Professional Documents

Culture Documents

Final Report - New

Uploaded by

dskumar49Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Report - New

Uploaded by

dskumar49Copyright:

Available Formats

EXTENSIVE SURVEY REPORT-2012

BATCH-2

INTRODUCTION

Mangalore is located at 1252N 7453Eto 12.87N 74.88E in the Dakshina Kannada

district of Karnataka. It has an average elevation of 22 meters (72 ft) above mean sea level.

Mangalore is situated on the west coast of India, and is bounded by the Arabian Sea to its

west and the Western Ghats to its east. Mangalore city, as a municipal entity, spans an area of

132.45 km2 (51.14 sq miles). The topography of the city is plain up to 30 km (18.64 miles)

inside the coast and changes to undulating hilly terrain sharply towards the east in Western

Ghats. The geology of the city is characterized by hard laterite in hilly tracts and sandy soil

along the seashore. The Geological Survey of India has identified Mangalore as a moderately

earthquake-prone urban center and categorized the city in the Seismic.

1. NEW TANK PROJECT

A New Tank (Earthen Dam) is proposed to construct across the valley in order to store the

water for irrigation and domestic water supply. The site for the proposed tank project should

be so selected that it should satisfy all the requirements of best possible site and to irrigate the

area of downstream side of the dam. Before taking up this work the following data must be

collected.

Nature of the Catchment Area.

Area to be irrigated.

Rainfall records of the area.

Nature of soil and crops to be grown.

Population of the area.

Communication.

Transportation.

Nature and availability of materials required for the construction of the dam.

To fix the height and storage capacity of tank the following survey works are necessary for

the NTP

Preliminary survey

Detailed survey

SSE, MUKKA, MANGALORE

Page 1

EXTENSIVE SURVEY REPORT-2012

BATCH-2

1.1 The Preliminary Survey Work consists of the following

Longitudinal and cross sections along and across the centerline of the Bund

Block Levels for the waste weir or Surplus weir

Capacity contours, for different reduced levels

Canal alignment

Longitudinal and Cross Sections of center line of the canal

Instruments use

Auto level/Dumpy level, Leveling staff, Chain, Arrows, Ranging rods, Prismatic compass ,

Tape, Cross staff, etc

1.2Survey Details

In order to obtain the bund level we need to locate the two points of equal elevation at each

side of the valley. The survey work is done along the bund line for the section of levels of

sluices maximum water level full tank level waste weir free board height of the bund. The

following survey works are conducted namely

Longitudinal and Cross section of bund

Capacity contour

1.2.1 Longitudinal section and cross section of the bund

In longitudinal leveling the back sight, intermediate sight and fore sight readings are taken at

regular intervals at every setup of instruments. The bearings of the line and the benchmark

are taken. The change points are noted in the level book. This station is taken up to determine

the undulation of the ground surface along the profile line. The reduced levels are calculated.

In the present survey work levels are taken at 5m intervals on steep terrain and at 20m

intervals on the flat terrain.

In cross section leveling, the levels are taken in the transverse direction to the longitudinal

leveling. The cross sections are taken at 5m intervals up to 20 m on either side of center

line. It is carried out to know the nature of the ground across the centre line alignment.

