Practices

Companion Workbook

1986/1993 AASHTO Guide Procedure

1998 AASHTO Supplement Procedure

Prepared for

Federal Highway Administration, Pavements Division

400 Seventh Street SW, Washington, DC 20590

and

National Highway Institute

4600 North Fairfax Drive, Suite 700, Arlington, VA 22203

Prepared by

Kathleen T. Hall

73 Bedford Road, Mundelein, IL 60060

and

Kurt D. Smith, Applied Pavement Technology, Inc.

3001 Research Road, Suite C, Champaign, IL 61822

If you have comments or questions about this workbook, please contact:

Katie Hall

kthall@wwa.com

847-549-8410

or

Kurt Smith

kurtsmith@aol.com

217-398-3977

Contents of this Workbook

Worksheet

Description

cover

cover page and table of contents

roadmap

roadmap to worksheets in this companion workbook

k correlation

k value correlations to soil type and properties

k backcalc

k value backcalculation equations

98 k steps

description of steps in determining design k value for 1998 AASHTO method

98 fill-rigid

adjustment to k value for embankment and/or shallow rigid layer for 1998 AASHTO method

98 seasonal k

calculation of seasonally adjusted design k value for 1998 AASHTO method

98 AASHTO

concrete slab thickness design by 1998 AASHTO method

98 fault chk

faulting check for undoweled and doweled pavements for 1998 AASHTO method

climate

climatic data for major US cities

86 seasonal k

calculation of seasonally adjusted design k value for 1986/1993 AASHTO method

86 AASHTO

concrete slab thickness design by 1986/1993 AASHTO method

cover

Roadmap for this Companion Workbook

Design by 1986/1993

AASHTO Guide Method

Design by 1998 AASHTO

Supplement Method

98 k steps

98 fill-rigid

k correlation

86 seasonal k

98 seasonal k

k backcalc

86 AASHTO

98 AASHTO

climate

98 fault chk

roadmap

Correlations Between K Value, Soil Type, Soil Properties, and Degree of Saturation

AASHTO

Class

Description

A-2-5, gravelly

A-2-4, sandy

silty sand

A-2-5, sandy

silty gravelly sand

A-2-6, gravelly

clayey gravel

A-2-7, gravelly

clayey sandy gravel

A-2-6, sandy

clayey sand

A-2-7, sandy

clayey gravelly sand

80

60

40

25

300

300

200

150

450

400

400

300

300 500

SM

120 135

20 40

300 400

GC

120 140

20 40

200 450

SC

105 130

10 20

150 350

Fine-Grained Soils (See Note):

90 105

ML, OL

silt/sand/gravel mix

100 125

silt

48

25 165

5 15

40 220

poorly graded silt

MH

80 - 100

48

25 190

A-6

plastic clay

CL

100 125

5 15

25 255

CL, OL

90 125

4 15

25 215

CH, OH

80 110

35

40 - 220

moderately plastic

elastic clay

highly plastic

A-7-6

Subgrade k v alue (psi/in)

60

35

20

15

k value

(psi/in)

A-5

A-7-5

200

CBR

(percent)

A-2 Soils (Granular Materials with High Fines):

silty gravel

GM

130 145

40 80

silty sandy gravel

A-2-4, gravelly

250

Dry Density

(lb/cu ft)

Coarse-Grained Soils

125 140

gravel

GW, GP

120 130

coarse sand

SW

110 130

fine sand

SP

105 120

A-1-a, well graded

A-1-a, poorly graded

A-1-b

A-3

A-4

Unified

Class

elastic clay

The recommended k value ranges apply to a homogeneous layer at least 10 ft thick. If an embankment layer less than 10 ft thick exists over a

softer subgrade, the k value of the underlying soil should be estimated from A-6

the above table and adjusted for the type and thickness of

embankment material (see fill-rigid worksheet). The k value should also be adjusted if a stiff layer (e.g., bedrock) exists within 10 ft of the top

A-7-6

of the soil (see fill-rigid worksheet).

A-7-5

The k value of fine-grained soil is highly dependent on the degree of saturation. See chart below.

A-5

A-4

150

100

50

50

60

70

80

90

Degree of saturation (percent)

k correlation

100

Backcalculation of k Value from Deflections

Equations are provided below for backcalulating the dynamic k value, including correction for finite slab size,

from deflections measured with a falling weight deflectometer or similar device, using the SHRP sensor configuration.

In the calculations below, the backcalculated dynamic k value is divided by 2 to obtain an estimated static k value

for use in the AASHTO design procedures.

For the purpose of backcalculating k value, it is not necessary to normalize the deflections to a particular load level,

nor is it necessary to know the layer thicknesses, nor to make any adjustments to the deflections for temperature.

However, deflections measured when the slab is curled out of contact with the base or foundation

should not be used to backcalculate k values without adjustment.

Enter the slab length (joint spacing) and slab width in feet below for use in the slab size correction.

