Professional Documents

Culture Documents

10-400FLSmidthKrebs SlurryMAX Brochure Email

Uploaded by

pacodmxCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10-400FLSmidthKrebs SlurryMAX Brochure Email

Uploaded by

pacodmxCopyright:

Available Formats

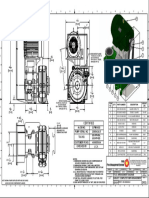

KREBS slurryMAX pumps

KREBS slurryMAX pump

Applications

Mining and mineral processing

SAG mill discharge

recirculation

Copper

Iron-ore

Gold

Oil Sands

Cyclone feed

Tailings

Mill discharge

Sand and gravel

Industrial processing

Heavy-duty abrasive slurries

Suction Side Hydraulic

Recirculation

Following the dramatic success of the

millMAX metal slurry pump,

FLSmidth Krebs has incorporated the

patented features into a new slurryMAX rubber lined pump product

range.

The patented feature has an externally

adjustable wear ring that closes the

suction side impeller clearance

between the suction liner and the eye

of the impeller. This clearance

eliminates the problem conventional

rubber lined pumps experience - that

of pressure pulsations caused by the

close proximity of the rotating raised

expelling vanes to the suction liner,

necessary to maintain flow, and

subsequently generating heat in the

liner and rubber devulcanization

failure.

The ability to control the suction side

clearance reduces the hydraulic

recirculation and therefore contributes

to maintaining the design flow over

the life of the pump, increasing the

life of the impeller.

The extra-thick rubber lining has rigid

reinforcement to prevent collapse

onto the rotating impeller under upset

vacuum conditions. Impellers are

oversized in diameter and available in

metal or elastomers. High pressure

casings are available for applications

requiring multiple pumps in series.

Pump sizes are available from 3

(75mm) to 16 (400mm).

Severe-Duty Rubber Lined Pumps

Inherent flaw in rubber-lined

pumps designs

Cannot run impeller in close

tolerance to the suction liner.

Pressure pulsations generated by

the expeller vanes will generate

heat in the rubber liner, resulting

in devulcanization.

Large clearance to prevent failure

of gland side liner allows high

slurry pressure at gland.

To overcome premature liner

failure, large clearances are

required, resulting in

recirculation, drop in flow and in

efficiently.

Large clearance to prevent

failure of suction liner. Allows

excessive slurry recirculation

and reduced pump hydraulic

performance.

And the solution is...

KREBS slurryMAX pump

Reverse Taper Roller Bearing

Increases effective load span to improve life

Eliminates major cause of bearing failure due to over greasing

Centrifugal pumping action of taper rollers discharges grease to the outside, preventing ingress of slurry or over greasing of bearing

No adjustment of impeller

once the pump is installed

For typical tailings application requiring 400 of head, slurryMAX can use two

pumps compared to competitors three pumps. The first stage can use a centrifugal

dry gland requiring only one pump with water flush...a major maintenance

headache on multi-stage pumping.

Thick rubber liners increase

operating life of wear parts

Steel reinforcing plates provides

stability to rubber liners and prevents

deflection under vacuum.

Large Clearance

Increases suction liner wear life

Reduced power consumption

Allows pump to operate at higher speed and generate

higher head without liner devulcanization.

Adjustable Wear Ring

Adjusted while pump is running

Takes up clearance at the impeller

Reduces suction side recirculation

Maintain design fl ow from performance curve.

Tight Clearance

Steel pipe in suction liner

prevents liner from

collapsing under vacuum.

Rib reinforced ductile

iron casings

Narrow Clearance

Reduced height vanes and fixed clearance reduce slurry

pressure at gland

Increases centrifugal seal performance

Reduces gland water pressure requirement for water flush seal

Rigid steel reinforcing support for liners to

prevent collapsing under upset vacuum

conditions

Suction side casing liner

Replaceable suction liner

Adjustable wear ring

Specifications

Metal impeller is standard.

Design is suitable for molded rubber at

a later date.

The casing is constructed of tough

spheroidal graphite iron. Casing and

suction inlet are lined with natural

rubber.

Impeller and other wet-end components constructed of highly abrasionresistant high-chrome white iron with a

Brinell hardness of 680 to 720.

machined face of the impeller near the

eye.

clearance - reducing solids grinding and

recirculation respectively.