SSE, MUKKA, MANGALORE

Page 2

EXTENSIVE SURVEY REPORT-2012

BATCH-2

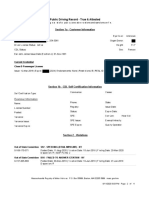

Table No.1:- LEVELING READINGS

LONGITUDINAL AND CROSS SECTION OF NTP

SI.NO

C0.00

B.S

I.S

0.335

F.S

H.I

R.L

48.410

48.075

R5

0.415

47.995

R10

0.450

47.960

L5

0.260

48.150

L10

0.185

48.225

C10.00

0.400

48.010

R5

0.420

47.990

R10

0.495

47.910

L5

0.400

48.010

L10

0.315

48.090

C16.85

0.460

47.950

R5

0.825

47.585

R10

1.315

47.090

R15

2.130

46.280

L5

0.585

47.825

L10

0.445

47.965

L15

0.125

48.285

C20.00

1.085

47.325

R5

1.090

47.320

R10

1.820

46.590

R15

2.500

45.910

L5

1.120

47.290

L10

1.045

47.365

L15

1.260

47.150

C30.00

3.055

45.355

R5

3.300

45.110

R10

3.630

44.780

R15

4.340

44.070

R20

2.815

43.310

L5

2.900

45.510

SSE, MUKKA, MANGALORE

Page 3

REMARK

EXTENSIVE SURVEY REPORT-2012

BATCH-2

L10

2.955

45.455

L15

3.240

45.170

L20

1.315

3.600

46.125

44.810

C40.00

2.775

43.350

R5

3.140

42.980

R10

3.250

42.870

R15

3.810

42.310

R20

3.490

42.630

L5

2.690

43.435

L10

2.950

43.175

L15

3.220

42.900

L20

3.920

42.205

C50.00

4.700

41.425

R5

1.765

4.855

433.035

41.270

R10

2.070

40.965

R15

2.420

40.610

R20

2.920

40.110

L5

1.645

41.390

L10

1.650

41.385

C60.00

3.395

39.640

R5

3.460

39.575

R10

3.700

39.330

R15

3.850

39.185

L5

3.065

39.970

L10

1.765

4.125

40.675

38.910

C65.00

1.870

38.800

R5

1.810

38.860

L5

2.110

38.560

L10

2.610

38.060

L15

2.790

37.880

C75.00

4.145

36.530

R5

4.245

36.430

R10

4.220

36.450

L5

4.060

36.615

L10

3.800

36.875

L15

4.150

36.525

SSE, MUKKA, MANGALORE

Page 4

EXTENSIVE SURVEY REPORT-2012

BATCH-2

L20

4.100

36.570

C85.00

4.180

36.495

R5

4.255

36.420

R10

4.215

36.460

R15

4.235

36.440

R20

R25

R30

L5

4.125

2.390

1.330

36.550

35.810

35.530

36.590

L10

1.345

36.570

L15

1.350

36.570

L20

1.280

36.640

L25

1.005

36.915

L30

0.560

37.360

C89.37

1.345

36.575

L5

1.350

36.570

L10

1.335

36.580

L15

1.330

36.590

L20

1.320

36.600

L25

1.290

36.620

L30

0.550

36.930

R5

1.990

35.930

R10

2.190

35.730

R15

2.400

35.520

R20

2.415

35.500

R25

2.415

35.500

R30

2.430

35.490

C92.22

2.290

35.630

L5

2.100

35.810

L10

1.580

36.340

L15

1.480

36.430

L20

1.310

36.610

L25

1.310

36.610

L30

0.520

37.390

R5

2.250

35.670

R10

2.200

35.720

2.110

SSE, MUKKA, MANGALORE

4.865

Page 5

37.920

EXTENSIVE SURVEY REPORT-2012

BATCH-2

R15

2.430

35.490

R20

2.440

35.480

R25

2.420

35.490

R30

2.430

35.480

C97.22

2.360

35.560

L5

2.320

35.600

L10

2.040

35.870

L15

2.060

35.850

L20

2.050

35.870

L25

2.060

35.850

L30

1.690

36.230

R5

2.340

35.570

R10

2.410

35.510

R15

2.420

35.490

R20

2.440

35.470

R25

2.430

35.480

R30

2.420

35.490

C102.22

R5

2.390

35.520

2.400

35.520

R10

2.260

35.650

R15

2.420

35.500

R20

2.420

35.490

R25

2.440

35.470

R30

2.430

35.490

L5

2.050

35.870

L10

2.020

35.900

L15

2.020

35.890

L20

2.030

35.890

L25

1.700

36.220

L30

1.520

36.400

C107.22

R5

2.400

35.520

2.390

35.520

R10

2.430

35.490

R15

2.370

35.540

R20

2.390

35.520

R25

2.440

35.480

SSE, MUKKA, MANGALORE

Page 6

EXTENSIVE SURVEY REPORT-2012

BATCH-2

R30

2.440

35.480

L5

1.900

36.020

L10

2.010

35.900

L15

2.000

35.920

L20

1.980

36.430

L25

1.520

36.390

L30

1.490

36.420

C112.22

R5

2.180

35.740

1.940

35.970

R10

2.530

35.390

R15

2.500

36.420

R20

2.300

35.620

R25

2.395

35.520

R30

2.420

35.500

L5

1.850

36.070

L10

1.990

35.930

L15

2.000

35.910

L20

1.990

35.930

L25

1.500

36.420

L30

1.530

36.390

C117.220

R5

1.270

36.650

1.490

36.420

R10

1.440

36.470

R15

1.900

36.010

R20

2.460

35.460

R25

1.800

36.110

R30

1.880

36.040

L5

1.620

36.300

L10

1.900

36.010

L15

1.910

36.010

L20

1.850

36.060

L25

1.520

36.400

L30

1.500

36.420

C122.22

R5

1.425

36.490

1.255

36.660

R10

0.495

37.425

SSE, MUKKA, MANGALORE

Page 7

EXTENSIVE SURVEY REPORT-2012

BATCH-2

L5

3.920

0.945

40.400

36.480

L10

2.440

0.450

42.390

39.950

C137.22

R5

1.235

41.155

1.290

41.090

R10

2.920

39.470

R15

3.895

38.490

L5

1.415

40.970

L10

1.000

41.390

L15

4.900

0.715

46.575

41.675

C147.22

L5

1.980

44.595

2.380

44.190

L10

2.590

43.980

R5

1.010

45.560

R10

3.210

43.360

R15

4.720

2.425

48.870

44.150

C161.52

L5

0.795

48.070

1.370

47.500

R5

0.585

48.280

R10

0.890

47.980

0.340

SSE, MUKKA, MANGALORE

Page 8

48.530

END

POINT

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Table No.2:- LONGITUDINAL AND CROSS SECTION OF SMALL BUND

CHAINAGE

BS

C0

L5

L10

R5

R10

0

C14.1

L5

L10

R5

R10

C29.10

L5

L10

R5

R10

1.460

IS

HI

RL

REMARK

99.560

98.100

97.140

96.125

98.685

99.060

95.270

94.405

93.705

92.870

94.905

94.990

90.980

90.540

90.035

91.125

91.205

89.900

89.900

89.950

89.960

90.100

90.170

92.050

91.985

91.935

92.185

92.080

95.350

95.955

95.910

95.045

94.975

97.325

97.495

97.275

96.895

96.810

END POINT

2.420

3.435

0.875

0.500

0.255

4.290

95.525

4.545

91.650

1.750

93.835

1.755

96.310

1.335

98.230

1.120

1.820

2.655

0.620

0.535

0.670

1.110

1.615

0.525

0.445

3.935

C51.1

L5

L10

R5

R10

C71.1

L5

L10

R5

R10

C91.1

L5

L10

R5

R10

C97.1

L5

L10

R5

R0

FS

3.935

3.885

3.875

3.735

3.665

1.785

1.850

1.900

1.650

1.230

0.960

0.355

0.400

0.265

0.605

0.735

0.955

1.335

1.420

SSE, MUKKA, MANGALORE

Page 9

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Fig No.1:- COMPONENTS OF EARTHEN DAM

Summary of the New Tank Project

NTP bund length

161.52m

Top of the bund

1.50m

Free board

1.20m

Upstream slope

2:1

Downstream slope

2:1

Maximum water level

46.125Mm

Length of the waste weir

3.02m

Storage capacity:

1. Maximum capacity of water

63004.25m3

2. @ FTL

53321.55m3

3. @ Dead storage

10264.17m3

SSE, MUKKA, MANGALORE

Page 10

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Table No.3:- Capacity of reservoir

Sl. No

1

2

3

4

5

6

RL in

m

37.325

39.325

41.325

43.325

45.325

47.325

Water

spread

area sqm

4465.42

5798.75

5369.18

3408.82

10019.93

9345.47

SSE, MUKKA, MANGALORE

From

To

R.L

R.L

0

37.325

39.325

41.325

43.325

45.325

Page 11

0

39.325

41.325

43.325

45.325

47.325

Contour

interval

in m

0

2

2

2

2

2

Volume by

Trapezoidal Cumulative

formula

Vol. cum

cum

0

10264.17

11167.93

8778

13428.75

19365.4

0

10264.17

21432.1

30210.1

43638.85

63004.25

EXTENSIVE SURVEY REPORT-2012

BATCH-2

1.3 Design Procedure

1.3.1 YIELD CALCULATION:

1. Catchment area = 3.00 km2

2. Rainfall data considered is for a period of 10 years (2001 to 2010) from rainfall table.

3. Yield /sq.km as per strangers table considering catchment yield average

For 1524.00mm

= 0.68582.cum/sq.km

For 3555.6mm

= 1.60 cum/sq.km

Total yield= catchment area x yield/km2

=3.00 x 1.60

Area

=designated

4.80 cum @

Chainage

20

30

40

50

60

70

80

90

Depth of

embankment

0.53

2.834

4.735

6.645

8.045

9.92

10.855

11.035

SSE, MUKKA, MANGALORE

Mid

rectangular

area

0.795

4.251

7.1025

9.9675

12.0675

14.88

16.2825

16.5525

Page 12

U/s triangular

area

0.2809

8.031556

22.420225

44.156025

64.722025

98.4064

117.831025

121.771225

D/s

triangular

area

0.2809

8.031556

22.420225

44.156025

64.722025

98.4064

117.831025

121.771225

Total area in

sq. Mt

1.3568

20.314112

51.94295

98.27955

141.51155

211.6928

251.94455

260.09495

EXTENSIVE SURVEY REPORT-2012

BATCH-2

100

110

120

130

140

150

161.42

11.54

11.475

10.9

8.687

5.755

2.245

0

17.31

17.2125

16.35

13.0305

8.6325

3.3675

0

133.1716

131.675625

118.81

75.463969

33.120025

5.040025

0

133.1716

131.675625

118.81

75.463969

33.120025

5.040025

0

Total=

283.6532

280.56375

253.97

163.958438

74.87255

13.44755

0

2107.60275

Volume of core

V=h[(A40+A140)/2+A50+A60+A70+A80+A90+A100+A110+A120+A130)]

V=1108.84 m3

Volume of bund by trapezoidal Rule

V=h[(A20 + A150)/2 + A30 + A40 + .A140] + 76.74

Where h=10mtr

Total volume of bund =21078.74 cu mtr

Volume of earthwork = Volume of bund - Volume of core

Volume of earthwork = 21078.74 - 1108.84

Volume of earthwork =19969.90 m3

Fig No.2:- VARIOUS LEVELS OF A STORAGE RESERVOIR

SSE, MUKKA, MANGALORE

Page 13

EXTENSIVE SURVEY REPORT-2012

BATCH-2

The maximum water level (MWL), to which the water will rise in the reservoir during

ordinary operation condition is called Normal pool level. The normal level is corresponding

to the level of the spillway crest, or to the spillway gates. The level to which water rises

during the flood is known as Maximum water level. The lowest operation to which the water

in the reservoir is to be drawn under ordinary operating conditions is called minimum pool

level.

The volume of water stored between the normal pool level and the minimum pool level is

known as the useful storage (live storage). The volume of water below the minimum pool

level is known as the dead storage and is not useful under ordinary operating conditions. The

volume of water stored between the normal pool level and maximum level corresponding to a

flood is surcharge storage, and is usually uncontrolled. The term bank storage and valley

storage are referred to the volume of water stored in the pervious formations of the river bank

and the soil above it. Such storage depends upon the geological conditions of the river banks.

The bank storage increase the capacity of the reservoir above that indicates by the elevationstorage curve.

Gross capacity of the Tank or Reservoir

The gross capacity of a tank is the cubic content of water impounded up to the Full Tank

Level (F.T.L). The total capacity of the tank is the sum of the capacities between the

successive contours.

1.4 Canal

SSE, MUKKA, MANGALORE

Page 14

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Canal project is a part of irrigation science which deals with the artificial carriage of water

from the reservoir to the required field. Canal is an artificial channel constructed to carry

water from river or reservoir for various purposes such as irrigation, power generation,

navigation etc. in general, canals are trapezoidal in cross section. The canals are usually

designated according to the purposes for which they are used.