Slab length

Slab width

15

12

ft

ft

Calculated L

13.42

ft

Bare Concrete Pavement

station

k static

psi/in

load P

pounds

d0

mils

d8

mils

d12

mils

d18

mils

d24

mils

d36

mils

d60

mils

AREA7

in

l init

in

d0*

k init

psi/in

AF d0

AF l

k adj

psi/in

k static

psi/in

106

8990

4.18

3.98

3.84

3.61

3.36

2.88

2.05

45.0

40.71

0.1237

160

0.868

0.934

212

106

Composite Pavement

station

k static

psi/in

load P

pounds

d12

mils

d18

mils

d24

mils

d36

mils

d60

mils

AREA5

in

l init

in

d12*

k init

psi/in

AF d0

AF l

k adj

psi/in

k static

psi/in

98

9025

3.49

3.32

3.13

2.73

2.02

37.8

48.83

0.1189

129

0.823

0.896

195

98

k backcalc

Steps in Determining k Value for Use in 1998 AASHTO Supplement Procedure

Correlation method

Estimate k for one or more seasons from

correlations with soil type, density, CBR, and

degree of saturation.

Backcalculation method

or

See k correlation worksheet.

Backcalculate dynamic k from deflections

measured on in-service pavement. Divide the

mean backcalculated k by 2 to estimate the

static k.

See k backcalc worksheet.

Fill/rigid layer adjustments

for correlation method

Correlations of k to soil type and properties

apply to a homogeneous soil layer at least 10 ft

[3 m] thick. If an embankment layer less than

10 ft [3 m] thick exists or will be placed over a

softer soil, the k value of the underlying soil

should be estimated from the available

correlations and adjusted for the type and

thickness of embankment.

If a stiff layer (e.g., bedrock) exists within 10 ft

[3 m] of the top of the soil, the k value should

be adjusted.

See 98 fill-rigid worksheet.

Fill/rigid layer adjustments

for backcalculation method

No fill or rigid layer adjustments are needed if

the type and depth of fill and the depth to a

rigid layer are the same for the pavement

being designed and the pavement on which

the deflections were measured.

A fill adjustment and/or a rigid layer adjustment

is needed if the fill and rigid layer

characteristics of the pavement being designed

differ from those of the pavement tested.

See 98 fill-rigid worksheet.

Plate load test method

or

Measure k according to AASHTO T221 or T222,

using a 30-in-diameter plate. In the repetitive

test (T221), k is the ratio of load to elastic

(recoverable) deformation. In the nonrepetitive

test (T222) k is the load-deformation ratio at a

deformation of 0.05 in.

Fill/rigid layer adjustments

for plate load testing method

AASHTO T 221 and T 222 specify that if the

pavement is to be built on an embankment, the

plate bearing tests should be conducted on a

test embankment.

If the testing is not conducted on a test

embankment equal in material and thickness to

the embankment which wll be constructed, a fill

adjustment is needed. See 98 fill-rigid

worksheet.

The effect of a rigid layer is reflected in the plate

load test results; no adjustment is needed.

Assign k to seasons of the year

Among the factors which should be considered in assigning seasonal k values are the seasonal movement of the

water table, seasonal precipitation levels, winter frost depths, number of freeze-thaw cycles, and the extent of

frost protection provided by embankment material.

A ''frozen" k may not be appropriate for winter, even in a cold climate, if the frost will not remain in a significant

thickness (a few feet) of the subgrade throughout the winter. A k value of 500 psi/in is reasonable for a subgrade

frozen to a significant depth.

The seasonal variation in degree of saturation is difficult to predict, but in locations where a water table is

constantly present at a depth of less than about 10 ft, it is reasonable to expect that fine-grained subgrades will

remain at least 70 to 90 percent saturation, and may be completely saturated for substantial periods in the

spring. The highest position of the water table, but not its annual variation, can be determined from county soil

reports.

See 98 seasonal k worksheet.

Calculate seasonally adjusted k value for use in design

The seasonally adjusted design k value is a damage-weighted average k which yields the same predicted

performance over the course of a year as the k values assigned to the different seasons.

See 98 seasonal k worksheet.

98 k steps

Density of fill (lb/cu ft)

Thickness of fill (ft)

12

90 100 110 120

130

140

150

10

8

6

4

2

psi/in

600

400

200

200

600

400

psi/in

Adjusted k value

200

Enter with k for

natural subgrade

< 10 ft

Depth to

rigid layer

400

> 10 ft

psi/in

98 fill-rigid

1 ft = 0.305 m,

1 psi/in = 0.27 kPa/mm,

1 lb/cu ft = 159 N/cu m

Seasonally Adjusted Design K Value for 1998 AASHTO Supplement Procedure

Enter the number of months for each season, so that total number of months is twelve.

Enter a k value for each season.

Press the "solve for seasonally adjusted k value" button.

Use this seasonally adjusted design k value in the 98 AASHTO thickness design worksheet.

Season

spring

summer

fall

winter

Months

k value

W'

(psi/in)

(millions)

3

50

6.90

3

125

4.81

3

125

4.81

3

250

3.33

Weighted Mean Relative Damage

Weighted Mean W' (millions)

Seasonally adjusted effective k value (psi/in)

log Relative

Damage

0.1450

0.2078

0.2078

0.3000

0.2151

4.648

135

For the purpose of calculating the seasonally adjusted design k value, a trial slab thickness is calculated using

the inputs from the 98 AASHTO worksheet and the arithmetic average of the seasonal k values above.

parameter

slab thickness

arithmetic average k value

symbol

value

units

D

kave

11.80

138

in

psi/in

The values for the following parameters are taken from the 98 AASHTO worksheet.