Wear ring can be adjusted up to eight

times throughout the life of the

wet-end parts and is adjusted while the

pump is running.

Tight back liner clearance maximizes

packing and shaft sleeve life - normally

this clearance is opened up as impeller

wears and needs adjusting.

Generous clearance between impeller

and suction liner limit the cyclical wear

of the rubber associated with the

trapping of solids between the liner and

the impeller.

Radial impeller vanes both clear solids

and reduce pressure at suction-side

Reverse taper roller bearings purge

grease to the outside - preventing

ingress of slurry and over-greasing of

bearing cartridge.

High-chrome impeller is resistant to

tramp metals and is capable of

higher tip speeds.

Tight clearance between wear ring and

impeller reduces suction-side slurry

recirculation by up to 95%. Pumps

feature a patented, adjustable, suctionside, sealing system that features a

wear ring that runs against the

KREBS slurryMAX product range

Pump size

Power frame

Maximum HP/kW

3x3-11

MMAA

50/37

4X4-12

MMAA

50/37

4X4-12

MMA

100/75

6X6-17

MMA

100/75

6X6-17

MMB

250/186

8X6-22

MMB

250/186

8X6-22

MMC

500/373

10X8-27

MMB

250/186

10X8-27

MMC

500/373

12X10-30

MMC

500/373

14X12-38

MMD

1,000/746

16X14-42

MMD

1,000/746

16X14-42 HP

MME

1,700/1,280

The primary applications for the Krebs

metal slurry pumps are mill discharge,

crusher slurry, sand and aggregate or

any coarse solids or other severe,

abrasive slurries especially in the

copper, gold, iron ore, lead-zinc, coal,

or phosphate plants. The most

dramatic savings will be in these

applications, though savings will also

be realized on fine solids, like fine

sand recovery or kaolin.

The key advantage of the Krebs metal

slurry pumps is the 10% to 30%

lower power, long even wear life and

less pump downtime, which results in

lower cost-per ton pumped, along

with better cyclone separation.

Adjustable Wear Ring - Allows

for on-line adjustment of wear

ring to minimize slurry

recirculation.

Hybrid Sealing System [patented]

- Offers a wide clearance

between the impeller and suction

wear faces, plus unique Expeller

Vane Profile, eliminates power

consuming solids crushing and

combined with the Adjustable

Wear Ring, reduces slurry

recirculation and wear to a

minimum.

www.flsmidth.com

Technology Center

FLSmidth Krebs

5505 W. Gillette Rd.

Tucson, AZ 85743-9501

USA

Tel: +1 520-744-8200

Fax: +1 520-744-8300

E-mail: KrebsGeneral@flsmidth.com

Copyright 2011 FLSmidth A/S. ALL RIGHTS RESERVED. FLSmidth is a (registered) trademark of FLSmidth A/S. This brochure makes no offers, representations or

warranties (express or implied), and information and data contained in this brochure are for general reference only and may change at any time.

Strategic Metal Distribution Extra metal at the cut water and

other high wear areas combined

with superior wear materials,

result in even wear life.

Ease of Installation - Customized

designed spool pieces to suit

existing pipe work.

Cartridge Replacement - With

even extended wear life, the

case, impeller and backliner can

all be replaced at the same time,

reducing down time and

maintenance costs.

Fully Floating Shaft Seal - Ensures

concentricity of gland packing

and shaft sleeve during assembly

for extended packing and sleeve

life.

Adaptor Plate - Wet end adapts

to a variety of existing power

frames.

Optional Water Flush or Dry

Gland Seal - Ability to eliminate

gland seal water.