Summary of the Canal Project

Length of the canalBase width of the canalTotal height of bankingFree board

Fig No.3:- CROSS SECTION OF CANAL

Table No.5:- LOGITUDINAL AND CROSS SECTION OF CANNAL

SSE, MUKKA, MANGALORE

Page 15

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Chainage

C0

L5

L10

L15

R5

R10

R15

BS

4.625

IS

0.650

40.825

3.175

39.150

3.290

36.580

1.930

35.830

2.585

1.310

0.635

0.225

4.850

5.390

5.260

1.500

0.915

0.495

2.265

3.545

1.500

1.535

1.370

2.065

3.250

3.260

3.290

3.380

3.210

3.470

0.720

C85.5

L5

L10

R5

R10

C125.5

L5

L10

R5

R10

HI

41.120

2.695

1.360

0.125

4.470

5.380

5.595

0.355

C15

L5

L10

L15

R5

R10

R15

C45

L5

L10

R5

R10

C45

L5

L10

R5

R10

C70.5

L5

L10

R5

R10

FS

1.840

1.860

1.850

1.860

1.560

1.930

1.870

1.860

1.920

1.180

SSE, MUKKA, MANGALORE

Page 16

RL

36.495

38.425

39.760

40.995

36.650

35.740

35.525

40.470

38.240

39.515

40.190

40.600

35.975

35.435

35.565

37.650

38.235

38.655

36.885

35.605

37.650

37.615

37.780

37.085

35.900

35.890

35.860

35.770

35.940

35.680

35.860

34.740

34.720

34.730

34.720

35.020

34.650

34.710

34.720

34.660

34.650

Remarks

change point

change point

change point

change point

EXTENSIVE SURVEY REPORT-2012

BATCH-2

C137.4

L5

L10

R5

R10

C170.5

L5

L10

R5

R10

C170.5

L5

L10

R5

R10

2.190

2.195

1.191

2.235

2.231

2.080

2.115

2.110

2.145

2.140

2.080

2.110

2.115

2.145

2.145

0.825

C185.5

L5

L10

R5

R10

C245.5

L5

L10

R5

R10

34.575

1.440

34.355

1.370

1.370

1.370

1.370

1.371

1.440

1.445

1.442

1.440

1.435

1.220

C268.9

L5

L10

R5

R10

C268.9

L5

L10

R5

R10

C298

L5

L10

R5

R10

2.080

2.070

2.075

2.070

2.080

2.075

2.750

2.080

2.070

2.085

2.080

2.085

2.015

2.010

2.060

0.065

SSE, MUKKA, MANGALORE

Page 17

33.640

33.635

34.635

33.595

33.595

33.750

33.715

33.720

33.685

33.690

33.750

33.720

33.715

33.685

33.685

33.750

33.205

33.205

33.205

33.205

33.204

33.135

33.130

33.133

33.135

33.140

33.135

32.285

32.284

32.285

32.275

32.280

32.285

32.275

32.285

32.270

32.275

32.270

32.340

32.345

32.295

32.290

change point

change point

EXTENSIVE SURVEY REPORT-2012

BATCH-2

C329.9

L5

L10

R5

R10

C335.9

L5

L10

R5

R10

C355

L5

L10

R5

R10

C390.1

L5

L10

R5

R10

C420.1

L5

L10

R5

R10

C450.1

L5

L10

R5

R10

C480.1

L5

L10

R5

R10

C500

L5

L10

R5

R10

1.289

2.365

33.270

1.785

32.770

1.255

1.250

1.305

1.295

1.545

1.540

1.545

1.555

1.550

1.740

1.785

1.780

1.780

1.280

1.515

1.520

1.520

1.540

1.540

1.910

1.805

1.805

1.865

1.860

2.150

2.155

2.150

2.225

2.220

2.650

2.645

2.640

2.660

2.655

2.750

2.960

2.965

2.970

2.975

1.4.1 TIME FACTOR

SSE, MUKKA, MANGALORE

Page 18

31.990

32.015

31.020

31.965

31.975

31.825

31.730

31.725

31.715

31.720

31.530

31.485

31.490

31.490

31.490

31.255

31.250

31.250

31.230

31.230

30.860

30.965

30.965

30.905

30.910

30.620

30.615

30.620

30.545

30.550

30.120

30.125

30.130

30.110

30.115

29.820

29.810

29.805

29.800

29.795

change point

change point

END POINT

EXTENSIVE SURVEY REPORT-2012

BATCH-2

It is the ratio of number of days the canal has actually to run, to the base period in days.

Water requirements of the channel (i.e., its capacity) should be divided by time factor, so as to

obtain the design capacity. Since the factor is less than 1.

1.4.2CAPACITY FACTOR

It is the ratio of the mean supply discharge to the full discharge capacity.

1.4.3 FULL SUPPLY COEFFICIENT

Area estimated to be irrigated during base period

Design full supply discharge at its head during peak demand.

It is also called Duty on capacity.

1.4.5 DETERMINATION OF REQUIRED CHANNEL CAPACITY

Whenever one plans for supplying irrigation water. One has to think of likely crops that are to

be sown in any one season. The peak rate of water requirement of all crops in each season is

also to be worked out. The capacity of the channel should be such so as to fulfill the

maximum of peak demand of the all crops that one required at any one time amongst all the

seasons it is explained in details.

The most important Rabi crop is wheat, which requires water from December to March,

during the Rabi season. Similarly paddy (rice) is the most important Kharif crop requiring

water from June to November so it can presume that when Rabi crops require water Kharif

crops do not and vice-versa. Sugarcane is a perennial crop which requires water through the

year. Hence the channel may be designed for a capacity equal to the greater of the water

requirement of rabi and sugar or kharif and sugar. This is very simple method for fixing the

capacity of channel. The entire Rabi area is supposed to be sown with wheat and entire kharif

area with paddy (sugarcane area excluded from both) and their water requirements in cumec

are worked out. The water requirement of sugarcane is separately worked out. The channel

capacity may be fixed for the maximum of the two values.

SSE, MUKKA, MANGALORE

Page 19

EXTENSIVE SURVEY REPORT-2012

BATCH-2

The most important point which must be kept in mind while fixing the channel capacity is

that we must take into account the keenest demand of the crop and not the average demand.

For example, Rice requires 120cm of water during 120days, thus giving an average outlet

factor of 864 hectares/cumecs

I.e. D = 864B/

= (864*12)/120

= 864

But the channel designed on this average outlet factor will prove to be very inadequate, as it

will fail to supply the required water to the crop at its peak demand i.e., at the time

Kor- watering, as explained below,

The kor depth of the rice is about 19cm and the kor period is about 2 weeks (i.e 14days). It

means that 19cm of water depth must be supplied in about 14 days.

The outlet factor for this works out to be 637 hectare / cumecs as

D = 864B /

= (864 * 14)/19

= 637.

Now, discharge requires maturing a hectare of land for an outlet factor of 864 is A/864

cumecs, while that for an outlet factor of 637 is A/637 cumecs. Out of these two values the

second value (i.e. A/637) is more and hence the discharge required for fulfilling the kor

demand of the crop is more than for the average demand.

Similarly wheat requires 40 cm of water in a total base period of about 160days. Thus giving

an average outlet factor of 3464 hectares/cumecs. But the kor water depth required by wheat

is about 14cm in about 4 weeks giving an outlet factor of 1728 hectares/cumecs.

Applying the previous reasoning, we can say that the discharge required to fulfill kor-demand

is much more than that for the average demand (almost double of average). Hence, it follows

that the peak demand, i.e kor-demand of the crop should be taken into account while fixing

the capacity of the channel. Moreover, the provision for channel losses should also be made,

while deciding the final channel capacity.

The method described above, for determining the channel capacity is a simplified

approximate process to be more precise, we can find out the monthly or 15 days water

requirement of various crops. The water depth required in this interval is multiplied by the

crop area. So as to give the volume of water required in this interval. Dividing the volume by

interval, we can find out the discharge required in each interval, by various crops. The

SSE, MUKKA, MANGALORE

Page 20

EXTENSIVE SURVEY REPORT-2012

BATCH-2

summation of which for all crops will give us the discharge required by all crops in each

interval. The channel may then be designed for maximum of these values.