W18

estimated future ESALs

design reliability

overall standard deviation

mean 28-day concrete elastic modulus

mean 28-day concrete flexural strength

concrete Poisson's ratio

base elastic modulus

base thickness

slab/base friction coefficient

design k value

initial serviceability

terminal serviceability

joint spacing

edge support adjustment factor

mean annual temperature

mean annual precipitation

mean annual wind speed

R

So

Ec

S'c

Eb

Hb

f

k

P1

P2

E

temp

precip

wind

49,988,514

90

0.35

4,200,000

600

0.15

25,000

12

1.5

135

4.3

2.5

20

1.00

67.5

55.8

7.7

%

psi

psi

psi

in

psi/in

ft

deg F

in

mph

Values for the following parameters are calculated from the trial thickness and above inputs.

standard normal deviate

effective positive temperature differential

slab length in inches

ratio of stress with friction to stress with bond

radius of relative stiffness

log of slope of TD effect on stress

stress due to load

total stress due to load and temperature

ZR

TD

L

F

l

log b

sigma l

sigma t

-1.282

11.12

240

1.04

45.73

-1.254

123.70

208.96

deg F

in

in

psi

psi

Values for the following parameters are calculated for the trial thickness and AASHO Road Test constants.

effective positive temperature differential

ratio of stress with friction to stress with bond

radius of relative stiffness

log of slope of TD effect on stress

stress due to load

total stress due to load and temperature

TD

F

l

log b

sigma l

sigma t

9.37

1.04

48.31

-1.428

132.79

187.04

deg F

in

psi

psi

Values for the following parameters are calculated to determine the trial thickness for the design ESALs.

allowable log ESALs for 50% reliability, new design

allowable log W for 50% reliability, AASHO Road Test

log rho term

serviceability loss term

beta term

allowable ESALs for design reliability, new design

expected ESALs for design reliability, new design

ratio of expected to allowable ESALs

log W'

log W

log R

G

B

W'

W18R

7.37

7.89

8.08

-0.19

1.01

8,357,394

49,988,514

5.98

Values for the following parameters are calculated during the seasonally adjusted effective k value calculation.

allowable ESALs for design reliability, new design

weighted mean W'

ratio weighted mean W' to allowable ESALs

98 seasonal k

8.36 millions

4.65 millions

0.556

G16:

This value will be updated amd copied to the 98 AASHTO worksheet whenever you click the recalculate seasonally adjusted effective k value button on that worksheet.

G38:

Fine-grained soils

Sand

Aggregate

Lime-stabilized clay

Asphalt-treated base

Cement-treated base

Lean concrete base

G40:

Fine-grained soil

0.5 to 2.0

Sand

0.5 to 1.0

Aggregate

0.7 to 2.0

Polyethlyene

0.5 to 1.0

Lime-stabilized clay

3.0 to 5.3

Cement-treated base

8 to 63

Asphalt-treated base

3.7 to 10

Lean concrete base

without curing compound

> 36

with curing compound

3.5 to 4.5

G45:

1.00 for 12-ft lane and AC shoulder

0.94 for 12-ft lane and tied PCC shoulder

0.92 for widened PCC slab

3,000 to 40,000 psi

10,000 to 25,000 psi

15,000 to 45,000 psi

20,000 to 70,000 psi

300,000 to 600,000 psi

1000 * (500 + compressive strength, psi)

1000 * (500 + compressive strength, psi)

Comments

1998 AASHTO Supplement Procedure for Concrete Pavement Thickness Design

Whenever you change input values below, first click the button "recalculate seasonally adjusted effective k value"

before solving for the required slab thickness or allowable ESALs.

Enter values for the following parameters in the 1998 AASHTO concrete pavement performance model.

parameter

symbol

slab thickness

estimated future ESALs

design reliability

overall standard deviation

mean 28-day concrete elastic modulus

mean 28-day concrete flexural strength

concrete Poisson's ratio

base elastic modulus

base thickness

slab/base friction coefficient

k value

initial serviceability

terminal serviceability

joint spacing

edge support adjustment factor

mean annual temperature

mean annual precipitation

mean annual wind speed

D

W18

R

So

Ec

S'c

Eb

Hb

f

k

P1

P2

L

E

temp

precip

wind

value units

15.37

49,988,514

90

0.35

4,200,000

600

0.15

25,000

12

1.5

135

4.3

2.5

20

1.00

67.5

55.8

7.7

in

ESALs

%

psi

psi

psi

in

psi/in

ft

deg F

in

mph

Values for the following parameters are calculated from the above inputs.