#10-400 Rev. 1/23/2014 al-us

Metal slurry pumps

You might also like

- Krebs Mill Max Centrifugal Slurry Pump We BXDocument8 pagesKrebs Mill Max Centrifugal Slurry Pump We BXPhaniNo ratings yet

- Mill MAX8 PG EmailversionDocument5 pagesMill MAX8 PG EmailversionPrimitivo GonzálezNo ratings yet

- Slurrymax Camur Pompasi 3 PDFDocument8 pagesSlurrymax Camur Pompasi 3 PDFTecnologia Fabricación MetalmecanicaNo ratings yet

- Products Pumps Mission-2500Document3 pagesProducts Pumps Mission-2500backieuphong1696No ratings yet

- b5860 For Slurry ApplicationDocument6 pagesb5860 For Slurry Applicationpeach5No ratings yet

- Krebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsDocument4 pagesKrebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsPhaniNo ratings yet

- MAT 3421 Data SheetDocument3 pagesMAT 3421 Data SheetDiógenes da Silva Pereira100% (1)

- CertifiedDocument1 pageCertifiedIta BarreraNo ratings yet

- A comprehensive parts list for a machinery assemblyDocument1 pageA comprehensive parts list for a machinery assemblyIta BarreraNo ratings yet

- Shaft Sealing OptionsDocument1 pageShaft Sealing OptionsMartin CalderonNo ratings yet

- A112 Comparison of Screen SizeDocument1 pageA112 Comparison of Screen SizeVincent IrawanNo ratings yet

- A102 Material GuideDocument6 pagesA102 Material GuideVincent Irawan100% (1)

- WPG 151AH31: 14 MM 14 MMDocument24 pagesWPG 151AH31: 14 MM 14 MMMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- R05323 P 001a X009 0042 PDFDocument464 pagesR05323 P 001a X009 0042 PDFcquibajoNo ratings yet

- GX Catalogue2013Document32 pagesGX Catalogue2013Leobardo DiazNo ratings yet

- AU0087 MC Mill Circuit BrochureFINAL - v2 - LoresDocument8 pagesAU0087 MC Mill Circuit BrochureFINAL - v2 - LoresEDDY PINONo ratings yet

- GIW pump conversions boost productivityDocument2 pagesGIW pump conversions boost productivitymarcosandia1974No ratings yet

- 00 Mill MAXSlurry Pump July 2016 CutawayDocument1 page00 Mill MAXSlurry Pump July 2016 CutawayPatricio AcuñaNo ratings yet

- 086EAHPPPGM Listado de PartesDocument1 page086EAHPPPGM Listado de PartesJavier Alejandro Rodriguez Melgoza100% (1)

- Iom en r03 Final Selene - 1xtzpm400m enDocument296 pagesIom en r03 Final Selene - 1xtzpm400m enavilasarNo ratings yet

- Warman International LTD.: 2700 R/minDocument1 pageWarman International LTD.: 2700 R/minFlávio Carvalho FlávioNo ratings yet

- Catalogo TownleyDocument12 pagesCatalogo TownleyVladimir SepulvedaNo ratings yet

- Mill Circuit Solutions: GIW Hard Rock Mining PumpsDocument8 pagesMill Circuit Solutions: GIW Hard Rock Mining PumpsbabarNo ratings yet

- Warman International LTD: Intake FlangeDocument3 pagesWarman International LTD: Intake FlangerickNo ratings yet

- Product Bulletin 22Document2 pagesProduct Bulletin 22RANAIVOARIMANANANo ratings yet

- Determining Why Objects Are RequiredDocument24 pagesDetermining Why Objects Are Requiredmaga2000No ratings yet

- KREBS slurryMAX Pump BrochureDocument12 pagesKREBS slurryMAX Pump Brochuredavidgaro12No ratings yet

- Technical Bulletin 3Document17 pagesTechnical Bulletin 3RANAIVOARIMANANANo ratings yet

- B.5 MillMAX 3x2-14x12 IOM (July 2015)Document67 pagesB.5 MillMAX 3x2-14x12 IOM (July 2015)Alief FadilNo ratings yet

- General Conditions of Sale: 1. ApplicationDocument3 pagesGeneral Conditions of Sale: 1. ApplicationsyamimialifahNo ratings yet

- 3 - 2C Ah-6vcmDocument1 page3 - 2C Ah-6vcmMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- Sump Pump Critical Speeds WDS 101Document3 pagesSump Pump Critical Speeds WDS 101RANAIVOARIMANANA0% (1)

- Manual Horizontal IOM Envirotech ESPDocument67 pagesManual Horizontal IOM Envirotech ESPOmar RodriguezNo ratings yet