It is evident that in order to be more precise, the interval should be as small as possible.

Generally, monthly water requirement studies are conducted and the channel capacity is

increased by 20% to 25% to cater for the peak demand in the months.

1.4.6 CONTOUR CAPACITY

This is a typical case of volume in which the finished surface (i.e surface of water) is level

surface. The volume is calculated by assuming it has been divided into a number of

horizontal slice by contour line is measured by planimeter and volume can be calculated.

Let A1, A2, A3..An the area of successive contour

H = contour interval

V = capacity of reservoir

By trapezoidal formula,

V = h [(A1+An)/2 +A2+A3+A4+An-1]

By Prismoidal rule,

V = h/3 [A1+ 4(A2+A4+.) + 2(A3+A5) =An]

Table No.6:- Rain fall data of the last 10 years:year

Rain fall data in mm

Rain fall in descending

2001

2002

2003

2004

2005

2006

2007

2008

2009

2010

2011

4343.5

3227.4

3532

3271

3114.2

3555.6

3838

2916.2

3119.6

5160.4

3775.4

5160.4

4343.5

3838

3775.3

3555.6

3533

3271

3227.4

3190.6

3114.2

2916.2

SSE, MUKKA, MANGALORE

Page 21

EXTENSIVE SURVEY REPORT-2012

BATCH-2

1.4.6 Design of Left Bank Canal:

GCA = CCA = 933.00hactors

Duty = 3168ha/cumec

Discharge = Area/duty

Q = 933.00/3168

Q = 0.29M3sec

Channels are to be designed for 20% excess requirement towards rush irrigation

(Engineers hand book)

= 0.29 x 0.2 = 0.058

= 0.058 + 0.29

Total discharge =0.348cumec

Now, using Continuity equation Q=AV

Area=Q/V

A=0.348/0.45

A=0.87M2

V=0.45 m/s for minor distributaries (allowable velocity)

(Engineers hand book)

Area =0.87/0.45=0.87m2

SSE, MUKKA, MANGALORE

Page 22

EXTENSIVE SURVEY REPORT-2012

BATCH-2

For most Economical Trapezoidal section,

We have condition

A={(B+2nd+B)/2}* d

A= (B+D)*D

0.87 = (B+D)*D-------- (1)

We have condition,

(B+2nD)/2=D {sqrt (n2+1)}

(B+2*1*D)/2=D {sqrt (12+1)}

B+D=1.41D

b=0.41D

From (1) we have,

0.87 = (0.41D+D)*D

0.87=1.41D2

D=0.78m

Say, D =0.80m

Therefore,

b =0.41*0.80

b=0.32m

So, D=0.80m & b=0.32m

Perimeter:P =b+2*2D

P=0.32+2*2*.80

SSE, MUKKA, MANGALORE

Page 23

EXTENSIVE SURVEY REPORT-2012

BATCH-2

P=2.58m

Mean depth:R=A/P

=0.87/2.58

R=0.34m

Mannings Constant N=0.0225

Velocity =1/n R2/3 S1/2

0.45 =1/0.0225(0.34)2/3 (S) 1/2

(since velocity is limited to 0.45m/s)

S =1 in 4211

Discharge (Q):Q=A x V

=0.87x0.45

Q= 0.39m3

Fig No.4:- Design of Sluice gates:-

Limiting Velocity through sluice gate is a maximum of 4.5 m/sec [S.K.Garg book,

page- 936].

By using Engineers Handbook

SSE, MUKKA, MANGALORE

Page 24

EXTENSIVE SURVEY REPORT-2012

BATCH-2

1.4.7

Design of sluice gate procedure

V= Cd x (2gh) 1/2

Cd= 0.62 for free flow

h= height of the F T L above sill level of Sluice.

V= Cd x (2gh) 1/2

V= 0.62x (2x9.81x10.605)1/2

= 8.94 m/sec > 4.5 m/sec

Limit value of velocity = 4.5 m/sec

A = Q/V

= 0.39/4.5

= 0.087 m2

A=

0.087=

/4

2

/4

d= 0.33m

d=0.33m can be provided.

Fig No.5:- DESIGN OF VERTICAL DROP WEIR

SSE, MUKKA, MANGALORE

Page 25

EXTENSIVE SURVEY REPORT-2012

BATCH-2

1. Hydraulic calculations for fixing various elevations.

2. Design of weir wall.

3. Design of impervious floor (or apron).

4. Design of protection works on upstream and downstream sides.

The following data must be known for the design of a vertical drop weir.

Maximum flood discharge(Q)

High flood level (H.F.L)before construction of weir

Downstream bed level

Fully supply level (F.S.L)of canal taking off from the river

Allowable afflux

Laceys silt factor

1.5 Design of vertical drop weir

i.

The length of waterway (L) is calculated from Laceys regime formula

L = 4.83Q^ (1/2)

Where L=Length of waterway in meters

Q= discharge in cumec

= 4.83*0.39^ (1/2)

L = 3.02m

ii.

The discharge q per unit length of waterway is calculated from the relation

Q = Q/L

Where q is in cumec per meter

= 0.39/3.02

Q = 0.13cumec per meter

iii.

The regime scour depth in calculated from Laceys formula

R=1.35[q^2/f]^(1/3)

Where

R=scour depth in meters

f=Laceys silt factor (assume f=1)

=1.35[0.13^2/1]^(1/2)

SSE, MUKKA, MANGALORE

Page 26

EXTENSIVE SURVEY REPORT-2012

BATCH-2

R=0.176m

iv.

The regime velocity and velocity head are calculated from the expressions

V= Q / R

=0.13 / 0.176

V =0.738m/sec

Velocity head= V^2/2g

= 0.738^2/2*9.81

= 0.0277m/sec

v.

Water levels and total energy line (T.E.L) on the downstream side (d/s) and

upstream side (u/s) are calculated as follows:

Level of d/s T.E.L= (H.F.L before construction) +V^2/2g

=46.125+0.0277

=46.402m

Level of u/s T.E.L=Level of d/s T.E.L+Afflux

Allowable Afflux=1

=46.129+1

=47.129m

Level of u/s H.F.L=Level of u/s T.E.L-V^2/2g

=47.129-0.0277

=47.1013m

vi.

Discharge over the crest of the weir is given by

q=1.70K^ (3/2)

Or

K= (q/1.70) ^ (2/3)

= (0.13/1.70) ^ (2/3)

K=0.18

Therefore crest level=u/s T.E.L-K

=47.129-0.18

Crest level=46.949m

SSE, MUKKA, MANGALORE

Page 27

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Table No.7:- VOLUME OF EARTHWORK FOR PROPOSED CANAL ALIGNMENT

Chainage

0

15

45

70

85.5

125.5

137.4

170.5

185.5

245.5

268.9

298

329.9

335.9

390

420

450

480

500

Area in

cutting(m3)

0.1097

6.6266

3.1811

Area in

filling(m3)

8.08

5.9591

2.6595

21.2618

38.8107

40.6488

59.362

60.3995

72.1408

73.7335

12.21

11.093

15.6

19.81

45.56

51.77

59.25

69.63

77.3744

Total Volume

Volume of

cutting(m3)

Volume of

filling(m3)

50.52

147.11

39.76

105.29

129.27

299.01

465.55

1589.19

595.06

1982.05

994.05

4376.229

1005.53

339.05

425.7

106.23

1768.2

1459.95

1665.3

1933.2

1470.044

20708.903

237.39

Total Volume of earthwork in cutting= 237.39 m3

Total Volume of earthwork in filling =20708.93 m3

Fig No.6:- SLUICE GATE OPENING:

SSE, MUKKA, MANGALORE

Page 28

EXTENSIVE SURVEY REPORT-2012

BATCH-2

1.6 CONCLUSION: The nearby wells can be recharged by construction of this bund. Thus the water

stored in the tank can be used for various purposes such as irrigation, power

generation, domestic water supply etc.

This project can also help to increase the ground water table in the region. Thus the

overall prosperity of the people will increase because of this project.