ZR

standard normal deviate

effective positive temperature differential

slab length in inches

ratio of stress with friction to stress with bond

radius of relative stiffness

log of slope of TD effect on stress

stress due to load

total stress due to load and temperature

TD

L

F

l

log b

sigma l

sigma t

-1.282

12.15 deg F

240

in

1.00

55.74

in

-1.273

82.21 psi

135.21

psi

ok

ok

ok

ok

ok

ok

ok

ok

Values for the following parameters are calculated for AASHO Road Test constants.

effective positive temperature differential

ratio of stress with friction to stress with bond

radius of relative stiffness

log of slope of TD effect on stress

stress due to load

total stress due to load and temperature

TD

F

l

log b

sigma l

sigma t

10.46 deg F

1.00

58.89

in

-1.438

87.47 psi

120.64

psi

ok

ok

ok

ok now (had 68 instead of 6)

ok

ok

Values for the following parameters are calculated to determine the required slab thickness for the design ESALs.

allowable log ESALs for 50% reliability, new design

allowable log W for 50% reliability, AASHO Road Test

log rho term

serviceability loss term

beta term

allowable ESALs for design reliability, new design

expected ESALs for design reliability, new design

ratio of expected to allowable ESALs

98 AASHTO

log W'

log W

log R

G

B

W'

W18R

8.15

8.67

8.86

-0.19

1.00

49,988,514

49,988,514

1.00

ok

ok

ok

ok

ok

ok

ok

ok

Joint Faulting Check for 1998 AASHTO Supplement Procedure

Predicted faulting

doweled

0.07 in

undoweled

Enter values for the following parameters to calculate faulting for doweled or undoweled joints.

parameter

dowel diameter

cumulative ESALs

age

modified drainage coefficient

friction adjustment factor

annual temperature range

Freezing Index

base type

widened slab

days above 90 deg F

symbol

dowel

cesal

age

Cd

con

trange

FI

basetype

widen

days90

value

units

1.25

in

40 millions

20

years

1.00

0.80

85

deg F

200 F deg-days

0

0

30

The values below are calculated or taken from the 98 AASHTO worksheet.