- Wear Reduction Technology: Centrifugal Slurry PumpsDocument12 pagesWear Reduction Technology: Centrifugal Slurry PumpstinoNo ratings yet

- Industrial Processes PDFDocument58 pagesIndustrial Processes PDFJOSEPH REFUERZONo ratings yet

- WPG 20L21: 13 MM 13 MMDocument1 pageWPG 20L21: 13 MM 13 MMMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- 11.1.06 Warman Pump Shaft SealsDocument12 pages11.1.06 Warman Pump Shaft SealsMartin Calderon100% (1)

- Warman Submersible Slurry Pumps GuideDocument4 pagesWarman Submersible Slurry Pumps GuideCristobal JM CreativNo ratings yet

- Product Bulletin 37Document2 pagesProduct Bulletin 37RANAIVOARIMANANANo ratings yet

- Product Bulletin 20Document5 pagesProduct Bulletin 20RANAIVOARIMANANANo ratings yet

- CH Warman Shaft Lifting Nut Product BulletinDocument2 pagesCH Warman Shaft Lifting Nut Product BulletinRANAIVOARIMANANANo ratings yet

- WPG 50MP10: For Contact Details - Visit WWW - Warman.co - Za For Contact Details - Visit WWW - Warman.co - ZaDocument22 pagesWPG 50MP10: For Contact Details - Visit WWW - Warman.co - Za For Contact Details - Visit WWW - Warman.co - ZaMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- Centrifugal Slurry Pumps: WarmanDocument2 pagesCentrifugal Slurry Pumps: WarmanDirceu ValadaresNo ratings yet

- A7 PumpDocument14 pagesA7 PumpIr Go JarNo ratings yet

- Slurry Pump The KproDocument11 pagesSlurry Pump The Kpro4lk0nNo ratings yet

- ABEL Positive Displacement Pumps for Sludge, Slurry and Solids HandlingDocument6 pagesABEL Positive Displacement Pumps for Sludge, Slurry and Solids HandlingPete PompesNo ratings yet

- 0-WD745-EJ610-00001 - Rev.1 - Operation and Maintenance Manuals For Control ValveDocument100 pages0-WD745-EJ610-00001 - Rev.1 - Operation and Maintenance Manuals For Control Valveraul gonzalezNo ratings yet

- New Materials for SAG MillsDocument12 pagesNew Materials for SAG MillsxtusNo ratings yet

- Orion Double AdjustmentDocument2 pagesOrion Double AdjustmentEmnNo ratings yet

- Technical Bulletin 5Document14 pagesTechnical Bulletin 5RANAIVOARIMANANANo ratings yet

- Product Bulletin 27Document23 pagesProduct Bulletin 27RANAIVOARIMANANANo ratings yet

- Install, Operate and Maintain SAM Turbo PumpDocument40 pagesInstall, Operate and Maintain SAM Turbo Pumpsanjayagrawal70-1No ratings yet

- Catalog & DrawingDocument89 pagesCatalog & Drawingronal siagianNo ratings yet

- Clyde Pumps WEIR API Brochures For Barrel Pumps EtcDocument22 pagesClyde Pumps WEIR API Brochures For Barrel Pumps EtcSSudhakarNo ratings yet

- Schurco Slurry Parts for Pumps & ImpellersDocument3 pagesSchurco Slurry Parts for Pumps & ImpellersEduardo MolanoNo ratings yet

- Shadeco Excellence Pump ManualDocument34 pagesShadeco Excellence Pump ManualRichard Reyes romeroNo ratings yet

- 1345 John CraneDocument2 pages1345 John CraneseptixNo ratings yet

- Technical Bulletin 1Document8 pagesTechnical Bulletin 1RANAIVOARIMANANANo ratings yet

- Slurrymax Pump: Split Casing Design For Multiple ApplicationsDocument8 pagesSlurrymax Pump: Split Casing Design For Multiple Applicationssergio.manuel ovandoNo ratings yet

- Krebs Products For The Coal IndustryDocument20 pagesKrebs Products For The Coal IndustryANo ratings yet

- Cat 11Document1 pageCat 11pacodmxNo ratings yet

- Tubero - Curva 3D 5DDocument1 pageTubero - Curva 3D 5DpacodmxNo ratings yet

- Casa Cerro Colorado-ModelDocument1 pageCasa Cerro Colorado-ModelpacodmxNo ratings yet