Fig No.7:- Catchment Area from AutoCAD:-

SSE, MUKKA, MANGALORE

Page 29

EXTENSIVE SURVEY REPORT-2012

BATCH-2

2. WATER SUPPLY

2.1 INTRODUCTION

Safe drinking water is the primary need for every human being. Water is absolutely essential

not only for survival of human being but also animals, plants and all living beings. The

purpose of Municipal water supply system is to provide portable water, which is chemically,

and bacteriological safe for human consumption. For domestic use, water should be free from

unpleasant taste, Odour and should be improved for human health.

While designing a water supply scheme it first of all, essential to search a source for village,

for which the scheme is to be designed. Basically there are two main water sources, i.e.

1. Surface water sources: River, Lakes, Ponds, Impounding reservoir, Canals, Stored

rain water, etc.

2. Ground water sources: Springs, Wells, Infiltration Galleries and Infiltration Wells.

Surface water sources are generally contaminated and cannot be used without proper

treatment and purification system, compared to Ground water source.

2.2 Main Objective

The main objective of this project is to provide pure and safe drinking water supply with

proper sewerage system to the proposed village.

SSE, MUKKA, MANGALORE

Page 30

EXTENSIVE SURVEY REPORT-2012

BATCH-2

2.3 Specific Objectives

To carry out this project under rural water supply scheme and to achieve the main objective

we have drawn some of the specific objectives.

Selection of project site for the proposed Village.

Identification of water sources, required for the proposed Village.

Survey work is to be carried out to obtain the key plan of the entire water supply

project and sewage system.

Location of Intake Works, Water Treatment Plant, Overhead Tank, Distribution

System and Sewage Treatment System.

Design of Water Treatment Plant, Rising Main and Water Distribution System.

Preparation of Village plan, Population projection and Quantity and Quality of water,

etc for the entire project.

2.4 Selection of Project site

We have selected a site for NTP project which is located on downstream side of the NTP

reservoir. Before commencement of the survey work we have made reconnaissance survey to

locate the site for intake works, water treatment plant, overhead tank, rising main, gravity

main and distribution system for the proposed village.

Detailed survey work is to be made for the entire project work and is given below:

Block levels for the proposed intake works (Reservoir Intake works).

Compass survey work is made from intake works to the Proposed Water

Treatment plant (L/S).

Block levels for the proposed Water Treatment plant.

Rising main (L/S) to Overhead Tank using compass.

Block leveling for proposed Overhead Tank on the hill station.

Gravity main (L/S) using compass up to the proposed village.

Block leveling for Water Distribution system to the proposed village.

Using the data available from survey work we have designed Water Supply and sewerage

system.

2.5 The Design work for the entire project is made in two Stages.

1. Water Supply Project - Intake works, Water Treatment Plant, Rising Main

Tank, and Distribution system.

SSE, MUKKA, MANGALORE

Page 31

Overhead

EXTENSIVE SURVEY REPORT-2012

BATCH-2

2. Sanitary project (sewerage system) - collection, transport, treatment and safe disposal of

sewage.

All the drawings connected to the above two stages are given in detail in a separate bounded

report.

2.5.1 Water Supply Project

After the selection of site for the proposed village, detailed survey work has been carried out.

Using survey data, we have made the following design. Based on the prepared Layout for the

proposed village and the no. of occupants in each residential unit, and total population of the

village is estimated as follows:

Total residential building in the proposed layout = 2000 nos.

No. of inhabitant in each house = 5 nos.

Total expected population for the proposed village = 2000 x 5 = 10000 for the

year 2010.

Design period consider for the water supply project = 20 years (2 Decades)

Population projection after 20 years (2030) by considering the factors like

Birth rate, Death rate and Migration etc. The future Population is about =25%,

increasing per decade.

So, expected population at the end of 2030 = 16000 (say).

Average Domestic Water Consumption

Whenever an engineer is given a duty to design the water supply scheme for a particular area

of the community, it becomes imperative upon him, to first of all, evaluate the amount of

water available and the amount of water demanded by the public. In fact very first duty is to

consider the actual Water Demand and then find out the source to fulfill that demand.

It is necessary to find out, not only daily demand but also total annual requirement is to be

determined.

2.6 Per Capita Demand

SSE, MUKKA, MANGALORE

Page 32

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Per Capita Demand is the average amount of daily water required by one person, and includes

the domestic use, industrial and commercial use, public use, waste, thefts, etc. In India, the

requirement of water in various uses is as follows:

Table No.8:- Per Capita Demand for various village/town/city populations

Population of town

Per Capita Demand (in Lpcd)

Up to 10000

70-100

10,000- 50,000

100-135

Above 50,000

135-250

2.7 Common Demands of a Community

1. Domestic water demand.

2. Commercial water demand.

3. Demand for public amenities.

4. Fire demand.

5. Water required for compensating losses in wastes, thefts etc

Table No.9:- Domestic Water Demand (Per Capita Demand) - (100-135 Lpcd)

S. No.

Use

Consumption in Lpcd

Drinking

Cooking

Bathing

30

Cloth washing

30

Utensils washing

20

Cleaning of houses

15

SSE, MUKKA, MANGALORE

Page 33

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Flushing of latrines

30

Total

135 Lpcd

2. Commercial Water Demand

This includes the quantity of water required to be supplied to offices, factories, hostels,

hospitals etc. This depends on the type of city or town & nature of establishments. On an

average a provision of 20-25% of the total water consumption of the community will be

considered.

3. Demand for Public amenities.

This includes the quantity of water required for public utility purpose such as watering for

public parks, gardening & sprinkling on roads, use in public sanitary units etc. Normally an

average of 5% of the total water consumption of the community will be considered.

4. Fire Demand

In thickly populated areas, fires generally break out & may lead to serious damages if not

controlled effectively. Generally water required for fire demand hardly amounts to about

1lt/person/day, which is also considered in our design.

5. Water required for compensating- losses in wastage, thefts etc

This includes the water lost in leakage due to poor plumbing fittings, unauthorized water

connection, other losses & wastes etc. These losses can be reduced by careful maintenance.

This amount is usually taken as 15% of the total consumption.

6. Quantity of Water

Based on the available population, it is assumed that the rate of water supply=

100LPCD, and the Maximum daily demand is also estimated= 1.8 MLD.

Qavg = (Population x WS)

= (1000 x 135)

SSE, MUKKA, MANGALORE

Page 34

EXTENSIVE SURVEY REPORT-2012

BATCH-2

= 135000Lpcd

= 0.135 MLD

Qmax = (1.8 x Qavg)

= (1.8 x 0.135)

Qmax = 0.243 MLD

Water samples were collected from the reservoir and analyzed for Drinking water

Quantity parameters as per BIS: 10500-2003 to know the quality of water, which is to be

supplied to the village. Based on the result is obtained for the available water source we have

designed the treatment plant.

Table No.10:- WATER QUALITY STANDARDS (BIS: 10500 - 2003)

Range

Serial No.

Permissible limit

Parameters

Excisable limit

Physical

Color ( Hz )

Odour and Taste

Turbidity ( NTU )

10

TDS ( mg/l )

500

2000

II

25

Not objectionable

Chemical

pH

6.5-8.5

6

7

9

Total alkalinity(as CaCo3in mg/l)

Total hardness (as CaCo3 in mg/l)

Chlorides (as Cl- in mg/l)

200

300

250

600

600

1000

9

10

11

Sulphate (as S04 in mg/l)

Fluoride (as F in mg/l)

Nitrates (as NO3 in mg/l)

150

1.0

50

400

1.5

50

12

Nitrites (as NO2 in mg/l)

13

Calcium (as Ca in mg/l)

75

200

14

Magnesium ( as Mg in mg/l)

30

100

15

Total iron (as Fe in mg/l)

0.3

1.0

SSE, MUKKA, MANGALORE

Page 35

EXTENSIVE SURVEY REPORT-2012

BATCH-2

III

16

Biological

MPN/100ml

Less than 1/100ml

2.8 Intake for Collecting Surface Water

The basic function of the intake structure is to help in survey with- drawing water from the

source over a predetermined range of pool levels & then to discharge this water in to the

withdrawal conduits through which it flown up to the water treatment plant.