joint spacing

distribution factor

moment of inertia dowel x-section

relative stiffness dowel-concrete

average joint opening

concrete bearing stress

annual precipitation

jtspace

fd

I

beta

opening

bstress

precip

98 fault chk

20

0.35

0.1198

0.6060

0.049

1412

55.80

ft

in

in4

in

psi

in

0.11 in

12

494

50

55

56

46

44

7

8

448

380

0

0

68

68

68

65

56

53

60

44

8

9

8

9

12

7

10

37

74

48

30

75

39

37

11

2224

45

44

966

55

42

306

101

0

MASSACHUSETTS

Boston

52

44

12

0

0

0

63

0

0

Worcester

MICHIGAN

Detroit

48

12

49

47

48

29

34

15

15

10

9

588

544

0

0

38

45

50

44

690

58

39

200

54

41

371

68

68

65

49

9

7

16

27

61

52

35

26

15

10

7

6

2385

5601

0

0

King Salmon

ARIZONA

Flagstaff

Phoenix

33

19

11

2898

45

71

21

7

7

6

585

0

0

157

Tucson

ARKANSAS

68

11

133

Little Rock

CALIFORNIA

Bakersfield

62

49

102

64

66

98

Fresno

Los Angeles

63

63

11

12

6

8

0

0

Sacramento

San Diego

San Francisco

61

64

57

17

9

20

8

7

11

Santa Barbara

COLORADO

59

16

Colorado Springs

Denver

CONNECTICUT

Hartford

49

50

Wichita

KENTUCKY

Lexington

Louisville

LOUISIANA

Baton Rouge

Lake Charles

New Orleans

Shreveport

MAINE

Caribou

Portland

MARYLAND

Baltimore

Flint

Grand Rapids

MINNESOTA

Duluth

Minneapolis

MISSISSIPPI

Jackson

MISSOURI

Kansas City

MONTANA

Great Falls

Mean Annual Days 90F

and Above

40

Mobile

Montgomery

ALASKA

Anchorage

Fairbanks

KANSAS

Topeka

Freezing Index, degreedays below 32F

56

Mean Annual Wind

Speed, mi/h

74

Mean Annual

Precipitation, in

673

Location

Mean Annual

Temperature, F

10

52

Wilmington

FLORIDA

Mean Annual Days 90F

and Above

Mean Annual Wind

Speed, mi/h

29

62

DC

Washington

DELAWARE

Freezing Index, degreedays below 32F

Mean Annual

Precipitation, in

Mean Annual Days 90F

and Above

Freezing Index, degreedays below 32F

54

Mean Annual

Precipitation, in

Mean Annual

Temperature, F

ALABAMA

Birmingham

Mean Annual

Temperature, F

Location

Mean Annual Wind

Speed, mph

Climatic Data for Use With 1998 AASHTO Supplement Thickness and Faulting Models

60

31

13

195

59

60

39

10

231

60

54

53

52

20

37

40

5

8

7

61

45

41

31

0

0

PENNSYLVANIA

Harrisburg

Philadelphia

Pittsburgh

53

54

50

39

41

36

8

10

9

454

376

686

0

0

0

RHODE ISLAND

Providence

Location

OKLAHOMA

Oklahoma City

Tulsa

OREGON

Medford

Portland

Salem

50

45

11

513

SOUTH CAROLINA

Charleston

65

Columbia

63

52

49

9

7

19

54

6

46

446

SOUTH DAKOTA

Huron

45

19

12

1840

860

47

16

11

1232

10

857

59

53

140

11

10

1015

996

0

0

Knoxville

Memphis

59

62

47

52

7

9

184

105

0

61

48

213

11

11

2472

1848

0

0

Nashville

TEXAS

Amarillo

Brownsville

59

30

26

57

74

19

25

14

12

200

0

41

97

65

53

52

82

56

35

11

724

Corpus Christi

Dallas

El Paso

72

66

63

30

29

8

12

11

9

0

40

0

87

89

98

45

15

13

1513

Galveston

Houston

70

68

40

45

11

8

0

0

0

76

47

Rapid City

TENNESSEE

Chattanooga

Jacksonville

Miami

Orlando

68

76

72

53

58

48

8

9

9

9

0

0

56

0

85

NEBRASKA

Omaha

NEVADA

50

30

11

1042

Lubbock

Midland

San Antonio

60

64

69

18

14

29

12

11

9

76

22

5

56

93

95

Tallahassee

Tampa

67

72

65

47

6

9

11

0

82

12

Las Vegas

Reno

66

49

4

7

9

7

0

258

127

39

Waco

Wichita Falls

67

64

31

27

11

12

27

91

96

85

West Palm Beach

GEORGIA

Atlanta

Augusta

75

60

53

42

10

374

52

15

519

38

61

63

49

43

9

7

81

40

0

52

56

122

53

UTAH

Salt Lake City

VERMONT

Burlington

44

34

1464

Macon

Savannah

HAWAII

Hilo

Honolulu

65

66

45

50

8

8

27

14

69

38

74

77

128

23

7

12

0

0

0

0

VIRGINIA

Norfolk

Richmond

Roanoke

WASHINGTON

60

58

56

45

44

39

11

8

8

111

175

227

0

0

0

51

47

12

11

9

10

576

958

23

0

Olympia

Seattle

Spokane

WEST VIRGINIA

Charleston

50

53

47

51

39

17

7

9

9

72

31

686

0

0

0

55

42

377

Huntington

WISCONSIN

Green Bay

Madison

Milwaukee

55

41

369

44

45

46

28

31

31

10

10

12

1630

1461

1202

0

0

0

45

46

11

13

13

13

1128

834

0

0

IDAHO

Boise

Pocatello

ILLINOIS

Chicago

49

33

10

1017

Peoria

Springfield

INDIANA

Evansville

Fort Wayne

50

53

35

34

10

11

988

828

0

0

56

50

42

34

8

10

483

910

0

0

Indianapolis

South Bend

IOWA

Des Moines

Sioux City

52

49

39

38

10

10

727

878

0

0

50

48

31

25

11

11

1202

1366

0

0

46

33

11

1602

Waterloo

NEW JERSEY

Atlantic City

NEW MEXICO

Albuquerque

NEW YORK

Albany

Buffalo

New York City

Rochester

47

48

55

48

36

38

44

31

9

12

12

10

1004

860

321

852

0

0

0

0

Syracuse

NORTH CAROLINA

Charlotte

Greensboro

Raleigh

48

39

10

922

60

58

59

43

42

42

8

8

8

78

137

104

0

0

0

Wilmington

NORTH DAKOTA

Bismarck

Fargo

OHIO

63

53

41

41

41

15

20

10

12

2319

2598

0

0

50

50

52

52

48

36

35

37

35

37

10

11

9

10

10

757

768

678

690

861

0

0

0

0

0

Akron-Canton

Cleveland

Columbus

Dayton

Youngstown

climate

WYOMING

Casper

Cheyenne

Seasonally Adjusted Design K Value for 1986/1993 AASHTO Guide Procedure

Enter the number of months for each season, so that total number of months is twelve.

Enter a k value for each season.

Press the "solve for seasonally adjusted k value" button.

Use this seasonally adjusted design k value in the 86 AASHTO thickness design worksheet.

Season

Months

k value

W'

log Relative

spring

(psi/in)

50

(millions)

43.69

Damage

0.0229

summer

fall

winter

3

3

3

150

150

200

51.05

51.05

53.56

0.0196

0.0196

0.0187

Weighted Mean Relative Damage

Weighted Mean W' (millions)

0.0202

49.545

Seasonally adjusted effective k value (psi/in)

124

For the purpose of calculating the seasonally adjusted design k value, a trial slab thickness is calculated using

the inputs from the 86 AASHTO worksheet and the arithmetic average of the seasonal k values above.

parameter

slab thickness

arithmetic average k value

symbol

value

units

D

kave

14.82

138

in

psi/in

The values for the following parameters are taken from the 86 AASHTO worksheet.

W18

estimated future ESALs

design reliability

overall standard deviation

mean 28-day concrete elastic modulus

mean 28-day concrete flexural strength

base elastic modulus

base thickness

Depth to rigid foundation

design k value

initial serviceability

terminal serviceability

drainage coefficient

load transfer coefficient

R

So

Ec

S'c

Eb

Hb

Hrig

k

P1

P2

Cd

J

3,716,407

97

0.37

4,200,000

600

25,000

8

20

124

4.3

2.5

1.00

3.2

%

psi

psi

psi

in

ft

psi/in

Values for the following parameters are calculated from the trial thickness and above inputs.