- Bar Bending ScheduleDocument1 pageBar Bending SchedulepacodmxNo ratings yet

- Brida Ciega (Blind) AWWA C207 Steel Class D - DNBridaDocument2 pagesBrida Ciega (Blind) AWWA C207 Steel Class D - DNBridapacodmx100% (1)

- Long Descriptions WorksheetDocument5 pagesLong Descriptions WorksheetpacodmxNo ratings yet

- V-Frame Parts ListDocument2 pagesV-Frame Parts ListpacodmxNo ratings yet

- Tekla 18 Structures Manual 2Document4 pagesTekla 18 Structures Manual 2pacodmx100% (1)

- ReadmeDocument1 pageReadmepacodmxNo ratings yet

- U Bolt StandardDocument1 pageU Bolt StandardRoshan ShanmughanNo ratings yet

- Two (2) Years (U.S. and Latin America) Standard Limited Warranty ("Limited Warranty") For Toshiba Branded Accessories and ElectronicsDocument6 pagesTwo (2) Years (U.S. and Latin America) Standard Limited Warranty ("Limited Warranty") For Toshiba Branded Accessories and Electronicscdla14No ratings yet

- Essentials Autocad Civil 3D 2012: Textbooks. LowerDocument54 pagesEssentials Autocad Civil 3D 2012: Textbooks. LowerpacodmxNo ratings yet

- HorasDocument1 pageHoraspacodmxNo ratings yet

- For Construction Issued: Thickener PlansDocument1 pageFor Construction Issued: Thickener PlanspacodmxNo ratings yet

- For Construction Issued: Plan AaDocument1 pageFor Construction Issued: Plan AapacodmxNo ratings yet

- DT 2500128 450 P 001Document1 pageDT 2500128 450 P 001pacodmxNo ratings yet

- Bypass Celda 15Document1 pageBypass Celda 15pacodmxNo ratings yet

- For Construction Issued: Enlarge Plan 1 Enlarge Plan 2Document1 pageFor Construction Issued: Enlarge Plan 1 Enlarge Plan 2pacodmxNo ratings yet

- Tubo Astm A53 PDFDocument2 pagesTubo Astm A53 PDFMelissa MccoyNo ratings yet

- 00 Indice 01-2015 PDFDocument1 page00 Indice 01-2015 PDFpacodmxNo ratings yet

- 804 Query ShoFFrt Spools SupportDocument3 pages804 Query ShoFFrt Spools Supportluonganh89No ratings yet

- Curvas Radio 3D - Codo FundidoDocument1 pageCurvas Radio 3D - Codo FundidopacodmxNo ratings yet

- Man 2d enDocument58 pagesMan 2d enpacodmxNo ratings yet

- Cad WorrrDocument1 pageCad WorrrpacodmxNo ratings yet

- CWfieldPipe-AustralianPipeliner PDFDocument3 pagesCWfieldPipe-AustralianPipeliner PDFpacodmxNo ratings yet

- ECE Design CADWorx DraftPro FAQ R1Document9 pagesECE Design CADWorx DraftPro FAQ R1pacodmxNo ratings yet

- Course Outline - CADWorx 2014 P&ID Professional PDFDocument1 pageCourse Outline - CADWorx 2014 P&ID Professional PDFpacodmxNo ratings yet

- Create User Isogen SymbolsDocument6 pagesCreate User Isogen SymbolspacodmxNo ratings yet

- How to add components to CADWorx 2013 specificationsDocument0 pagesHow to add components to CADWorx 2013 specificationsAngel Andres Olano MendozaNo ratings yet

- Mastercam Book 5 Axis Bai 1Document31 pagesMastercam Book 5 Axis Bai 1tuanvn76100% (3)

- Causal Inference For The Brave and True - Causal Inference For The Brave and TrueDocument2 pagesCausal Inference For The Brave and True - Causal Inference For The Brave and TrueVkook ForeverNo ratings yet