Reservoir Intake

The Reservoir Intake shows a clear idea about the intake structures which is used to draw the

water from earthen dam reservoir. It is essentially consists of an intake tower constructed on

the slope of the dam on U/S at such a place from where, intake can draw sufficient quantity of

water even in the driest period. Intake pipes are fixed at different levels as so as to draw water

near the surface in all variations of water level. All the inlet pipes are connected to the one

surface in all variations of water level. All the inlet pipes are connected to the one vertical

pipe inside intake well. Screens are provided at the mouth of all intake pipes to prevent the

entrance of floating and suspended objects in them. The water which enters the vertical pipe

intakes to the other side of the dam by means of an outlet pipe. At the top of the intake tower,

sleeve valves are provided to control the flow of water. The valve tower is connected to the

top of the dam by means of the foot bridge for reaching it.

2.9 Aeration unit

Aeration is necessary to promote the exchange of gases between water and atmosphere. In

water treatment aeration is preceded for the following purpose.

1. To add oxygen to water for freshness.

2. Removal of CO2, H2S and other substances and to bring taste and odour.

3. To precipitate impurities like iron and manganese etc.

The raw water from reservoir is conveyed from reservoir intake works collected in a storage

tank (sump) and lead to aerobic unit. Water fall or cascade type of aerator is normally

recommended and is generally provided.

SSE, MUKKA, MANGALORE

Page 36

EXTENSIVE SURVEY REPORT-2012

BATCH-2

2.10 Reaction with Alum

When Aluminum Sulphate (Al2 (SO4)3.18H2O) (Alum) is added to water it reacts with the

natural alkalinity which is present in the raw water and produces, a gelatinous precipitate

(flock) of aluminum hydroxide. The flock attracts the fine suspended colloidal particles and

grows in size and finally settles down to bottom of the tank.

The chemical reaction is as follows:

Al2 (SO4)3.18H2O + 3Ca(HCO3)2 2Al(OH)3 + 3CaSO4 + 18H2O + 6CO2

Amount of alum required for coagulation is depending on the turbidity and color of raw

water. It is an effective coagulant extensively used throughout. It does not require any skill

supervision for handling. The water obtained from this treatment is quite clear and taste and

color of raw water is considerably reduced.

2.11 Filtration Unit

Filtration is defined as, passing passage of fluid through a porous media to remove the

floating matter held in suspension in water purification.

The matter to be removed includes suspended and colloidal particles, clay and microorganisms including algae and bacteria.

There are three types of Gravity Filters,

1. Rapid sand filter

2. Slow sand filter

3. Pressure filter

Among them, Rapid Sand Filter is most commonly used and same is designed

Design of Rapid Sand Filter is governed by many factors such as;

The quality of raw water

The nature and efficiency of pre-treatment

The characteristics of filter media

The hydraulic loading of filters

The method of disinfection

The method of internal cleaning

SSE, MUKKA, MANGALORE

Page 37

EXTENSIVE SURVEY REPORT-2012

BATCH-2

2.12 Disinfection

The filtered water still contain some kinds of impurities present in it, mainly in the form of

harmful disease causing pathogenic bacteria and they must be killed in order to make the

water safe for drinking. This can be used by the chemicals called disinfectants and this

process is called disinfection.

The main purpose of disinfection is to prevent contamination of water during its transit from

treatment plant to the place of its consumption. Chlorine is an ideal material for treating water

in a large scale.

2.13 Distribution System

There are 3 different types of distribution systems;

1. Gravity system

2. Pumping system

3. Combined system

In our project, combined system is used, in which the water is pumped from source which is

at lower level, to overhead tank at the higher level and then, from the overhead tank, the

water is supplied to the public, by gravity.

As the layout of village in haphazard manner, the dead end system is adopted.

2.14 System of Supply

1. Continuous supply

2. Intermittent supply

For this project intermittent supply is adopted.

2.15 Pressure in Distribution System

The pressure which is required to be maintained in the distribution system depends upon the

following factors:

1. The height of highest building up to which water should reach without boosting.

2. The distance to the locality from the distribution reservoir.

3. The supply is to be metered or not. Higher pressure will be required to compensate

for the high loss of head in meters.

4. The funds available for the project work.

SSE, MUKKA, MANGALORE

Page 38

EXTENSIVE SURVEY REPORT-2012

BATCH-2

In multistory structures the following pressure are considered satisfactory

Up to 3 storey

2.1 kg/sq.cm

From 3 to 6 storey

2.1 to 4.2 kg/sq.cm

From 6 to12storey

4.2 to 5.27 kg/sq.cm

2.16 Pipe Appurtenances

The distribution pipes are provided with various pipe appurtenances or accessories so as to

make the distribution of water easy and effective. The pipe appurtenances are air valves, bib

cocks, fire hydrants, reflux valves, sluice valves, stop cocks, water meters etc...

2.17 Economical Diameter of Main pipe

For pumping a particular fixed discharge of water, it can be pumped through bigger diameter

pipe at low velocity or through lesser diameter pipe at high velocity. But if the diameter of the

pipe is increased, it will lead to the cost of the pipe line on the other hand if diameter of the

pipe is reduced, and the increased velocity will lead to the higher frictional head loss and will

require most of the required pumping, hereby increasing the cost of the construction.

For obtaining the efficiency it is almost necessary to design the pumping main, which will

be overall most economical in initial cost as well as maintenances cost of the pumping the

required quantity of the water.

Following formula given by Lea is commonly used in determining the diameter of the

pumping main:

D = 0.97 to 1.22 Q 0.5

Where,

D = Economical diameter of the pipe in m

Q = Required discharge of water to be pumped in cumec/second

The above formula given optimum velocity of water flow between 0.8 to1.35 m/s.

SSE, MUKKA, MANGALORE

Page 39

EXTENSIVE SURVEY REPORT-2012

BATCH-2

2.18 Design Details for Water Supply System

Table No.11:- Water Demand for Domestic Purposes:

Sl. NO.

USE

CONSUMPTION IN LPCD

Drinking

Cooking

Bathing

30

Cloth washing

30

Utensils washing

20

Cleaning of houses

15

Flushing of latrines

30

Total

135 Lpcd

Assume total population of the area = 1000

Table No.12:-population with respect to year

YEAR

POPULATION

1992

2002

2012

2032

620

780

1000

SSE, MUKKA, MANGALORE

Page 40

DECREASE IN

DECADE

160

220

Avg = 190

% INCREASE IN

DECADE

25.80

28.20

Avg = 27.00

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Arithmetic increase:x =190

Population at 2032 = P0 + xn

= 1000 + (2 x 190)

= 1380

Geometric method:r = (25.80 x 28.20)

2

= 27.00

Population at 2032 = P0 (1 + (r / 100)) n

= 1000(1 + (27.00 / 100)) 2

1612.90 say 1612.

Design period = 20 years.

Average water consumption = 135 Lpcd.

Average daily demand = 135 x 1612

= 0.218 MLD

Required capacity of major component of proposed water work:

1) Average daily draft = 0.218MLD.

2) Maximum daily draft = may be assumed as 180%

Average daily draft = 0.218 x 180

100

= 0.392 MLD

Capacities of various components:

1) Intake structure may be designed for maximum daily draft of 0.392MLD.

2) Pipe mains carrying the water from intake to the reservoir may be designed for.

DESIGN OF RISING MAINS:

Design of pump:

SSE, MUKKA, MANGALORE

Page 41

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Assume the pumping is done for 5 hours.

Average quantity of water = 0.392 MLD

Q=

0.392 x 106 x 24

24 x 1000 x 3600 x 5

Q = 0.022 cumec

D = 0.972Q to 1.22Q

= 0.9720.022 to 1.220.022

D= 14.5 cm to 18 cm say 18cm pipe dia.

Using Hazen Williams formula

HL=

HL=

HL= 6.17mt

Minor loss, hf = 4 f L v2

2gd

f= friction factor of PVC pipe

L= Length of the pipe

v = Velocity of water

g = Gravitational constant

d = Diameter of the pipe

= 4x 0.00625 x 800 x 0.452

= 1.14 m due to friction.