ZR

kinf

kfin

standard normal deviate

composite k value for semi-infinite foundation

composite k value for finite depth to rigid layer

allowable log ESALs for design reliability

allowable ESALs for design reliability

expected ESALs

ratio of expected to allowable ESALs

log W'

W'

W18

-1.881

169

145

7.70

49,552,485

3,716,407

0.07

psi/in

psi/in

Values for the following parameters are calculated during the seasonally adjusted effective k value calculation.

allowable ESALs for design reliability, new design

weighted mean W'

ratio weighted mean W' to allowable ESALs

86 seasonal k

49.55 millions

49.54 millions

1.000

1986 AASHTO Guide Procedure for Concrete Pavement Thickness Design

Whenever you change input values below, first click the button "recalculate seasonally adjusted effective k value"

before solving for the required slab thickness or allowable ESALs.

Enter values for the following parameters in the 1986/1993 AASHTO concrete pavement performance model.

parameter

symbol

slab thickness

estimated future ESALs

design reliability

overall standard deviation

mean 28-day concrete elastic modulus

mean 28-day concrete flexural strength

base elastic modulus

base thickness

depth to rigid foundation

roadbed soil k value

initial serviceability

terminal serviceability

drainage coefficient

load transfer coefficient

D

W18

R

So

Ec

S'c

Eb

Hb

Hrig

k

P1

P2

Cd

J

value units

10.00

in

3,716,407

97

%

0.37

4,200,000

psi

600

psi

25,000

psi

8

in

20

ft

124 psi/in

4.3

2.5

1.00

3.2

Values for the following parameters are calculated to determine the required slab thickness for the design ESALs.

ZR

kinf

kfin

standard normal deviate

composite k value for semi-infinite foundation

composite k value for finite depth to rigid layer

allowable log ESALs for design reliability

allowable ESALs for design reliability

expected ESALs

ratio of expected to allowable ESALs

log W'

W'

W18

86 AASHTO

-1.881

169 psi/in

145 psi/in

6.57

3,716,407

3,716,407

1.00

You might also like

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- EsalcalcDocument28 pagesEsalcalcRaul Zapana ZelaNo ratings yet

- Kopya NG PAES613-DesignofaDiversionDam PDFDocument57 pagesKopya NG PAES613-DesignofaDiversionDam PDFJohn Paulo PeridoNo ratings yet

- CompactionDocument100 pagesCompactionVaibhav PatilNo ratings yet

- Properties of Vertical CurvesDocument9 pagesProperties of Vertical CurvesJayanth MysoreNo ratings yet

- Typical Unit Weights and Densities of SoilDocument7 pagesTypical Unit Weights and Densities of SoilkayshephNo ratings yet

- Flexible Pavement Design IRC37 2001 1Document5 pagesFlexible Pavement Design IRC37 2001 1Chatnoir NoirNo ratings yet

- CBR Test ManualDocument6 pagesCBR Test ManualmmNo ratings yet

- Paper For Bearing Capacity PDFDocument4 pagesPaper For Bearing Capacity PDFernestnsabimana74No ratings yet

- Mehran Naghizadehrokni, RWTHDocument112 pagesMehran Naghizadehrokni, RWTHNaghizadehrokniNo ratings yet

- Axle Load Spectrum - Jhurai-SaraiDocument18 pagesAxle Load Spectrum - Jhurai-Sarairajiv kumarNo ratings yet

- Example of Stress Absorbing Membrane InterlayerDocument7 pagesExample of Stress Absorbing Membrane Interlayershanil3001No ratings yet

- DCS Addl Soil Investigation Type II RatnagiriDocument14 pagesDCS Addl Soil Investigation Type II RatnagiriSoigne ConsultantsNo ratings yet

- Bearing N Settlement 3Document13 pagesBearing N Settlement 3U4rayNo ratings yet

- Efficiency of Pile Groups in Clay Under Different Loading RatesDocument6 pagesEfficiency of Pile Groups in Clay Under Different Loading RatessenhuNo ratings yet

- Repair of Rip-Rap (Beltran Comp)Document1 pageRepair of Rip-Rap (Beltran Comp)Edison G. CaluzaNo ratings yet

- DCTP ReportDocument10 pagesDCTP ReportAtubrah PrinceNo ratings yet

- Borehole LogDocument5 pagesBorehole LogMark Iliw-Iliw RelingadoNo ratings yet

- Proyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Document4 pagesProyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Ikhromul Khoirul AqshomNo ratings yet

- Shearbox - Gabgapa Project (E)Document55 pagesShearbox - Gabgapa Project (E)abdallah abdurhman aliNo ratings yet

- Final Report 00 - 1187-Rev00Document31 pagesFinal Report 00 - 1187-Rev00wafikmh4No ratings yet

- Gradation of Filter Material: (Waduk Telagawaja)Document7 pagesGradation of Filter Material: (Waduk Telagawaja)Ady Darwiyasa Manson BatNo ratings yet

- Design PCCP Thickness Computation Protected FileDocument1 pageDesign PCCP Thickness Computation Protected FileCent TorresNo ratings yet

- Republik Indonesia: Departemant Pekerjaan Umum Direktorat Jenderal Bina MargaDocument12 pagesRepublik Indonesia: Departemant Pekerjaan Umum Direktorat Jenderal Bina MargaSetiawanNo ratings yet

- Concrete CalculationDocument10 pagesConcrete CalculationkwameNo ratings yet

- Design of Shallow FootingDocument3 pagesDesign of Shallow FootingShoyeeb AhmedNo ratings yet