- AssignmentDocument15 pagesAssignmentWahab MirzaNo ratings yet

- Axion DatabaseDocument25 pagesAxion Databasemacy williamsNo ratings yet

- Problem set 1 covers energy, heat, gases, and thermodynamicsDocument15 pagesProblem set 1 covers energy, heat, gases, and thermodynamicsFikret BazNo ratings yet

- Directory of Importers Associations Worldwide 2009Document57 pagesDirectory of Importers Associations Worldwide 2009Thanh Tam75% (12)

- PowerFlex 4M LabDocument22 pagesPowerFlex 4M Labmaria laura delgado morenoNo ratings yet

- Machine Guarding PrinciplesDocument5 pagesMachine Guarding Principlesliveconnectionz282No ratings yet

- A Pilot's Guide To ILS PRM ApproachesDocument4 pagesA Pilot's Guide To ILS PRM ApproachesgregmNo ratings yet

- "Smart Attendance Using F Ttendance Management Using Face Recognition" Anagement SystemDocument13 pages"Smart Attendance Using F Ttendance Management Using Face Recognition" Anagement Systemamer HNo ratings yet

- How To Review A Book in Up To 5,000 Words: First StepsDocument3 pagesHow To Review A Book in Up To 5,000 Words: First StepsAnnaNo ratings yet

- FMVSS 139 2022-10-01Document7 pagesFMVSS 139 2022-10-01skr_757No ratings yet

- Lesson 5: Cultural Relativism: Learning OutcomesDocument4 pagesLesson 5: Cultural Relativism: Learning OutcomesGanda GandaNo ratings yet

- GRADES 1 To 12 Daily Lesson Log Monday Tuesday Wednesday Thursday FridayDocument3 pagesGRADES 1 To 12 Daily Lesson Log Monday Tuesday Wednesday Thursday FridaySheilaMarB.Esteban100% (1)

- Appendix 1c Bridge Profiles Allan TrussesDocument43 pagesAppendix 1c Bridge Profiles Allan TrussesJosue LewandowskiNo ratings yet

- Keurig Gourmet Single Cup Home Brewing System: Section 1Document11 pagesKeurig Gourmet Single Cup Home Brewing System: Section 1Tijuan MuhammadNo ratings yet

- New Membership Application GemsDocument5 pagesNew Membership Application Gemslaguila18No ratings yet

- Intermediate Financial Management 13th Edition Brigham Test BankDocument25 pagesIntermediate Financial Management 13th Edition Brigham Test BankMonicaHoustonwjtgz100% (56)

- Idea of CultureDocument28 pagesIdea of CultureGustavo Dias VallejoNo ratings yet

- Logisitim CircuitDocument7 pagesLogisitim CircuitDragos ManoleaNo ratings yet

- IGNOU FEG-02 (2011) AssignmentDocument4 pagesIGNOU FEG-02 (2011) AssignmentSyed AhmadNo ratings yet

- ION-CEDI-BR Ion PureDocument8 pagesION-CEDI-BR Ion PureAndri YantoNo ratings yet

- OSRAM LEDriving XENARC Headlamp Brochure For Audi A4 B7Document8 pagesOSRAM LEDriving XENARC Headlamp Brochure For Audi A4 B7Fourtitude.comNo ratings yet

- Temp Gradient For Warping Stress in Rigid PavementDocument9 pagesTemp Gradient For Warping Stress in Rigid PavementAmul KotharkarNo ratings yet

- OAF Hello Word Page PDFDocument20 pagesOAF Hello Word Page PDFNaveen KumarNo ratings yet

- Elon Musk: AI Is A Fundamental Risk To The Existence of Human CivilizationDocument19 pagesElon Musk: AI Is A Fundamental Risk To The Existence of Human CivilizationBDApp StarNo ratings yet

- Reflection 4Document7 pagesReflection 4danilo miguelNo ratings yet

- Rexroth HABDocument20 pagesRexroth HABeleceng1979No ratings yet

- Original Prusa I3 MK2S To MK3 Upgrade Parts ListDocument2 pagesOriginal Prusa I3 MK2S To MK3 Upgrade Parts ListLuan AlvesNo ratings yet

- Win Top Prizes in Investizo's SuperTrader ContestDocument3 pagesWin Top Prizes in Investizo's SuperTrader ContestJafrid NassifNo ratings yet