2 x 9.81 x 0.18

SSE, MUKKA, MANGALORE

Page 42

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Assume 10% losses in fitting = 6.17 = 0.617mt

10

Total head losses = 6.17 + 1.14 + 0.617 = 7.93mts

Power of pump:

Total Height from the dead storage to the over head tank = (Height from the dead storage to

top bund level + Height from top bund level to tank ground level + Height of the over head

tank + total head loss)

H = 10.8+ 10+12+ 7.93 =40.73m

Say H = 40m

Water Horse Power (WHP) =

Where,

= Density of water

Q = Discharge

H = Head loss due to friction

= Efficiency of water 70%

= 13.20 HP

Breaking horse power

SSE, MUKKA, MANGALORE

Page 43

EXTENSIVE SURVEY REPORT-2012

BATCH-2

(BHP) = 16.77 HP

3.

HIGHWAY PROJECT

3.1 Introduction

Transportation is a vital infrastructure for the speedy economic growth of a developing

country. Road transportation is one of the important modes of transport having many

desirable characteristics. Such as flexibility, door to door service and accessibility to remote

areas.

Highways in road transport system have been rightly compared to the arteries of a human

being and their importance in the social and economic up lift of a nation cannot be over

emphasized.

SSE, MUKKA, MANGALORE

Page 44

EXTENSIVE SURVEY REPORT-2012

BATCH-2

In the present era planning is considered as a pre-requisite and basic need for any new

project or an expansion program. Thus highway planning is also a basic need for highway

development. Since, we have undertaken HIGHWAY PROJECT as our project work; we

have considered the following objectives:

Efficient and safe traffic operation but a minimum cost.

Attainment of maximum utility.

Construction with locally available resources to minimize the cost of project.

Future requirements and improvements in view of anticipated developments.

Availability of funds and economic considerations.

Incorporation of technical recommendations framed by Indian Roads Congress

(IRC) for various aspect of Highway construction.

Proposal

This project deals with the design of road and can be executed in following manner.

A road was selected and detailed surveys including cross section and longitudinal

sections were carried out.

Plan of road alignment longitudinal section were drawn to scale and final alignment

was fixed, as per IRC specifications, confirming to village roads.

Block leveling for the culvert.

SSE, MUKKA, MANGALORE

Page 45

EXTENSIVE SURVEY REPORT-2012

BATCH-2

3.2 Geometric Design of Highway Pavement

The geometric design of a highway deals with the dimensions & layout of visible features of

highway such as alignment, sight distance, curves, super elevation & intersections etc. The

geometrics of highway should be designed to provide optimum efficiency in traffic operation

with maximum safety at reasonable cost. The designer may be exposed to planning of new

highway network to meet the requirements of the anticipated traffic. The design is also

includes the sizes of drainage, aggregates, cross slopes, super elevation etc.

3.2.1 Requirements

The basic important requirements of an ideal alignment should be as follows:

The proposed alignment should be short as possible.

The road should be easy for construction & maintenance.

The road should be safe to operation and economical.

3.3 Factors Controlling Alignment

3.3.1 Obligatory points

These are control points governing the alignment of the highways. These control points are

divided into two categories, namely

Obligatory points through which the road alignment should pass.

Points through which the alignment should not pass. These will cause the alignment

often deviated from the shortest or easiest path.

3.4 Traffic

The proposed alignment should suit the traffic requirement. Origin and destination study

should be carried out in the area and desire lines be drawn showing the trend of traffic flow.

The new road to be aligned should keep in view the traffic flow patterns and future trends.

3.5 Geometric design

SSE, MUKKA, MANGALORE

Page 46

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Geometric design factors such as gradients, radius of curve and sight distance also would

govern final alignment of highway. If straight alignment is aimed at, often it may be

necessary to provide very steep gradients. As far as possible while aligning a new road, the

gradient should be flat and less than the ruling or design gradient. Thus it may be necessary to

change the alignment in view of design speed, maximum allowable super elevation and

coefficient of lateral friction. It may be necessary to make the adjustment in the horizontal

alignment of roads keeping view the minimum radius of the curve and the transition curves.

Economy

The alignment should be economical. The initial cost, maintenance cost & vehicle operation

cost should be minimum, high embankment or deep cuttings are avoided & choose the

balance cutting & filling sight. These factors also control the alignments of road.

3.6 Engineering Surveys for Highway Location

The engineering surveys have to be carried out before finalizing the highway project. The

stages of engineering surveys are:

Map Study

Map study gives a rough guidance of routes to be surveyed in the field. The main features

like river, hills and valleys, etc. are known by map study. B y careful study of maps, the idea

of aligning a new highway can be obtained.

Reconnaissance Survey

In this survey, the land along the various proposed highway routes are inspected. All the

relevant details not available in the map study are collected and noted down.

Preliminary Survey

SSE, MUKKA, MANGALORE

Page 47

EXTENSIVE SURVEY REPORT-2012

BATCH-2

This is carried out to collect all the physical informations, which is necessary in connection

with the proposed highway alignment. The quantity of earth work and cost of construction

are worked out. The best proposal is selected after preliminary survey.

Detailed Survey

After preliminary survey, a detailed survey is carried out. Here Temporary Bench Marks are

fixed and leveling works are performed. Here an elaborate and complete data are collected

for preparing detailed plan and estimates of the project.

3.7 Curves

Curves are usually employed in the lines of communication in order that the change in

direction at the intersection of the straight lines shall be gradual. The curves are generally

circular arcs.

Circular Curves

The circular curves are divided into three types, namely;

Simple curve: It is a single arc connecting two tangents.

Compound curve: It consists of two arcs of different radii bending in the same

direction and lying on the same side of their common tangent.

Reverse curve: A reverse curve is composed of two arcs of equal or different radii

bending in opposite direction.

Transition Curves

A transition curve has a radius, which decreases from infinity at the tangent point to a

designed radius of circular curve. The rate of change of radius of transition curve will depend

on the equation of the curve or its shape.

Vertical Curve

There are two types of vertical curves, namely

Summit curve: These are the curves with convexity upwards.

Valley curve: These are also called as sag curves, where the convexity is downwards.

SSE, MUKKA, MANGALORE

Page 48

EXTENSIVE SURVEY REPORT-2012

BATCH-2

3.8 Super Elevation

In order to counteract the effect of centrifugal force and to reduce the tendency of vehicles to

overturn or skid, the outer edge of the pavement is raised with respect to its inner edge, thus

providing transverse slope throughout the length of a horizontal curve. This transverse

inclination of the pavement surface is known as Super elevation

3.9 Surveying Details

Introduction

In road survey, the first step is leveling. This is carried out using, instruments such as dumpy

level, cross staff and leveling staff. Other instruments used are prismatic compass to note the

bearings, arrows and ranging rods which are used to mark the points on the field. The

leveling operation starts from the benchmark. A benchmark is a point of known elevation.

The road is aligned by two operations, namely,

Longitudinal Sectioning.

Cross Sectioning

Where ever there is a necessity of providing a culvert, block leveling is carried out.

Longitudinal Sectioning or Profile Leveling

Profile leveling is a process of determining the elevation of points at fixed intervals along the

chain line. Here the line along which the section to be taken is marked by ranging rods, and

the fore bearing of the line is taken with the help of a prismatic compass. The level is then

setup at a point. The telescope is then directed to a staff, held on the temporary benchmark of

R. L. 100.00 m and the reading is taken. This reading is called as the back sight. Height of

collimation is determined. All these readings are noted down in a level book. Then the

intermediate sight is taken on the starting point of the line by holding the staff. For each

setup, intermediate sights should be taken after the fore sight on the next turning station has

been taken. To find the R.L. the intermediate sights are subtracted from the height of

collimation. When the instrument is removed, a change point is selected and a staff is held on

the same point and read it, which is fore sight.

It is then subtracted from the height of instrument to find the R.L. of the change point. The

instrument is then transferred to the second position. Having adjusted the instrument, a back

SSE, MUKKA, MANGALORE

Page 49

EXTENSIVE SURVEY REPORT-2012

BATCH-2

sight is taken on the change point just established. This reading when added to the change

point gives the R.L. of the new line of collimation. Then successive intermediate sights are

taken.