- Test Report On The California Bearing Ratio AASHTO T 193 - 99Document1 pageTest Report On The California Bearing Ratio AASHTO T 193 - 99Dominto MicoNo ratings yet

- Soil Embankment Settlement 3d AnalysisDocument15 pagesSoil Embankment Settlement 3d AnalysisSajid IqbalNo ratings yet

- Table of Pavement Design ValuesDocument12 pagesTable of Pavement Design ValuesCity AspireNo ratings yet

- consolidationشارع النيلDocument2 pagesconsolidationشارع النيلabdallah abdurhman aliNo ratings yet

- Hydrology Assignment 1Document7 pagesHydrology Assignment 1sunsleyndhlakama100% (1)

- Dynamic Probing Devices ComparisonDocument1 pageDynamic Probing Devices ComparisonDr Wong Kim YuenNo ratings yet

- Liquefaction AnalysisDocument75 pagesLiquefaction AnalysisRyanYuNo ratings yet

- r1 - Main Entrance Bitumen RoadDocument8 pagesr1 - Main Entrance Bitumen RoadEr. Naseem SayyedNo ratings yet

- Flexible Pavement DesignDocument39 pagesFlexible Pavement DesignSaurabh KumarNo ratings yet

- Estimating and Costing of Civil Engineering Projects (Lectured By: Engr. Waseem Raja)Document6 pagesEstimating and Costing of Civil Engineering Projects (Lectured By: Engr. Waseem Raja)Maiwand KhanNo ratings yet

- Large Strain Consolidation: TitleDocument41 pagesLarge Strain Consolidation: Titlerelu59No ratings yet

- Design of Rigid Pavement: A) Design Period and Traffic ProjectionDocument2 pagesDesign of Rigid Pavement: A) Design Period and Traffic ProjectionMitali MajumderNo ratings yet

- Soil Stress 8Document1 pageSoil Stress 8Akhtar BahramNo ratings yet

- Mekanika Tanah 2Document30 pagesMekanika Tanah 2Anggardha YanotamaNo ratings yet

- Unconsolidated-Undrained Triaxial Test: ASTM D-2850Document2 pagesUnconsolidated-Undrained Triaxial Test: ASTM D-2850Rajinda BintangNo ratings yet

- Friction of RunwayDocument15 pagesFriction of RunwayjaffnaNo ratings yet

- Axial Capacity of Pile FoundationDocument32 pagesAxial Capacity of Pile FoundationChowdhury Priodeep100% (1)

- A Plasticity Model For Swedish Weight Sounding TestsDocument8 pagesA Plasticity Model For Swedish Weight Sounding TestsKieu Le Thuy ChungNo ratings yet

- Design Load CalculationsDocument5 pagesDesign Load CalculationsHabsi SharmaNo ratings yet

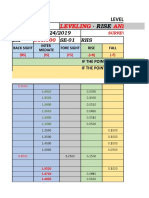

- Leveling AND Calculation: - Rise Fall MethodeDocument9 pagesLeveling AND Calculation: - Rise Fall MethodeKhajaNo ratings yet

- Descriptio Station Length Elev GRADE M-Value: Length of Vert. Curve ADDocument4 pagesDescriptio Station Length Elev GRADE M-Value: Length of Vert. Curve ADRain GarvidaNo ratings yet

- nrcs143 - 014805Document1 pagenrcs143 - 014805Bhaskar ReddyNo ratings yet

- PDR Method For Piled Raft Foundation (Primary Assessment Only)Document6 pagesPDR Method For Piled Raft Foundation (Primary Assessment Only)Trúc Nguyễn100% (1)

- Rise and Fall Excel SheetDocument106 pagesRise and Fall Excel SheetHuseen MohamudNo ratings yet

- Client: Project: Subject:: Noise Wall DesignDocument5 pagesClient: Project: Subject:: Noise Wall Designsudhir12345No ratings yet

- Titik C: Data Vine Shear TestDocument4 pagesTitik C: Data Vine Shear TestRuspyanto UpyNo ratings yet

- 1116-GI REport PDFDocument31 pages1116-GI REport PDFNilay Gandhi100% (1)

- Pile Bearing CapacityDocument5 pagesPile Bearing Capacitymtuanlatoi9704No ratings yet

- Atterberg LimitDocument7 pagesAtterberg LimitAnilAmatNo ratings yet

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Document37 pagesSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarNo ratings yet

- Timesheet Heavy EquipmentDocument4 pagesTimesheet Heavy Equipmentnasution22No ratings yet

- Shear TestDocument3 pagesShear TestRajesh Kumar SrivastavaNo ratings yet

- Lesson 09-Chapter 9 Deep Foundations - Part 1 A (Piles)Document59 pagesLesson 09-Chapter 9 Deep Foundations - Part 1 A (Piles)vipkolonNo ratings yet

- FLYRW2 Foundation RecommendationsDocument13 pagesFLYRW2 Foundation RecommendationshiyeonNo ratings yet

- C33C33M 12806Document11 pagesC33C33M 12806robert_salas_14No ratings yet

- Guidelines For The Design and Construction of Suspension FootbridgesDocument141 pagesGuidelines For The Design and Construction of Suspension Footbridgesjavali2100% (2)