The horizontal distances are plotted along the horizontal axis to some convenient scale and

the distances are also marked. The elevations are plotted along the vertical axis. The various

points obtained are joined by straight lines.

Checking the levels

For checking the levels, we use the technique called Fly Levelling. In this, we start from the

last point and go to the first point, taking back sights and fore sights only, At the end, the last

point should be in the vicinity of the bench mark.

Cross Sectioning

Cross sections arc run at right angles to the horizontal profile and at either side of it for the

purpose of lateral outline of the, round surface. It provides data for estimating quantities of

earth work and other purposes. The cross sections are plotted in the same manner as the

longitudinal sections.

Contouring

On a plan, the relative altitudes of the points can be represented by contour lines as they

indicate the elevators directly. The area to be surveyed is divided into a number of squares.

The levels on the comer of these squares are determined by direct levelling. The contour

interpolation is done by graphical methods

Design Speed

It is the speed to which a road is designed.

Design speed on rural highways.

Design speed in kmph for various terrains.

Table No.13:-Design speeds for various terrains

Design speed in Kmph for various terrains

SSE, MUKKA, MANGALORE

Page 50

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Road

Classification

Plain

Rolling

Mountainous

Steep

Rolling

Min

Rolling

Min

Rolling

Min

Rolling

Min

100

80

80

65

50

40

40

30

National and

State

Highway

Gradients

Gradient is the rate of rise or fall along the length of the road with respect to the horizontal. In

road design as much as possible les gradient are provided to increase the design speed.

Gradient are divided into following types.

a) Ruling gradient: It is the maximum gradient within which the designer attempts to

design the vertical profile of the road.

b) Limiting gradients: It is the gradient steeper than the ruling gradient.

c) Exceptional gradients: It is the unavoidable steeper gradient provided for a smaller

road stretch of the road.

d) Minimum gradient: It is the minimum gradient provided in the roads for the drainage

of rain water as quick as possible. It will depends on the soil property, rainfall, runoff,

etc.

Table No.14:-Gradient according to IRC

Terrain

Ruling Gradient

Limiting Gradient

Exceptional

Plain and rolling

Mountainous

3.3% (1 in 30)

5% (1 in 20)

6.7%(1 in 15)

having elevation

5%( 1in 20)

6%(1 in 16.7)

7%(1 in 14.3)

6%(1 in 16.7)

7%(1 in 14.3)

8%( 1 in 12.5)

gradient

>3000m above

MSL

Steep terrain up to

3000m above MSL

Width of Roadway or Formation

It is the sum of widths of pavements or carriageway including separators if any and

shoulders. Formation width is the top width of the highway embankment or the bottom width

of the highway cutting excluding the side drains.

SSE, MUKKA, MANGALORE

Page 51

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Table No.15:-Width of roadway recommended by IRC

SL. No.

Road Classification

Roadway width for plain &

rolling terrain, m

1.

2.

NH & SH

a) Single lane

12

b) Double lane

12

MDR

a) Single lane

b) Double lane

Camber

Cross slope or camber is the slope provided on the road pavement to drain off the rainwater

from the road pavement surface. It usually maximum at center of the road & at edge camber

value is zero in a stretch.

Table No.16:-IRC recommended values of camber

SL. No.

1.

Types of road

Range of cambers in areas of rainfall

Surfaces

range

Heavy to light

Cement concrete and

high type bituminous

1 in 50 (2%)

1 in 60 (1.7%)

surface

2.

Thin bituminous

1 in 40 (2.5%)

1 in 50 (2%)

3.

surfaces

WBM and gravel

pavement

1 in 33(3%)

1 in 40 (2.5%)

Earth

1 in 25(4%)

1 in 33(3%)

4.

SSE, MUKKA, MANGALORE

Page 52

EXTENSIVE SURVEY REPORT-2012

BATCH-2

Kerb

Kerbs are provided at the edge of road b/w the road & shoulders. It prevents the direct entry

of road vehicles in to the shoulders.

Shoulders

It is the thin strip of land provided along the road edge for the emergency lane for parking or

to repair the damaged vehicles.

The minimum shoulder width recommended by IRC is 2.5m

3.10 Design of horizontal alignment

Horizontal curves

When the centerline of the road changes the direction along the horizontal plane, horizontal

curves are provided & the same are designed as follows.

Super Elevation

To counteract the effect of centrifugal force and to reduce the tendency of vehicle to overturn

or skid the, outer edge of pavement is raised with respect to inner edge. Such provision of

transverse slope is provided on horizontal curves. The design of super elevation is illustrated

as below

Extra Widening

Extra widening is provided to provide extra space required for mechanical and psychological

reasons along the horizontal curve, which is provided as per the table below

Table No.17:-Extra widening valve IRC recommended

SL. No.

Radius of curve (m)

Up to 20m

1.5

20-40m

1.5

41-60m

1.2

61-100m

0.9

5

101-300m

SSE,

MUKKA,

MANGALORE

6

Above 300m

Extra width for two lane road (m)

Page 53

0.6

nil

EXTENSIVE SURVEY REPORT-2012

BATCH-2

3.11 Vertical Alignment

When two different or contrary gradients meet, they are connected by a curve in the vertical

plane known as vertical curve. These are needed to secure a gradual change in grade so that

abrupt change in grade at the apex is not allowed. The vertical curves used in highway may

be classified in to two categories.

Summit curve

Valley curve

a) Summit curve:

A curve with convexity up wards is called a summit curve. This occurs when an ascending

intersect a descending gradient or when an ascending meets on other ascending gradient or an

ascending gradient meeting a horizontal a summit curve is provided here as there is change in

gradient matching the requirements of a summit curve. The summit curve is designed end as

below.

b) Valley Curve:

A vertical curve, concave upwards is called as valley curve. This is formed when a

descending gradient intersect an ascending gradient or when a descending gradient meets

another descending gradient or when a descending gradient gains a horizontal path, they

should be designed for:

Comfort

Head light sight distance condition.

3.12 Pavement Design

For the safety and comfort ability of fast vehicles road surface should be even along the

longitudinal profile. The surface should also so be stable and unyielding in different

conditions and it should allow the heavy load of traffic to move with least possible resistance.

SSE, MUKKA, MANGALORE

Page 54

EXTENSIVE SURVEY REPORT-2012

BATCH-2

In order to provide a stable and even surface for traffic the road way is provided with a

suitably designed and constructed pavement structure. Pavement is designed and to distribute

wheel load in larger area and elastic deformation caused by the load to fall within the

permissible limit.

Table No.18:-LONGITUDINAL AND CROSS SECTION OF HIGHWAY ALIGNMENT

SI.NO

B.S

0.650

C0.00

0.750

R.L

90.000

89.900

L5

0.645

90.000

L10

0.525

90.120

L15

0.395

90.255

R5

1.160

89.490

R10

1.425

89.225

R15

1.800

88.850

C20.00

1.265

89.385

L5

1.135

89.515

L10

1.215

89.435

L15

1.610

89.040

R5

1.495

89.155

R10

1.795

88.855

R15

2.155

88.495

C40.00

1.790

88.860

L5

1.640

89.010

L10

1.810

88.840

L15

2.040

88.600

R5

1.955

88.690

R10

2.150

88.500

R15

0.120

88.380

C60.00

2.200

88.450

L5

2.290

88.360

L10

2.435

88.215

L15

2.630

88.020

R5

2.220

88.405

R10

2.360

88.285

R15

2.260

88.385

SSE, MUKKA, MANGALORE

I.S

Page 55

F.S

H.I

90.650

REMARKS

Bench Mark

EXTENSIVE SURVEY REPORT-2012

BATCH-2

C83.94

2.220

88.430

L5

2.375

88.275

L10

2.755

87.895

L15

3.195

87.405

R5

2.155

88.495

R10

2.205

88.445

R15

2.545

88.100

C98.94

1.100

86.615

L5

0.595

87.120

L10

0.635

87.080

L15

0.685

87.030

R5

1.165

86.550

R10

1.335

86.380

R15

1.365

86.350

C113.34

2.445

85.270

L5

2.000

85.710

L10

4.580

83.135

L15

4.930

82.780

R5

1.890

85.820

R10

1.900

85.810

R15