- 2003 01tail SeepDocument143 pages2003 01tail SeepRobert SalasNo ratings yet

- 2003 01tail SeepDocument143 pages2003 01tail SeepRobert SalasNo ratings yet

- Bali01 Train CourseDocument77 pagesBali01 Train Courserobert_salas_14No ratings yet

- Aniuk SpecimenDocument10 pagesAniuk SpecimenMario ParraNo ratings yet

- Dell's Marketing Strategy - 2006Document58 pagesDell's Marketing Strategy - 2006Preeti IyerNo ratings yet

- List of Algorithms Interview QuestionsDocument9 pagesList of Algorithms Interview QuestionsSivaselvi RNo ratings yet

- Literature ReviewDocument3 pagesLiterature ReviewHakim Abdul Rahim100% (1)

- 15ME11E - Solar PV - Question BankDocument15 pages15ME11E - Solar PV - Question BankvigneshNo ratings yet

- Technical Data - Fan Model ECE152SM: Location: Designation: Performance - Required ActualDocument2 pagesTechnical Data - Fan Model ECE152SM: Location: Designation: Performance - Required ActualJNo ratings yet

- Clean Energy Council Installers Checklist PDFDocument3 pagesClean Energy Council Installers Checklist PDFAndre SNo ratings yet

- DatasheetDocument2 pagesDatasheetTesfay Zemuy GebrekidanNo ratings yet

- E-Paper Technology DocumentDocument32 pagesE-Paper Technology DocumentZuber Md54% (13)

- Sony CFD s100lDocument11 pagesSony CFD s100lGeremias KunohNo ratings yet

- Service Manual Repair 552-557 PDFDocument3,278 pagesService Manual Repair 552-557 PDFSerg la RoshNo ratings yet

- Fundamentals and History of Cybernetics 2Document46 pagesFundamentals and History of Cybernetics 2izzul_125z1419No ratings yet

- Welding Machine Project Report FinalDocument44 pagesWelding Machine Project Report FinalJAYAPRABHAKARAN N NNo ratings yet

- Updated After 11th BoS Course Curriculum - B.tech CSEDocument120 pagesUpdated After 11th BoS Course Curriculum - B.tech CSEAnonymous 9etQKwWNo ratings yet

- EV 10 Best Practice - Implementing Enterprise Vault On VMware (January 2012)Document31 pagesEV 10 Best Practice - Implementing Enterprise Vault On VMware (January 2012)TekkieNo ratings yet

- Patch Apply Instructions 19852360.HTMLDocument60 pagesPatch Apply Instructions 19852360.HTMLdineshNo ratings yet

- TD62382APG, TD62382AFG: 8Ch Low Input Active Sink DriverDocument11 pagesTD62382APG, TD62382AFG: 8Ch Low Input Active Sink DriverDiego GrisalesNo ratings yet

- Fdocuments - in Companies List With Contact DetailsDocument80 pagesFdocuments - in Companies List With Contact DetailsNaren RawatNo ratings yet

- 7810-8110-Ca-1540-651-001 - HP FG KodDocument68 pages7810-8110-Ca-1540-651-001 - HP FG Kodgopal krishnan0% (1)

- Operating Check List For Disel Generator: Date: TimeDocument2 pagesOperating Check List For Disel Generator: Date: TimeAshfaq BilwarNo ratings yet

- Spring Setting of Piping Connected To A CompressorDocument4 pagesSpring Setting of Piping Connected To A CompressorSharun SureshNo ratings yet

- PC Hardware Servicing Teacher's GuideDocument7 pagesPC Hardware Servicing Teacher's GuidedanballaisNo ratings yet

- 0811 IndiadxerDocument6 pages0811 IndiadxerAlexander WieseNo ratings yet

- Collateral Document Management System: User'S ManualDocument10 pagesCollateral Document Management System: User'S ManualGerard DGNo ratings yet

- Yamaha Model Index 1958 2010 PDFDocument442 pagesYamaha Model Index 1958 2010 PDFSanja Krajinovic100% (2)

- Philips AZ 1839 Service ManualDocument7 pagesPhilips AZ 1839 Service ManualEdwardNo ratings yet

- A Grand Vision of Man's Role in Colonizing The Universe: BooksDocument3 pagesA Grand Vision of Man's Role in Colonizing The Universe: Bookspeter lonterNo ratings yet

- Method Statement For PaintDocument5 pagesMethod Statement For Paintxxx100% (2)

- LX Capacity Chart Hydrogen SCFM 10-2008 PDFDocument5 pagesLX Capacity Chart Hydrogen SCFM 10-2008 PDFZack AmerNo ratings yet

- NovaSeq X - Site PreparationDocument3 pagesNovaSeq X - Site Preparationlifir67730No ratings yet

- Arizona, Utah & New Mexico: A Guide to the State & National ParksFrom EverandArizona, Utah & New Mexico: A Guide to the State & National ParksRating: 4 out of 5 stars4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensFrom EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo ratings yet

- The Bahamas a Taste of the Islands ExcerptFrom EverandThe Bahamas a Taste of the Islands ExcerptRating: 4 out of 5 stars4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoFrom EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoRating: 5 out of 5 stars5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksFrom EverandNew York & New Jersey: A Guide to the State & National ParksNo ratings yet

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptFrom EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptRating: 5 out of 5 stars5/5 (1)